Mercury Villager 1999 Owner's Manuals

Manufacturer: MERCURY, Model Year: 1999, Model line: Villager, Model: Mercury Villager 1999Pages: 264, PDF Size: 2.19 MB

Page 201 of 264

To avoid scalding hot steam or coolant from being released from

the engine cooling system, never remove the radiator cap while

the engine is running or hot. Failure to follow this warning may result

in damage to the engine's cooling system and possible severe personal

injury.

If you must remove the radiator cap, follow these steps to avoid personal

injury:

1. Before you remove the cap, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the cap. Slowly

turn cap counterclockwise until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

Recycled engine coolant

Ford Motor Company recommends the use of recycled engine coolant

produced by Ford-approved processes.

Not all coolant recycling processes produce coolant which meets Ford

specification ESE-M97B44-A, and use of such coolant may harm engine

and cooling system components.

Always dispose of used automotive fluids in a responsible manner.

Follow your community's regulations and standards for recycling and

disposing of automotive fluids.

Coolant refill capacity

To find out how much fluid your vehicle's cooling system can hold, refer

toRefill capacitiesin theCapacities and specificationschapter.

Fill your engine coolant reservoir as outlined inAdding engine coolant

in this chapter.

Severe winter climate

If you drive in extremely cold climates (less than ±36ÉC [±34ÉF]), it may

be necessary to increase the coolant concentration above 50%. Refer to

the chart on the coolant container to ensure the coolant concentration in

your vehicle is such that the coolant will not freeze at the temperature

level in which you drive during winter months.

Maintenance and care

201

Page 202 of 264

²NEVER increase the coolant concentration above 60%.

²Increased engine coolant concentrations above 60% will

decrease the freeze protection characteristics of the engine

coolant and may cause engine damage.

Vehicles driven year-round in non-extreme climates should use a 50/50

mixture of engine coolant and distilled water for optimum freeze

protection.

