maintenance Mercury Sable 2000 s User Guide

[x] Cancel search | Manufacturer: MERCURY, Model Year: 2000, Model line: Sable, Model: Mercury Sable 2000Pages: 232, PDF Size: 2.09 MB

Page 112 of 232

BRAKES

Your service brakes are self-adjusting. Refer to the scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

Anti-lock brake system (ABS) (if equipped)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. The ABS performs a self-check after you start

the engine and begin to drive away. A brief mechanical noise may be

heard during this test. This is normal. If a malfunction is found, the ABS

warning light will come on. If the vehicle has continuous vibration or

shudder in the steering wheel while braking, the vehicle should be

inspected by a qualified service technician.

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

Driving

112

Page 124 of 232

If driving through deep or standing water is unavoidable, proceed very

slowly. Never drive through water that is higher than the bottom of the

hubs (for trucks) or the bottom of the wheel rims (for cars).

Once through the water, always try the brakes. Wet brakes do not stop

the vehicle as effectively as dry brakes. Drying can be improved by

moving your vehicle slowly while applying light pressure on the brake

pedal.

Driving through deep water where the transmission vent tube is

submerged may allow water into the transmission and cause

internal transmission damage.

TRAILER TOWING

Your vehicle is classified as a light duty towing vehicle. The amount of

weight you can safely tow depends on the type of engine you have in

your vehicle. Your vehicle does not come from the factory fully equipped

to tow. No towing packages are available through Ford or

Mercury/Lincoln dealers. Do not tow a trailer until your vehicle has been

driven at least 800 km (500 miles). If towing with a station wagon, inflate

the rear tires to 35 psi.

Towing a trailer places an additional load on your vehicle's engine,

transaxle, brakes, tires and suspension. Inspect these components

carefully after towing.

In order to identify your vehicle's engine, refer toIdentifying

components in the engine compartmentin the Maintenance and Care

chapter.

Driving

124

Page 127 of 232

Driving while you tow

When towing a trailer:

²Ensure that you turn off your speed control. The speed control may

shut off automatically when you are towing on long, steep grades.

²Consult your local motor vehicle speed regulations for towing a trailer.

²Use D (Drive) or a lower gear when towing up or down steep hills.

This will eliminate excessive downshifting and upshifting for optimum

fuel economy and transaxle cooling.

²Anticipate stops and brake gradually.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to your scheduled maintenance guide for

more information.

Trailer towing tips

²Practice turning, stopping and backing up in an area before starting on

a trip to get the feel of the vehicle trailer combination. When turning,

make wider turns so the trailer wheels will clear curbs and other

obstacles.

²Allow more distance for stopping with a trailer attached.

²The trailer tongue weight should be 10% of the loaded trailer weight.

²After you have traveled 80 km (50 miles), thoroughly check your

hitch, electrical connections and trailer wheel lug nuts.

²When stopped in traffic for long periods of time in hot weather, place

the gearshift in P (Park) and increase idle speed. This aids engine

cooling and air conditioner efficiency.

²Vehicles with trailers should not be parked on a grade. If you must

park on a grade, place wheel chocks under the trailer's wheels.

Recreational towing

Follow these guidelines for your specific powertrain combination to tow

your vehicle with all four wheels on the ground (such as behind a

recreational vehicle).

These guidelines are designed to ensure that your transmission is not

damaged due to insufficient lubrication.

Driving

127

Page 135 of 232

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment

Fuse Panel Description

37 15A Transmission Position Switch

38 5A GEM Park Neutral Switch

39 Ð Not Used

40 Ð Not Used

41 Ð Not Used

42 Ð Not Used

Power distribution box

The power distribution box is

located in the engine compartment.

The power distribution box contains

high-current fuses that protect your

vehicle's main electrical systems

from overloads.

Always disconnect the battery before servicing high current

fuses.

Always replace the cover to the Power Distribution Box before

reconnecting the battery or refilling fluid reservoirs.

If the battery has been disconnected and reconnected, refer to the

Batterysection of theMaintenance and carechapter.

Roadside emergencies

135

Page 147 of 232

SERVICE RECOMMENDATIONS

To help you service your vehicle:

²We highlight do-it-yourself items in the engine compartment for easy

location.

²We provide a Scheduled Maintenance Guide which makes tracking

routine service easy.

If your vehicle requires professional service, your dealership can provide

necessary parts and service. Check your ªWarranty Guideº to find out

which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

Be especially careful when inspecting or servicing your vehicle.

²Do not work on a hot engine.

²When the engine is running, keep loose clothing, jewelry or long hair

away from moving parts.

²Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

²Keep all lit cigarettes, open flames and other lit material away from

the battery and all fuel related parts.

