maintenance Mercury Mountaineer 2002 s Repair Manual

[x] Cancel search | Manufacturer: MERCURY, Model Year: 2002, Model line: Mountaineer, Model: Mercury Mountaineer 2002Pages: 312, PDF Size: 3.02 MB

Page 269 of 312

3. Remove the protective dust cap

from the housing by turning

counterclockwise (when viewed

from the rear).

4. Disconnect the electrical

connector from the bulb by pulling

rearward.

5. Remove the bulb retaining ring by

rotating it counterclockwise.

6. Remove the old bulb from the lamp assembly by pulling it straight out

of the lamp assembly.

To install the new bulb:

Handle a halogen headlamp bulb carefully and keep out of

children’s reach. Grasp the bulb only by its plastic base and do

not touch the glass. The oil from your hand could cause the bulb to

break the next time the headlamps are operated.

1. Install the new bulb in lamp

assembly by pushing straight in with

the flat surface of the bulb’s plastic

base facing upward. You may need

to turn the bulb slightly to align the

grooves in the plastic base with the

tabs in the lamp assembly.

2. Install the bulb retaining ring over

the plastic base and lock the ring by

rotating clockwise until it snaps into place.

3. Connect the electrical connector to the bulb.

4. Install the protective dust cap and lock by rotating the cap clockwise

until it locks into position.

5. Install the headlamp on vehicle by aligning the lamp on the vehicle,

push rearward to fully seat the lamp assembly then insert and push the

two retainer pins down.

6. Turn the headlamps on and make sure they work properly. If the

headlamp was correctly aligned before you changed the bulb, you should

not need to align it again.

Maintenance and care

269

Page 270 of 312

Replacing front parking lamp/turn signal bulbs

1. Make sure headlamp switch is in

OFF position, then open the hood.

2. At the back of the headlamp, pry

up and remove the two retainer pins

to release the headlamp assembly

from the vehicle and pull headlamp

forward.

3. Rotate the bulb socket

counterclockwise and remove from

lamp assembly.

4. Carefully pull bulb straight out of

socket and push in the new bulb.

5. Install bulb socket in lamp

assembly by turning clockwise.

6. Install the headlamp on vehicle by

aligning the lamp on the vehicle,

push rearward to fully seat the lamp

assembly then insert and push the

two retainer pins down.

7. Turn the lamps on and make sure

they work properly.

Maintenance and care

270

Page 271 of 312

Replacing side repeater bulbs

1. Carefully pry the lamp assembly

away from the fender.

2. Rotate the bulb socket

counterclockwise and remove from

lamp assembly.

3. Carefully pull bulb straight out of

socket and push in the new bulb.

4. Install the bulb socket in lamp

assembly by turning clockwise.

5. Carefully install the lamp

assembly on the fender snapping it in place.

Replacing front/rear side marker bulbs

1. Reach under the side of the front

or rear bumper, rotate bulb socket

counterclockwise and remove from

lamp assembly.

2. Carefully pull bulb straight out of

socket and push in the new bulb.

3. Install bulb socket in lamp

assembly by turning clockwise.

Replacing tail/brake/turn/backup lamp bulbs

The tail/brake/turn/backup bulbs are located in the tail lamp assembly,

one just below the other. Follow the same steps to replace each bulb:

1. Open the liftgate to expose the

lamp assemblies.

2. Remove the two screws from the

lamp assembly.

3. Pull the lamp assembly towards

the rear and side of the vehicle at

an angle carefully removing it from

the vehicle.

4. Rotate the bulb socket

counterclockwise and remove from

lamp assembly.

Maintenance and care

271

Page 272 of 312

5. Pull the bulb straight out of the socket and push in the new bulb.

6. To complete installation, follow the removal procedure in reverse

order.