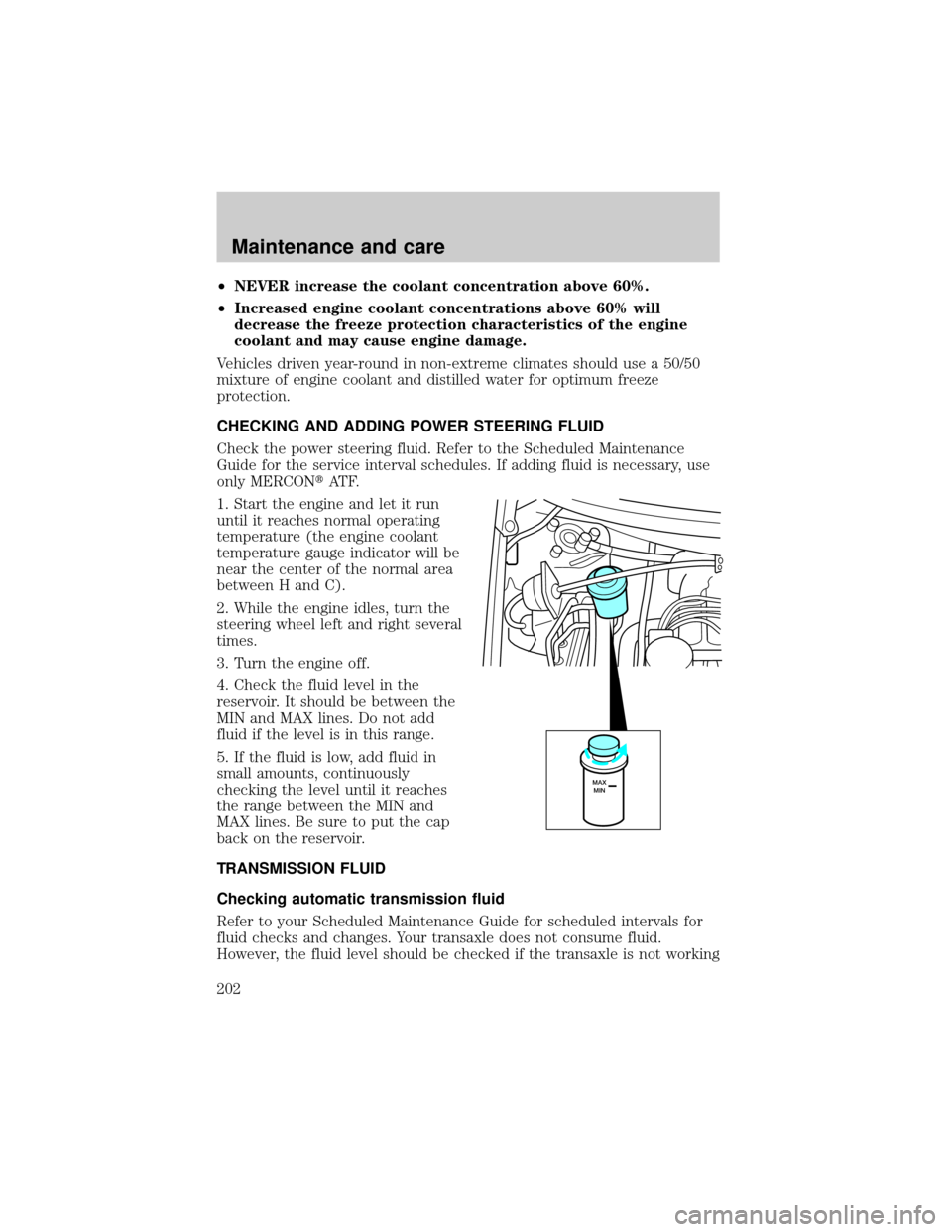

CHECKING AND ADDING POWER STEERING FLUID

Check the power steering fluid. Refer to the Scheduled Maintenance

Guide for the service interval schedules. If adding fluid is necessary, use

only MERCONtAT F.

1. Start the engine and let it run

until it reaches normal operating

temperature (the engine coolant

temperature gauge indicator will be

near the center of the normal area

between H and C).

2. While the engine idles, turn the

steering wheel left and right several

times.

3. Turn the engine off.

4. Check the fluid level in the

reservoir. It should be between the

MIN and MAX lines. Do not add

fluid if the level is in this range.

5. If the fluid is low, add fluid in

small amounts, continuously

checking the level until it reaches

the range between the MIN and

MAX lines. Be sure to put the cap

back on the reservoir.

TRANSMISSION FLUID

Checking automatic transmission fluid

Refer to your Scheduled Maintenance Guide for scheduled intervals for

fluid checks and changes. Your transaxle does not consume fluid.

However, the fluid level should be checked if the transaxle is not working

MAX

MIN

Maintenance and care

202

Page 203 of 264

properly, i.e., if the transaxle slips or shifts slowly or if you notice some

sign of fluid leakage.

Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is warmed up

(approximately 30 km [20 miles]). If your vehicle has been

operated for an extended period at high speeds, in city traffic

during hot weather or pulling a trailer, the vehicle should be

turned off for about 30 minutes to allow fluid to cool before

checking.

1. Drive the vehicle 30 km (20 miles) or until it reaches normal operating

temperature.

2. Park the vehicle on a level surface and engage the parking brake.

3. With the parking brake engaged and your foot on the brake pedal,

start the engine and move the gearshift lever through all of the gear

ranges. Allow sufficient time for each gear to engage.

4. Latch the gearshift lever in P (Park) and leave the engine running.

5. Remove the dipstick, wiping it clean with a clean, dry lint free rag.

6. Install the dipstick making sure it is fully seated in the filler tube.

7. Remove the dipstick and inspect the fluid level. The fluid should be in

the designated areas for normal operating temperature.