If you disconnect the battery, the engine must ªrelearnº its idle

conditions before your vehicle will drive properly, as explained in the

Batterysection in this chapter.

Working with the engine off

1. Set the parking brake, and ensure the gearshift is securely latched in

park.

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

Working with the engine on

1. Set the parking brake and ensure the gearshift is securely latched in

P (Park).

2. Block the wheels to prevent the vehicle from moving unexpectedly.

Maintenance and care

147

Page 148 of 232

Do not start your engine with the air cleaner removed and do

not remove it while the engine is running.

OPENING THE HOOD

1. Inside the vehicle, pull the hood

release handle located under the

bottom of the instrument panel.

2. Go to the front of the vehicle and

release the auxiliary latch located in

the center between the hood and

the grille.

3. Lift the hood until the lift

cylinders hold it open.

Maintenance and care

148

Page 149 of 232

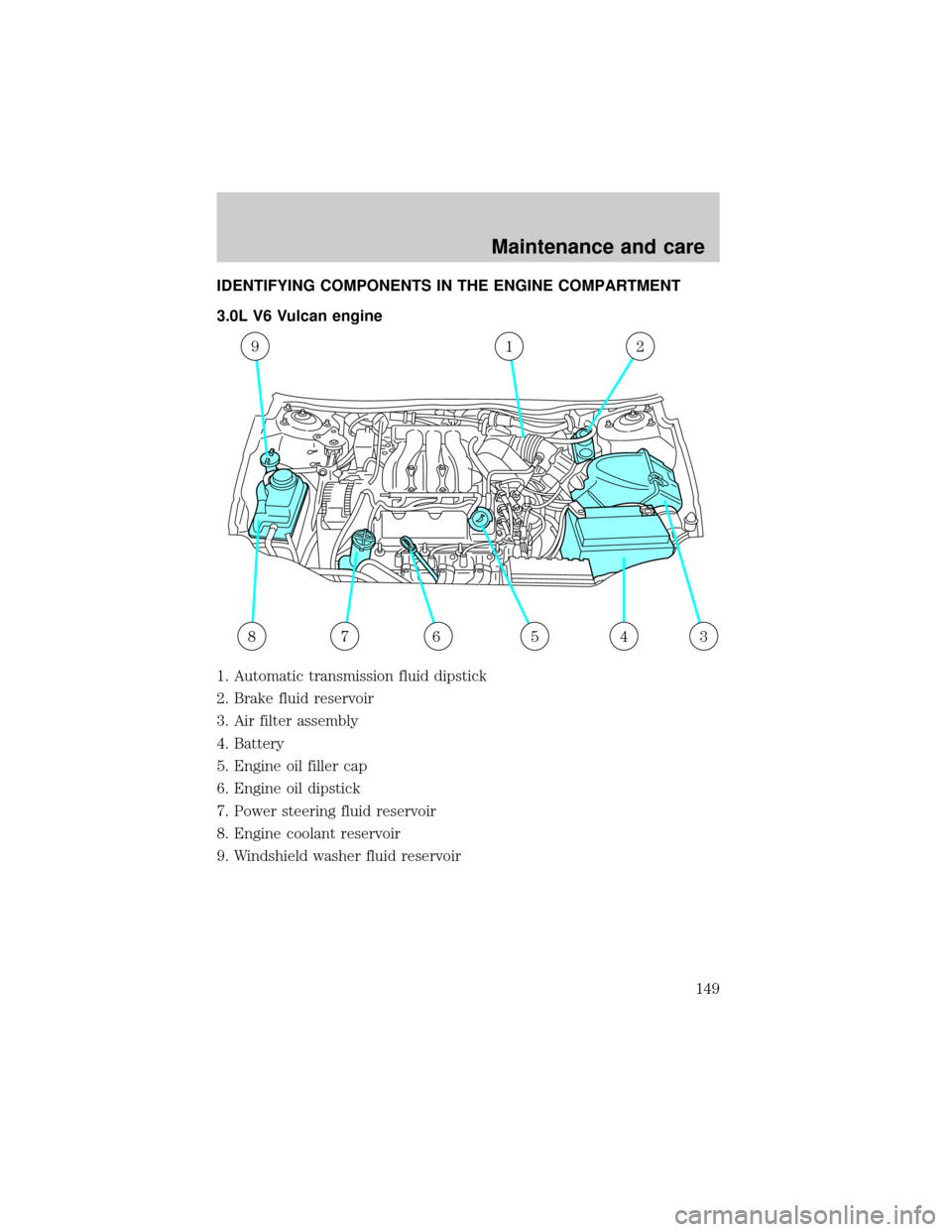

