lock Mercury Sable 1998 s Workshop Manual

[x] Cancel search | Manufacturer: MERCURY, Model Year: 1998, Model line: Sable, Model: Mercury Sable 1998Pages: 190, PDF Size: 1.29 MB

Page 148 of 190

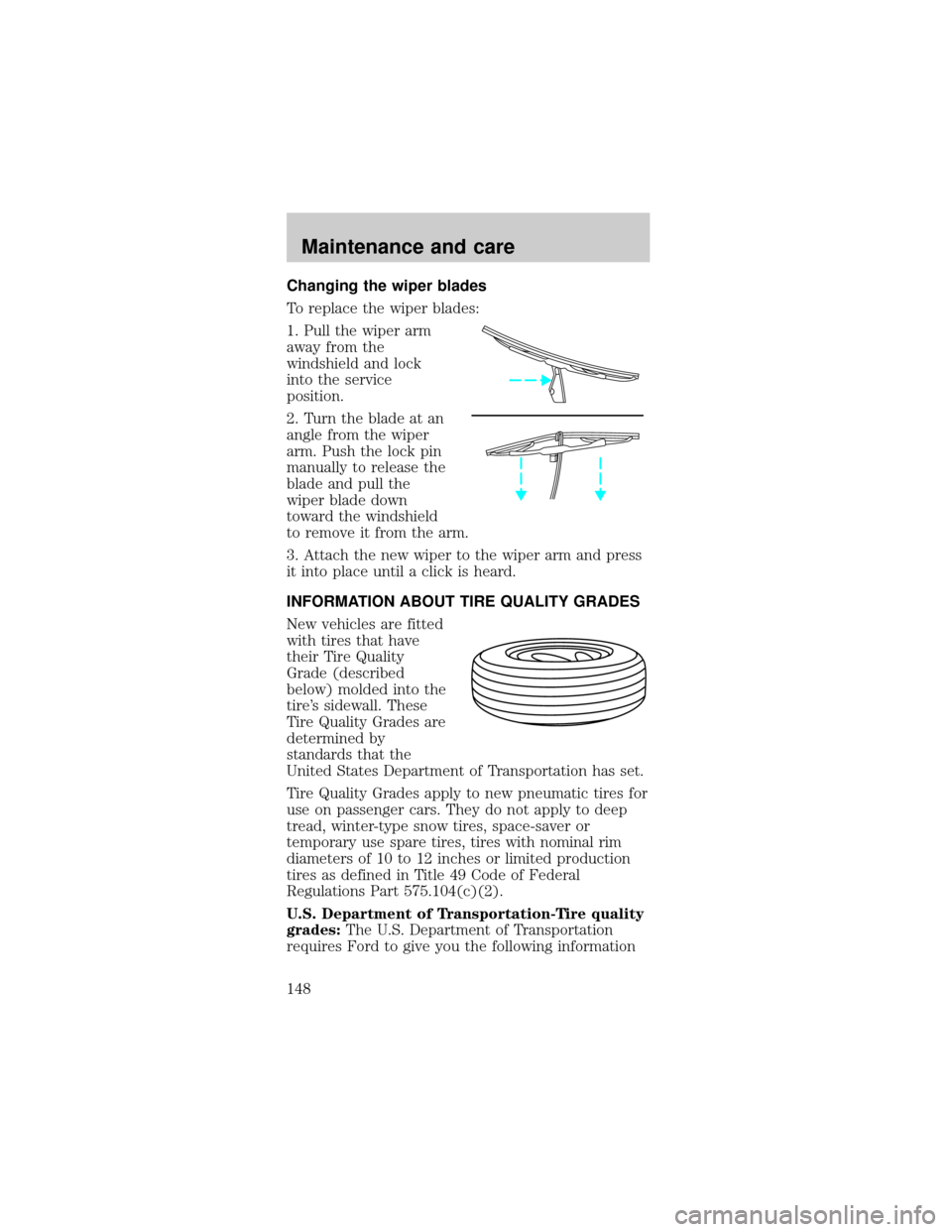

Changing the wiper blades

To replace the wiper blades:

1. Pull the wiper arm

away from the

windshield and lock

into the service

position.