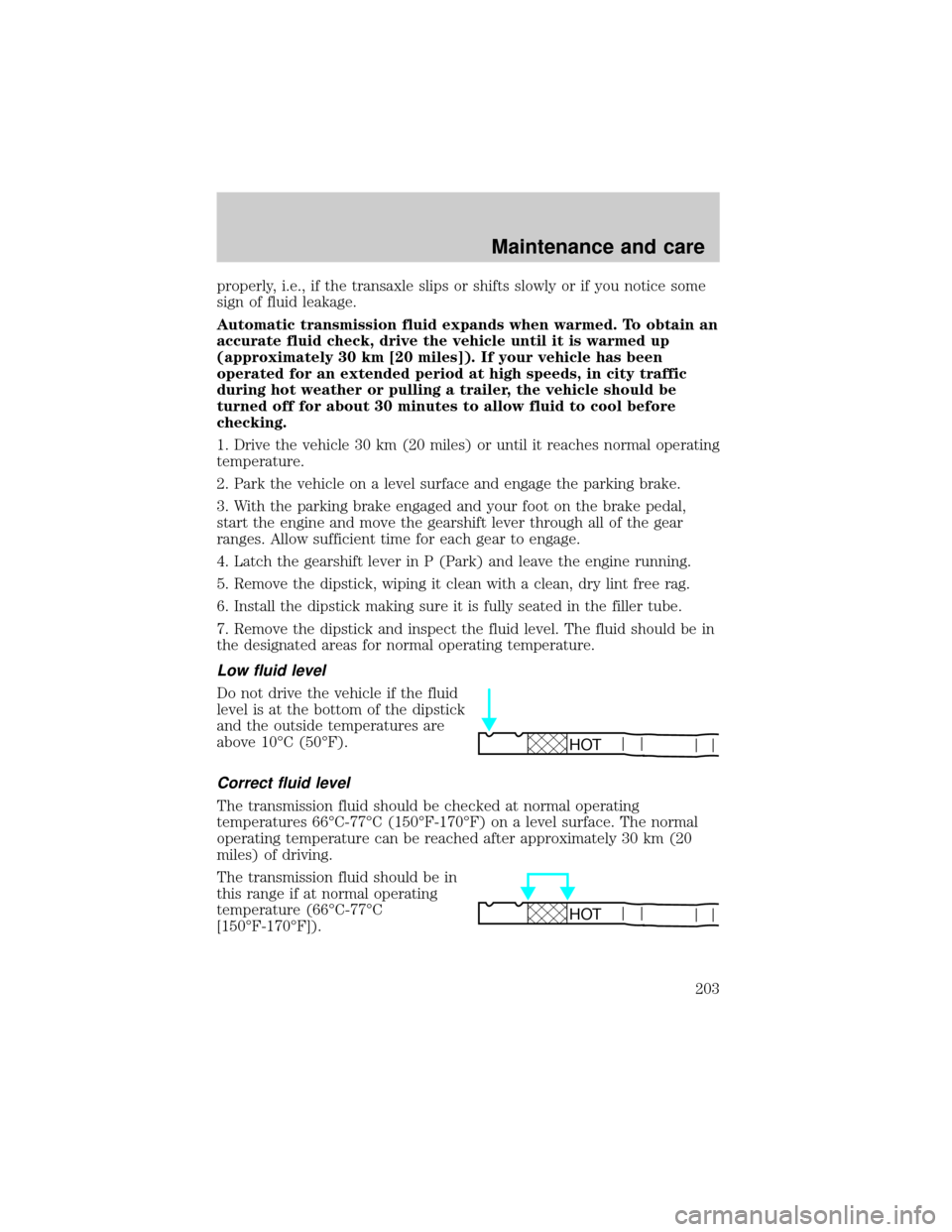

Low fluid level

Do not drive the vehicle if the fluid

level is at the bottom of the dipstick

and the outside temperatures are

above 10ÉC (50ÉF).

Correct fluid level

The transmission fluid should be checked at normal operating

temperatures 66ÉC-77ÉC (150ÉF-170ÉF) on a level surface. The normal

operating temperature can be reached after approximately 30 km (20

miles) of driving.

The transmission fluid should be in

this range if at normal operating

temperature (66ÉC-77ÉC

[150ÉF-170ÉF]).