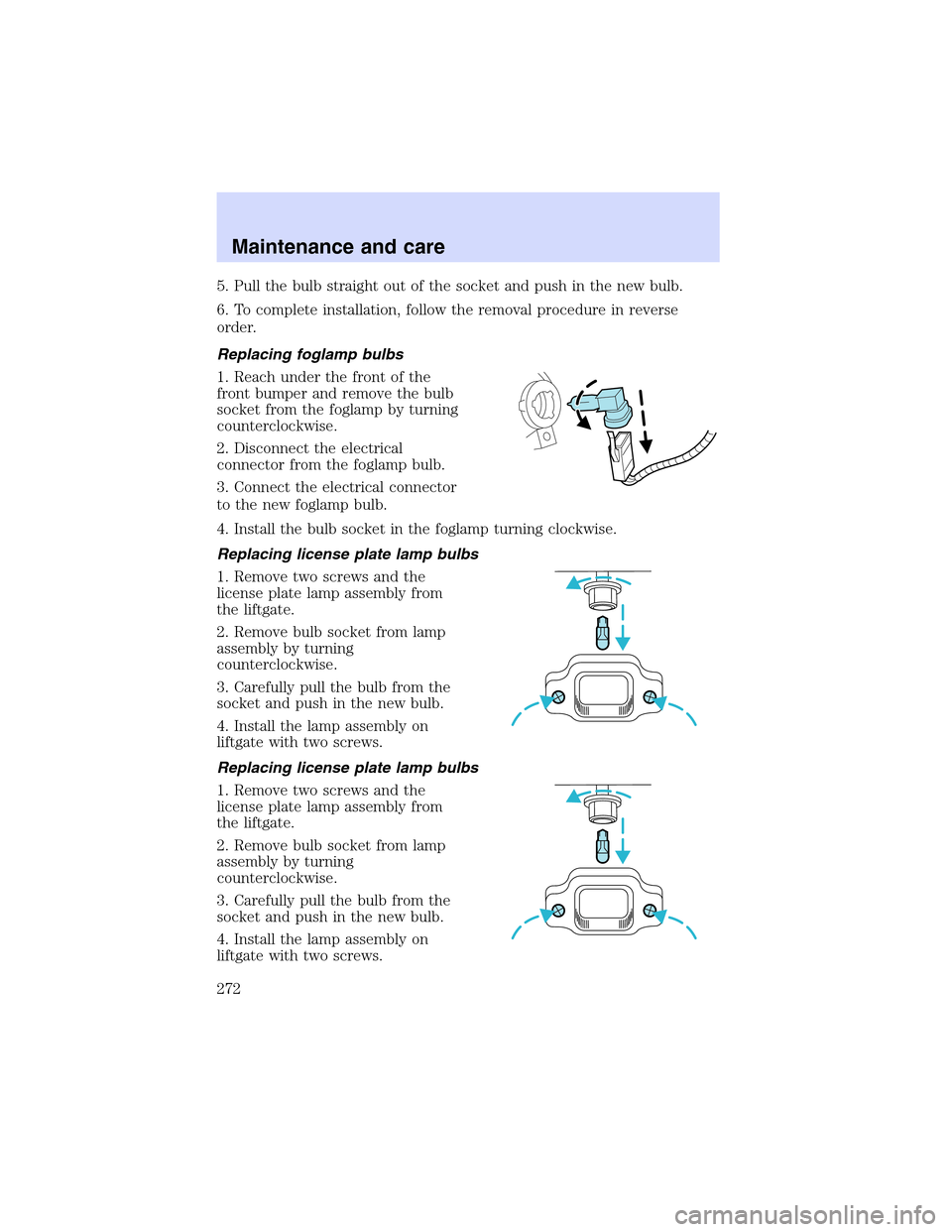

Replacing foglamp bulbs

1. Reach under the front of the

front bumper and remove the bulb

socket from the foglamp by turning

counterclockwise.

2. Disconnect the electrical

connector from the foglamp bulb.

3. Connect the electrical connector

to the new foglamp bulb.

4. Install the bulb socket in the foglamp turning clockwise.

Replacing license plate lamp bulbs

1. Remove two screws and the

license plate lamp assembly from

the liftgate.

2. Remove bulb socket from lamp

assembly by turning

counterclockwise.

3. Carefully pull the bulb from the

socket and push in the new bulb.

4. Install the lamp assembly on

liftgate with two screws.

Replacing license plate lamp bulbs

1. Remove two screws and the

license plate lamp assembly from

the liftgate.

2. Remove bulb socket from lamp

assembly by turning

counterclockwise.

3. Carefully pull the bulb from the

socket and push in the new bulb.

4. Install the lamp assembly on

liftgate with two screws.

Maintenance and care

272

Page 273 of 312

Replacing high-mount brake lamp bulbs

1. Remove the two screws and move

the lamp assembly away from the

liftgate.

2. Remove the bulb holder from the

lamp assembly by depressing the

snaps.

3. Pull the bulb straight out of the

socket and push in the new bulb.

Install the new bulbs in reverse

order.

USING THE RIGHT BULBS

Replacement bulbs are specified in the chart below. Headlamp bulbs

must be marked with an authorized“D.O.T.”for North America and an

“E”for Europe to assure lamp performance, light brightness and pattern

and safe visibility. The correct bulbs will not damage the lamp assembly

or void the lamp assembly warranty and will provide quality bulb burn

time.

Maintenance and care

273

Page 274 of 312

Function Number of bulbs Trade number

Park/turn lamps (front) 2 3157 AK (amber)

Headlamps 2 9007

Rear stop/turn/tail lamps 4 3057

Rear license plate lamps 2 168

Backup lamp 2 3156K

High-mount brake lamps 5 W5W

Side repeater 2 WY5W (amber)

Front sidemarker 2 194

Rear sidemarker 2 194

Fog lamp 2 9145

Cargo lamp 1 211-2

Interior overhead lamp 1 912 (906)

Front door courtesy

lamp1

168

Map lamps 2 168 (T10)

Ashtray lamp 1 161

All replacement bulbs are clear in color except where noted.

To replace all instrument panel lights - see your dealer.

