light Mercury Villager 1999 s Owner's Guide

[x] Cancel search | Manufacturer: MERCURY, Model Year: 1999, Model line: Villager, Model: Mercury Villager 1999Pages: 264, PDF Size: 2.19 MB

Page 114 of 264

2. Press and hold the desired memory position button. Within ten

seconds, press the unlock button on the transmitter while the memory

button is pressed.

3. When the transmitter has been programmed, the indicator will flash

five times. The indicator light will remain illuminated until the memory

button is pressed again or ten seconds lapse.

To remove a remote entry transmitter from memory:

1. Press and hold both memory seat buttons 1 and 2 and then press the

unlock button on the remote entry transmitter.

REAR SEATS

Removable floor mats

Whenever the floor mats are removed to adjust or move any of the rear

seats, always reinstall the mats before passengers ride in the vehicle. The

floor mats are specifically designed to keep objects out of the seat

tracks.

The cargo mat (A.) can be reversed (top to bottom) to retain soils and

liquids.

²7 passenger vehicle

A. Cargo mat

B. Narrow mats

C. Sliding door mats, LH/RH

ACB

Seating and safety restraints

114

Page 129 of 264

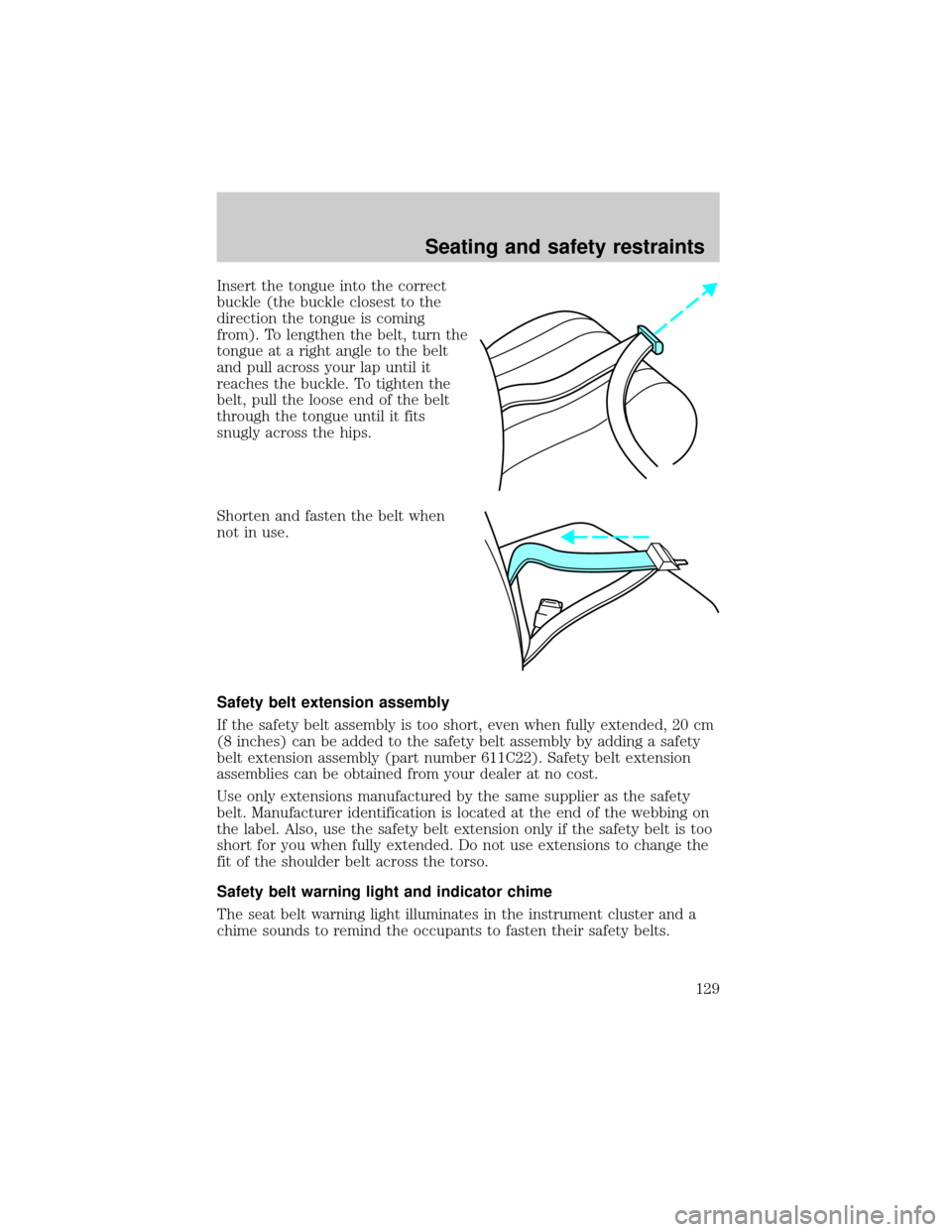

Insert the tongue into the correct

buckle (the buckle closest to the

direction the tongue is coming

from). To lengthen the belt, turn the

tongue at a right angle to the belt

and pull across your lap until it

reaches the buckle. To tighten the

belt, pull the loose end of the belt

through the tongue until it fits

snugly across the hips.

Shorten and fasten the belt when

not in use.

Safety belt extension assembly

If the safety belt assembly is too short, even when fully extended, 20 cm

(8 inches) can be added to the safety belt assembly by adding a safety

belt extension assembly (part number 611C22). Safety belt extension

assemblies can be obtained from your dealer at no cost.

Use only extensions manufactured by the same supplier as the safety

belt. Manufacturer identification is located at the end of the webbing on

the label. Also, use the safety belt extension only if the safety belt is too

short for you when fully extended. Do not use extensions to change the

fit of the shoulder belt across the torso.

Safety belt warning light and indicator chime

The seat belt warning light illuminates in the instrument cluster and a

chime sounds to remind the occupants to fasten their safety belts.