HOT

HOT

Maintenance and care

203

Page 204 of 264

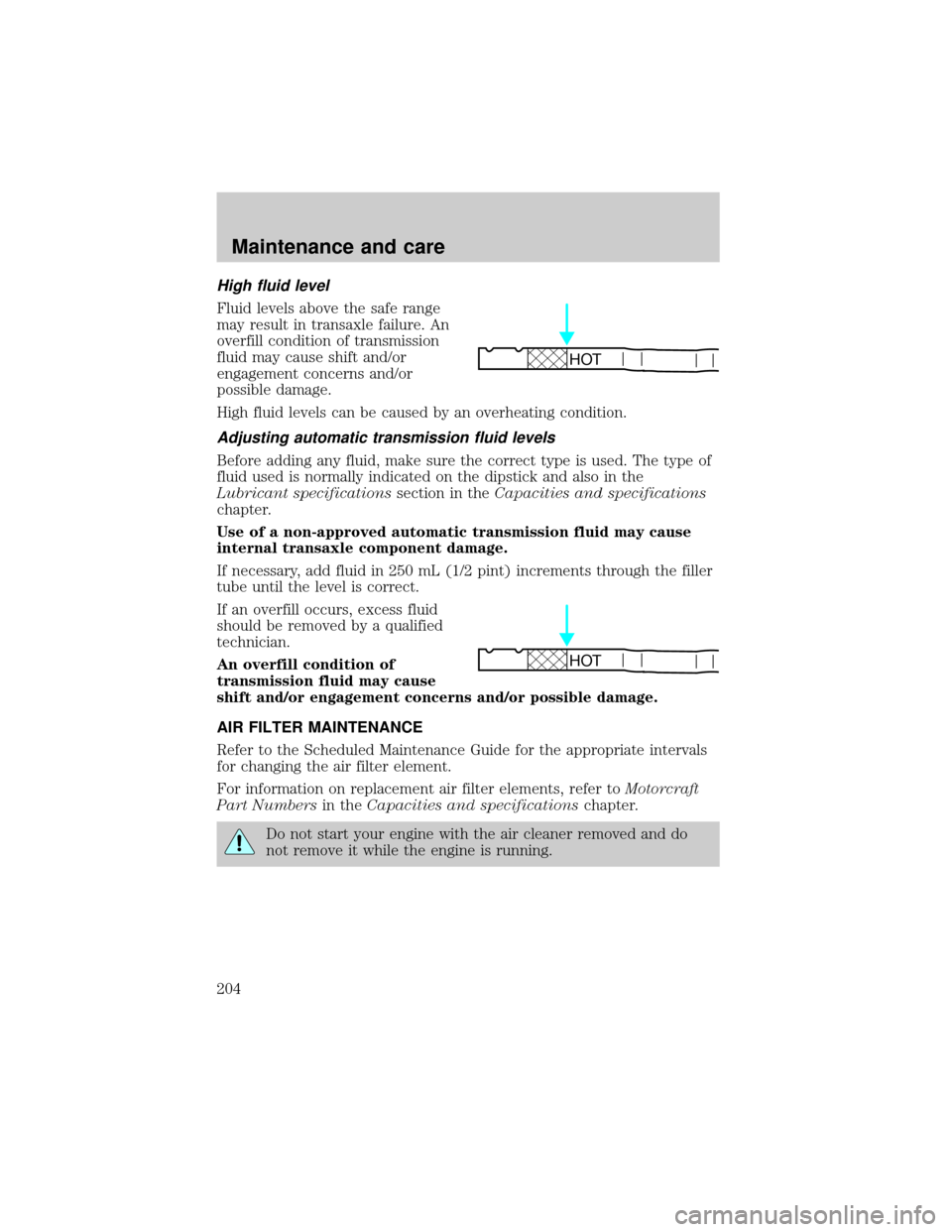

High fluid level

Fluid levels above the safe range

may result in transaxle failure. An

overfill condition of transmission

fluid may cause shift and/or

engagement concerns and/or

possible damage.

High fluid levels can be caused by an overheating condition.

Adjusting automatic transmission fluid levels

Before adding any fluid, make sure the correct type is used. The type of

fluid used is normally indicated on the dipstick and also in the

Lubricant specificationssection in theCapacities and specifications

chapter.

Use of a non-approved automatic transmission fluid may cause

internal transaxle component damage.

If necessary, add fluid in 250 mL (1/2 pint) increments through the filler

tube until the level is correct.

If an overfill occurs, excess fluid

should be removed by a qualified

technician.

An overfill condition of

transmission fluid may cause

shift and/or engagement concerns and/or possible damage.

AIR FILTER MAINTENANCE

Refer to the Scheduled Maintenance Guide for the appropriate intervals

for changing the air filter element.

