maintenance Mercury Mercury Cougar 2002 Owner's Manual

[x] Cancel search | Manufacturer: MERCURY, Model Year: 2002, Model line: Mercury Cougar, Model: Mercury Mercury Cougar 2002Pages: 216, PDF Size: 4.04 MB

Page 3 of 216

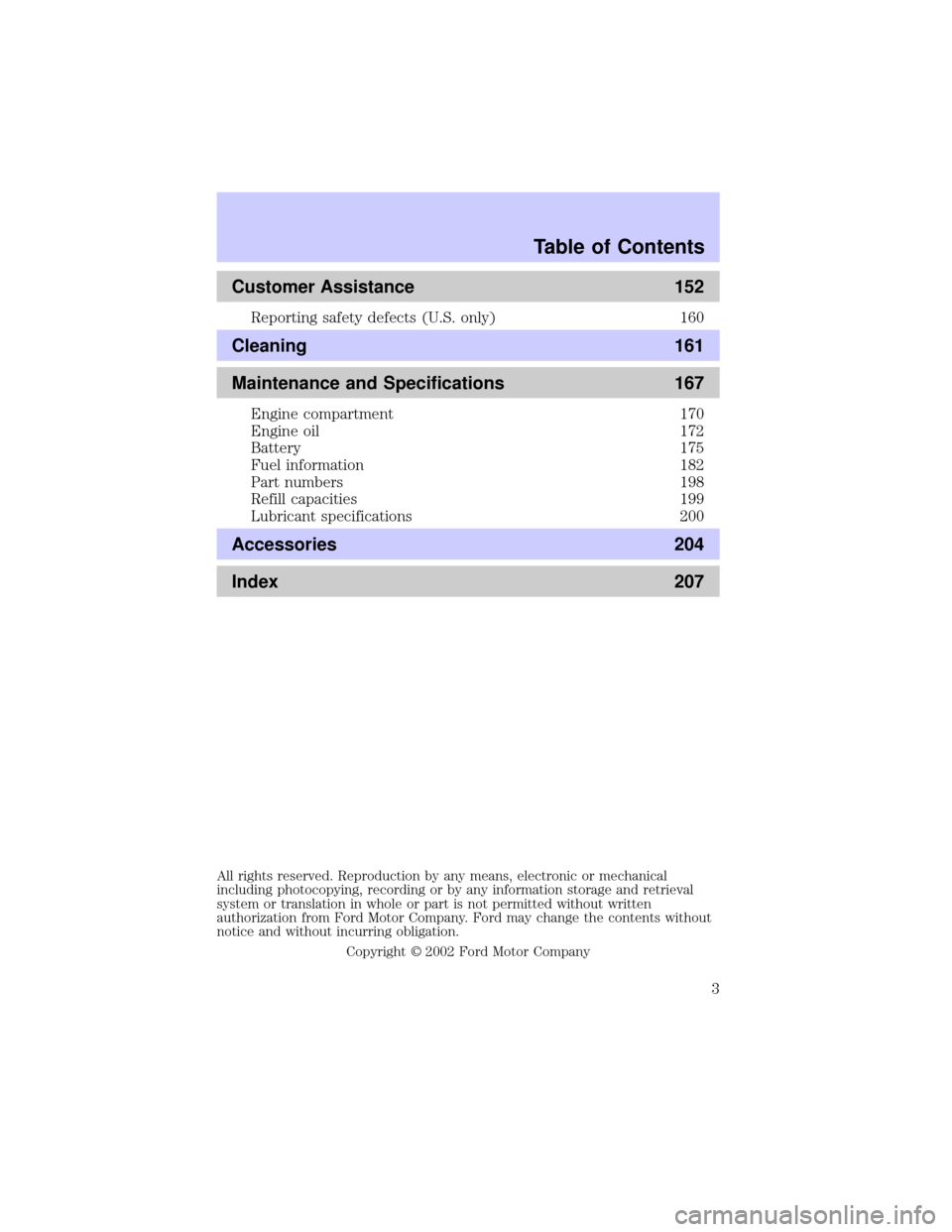

Customer Assistance 152

Reporting safety defects (U.S. only) 160

Cleaning 161

Maintenance and Specifications 167

Engine compartment 170

Engine oil 172

Battery 175

Fuel information 182

Part numbers 198

Refill capacities 199

Lubricant specifications 200

Accessories 204

Index 207

All rights reserved. Reproduction by any means, electronic or mechanical

including photocopying, recording or by any information storage and retrieval

system or translation in whole or part is not permitted without written

authorization from Ford Motor Company. Ford may change the contents without

notice and without incurring obligation.

Copyright 2002 Ford Motor Company

Table of Contents

3

Page 12 of 216

Safety belt

Illuminates to remind you to fasten

your safety belts. For more

information, refer to theSeating

and safety restraintschapter.

Air bag readiness

Illuminates to confirm that the air

bags (front and side) are

operational. If the light fails to

illuminate, continues to flash or

remains on, have the system

serviced immediately.