Seating and safety restraints

129

Page 130 of 264

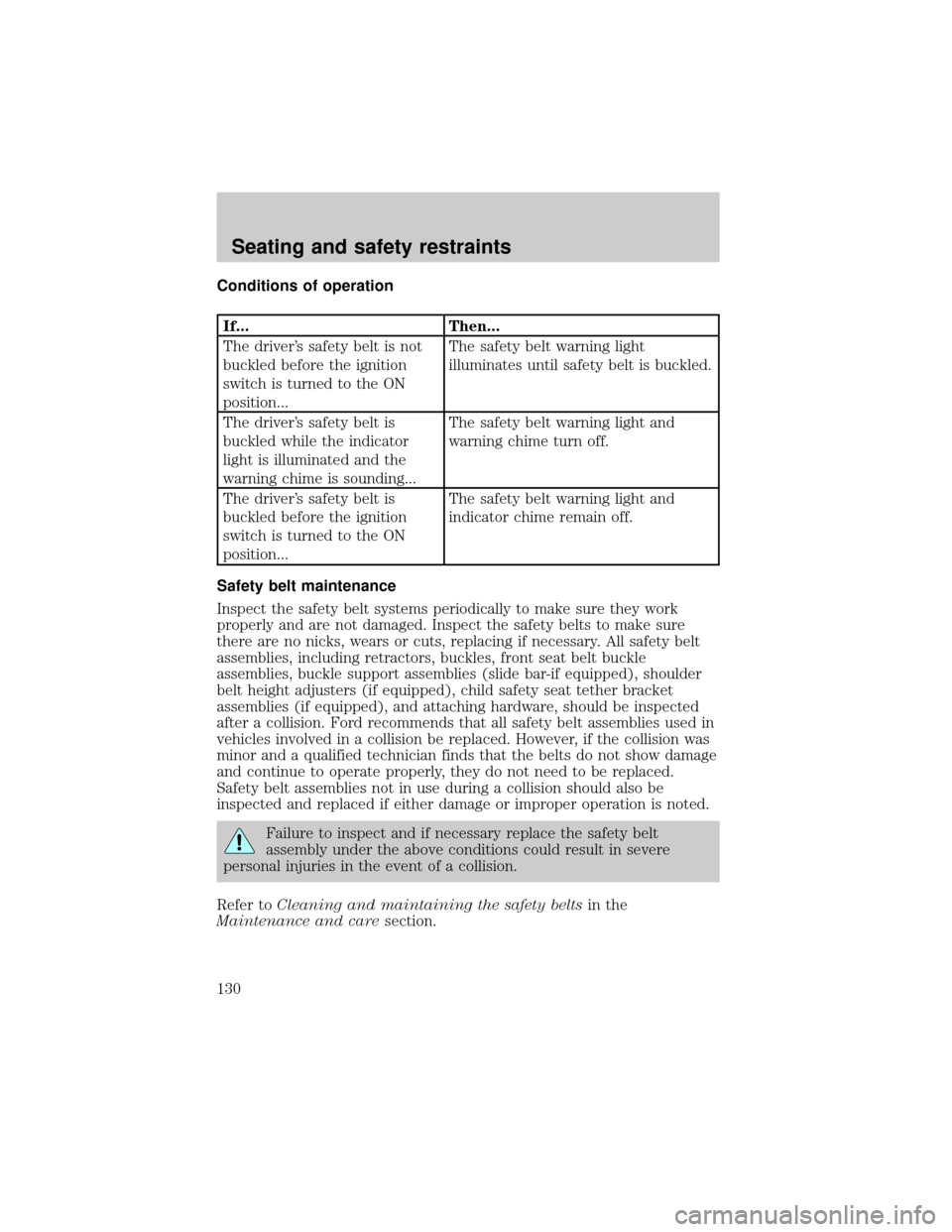

Conditions of operation

If... Then...

The driver's safety belt is not

buckled before the ignition

switch is turned to the ON

position...The safety belt warning light

illuminates until safety belt is buckled.

The driver's safety belt is

buckled while the indicator

light is illuminated and the

warning chime is sounding...The safety belt warning light and

warning chime turn off.

The driver's safety belt is

buckled before the ignition

switch is turned to the ON

position...The safety belt warning light and

indicator chime remain off.

Safety belt maintenance

Inspect the safety belt systems periodically to make sure they work

properly and are not damaged. Inspect the safety belts to make sure

there are no nicks, wears or cuts, replacing if necessary. All safety belt

assemblies, including retractors, buckles, front seat belt buckle

assemblies, buckle support assemblies (slide bar-if equipped), shoulder

belt height adjusters (if equipped), child safety seat tether bracket

assemblies (if equipped), and attaching hardware, should be inspected

after a collision. Ford recommends that all safety belt assemblies used in

vehicles involved in a collision be replaced. However, if the collision was

minor and a qualified technician finds that the belts do not show damage

and continue to operate properly, they do not need to be replaced.

Safety belt assemblies not in use during a collision should also be

inspected and replaced if either damage or improper operation is noted.

Failure to inspect and if necessary replace the safety belt