2. Turn the blade at an

angle from the wiper

arm. Push the lock pin

manually to release the

blade and pull the

wiper blade down

toward the windshield

to remove it from the arm.

3. Attach the new wiper to the wiper arm and press

it into place until a click is heard.

INFORMATION ABOUT TIRE QUALITY GRADES

New vehicles are fitted

with tires that have

their Tire Quality

Grade (described

below) molded into the

tire's sidewall. These

Tire Quality Grades are

determined by

standards that the

United States Department of Transportation has set.

Tire Quality Grades apply to new pneumatic tires for

use on passenger cars. They do not apply to deep

tread, winter-type snow tires, space-saver or

temporary use spare tires, tires with nominal rim

diameters of 10 to 12 inches or limited production

tires as defined in Title 49 Code of Federal

Regulations Part 575.104(c)(2).

U.S. Department of Transportation-Tire quality

grades:The U.S. Department of Transportation

requires Ford to give you the following information

Maintenance and care

148

Page 155 of 190

Fuel Filler Cap

Your fuel tank filler cap has an indexed design with

a one-eighth turn on/off feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise 1/8

of a turn until it stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with

the notches on the filler pipe.

5. Turn the filler cap clockwise 1/8 of a turn until it

stops.

If the ªService Engine Soon/Check Engine ª indicator

comes on and stays on when you start the engine,

the fuel filler cap may not be properly installed.

Turn off the engine, remove the fuel filler cap and

reinstall it being careful to align the cap properly.

If you must replace the fuel filler cap, replace

it with an authorized Motorcraft part. The

customer warranty may be void for any damage

to the fuel tank or fuel system if an authorized

Motorcraft fuel filler cap is not used.

The fuel system may be under pressure. If

the fuel filler cap is venting vapor or if you

hear a hissing sound, wait until it stops before

completely removing the fuel filler cap. Otherwise,

fuel may spray out and injure you or others.

If you do not use the proper fuel filler cap,

the pressure in the fuel tank can damage

the fuel system or cause it to work improperly in a

collision.

Maintenance and care

155

Page 161 of 190

Replacing headlamp bulbs

Handle a halogen headlamp bulb carefully

and keep out of children's reach. Grasp the

bulb only by its plastic base and do not touch the

glass. The oil from your hand could cause the bulb

to break the next time the headlamps are

operated.

If the bulb is accidentally touched, it should be

cleaned with rubbing alcohol before being used.

To remove the headlamp bulb:

1. Make sure headlamp switch is in OFF position,

then open the hood. If you are replacing the driver

side headlamp, unclip the electronic module on the

right side of the battery and move it out of the way.

2. Locate the headlamp bulb through the hole in the

upper radiator support assembly.

3. Release clip and

disconnect the

electrical connector

from the bulb.

4. Remove the bulb

retaining ring by

rotating it

counterclockwise

(when viewed from the

rear) about 1/8 turn to

free it from the bulb socket, and slide the ring off

the plastic base. Keep the ring to retain the new

bulb.

5. With out turning, remove the old bulb from the

lamp assembly by gently pulling it straight out of the

lamp assembly.

Maintenance and care

161

Page 162 of 190

To install the new bulb:

1. With the flat side of

the bulb's plastic base

facing upward, insert

the glass end of the

bulb into the lamp

assembly. You may

need to turn the bulb left or right to align the

grooves in the plastic base with the tabs in the lamp

assembly. When the grooves are aligned, push the

bulb into the lamp assembly until the plastic base

contacts the rear of the lamp assembly.

2. Install the bulb retaining ring over the plastic base

until it contacts the rear of the socket by rotating

clockwise until you feel a ªstop.º

3. Install the electrical connector into the rear of the

plastic base until it snaps, locking it into position.