Charging system

Illuminates when the battery is not

charging properly.

Engine oil pressure

Illuminates when the oil pressure

falls below the normal range. Check

the oil level and add oil if needed.

Refer toEngine oilin the

Maintenance and specificationschapter.

Check coolant (if equipped)

Illuminates when the coolant level in

the coolant reservoir is low and

more needs to be added. For more

information on adding engine

coolant, refer toEngine coolantin

theMaintenance and specificationschapter.

Check transaxle

Illuminates when a transaxle

problem has been detected and

shifting may be restricted. If this

lamp remains on, have your vehicle

serviced immediately.

Instrument Cluster

12

Page 14 of 216

High beams

Illuminates when the high beam

headlamps are turned on.

Foglamps

Illuminates when the foglamps are

turned on.

Refer toFoglamp controlin the

Lightschapter.

OVERHEAD WARNING LIGHTS (if equipped)

These lights illuminate briefly to ensure the systems are functional.

Service intervals

Illuminates to indicate that routine

service should be performed. Check

your maintenance schedule to

determine the routine service to be

completed.

To reset the light, hold the SELECT

and UNITS controls on the trip

computer for five seconds. The light

will be illuminated and then extinguish after approximately four seconds.

Frost warning

Illuminates when ambient air

temperatures are between 0É C (32É

F) and 4É C (39É F). Theyellow

light warns of possible ice on the

roads.

Instrument Cluster

14

Page 16 of 216

Key-in-ignition warning chime

Sounds when the key is left in the ignition and the driver's door is

opened.

Liftgate ajar warning chime (if equipped)

Sounds when the liftgate is ajar or open and the key is in the ignition.

The interior dome lamp will also be illuminated.

GAUGES

Engine coolant temperature gauge

Indicates the temperature of the

engine coolant. At normal operating

temperature, the needle remains

within the normal area (the area

between the ªHº and ªCº); if the

needle goes above the normal range,

the engine is overheating. Stop the

vehicle as soon as safely possible,

switch off the engine immediately

and let the engine cool. Refer to

Engine coolantin the

Maintenance and specificationschapter.

Never remove the coolant reservoir cap while the engine is

running or hot. Steam and scalding liquid from a hot cooling

system can burn you badly.

This gauge indicates the temperature of the engine coolant, not the

coolant level. If the coolant is not at its proper level the gauge indication

will not be accurate.

Instrument Cluster

16

Page 93 of 216

Safety belt extension assembly

If the safety belt is too short when

fully extended, there is a 20 cm (8

inch) safety belt extension assembly

that can be added (part number

611C22). This assembly can be

obtained from your dealer at no

cost.

Use only extensions manufactured

by the same supplier as the safety

belt. Manufacturer identification is

located at the end of the webbing

on the label. Also, use the safety

belt extension only if the safety belt

is too short for you when fully

extended. Do not use extensions to

change the fit of the shoulder belt

across the torso.

Safety belt maintenance

Inspect the safety belt systems periodically to make sure they work

properly and are not damaged. Inspect the safety belts to make sure

there are no nicks, tears or cuts. Replace if necessary. All safety belt

assemblies, including retractors, buckles, front seat belt buckle

assemblies, buckle support assemblies (slide bar-if equipped), shoulder

belt height adjusters (if equipped), shoulder belt guide on seatback (if

equipped), child safety seat tether bracket assemblies (if equipped),

LATCH child seat tether anchors and lower anchors (if equipped), and

attaching hardware, should be inspected after a collision.

Ford recommends that all safety belt assemblies used in vehicles

involved in a collision be replaced. However, if the collision was minor

and a qualified technician finds that the belts do not show damage and

continue to operate properly, they do not need to be replaced. Safety

belt assemblies not in use during a collision should also be inspected and

replaced if either damage or improper operation is noted.

Due to the energy management feature on the front safety belts, the

safety beltsmustbe replaced after any collision causing the deployment

of the front air bags.

Seating and Safety Restraints

93

Page 98 of 216

The SRS consists of:

²driver and passenger air bag modules (which include the inflators and

air bags)

²one or more impact and safing sensors

²a readiness light and tone

²a diagnostic module

²and the electrical wiring which connects the components

The diagnostic module monitors its own internal circuits and the

supplemental air bag electrical system warning (including the impact

sensors), the system wiring, the air bag system readiness light, the air

bag back up power and the air bag ignitors.

Several air bag system components get hot after inflation. Do not

touch them after inflation.

If the air bag has deployed,the air bag will not function

again and must be replaced immediately.If the air bag is not

replaced, the unrepaired area will increase the risk of injury in a

collision.

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer toAir bag readinesssection

in theInstrument clusterchapter. Routine maintenance of the air bag is

not required.

A difficulty with the system is indicated by one or more of the following:

²The readiness light will either

flash or stay lit.

²The readiness light will not

illuminate immediately after

ignition is turned on.

²A series of five beeps will be heard. The tone pattern will repeat

periodically until the problem and/or light are repaired.

