torque Mercury Mountaineer 2004 Owner's Manuals

[x] Cancel search | Manufacturer: MERCURY, Model Year: 2004, Model line: Mountaineer, Model: Mercury Mountaineer 2004Pages: 280, PDF Size: 5.38 MB

Page 193 of 280

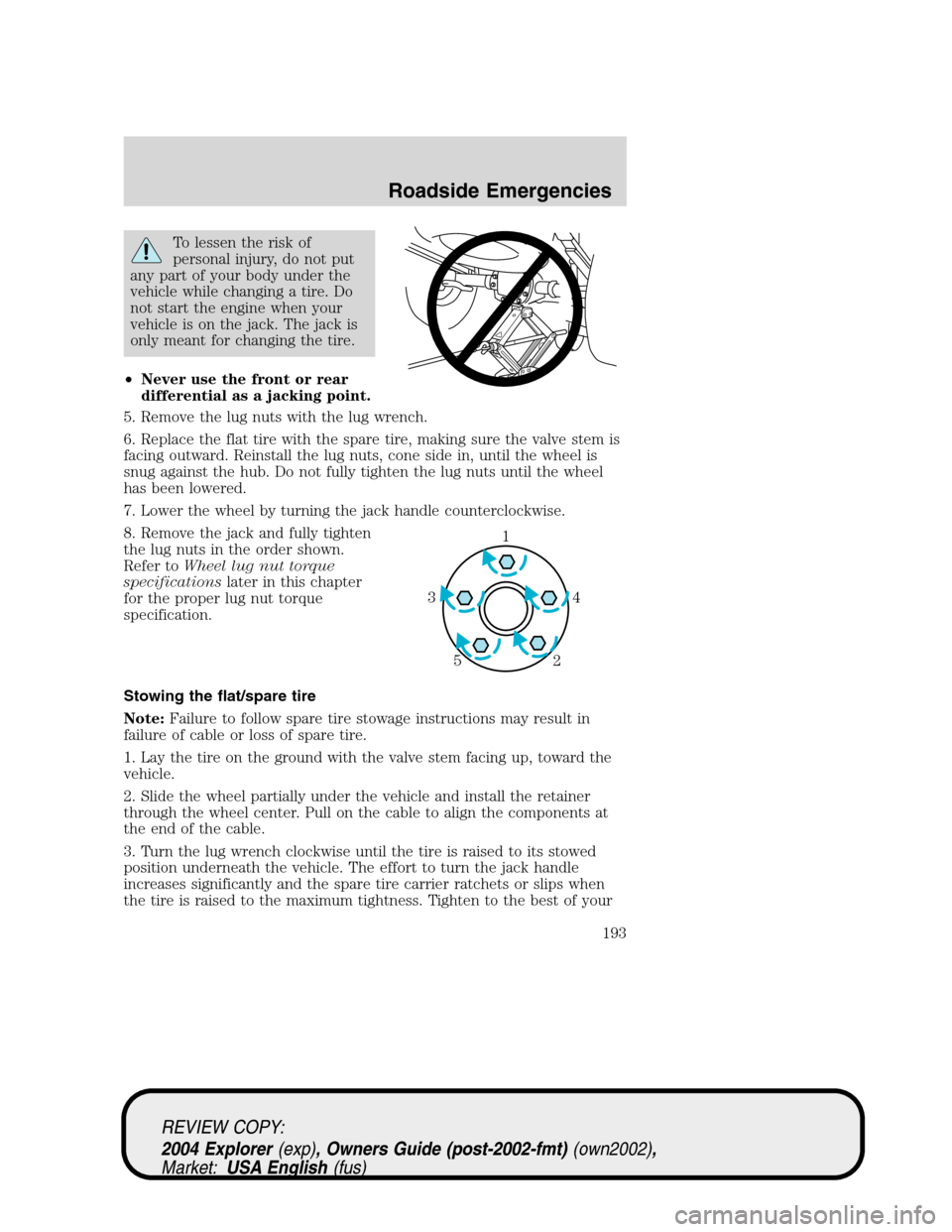

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

•Never use the front or rear

differential as a jacking point.

5. Remove the lug nuts with the lug wrench.

6. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall the lug nuts, cone side in, until the wheel is

snug against the hub. Do not fully tighten the lug nuts until the wheel

has been lowered.