4. Turn the headlamps on and make sure they work

properly. If the headlamp was correctly aligned

before you changed the bulb, you should not need to

align it again.

High-mount brakelamp bulbs

The following

procedure is for sedans

only. For wagon, refer

to a qualified

technician.

1. Open trunk.

2. Inside trunk, locate

access hole under the

rear window

3. Remove the bulb

socket by rotating it 45 degrees and pulling it out of

the lamp assembly.

4. Carefully pull bulb straight out of socket and push

in new bulb.

5. To complete installation, follow the removal

procedure in reverse order.

Maintenance and care

162

Page 163 of 190

License plate lamp bulbs

To change the license plate bulbs:

Sedan

1. Remove two screws

and the license plate

lamp assembly from

the rear bumper.

2. Remove bulb socket

by turning

counterclockwise .

3. Carefully pull the

bulb out from the

socket and push in the

new bulb.

4. Install the lamp assembly on rear bumper with

two screws.

Wagon

1. Remove screw and

the license plate lamp

assembly from liftgate.

2. Remove bulb socket

by turning

counterclockwise .

3. Carefully pull the

bulb out from the

socket and push in the

new bulb.

4. Install the lamp assembly on liftgate with screw.

Replacing front parking lamp/turn signal bulbs

For bulb replacement, see a dealer or qualified

technician.

Replacing tail lamp/backup bulbs

For bulb replacement, see a dealer or qualified

technician.

Maintenance and care

163

Page 166 of 190

3. Turn the horizontal

adjusting screw in the

direction of the arrow

to change the

horizontal aim as

shown.

4.Usea7mmwrench

or socket to turn the

horizontal adjusting screw until the ª0º reference

mark on the view dial is aligned with the rearward

facing tab (as shown) on the plastic housing.

Vertical aim adjustment

1. Park the vehicle on a level surface.

2. With the hood open,

locate the bubble level

vertical aim indicator.

It is visible when

viewed from above

center rear of the

headlamp. Locate the

vertical adjusting

screw, located on the

outboard side of the headlamp adjacent to the

headlamp upper outboard attachment.

3. The ªUPº and ªDNº on the bubble label indicate

the directional change (up or down) of the vertical

aim.

4.Usea7mmwrench or socket to turn the vertical

adjusting screw clockwise or counterclockwise until

the bubble aligns with the ª0º reference mark on the

vertical indicator when viewed directly from above.

Repeat the above procedures to the other headlamp,

if necessary.

Maintenance and care

166

Page 169 of 190

²Do not spray with cold water to avoid cracking

the engine block or other engine components.

²Cover the highlighted areas to prevent water

damage when cleaning the engine.

²3.0L Vulcan engine

²3.0L Duratec engine

²Never wash or rinse the engine while it is

running; water in the running engine may cause

internal damage.