If any of these things happen, even intermittently, have the SRS serviced

at your dealership or by a qualified technician immediately. Unless

serviced, the system may not function properly in the event of a

collision.

Seating and Safety Restraints

98

Page 101 of 216

The fact that the air bags did not inflate in a collision does not mean that

something is wrong with the system. Rather, it means the forces were

not of the type sufficient to cause activation. Side air bags are designed

to inflate in side-impact collisions, not roll-over, rear-impact, frontal or

near-frontal collisions, unless the collision causes sufficient lateral

deceleration.

Several air bag system

components get hot after

inflation. Do not touch them after

inflation.

If the side air bag has

deployed,the air bag will

not function again. The side

air bag system (including the

seat) must be inspected and

serviced by a qualified

technician in accordance with

the vehicle service manual.If

the air bag is not replaced, the

unrepaired area will increase the

risk of injury in a collision.

Keep the sensors free from contact with water. If water has

entered the floor area (i.e., due to flooding conditions) do not

start the vehicle until the floor area is dry. Failure to do so may result

in a malfunction of the side air bag or inadvertent side air bag

deployment.

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer to theAir bag readiness

section in theInstrument clusterchapter. Routine maintenance of the

air bag is not required.

Seating and Safety Restraints

101

Page 116 of 216

Guarding against exhaust fumes

Although odorless and colorless, carbon monoxide is present in exhaust

fumes. Take precautions to avoid its dangerous effects.

If you ever smell exhaust fumes of any kind inside your vehicle,

have your dealer inspect and fix your vehicle immediately. Do

not drive if you smell exhaust fumes. These fumes are harmful and

could kill you.

Have the exhaust and body ventilation systems checked whenever:

²the vehicle is raised for service.

²the sound of the exhaust system changes.

²the vehicle has been damaged in a collision.

WARNING:Engine exhaust, some of its constituents, and

certain vehicle components contain or emit chemicals known to

the State of California to cause cancer and birth defects or other

reproductive harm. In addition, certain fluids contained in vehicles and

certain products of component wear contain or emit chemicals known

to the State of California to cause cancer and birth defects or other

reproductive harm.

Important ventilating information

If the engine is idling while the vehicle is stopped in an open area for

long periods of time, open the windows at least 2.5 cm (one inch).

Adjust the heating or air conditioning (if equipped) to bring in fresh air.

Improve vehicle ventilation by keeping all air inlet vents clear of snow,

leaves and other debris.

BRAKES

Your service brakes are self-adjusting. Refer to the scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

Driving

116

Page 132 of 216

Driving while you tow

When towing a trailer:

²Turn off the speed control. The speed control may shut off

automatically when you are towing on long, steep grades.

²Consult your local motor vehicle speed regulations for towing a trailer.

²To eliminate excessive shifting, use a lower gear. This will also assist

in transaxle cooling.

²Anticipate stops and brake gradually.

²Do not exceed the GCWR rating or transaxle damage may occur.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to your scheduled maintenance guide for

more information.

Trailer towing tips

²Practice turning, stopping and backing up before starting on a trip to

get the feel of the vehicle trailer combination. When turning, make

wider turns so the trailer wheels will clear curbs and other obstacles.

²Allow more distance for stopping with a trailer attached.

²If you are driving down a long or steep hill, shift to a lower gear. Do

not apply the brakes continuously, as they may overheat and become

less effective.

²The trailer tongue weight should be 10±15% of the loaded trailer

weight.

²After you have traveled 80 km (50 miles), thoroughly check your

hitch, electrical connections and trailer wheel lug nuts.

²To aid in engine/transmission cooling and A/C efficiency during hot

weather while stopped in traffic, place the gearshift lever in P (Park).

²Vehicles with trailers should not be parked on a grade. If you must

park on a grade, place wheel chocks under the trailer's wheels.

Driving

132

Page 139 of 216

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse

Panel Description

30 7.5A Engine management, Locking

system, Instrument cluster

31 7.5A Panel dimmer, License plate

lamps, Glove box lamp, Belt

minder module

32 Ð Not used

33 7.5A Left-side lamps

34 7.5A Power mirrors, Clock, Interior

lamps

35 7.5A Right-side lamps

36 15A Radio

37 30A Heater blower

38 7.5A Air bags

R12 Ð Courtesy lamps

R13 Ð Rear window defrost

R14 Ð Blower motor

R15 Ð Front wiper

R16 Ð Ignition

D2 Ð Reverse voltage protection

*Have these fuses replaced by your dealer or qualified technician.

Power distribution box

The power distribution box is located in the engine compartment. The

power distribution box contains high-current fuses that protect your

vehicle's main electrical systems from overloads.

Always disconnect the battery before servicing high current

fuses.

Always replace the cover to the power distribution box before

reconnecting the battery or refilling fluid reservoirs

If the battery has been disconnected and reconnected, refer to the

Batterysection of theMaintenance and specificationschapter.

Roadside Emergencies

139