assembly under the above conditions could result in severe

personal injuries in the event of a collision.

Refer toCleaning and maintaining the safety beltsin the

Maintenance and caresection.

Seating and safety restraints

130

Page 132 of 264

![Mercury Villager 1999 s Owners Guide National Highway Traffic Safety Administration (NHTSA)

recommends a minimum distance of at least 25 cm (ten [10]

inches) between an occupants chest and the driver air bag module.

Never place your arm Mercury Villager 1999 s Owners Guide National Highway Traffic Safety Administration (NHTSA)

recommends a minimum distance of at least 25 cm (ten [10]

inches) between an occupants chest and the driver air bag module.

Never place your arm](/img/33/11172/w960_11172-131.png)

National Highway Traffic Safety Administration (NHTSA)

recommends a minimum distance of at least 25 cm (ten [10]

inches) between an occupant's chest and the driver air bag module.

Never place your arm over the air bag module as a deploying air

bag can result in serious arm fractures or other injuries.

Steps you can take to properly position yourself away from the airbag:

²Move your seat to the rear as far as you can while still reaching the

pedals comfortably.

²Recline the seat slightly (one or two degrees) from the upright

position.

Do not put anything on or over the air bag module. Placing

objects on or over the air bag inflation area may cause those

objects to be propelled by the air bag into your face and torso causing

serious injury.

Do not attempt to service, repair, or modify the Air Bag

Supplemental Restraint System or its fuses. See your Ford or

Lincoln-Mercury dealer.