Maintenance and care

169

Page 175 of 190

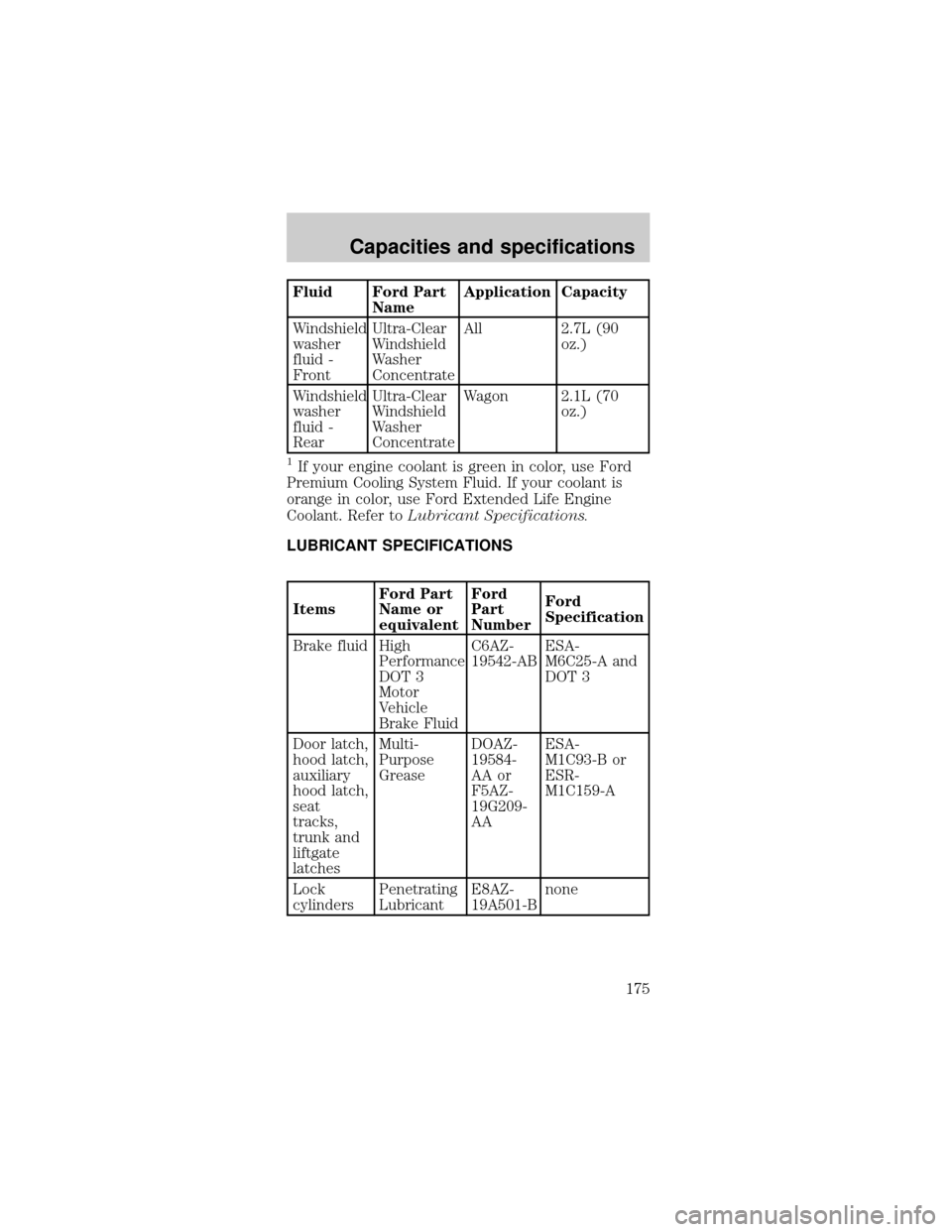

Fluid Ford Part

NameApplication Capacity

Windshield

washer

fluid -

FrontUltra-Clear

Windshield

Washer

ConcentrateAll 2.7L (90

oz.)

Windshield

washer

fluid -

RearUltra-Clear

Windshield

Washer

ConcentrateWagon 2.1L (70

oz.)

1If your engine coolant is green in color, use Ford

Premium Cooling System Fluid. If your coolant is

orange in color, use Ford Extended Life Engine

Coolant. Refer toLubricant Specifications.

LUBRICANT SPECIFICATIONS

ItemsFord Part

Name or

equivalentFord

Part

NumberFord

Specification

Brake fluid High

Performance

DOT 3

Motor

Vehicle

Brake FluidC6AZ-

19542-ABESA-

M6C25-A and

DOT 3

Door latch,

hood latch,

auxiliary

hood latch,

seat

tracks,

trunk and

liftgate

latchesMulti-

Purpose

GreaseDOAZ-

19584-

AA or

F5AZ-

19G209-

AAESA-

M1C93-B or

ESR-

M1C159-A

Lock

cylindersPenetrating

LubricantE8AZ-

19A501-Bnone

Capacities and specifications

175

Page 180 of 190

IDENTIFYING YOUR VEHICLE

Safety compliance label

The National Highway

Traffic Safety

Administration

Regulations require

that a Safety

Compliance

Certification Label be

affixed to a vehicle and

prescribe where the

Safety Compliance

Certification Label may

be located. The Safety Compliance Certification

Label is located on the front door latch pillar on the

driver's side.