VERTICAL AIM ADJUSTMENT

1. Park the vehicle on a level surface approximately 7.6 meters (25 feet)

from a vertical wall or screen directly in front of it.

•(1) Eight feet

•(2) Center height of lamp to ground

•(3) Twenty-five feet

Maintenance and care

274

Page 275 of 312

•(4) Horizontal reference line

2. Measure the height from the

center of your headlamp to the

ground and mark a 2.4 meter (8

foot) horizontal reference line on

the vertical wall or screen at this

height (a piece of masking tape

works well). The center of the lamp

is marked by a 3.0 mm circle on the

headlamp lens.

3. Turn on the low beam headlamps to illuminate the wall or screen and

open the hood.

4. On the wall or screen you will

observe a light pattern with a

distinct horizontal edge of high

intensity light with a slight angle

towards the right. If this edge is not

at the horizontal reference line, the

beam will need to be adjusted.

5. Locate the vertical adjuster on

each headlamp, then usea4mm

socket/wrench to turn the adjuster

either counterclockwise (to adjust

down) or clockwise (to adjust up)

aligning the upper edge of the light

pattern up to the horizontal line.

6. HORIZONTAL AIM IS NOT

REQUIRED FOR THIS VEHICLE

AND IS NON-ADJUSTABLE.

7. Close the hood and turn off the lamps.

CLEANING AND CARING FOR YOUR VEHICLE

Refer to the Accessories chapter for a list of Ford-approved cleaners,

polishes and sealants.

Washing the exterior

Wash your vehicle regularly with cool or lukewarm water and a neutral

Ph shampoo, such as Detail Wash (ZC-3–A), which is available from your

dealer.

Maintenance and care

275

Page 276 of 312

•Never use strong household detergents or soap, such as dish washing

or laundry liquid. These products can discolor and spot painted

surfaces.

•Never wash a vehicle that is“hot to the touch”or during exposure to

strong, direct sunlight.

•Always use a clean sponge or carwash mitt with plenty of water for

best results.

•Dry the vehicle with a chamois or soft terry cloth towel in order to

eliminate water spotting.

•It is especially important to wash the vehicle regularly during the

winter months, as dirt and road salt are difficult to remove and cause

damage to the vehicle.

•Immediately remove items such as gasoline, diesel fuel, bird droppings

and insect deposits because they can cause damage to the vehicle’s

paintwork and trim over time.

•Remove any exterior accessories, such as antennas, before entering a

car wash.

•Suntan lotions and insect repellents can damage any painted

surface; if these substances come in contact with your vehicle,

wash off as soon as possible.

Waxing

Applying a polymer paint sealant to your vehicle every six months will

assist in reducing minor scratches and paint damage.

•Wash the vehicle first.

•Do not use waxes that contain abrasives.

•Do not allow paint sealant to come in contact with any non-body

(low-gloss black) colored trim, such as grained door handles, roof

racks, bumpers, side moldings, mirror housings or the windshield cowl

area. The paint sealant will“gray”or stain the parts over time.

Paint chips

Your dealer has touch-up paint and sprays to match your vehicle’s color.

Take your color code (printed on a sticker in the driver’s door jam) to

your dealer to ensure you get the correct color.

•Remove particles such as bird droppings, tree sap, insect deposits, tar

spots, road salt and industrial fallout before repairing paint chips.

•Always read the instructions before using the products.

Maintenance and care

276

Page 277 of 312

Aluminum wheels and covers

Aluminum wheel rims or covers are coated with a clearcoat paint finish.

In order to maintain their shine:

•Clean with Motorcraft Wheel and Tire Cleaner (ZC-37–A), which is

available from your dealer.

•Never apply any cleaning chemical to hot or warm wheel rims or

covers.

•Some automatic car washes may cause damage to the finish on your

wheel rims or covers. Chemical-strength cleaners, or cleaning

chemicals, in combination with brush agitation to remove brake dust

and dirt, could wear away the clearcoat finish over time.

•Do not use hydrofluoric acid-based or high caustic-based wheel

cleaners, steel wool, fuels or strong household detergent.

•To remove tar and grease, use Ford Extra Strength Tar and Road Oil

Removal (B7A-19520–AA), available from your dealer.

Engine

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal. When washing:

•Take care when using a power washer to clean the engine. The high

pressure fluid could penetrate the sealed parts and cause damage.

•Do not spray a hot engine with cold water to avoid cracking the

engine block or other engine components.

•Spray Motorcraft Engine Shampoo and Degreaser (ZC-20) on all parts

that require cleaning and pressure rinse clean.

Maintenance and care

277

Page 278 of 312

•Coverthehighlighted areas to prevent water damage when cleaning

the engine.

4.6L V8 Engine

4.0L SOHC V6 Engine

•Never wash or rinse the engine while it is running; water in the

running engine may cause internal damage.

Plastic (non-painted) exterior parts

Use only approved products to clean plastic parts. These products are

available from your dealer.

•For routine cleaning, use Detail Wash (ZC-3–A).

Maintenance and care

278