IDENTIFYING COMPONENTS IN THE ENGINE COMPARTMENT

3.0L V6 Vulcan engine

1. Automatic transmission fluid dipstick

2. Brake fluid reservoir

3. Air filter assembly

4. Battery

5. Engine oil filler cap

6. Engine oil dipstick

7. Power steering fluid reservoir

8. Engine coolant reservoir

9. Windshield washer fluid reservoir

786 543

912

Maintenance and care

149

Page 150 of 232

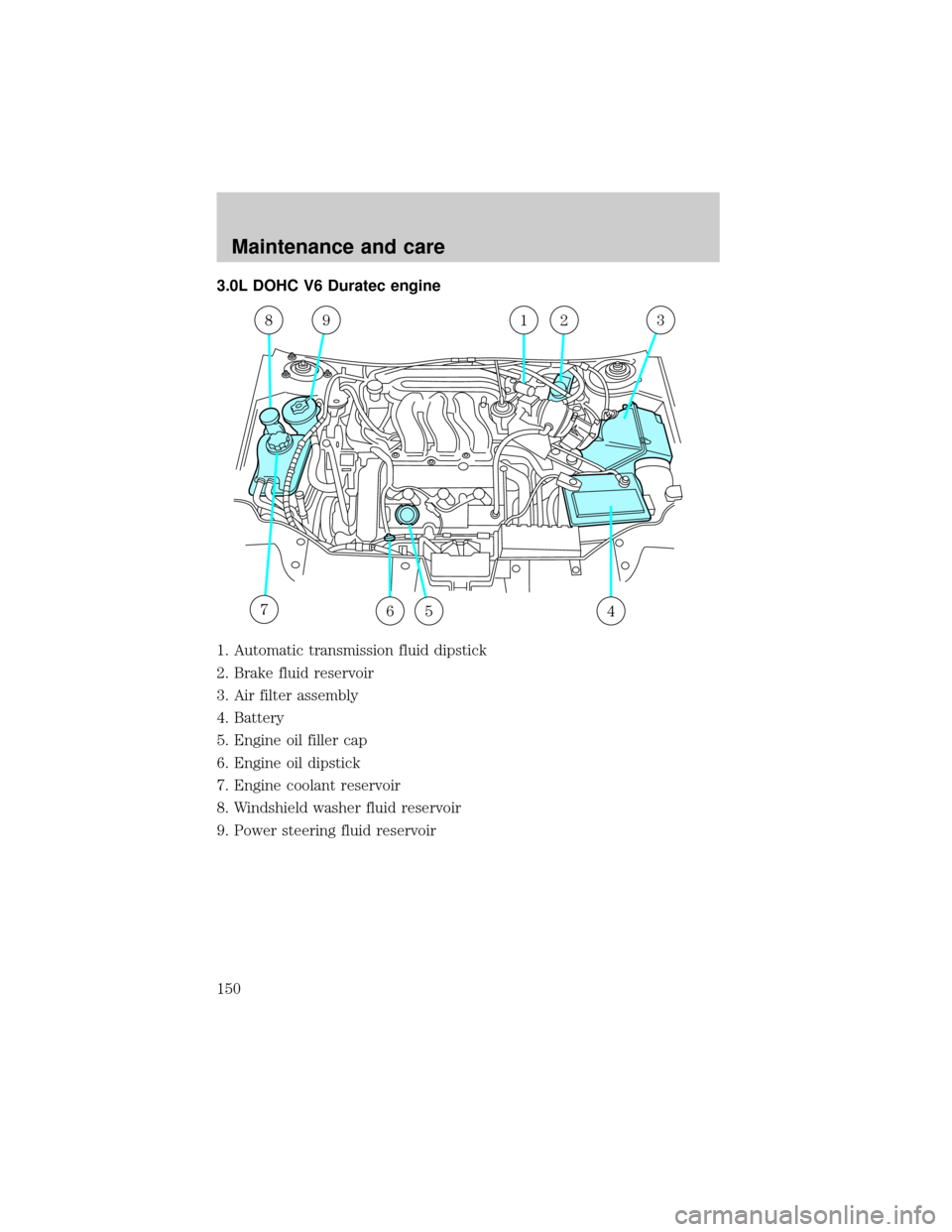

3.0L DOHC V6 Duratec engine

1. Automatic transmission fluid dipstick

2. Brake fluid reservoir

3. Air filter assembly

4. Battery

5. Engine oil filler cap

6. Engine oil dipstick

7. Engine coolant reservoir

8. Windshield washer fluid reservoir

9. Power steering fluid reservoir

7654

89123

Maintenance and care

150

Page 151 of 232

ENGINE OIL

Checking the engine oil

Refer to the Scheduled Maintenance Guide for the appropriate intervals

for checking the engine oil.

1. Make sure the vehicle is on level ground.

2. Turn the engine off and wait a few minutes for the oil to drain into the

oil pan.