7. Lower the wheel by turning the jack handle counterclockwise.

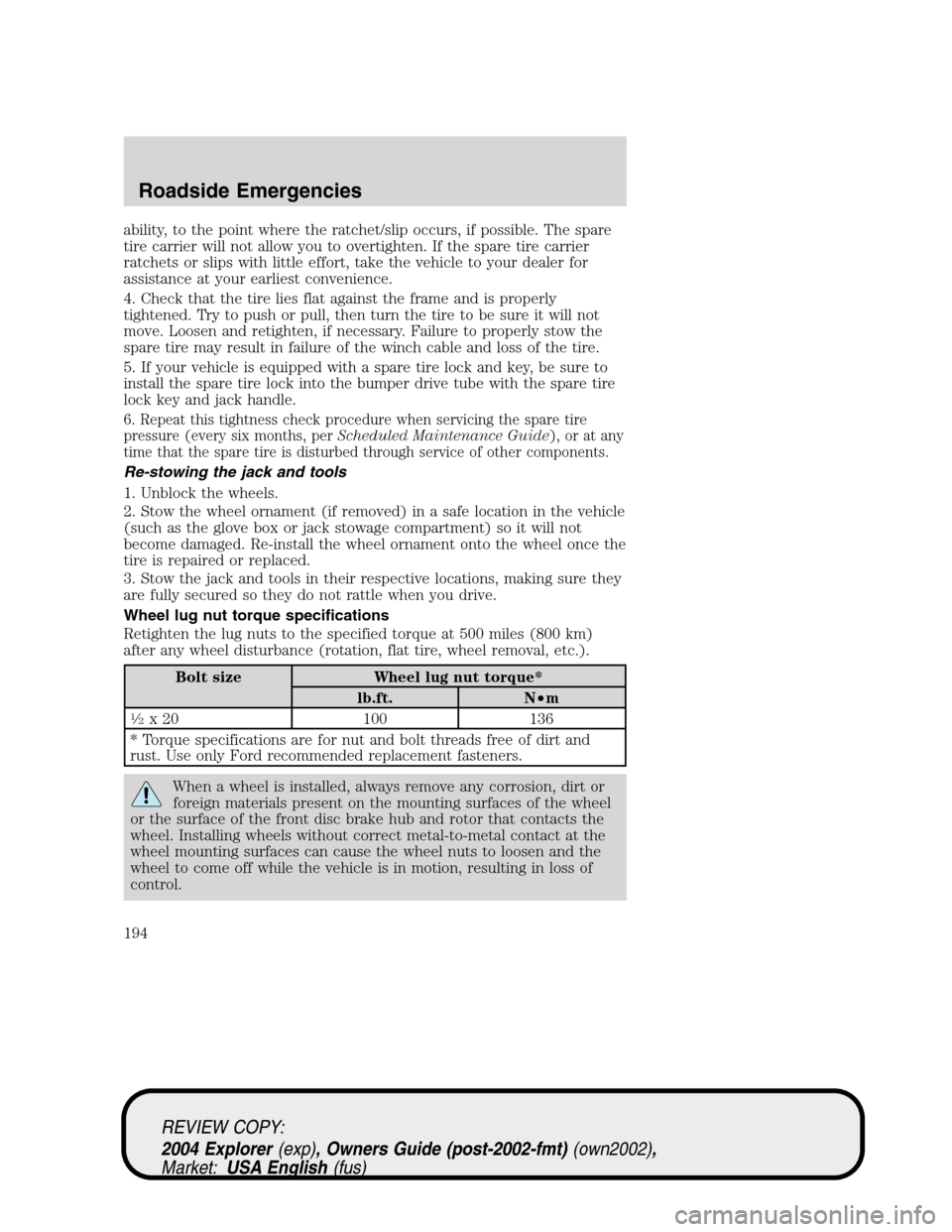

8. Remove the jack and fully tighten

the lug nuts in the order shown.

Refer toWheel lug nut torque

specificationslater in this chapter

for the proper lug nut torque

specification.

Stowing the flat/spare tire

Note:Failure to follow spare tire stowage instructions may result in

failure of cable or loss of spare tire.

1. Lay the tire on the ground with the valve stem facing up, toward the

vehicle.

2. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

3. Turn the lug wrench clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

1

4 3

2 5

REVIEW COPY:

2004 Explorer(exp), Owners Guide (post-2002-fmt)(own2002),

Market:USA English(fus)

Roadside Emergencies

193

Page 194 of 280

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your dealer for

assistance at your earliest convenience.

4. Check that the tire lies flat against the frame and is properly

tightened. Try to push or pull, then turn the tire to be sure it will not

move. Loosen and retighten, if necessary. Failure to properly stow the

spare tire may result in failure of the winch cable and loss of the tire.

5. If your vehicle is equipped with a spare tire lock and key, be sure to

install the spare tire lock into the bumper drive tube with the spare tire

lock key and jack handle.

6. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, perScheduled Maintenance Guide), or at any

time that the spare tire is disturbed through service of other components.

Re-stowing the jack and tools

1. Unblock the wheels.

2. Stow the wheel ornament (if removed) in a safe location in the vehicle

(such as the glove box or jack stowage compartment) so it will not

become damaged. Re-install the wheel ornament onto the wheel once the

tire is repaired or replaced.

3. Stow the jack and tools in their respective locations, making sure they

are fully secured so they do not rattle when you drive.

Wheel lug nut torque specifications

Retighten the lug nuts to the specified torque at 500 miles (800 km)

after any wheel disturbance (rotation, flat tire, wheel removal, etc.).

Bolt size Wheel lug nut torque*

lb.ft. N•m

1�2x 20 100 136

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use only Ford recommended replacement fasteners.

When a wheel is installed, always remove any corrosion, dirt or

foreign materials present on the mounting surfaces of the wheel

or the surface of the front disc brake hub and rotor that contacts the

wheel. Installing wheels without correct metal-to-metal contact at the

wheel mounting surfaces can cause the wheel nuts to loosen and the

wheel to come off while the vehicle is in motion, resulting in loss of

control.

REVIEW COPY:

2004 Explorer(exp), Owners Guide (post-2002-fmt)(own2002),

Market:USA English(fus)

Roadside Emergencies

194