For information on replacement air filter elements, refer toMotorcraft

Part Numbersin theCapacities and specificationschapter.

Do not start your engine with the air cleaner removed and do

not remove it while the engine is running.

HOT

HOT

Maintenance and care

204

Page 205 of 264

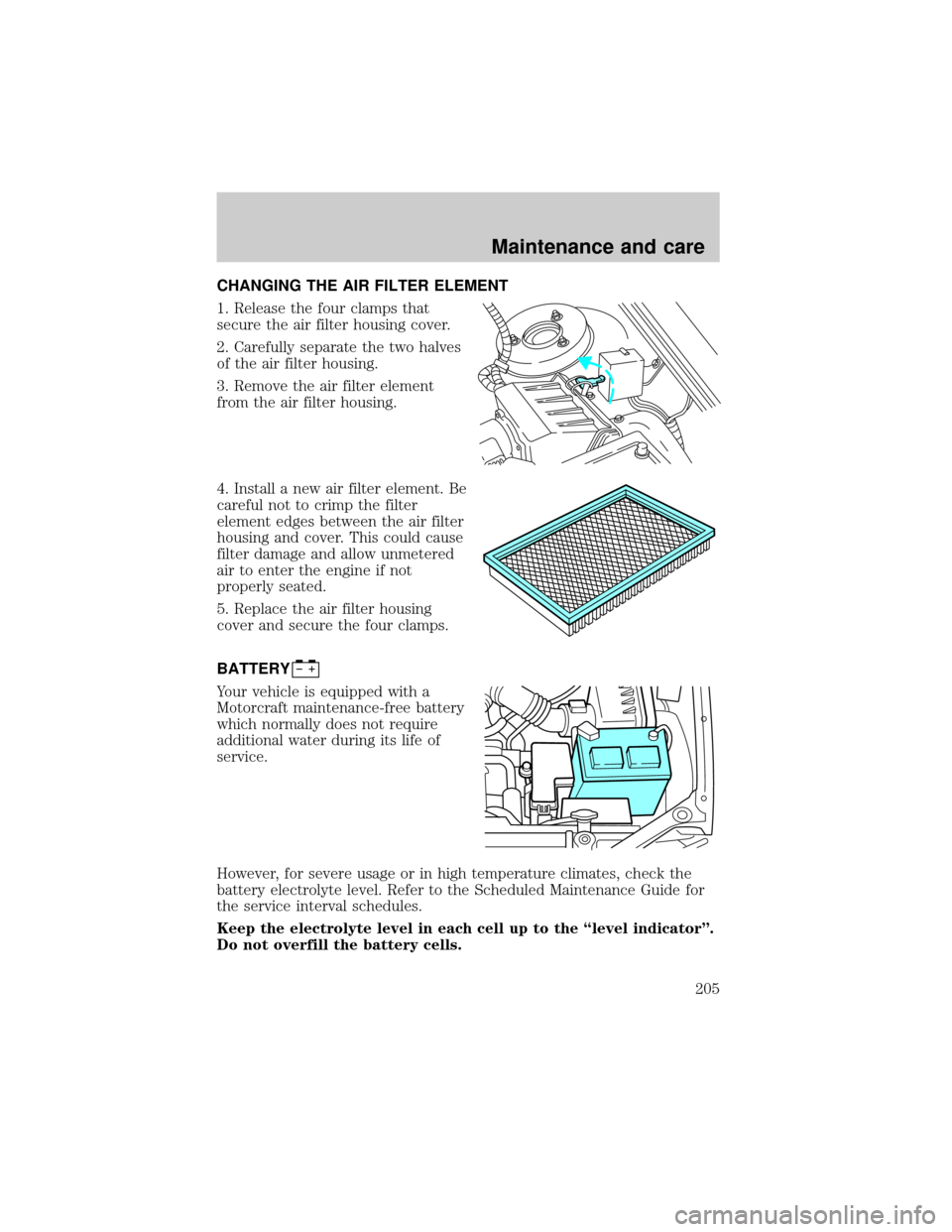

CHANGING THE AIR FILTER ELEMENT

1. Release the four clamps that

secure the air filter housing cover.