Seating and safety restraints

132

Page 134 of 264

The air bags inflate and deflate

rapidly upon activation. After air bag

deployment, it is normal to notice a

smoke-like, powdery residue or

smell the burnt propellant. This may

consist of cornstarch, talcum

powder (to lubricate the bag) or

sodium compounds (e.g., baking

soda) that result from the

combustion process that inflates the

air bag. Small amounts of sodium

hydroxide may be present which

may irritate the skin and eyes, but

none of the residue is toxic.

While the system is designed to help

reduce serious injuries, it may also

cause minor burns, abrasions, swelling or temporary hearing loss.

Because air bags must inflate rapidly and with considerable force, there

is the risk of death or serious injuries such as fractures, facial and eye

injuries or internal injuries, particularly to occupants who are not

properly restrained or are otherwise out of position at the time of air bag

deployment. Thus, it is extremely important that occupants be properly

restrained as far away from the air bag module as possible while

maintaining vehicle control.

Several air bag system components get hot after inflation. Do not

touch them after inflation.

If the air bag is deployed,the air bag will not function again

and must be replaced immediately.If the air bag is not

replaced, the unrepaired area will increase the risk of injury in a

collision.

The SRS consists of:

²driver and passenger air bag modules (which include the inflators and

air bags),

²one or more impact and safing sensors,

²a readiness light

²and the electrical wiring which connects the components.

Seating and safety restraints

134

Page 135 of 264

The diagnostic module monitors its own internal circuits and the

supplemental air bag electrical system warning (including the impact

sensors), the system wiring, the air bag system readiness light, the air

bag back up power and the air bag ignitors.

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster to indicate the

condition of the system. Refer to theAir bag readinesssection in the

Instrumentationchapter. Routine maintenance of the air bag is not

required.

A difficulty with the system is indicated by one or more of the following:

²The readiness light will either

flash or stay lit.

²The readiness light will not

illuminate immediately after

ignition is turned on.

If any of these things happen, even intermittently, have the SRS serviced at

your dealership or by a qualified technician immediately. Unless serviced,

the system may not function properly in the event of a collision.

Disposal of air bags and air bag equipped vehicles (including

pretensioners)

For disposal of air bags or air bag equipped vehicles, see your local

dealership or qualified technician. Air bags MUST BE disposed of by

qualified personnel.

SAFETY RESTRAINTS FOR CHILDREN

See the following sections for directions on how to properly use safety

restraints for children. Also seeAir Bag Supplemental Restraint

System (SRS)in this chapter for special instructions about using air

bags.

Important child restraint precautions

You are required by law to use safety restraints for children in the U.S.

and Canada. If small children ride in your vehicle (generally children who

are four years old or younger and who weigh 18 kg [40 lbs] or less), you

must put them in safety seats made especially for children. Check your

local and state or provincial laws for specific requirements regarding the

safety of children in your vehicle.