Vehicle identification number

The vehicle

identification number

is attached to a metal

tag and is located on

the driver side

instrument panel.

Engine number

The engine number (the last eight numbers of the

vehicle identification number) is stamped on the

engine block, transmission, frame and transfer case

(if equipped).

MFD. BY FORD MOTOR CO. IN U.S.A.

EXT PNT: XXXXXX XXXXXX RC: XX DSO: XXXX F0000

BAR INT TR TP/PS R AXLE TR SPR T0000

X XX XXX X XX X XXXX

UTC

ÑFOHT-15294A10-GA

MAXIMUM LOAD=OCCUPANTS + LUGGAGE=XXXKG/XXXXLB

OCCUPANTS: X TOTAL X FR X 2ND X RR OCCUPANTS LUGGAGE

XX XXXKG/XXXXLB

TIRE: XXXX/XXXXX XXX X XXXKG/XXXXLB

PRESSURE (FR) XXX kPa/33 PSI COLD

PRESSURE (RR) XXX kPa/33 PSI COLD

TRAILER TOWING - SEE OWNER GUIDE

DATE: XXXXX GVWR:XXXXX LB/ XXXXX KG

VIN: XXXXXXXXXXXXXXXXX TYPE: XXXXXXXXXXXXXXX FGAWR: XXXXXX/XXXXXXX RGAWR: XXXXXXX/XXXXXXXTHIS VEHICLE CONFORMS TO ALL APPLICABLE FEDERAL

MOTOR VEHICLE SAFETY STANDARDS IN EFFECT ON THE

DATE OF MANUFACTURE SHOWN ABOVE.

XXXXXXXXXXXXXXXXXAIR BAG

Capacities and specifications

180

Page 182 of 190

Air bag supplemental

restraint system ........ 66

and child

safety seats ............. 69

description .............. 67

disposal .................... 72

indicator light ......... 72

passenger air bag ... 70

Air conditioning

automatic temperature

control

system . 21,22,23,24,26

Anti-theft system ...... 47

arming the system .. 47

Automatic transaxle . 93

driving

with ........... 96,97,98,99

Brakes ........................ 89

anti-lock ................... 89

anti-lock brake system

(ABS) warning

light .......................... 90

fluid, checking and

adding .................... 133

shift interlock .......... 93

Break-in period ........... 3

Cargo cover .......... 41,42

Cargo net ................... 41

Cellular telephone

(see your Cellular

Phone Guide) ............ 39

Child safety seats

attaching with tether

straps ....................... 78

in rear seat ......... 76,78

tether anchorage

hardware ................. 79

Cleaning your

vehicle ...................... 167

built-in child

seat ..................... 80,83engine

compartment ......... 168

exterior lamps ....... 170

plastic parts .......... 170

washing .................. 167

waxing ................... 168

wheels .................... 168

wiper blades .......... 170

Console ...................... 38

Controls

power seat ............... 55

Coolant ............. 137,138

checking and

adding .................... 135

refill capacities ...... 137

Defrost

rear window ............ 17

Doors

central unlocking 36,37

Emission control

system ...................... 158

Engine

coolant ................... 134

idle speed control . 142

service points . 129,130

starting after a

collision ................. 108

Engine block heater . 87

Engine oil

checking and

adding .................... 132

dipstick .................. 130

specifications . 130,132

Exhaust fumes .......... 87

Floor mats ................. 39

Fuel

choosing the

right fuel ................ 156

detergent in fuel ... 157

filling your vehicle

with fuel ......... 153,155

quality .................... 156

Index

182