2. Carefully separate the two halves

of the air filter housing.

3. Remove the air filter element

from the air filter housing.

4. Install a new air filter element. Be

careful not to crimp the filter

element edges between the air filter

housing and cover. This could cause

filter damage and allow unmetered

air to enter the engine if not

properly seated.

5. Replace the air filter housing

cover and secure the four clamps.

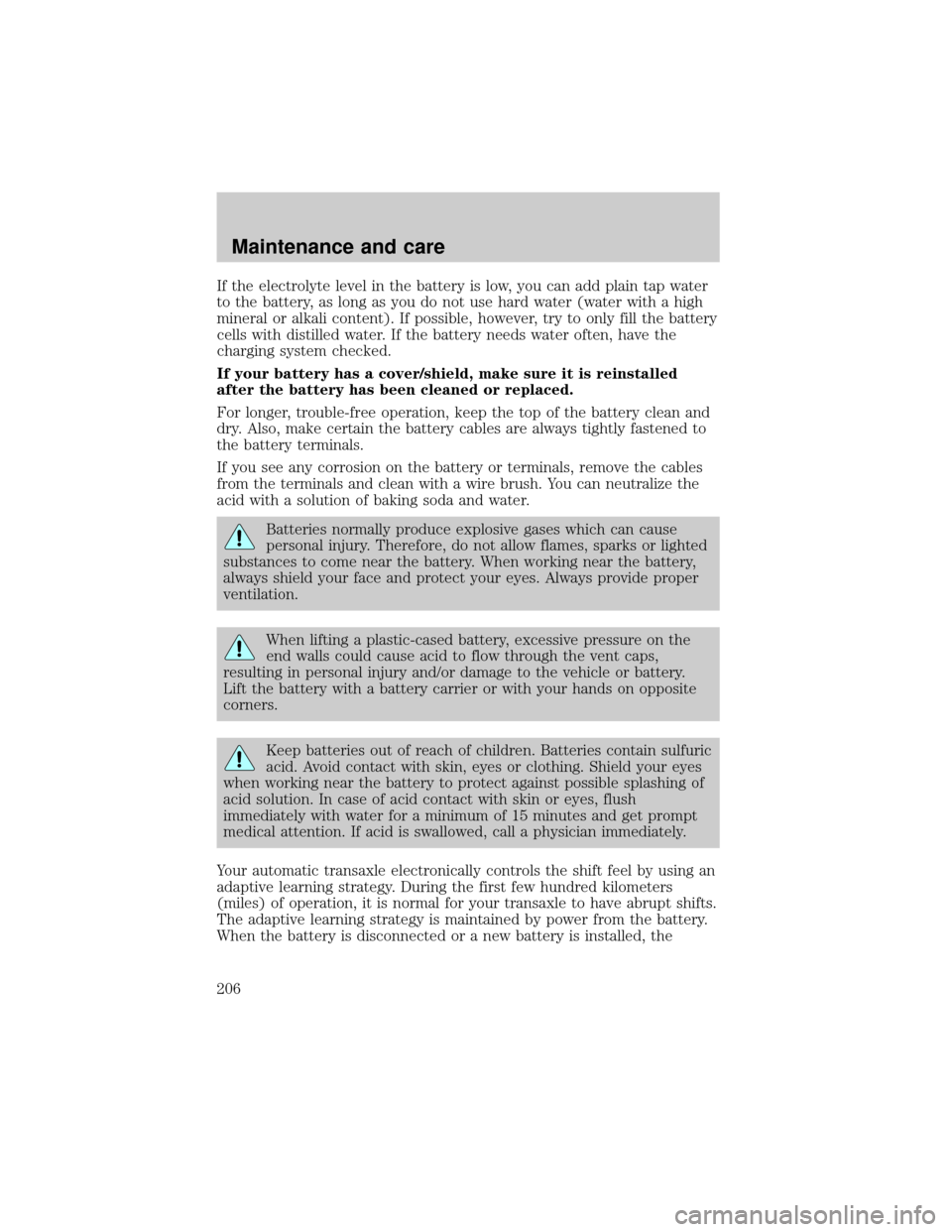

BATTERY

Your vehicle is equipped with a

Motorcraft maintenance-free battery

which normally does not require

additional water during its life of

service.