3. Set the parking brake and ensure the gearshift is securely latched in P.

4. Open the hood. Protect yourself from engine heat.

5. Locate and carefully remove the

engine oil indicator (dipstick).

6. Wipe the indicator clean. Insert the indicator fully, then remove it

again.

²If the oil level isbetween the add 1QT and FULL marks or

between the MIN and MAX marks (depending on application),

the oil level is acceptable.DO NOT ADD OIL.

MAX MIN

FULL 1QT

Maintenance and care

151

Page 152 of 232

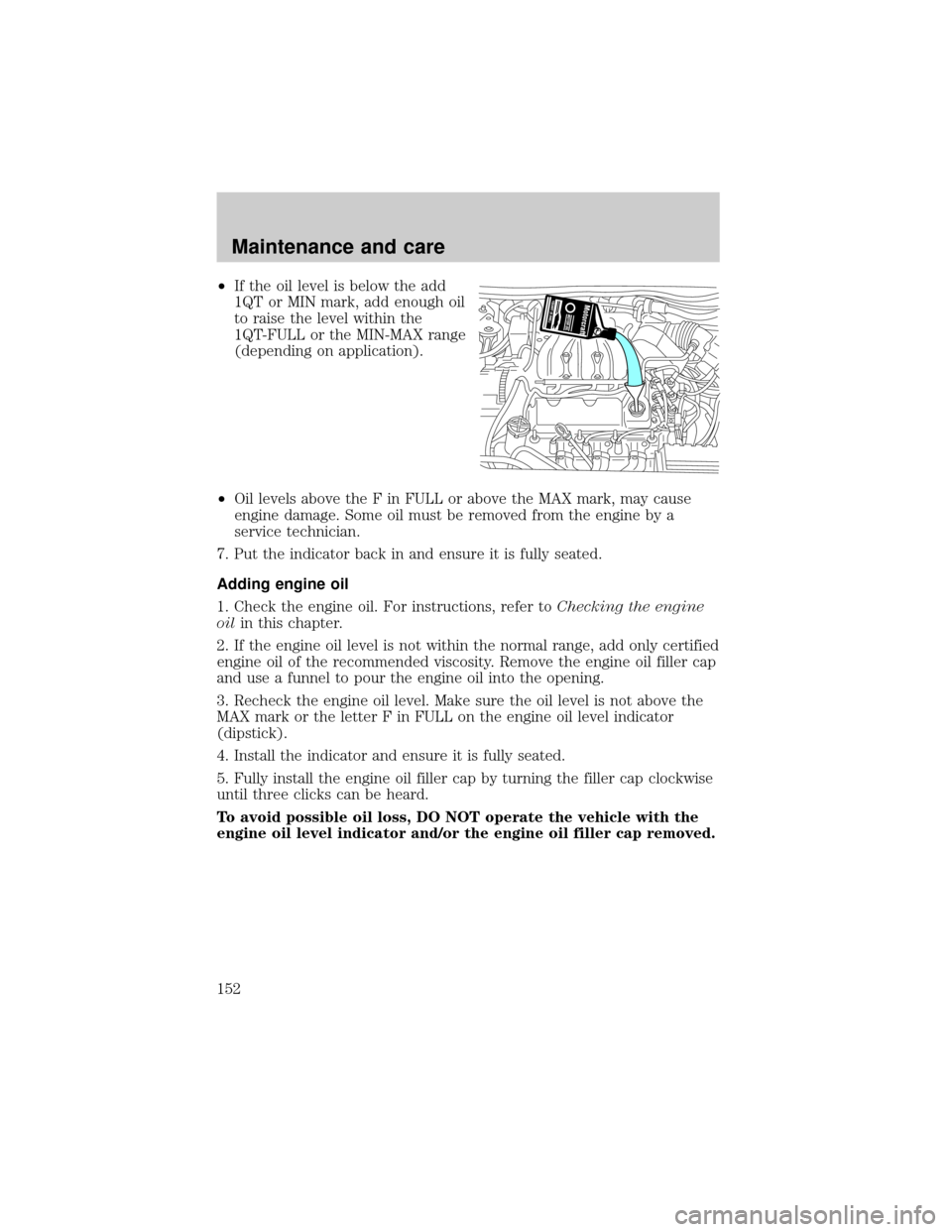

²If the oil level is below the add

1QT or MIN mark, add enough oil

to raise the level within the

1QT-FULL or the MIN-MAX range

(depending on application).

²Oil levels above the F in FULL or above the MAX mark, may cause

engine damage. Some oil must be removed from the engine by a

service technician.

7. Put the indicator back in and ensure it is fully seated.

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

MAX mark or the letter F in FULL on the engine oil level indicator

(dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

until three clicks can be heard.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

Maintenance and care

152