However, for severe usage or in high temperature climates, check the

battery electrolyte level. Refer to the Scheduled Maintenance Guide for

the service interval schedules.

Keep the electrolyte level in each cell up to the ªlevel indicatorº.

Do not overfill the battery cells.

Maintenance and care

205

Page 206 of 264

If the electrolyte level in the battery is low, you can add plain tap water

to the battery, as long as you do not use hard water (water with a high

mineral or alkali content). If possible, however, try to only fill the battery

cells with distilled water. If the battery needs water often, have the

charging system checked.

If your battery has a cover/shield, make sure it is reinstalled

after the battery has been cleaned or replaced.

For longer, trouble-free operation, keep the top of the battery clean and

dry. Also, make certain the battery cables are always tightly fastened to

the battery terminals.

If you see any corrosion on the battery or terminals, remove the cables

from the terminals and clean with a wire brush. You can neutralize the

acid with a solution of baking soda and water.

Batteries normally produce explosive gases which can cause

personal injury. Therefore, do not allow flames, sparks or lighted

substances to come near the battery. When working near the battery,

always shield your face and protect your eyes. Always provide proper

ventilation.

When lifting a plastic-cased battery, excessive pressure on the

end walls could cause acid to flow through the vent caps,

resulting in personal injury and/or damage to the vehicle or battery.

Lift the battery with a battery carrier or with your hands on opposite

corners.

Keep batteries out of reach of children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or clothing. Shield your eyes

when working near the battery to protect against possible splashing of

acid solution. In case of acid contact with skin or eyes, flush

immediately with water for a minimum of 15 minutes and get prompt

medical attention. If acid is swallowed, call a physician immediately.

Your automatic transaxle electronically controls the shift feel by using an

adaptive learning strategy. During the first few hundred kilometers

(miles) of operation, it is normal for your transaxle to have abrupt shifts.

The adaptive learning strategy is maintained by power from the battery.

When the battery is disconnected or a new battery is installed, the

Maintenance and care

206

Page 207 of 264

transaxle must relearn its adaptive strategy. Optimal shifting will resume

within a few hundred kilometers (miles) of operation.

If the battery has been disconnected or a new battery has been installed,

the clock and the preset radio stations must be reset once the battery is

reconnected.

²Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

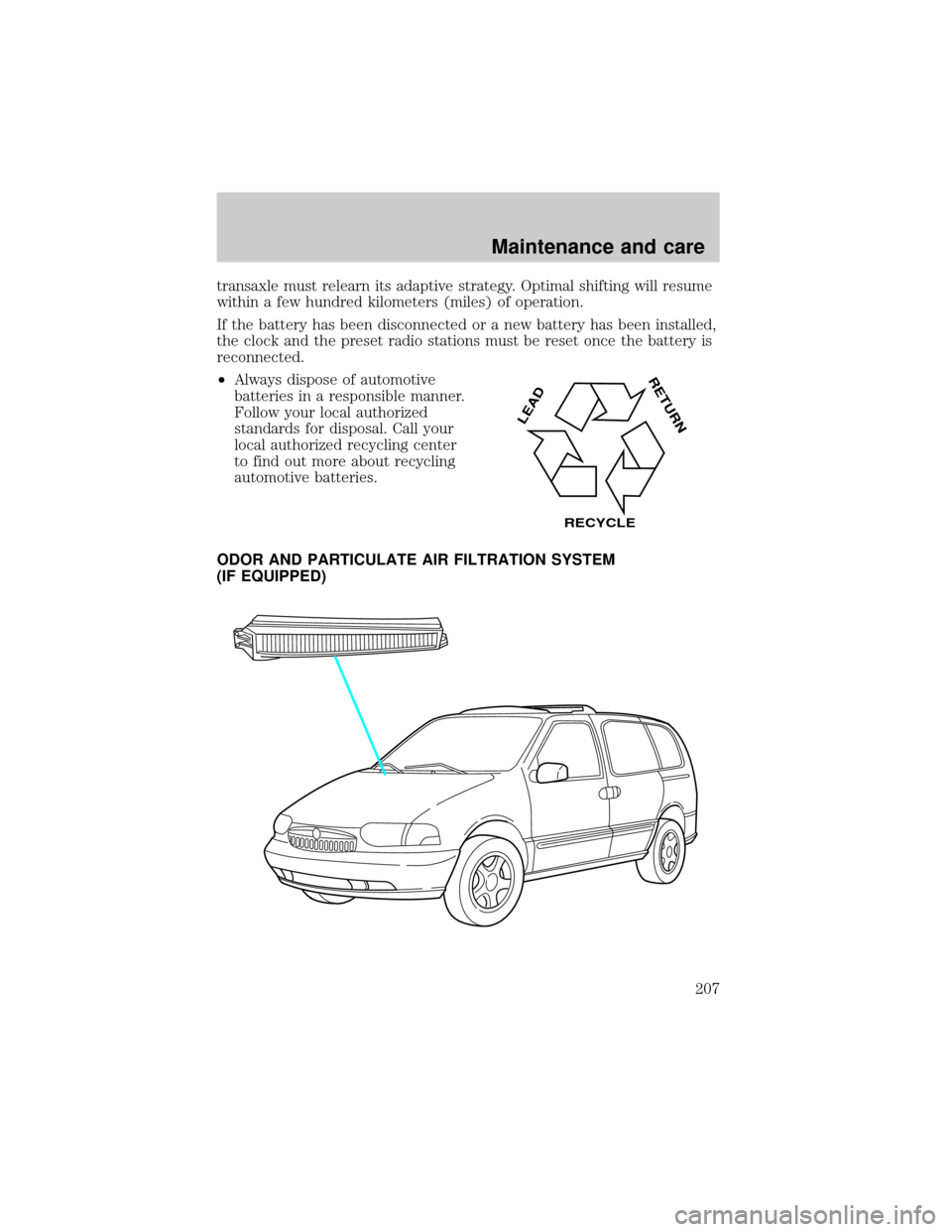

ODOR AND PARTICULATE AIR FILTRATION SYSTEM

(IF EQUIPPED)

LEAD

RETURN

RECYCLE

Maintenance and care

207

Page 208 of 264

The odor and particulate air filtration system is designed to reduce the

concentration of objectionable exterior odors as well as airborne particles

such as dust, spores and pollen in the air being supplied to the interior

of the vehicle. The extent of EXTERIOR odor reduction depends on the

odor itself and the perceptional threshold of the individual. The odor and

particulate filtration system gives the following benefits to customers:

²Improves the customer's driving comfort by reducing odor and particle

concentration

²Improves the interior compartment cleanliness

²Protects the climate control components from particle deposits

The filter is located just in front of the windshield under the cowl grille

on the passenger side of the vehicle.

To replace the filter, perform the following procedure:

1. Remove both windshield wiper

arms.

²Lift the wiper arm away from the

windshield surface until the wiper

arm is perpendicular to the

windshield surface.

²Rotate the small retaining clip at

the base of the wiper arm

counterclockwise while holding

the wiper arm.

²Lift and remove the wiper arm

while holding the retaining clip

outward. Note the LH and RH

wiper arms.

Maintenance and care

208

Page 209 of 264

2. Remove the six (6) screws (B) from the cowl grille (A) at the base of

the windshield.

3. Open the hood.

4. Remove the four (4) plastic screws (C) from the forward edge of the

cowl leaf screen under the hood.

²Remove the four (4) screw anchors by pushing upward on the screw

anchor.

5. Disconnect the windshield washer

hose at the Y connector at the rear

corner of the engine compartment.

6. Lift the cowl grille from the vehicle.

7. Locate the cabin air filter on the passenger side of the vehicle.

A

B

C

Maintenance and care

209

Page 210 of 264

8. Remove four (4) screws from the top surface of the cabin air filter top

cover.

9. Remove the cover.

10. Remove the filter element by

pulling forward on the top surface of

the filter and lifting.

11. Install the new filter (A)

element into the filter retaining

frame (B). Ensure that you insert

the three retaining tabs in the

bottom of the filter frame.

12. Reinstall the filter top cover and

the four (4) screws.

13. Reconnect the washer hose.

A

B

Maintenance and care

210