AIR

BAG

Seating and safety restraints

135

Page 154 of 264

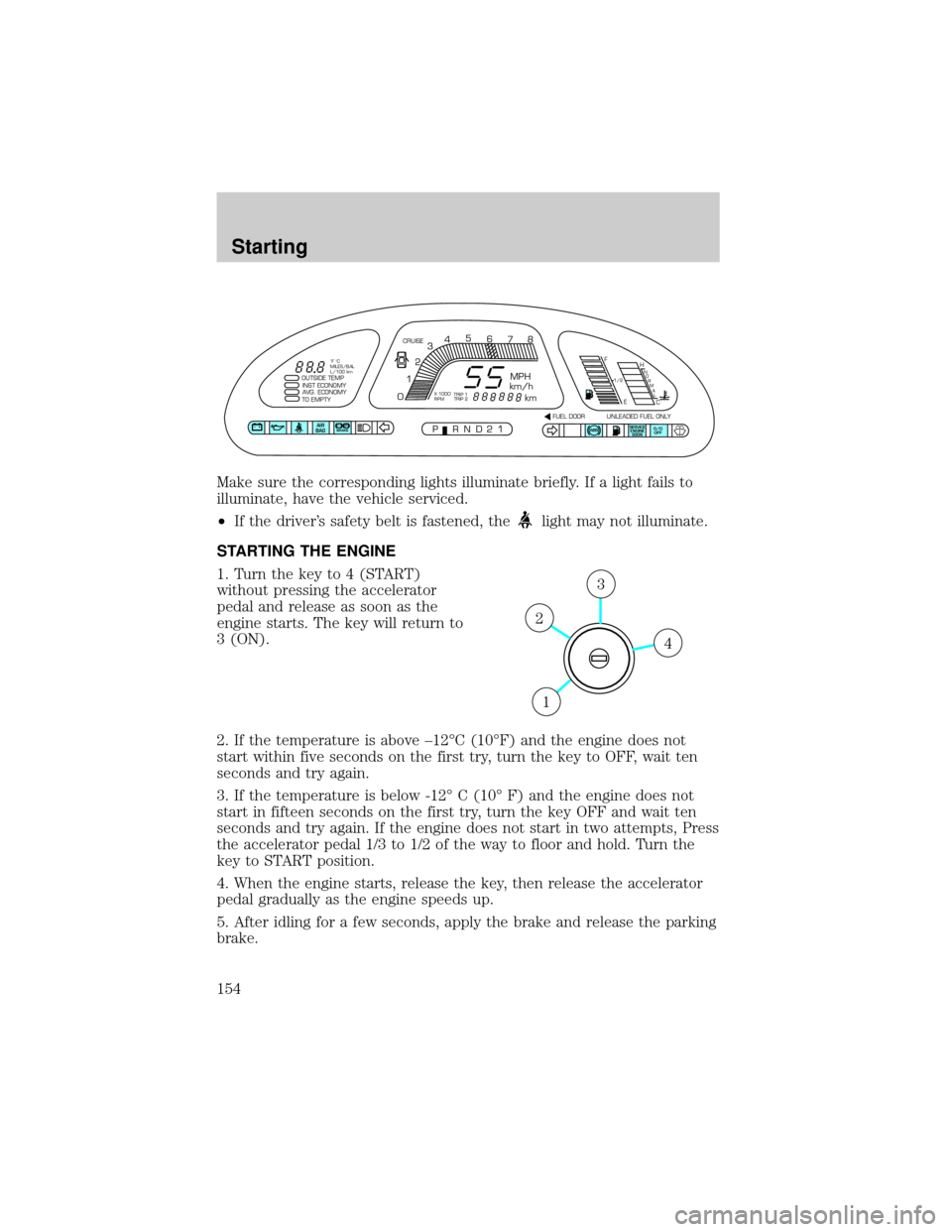

Make sure the corresponding lights illuminate briefly. If a light fails to

illuminate, have the vehicle serviced.

²If the driver's safety belt is fastened, the

light may not illuminate.

STARTING THE ENGINE

1. Turn the key to 4 (START)

without pressing the accelerator

pedal and release as soon as the

engine starts. The key will return to

3 (ON).

2. If the temperature is above ±12ÉC (10ÉF) and the engine does not

start within five seconds on the first try, turn the key to OFF, wait ten

seconds and try again.

3. If the temperature is below -12É C (10É F) and the engine does not

start in fifteen seconds on the first try, turn the key OFF and wait ten

seconds and try again. If the engine does not start in two attempts, Press

the accelerator pedal 1/3 to 1/2 of the way to floor and hold. Turn the

key to START position.

4. When the engine starts, release the key, then release the accelerator

pedal gradually as the engine speeds up.

5. After idling for a few seconds, apply the brake and release the parking

brake.

SERVICE

ENGINE

SOONABSAIR

BAGABSO/D

OFF

OUTSIDE TEMP

INST ECONOMY

AVG. ECONOMY

TO EMPTY

PRND21FUEL DOOR UNLEADED FUEL ONLY CRUISE

MPH

km/h

km

F

EH

C

1/2N

O

R

M

A

L

012345

6

78

P!BRAKE

X 1000

RPMTRIP 1

TRIP 2 ˚F ˚C

MILES/BAL

L/100 km

4

3

2

1

Starting

154

Page 157 of 264

BRAKES

Your service brakes are self-adjusting. Refer to the scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

Anti-lock brake system (ABS) (if equipped)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. The ABS performs a self-check at approximately

17 km/h (10 mph) after you start the engine and begin to drive away. A

brief mechanical noise may be heard during this test. This is normal. If a

malfunction is found, the ABS warning light will come on. If the vehicle

has continuous vibration or shudder in the steering wheel while braking,

the vehicle should be inspected by a qualified service technician.

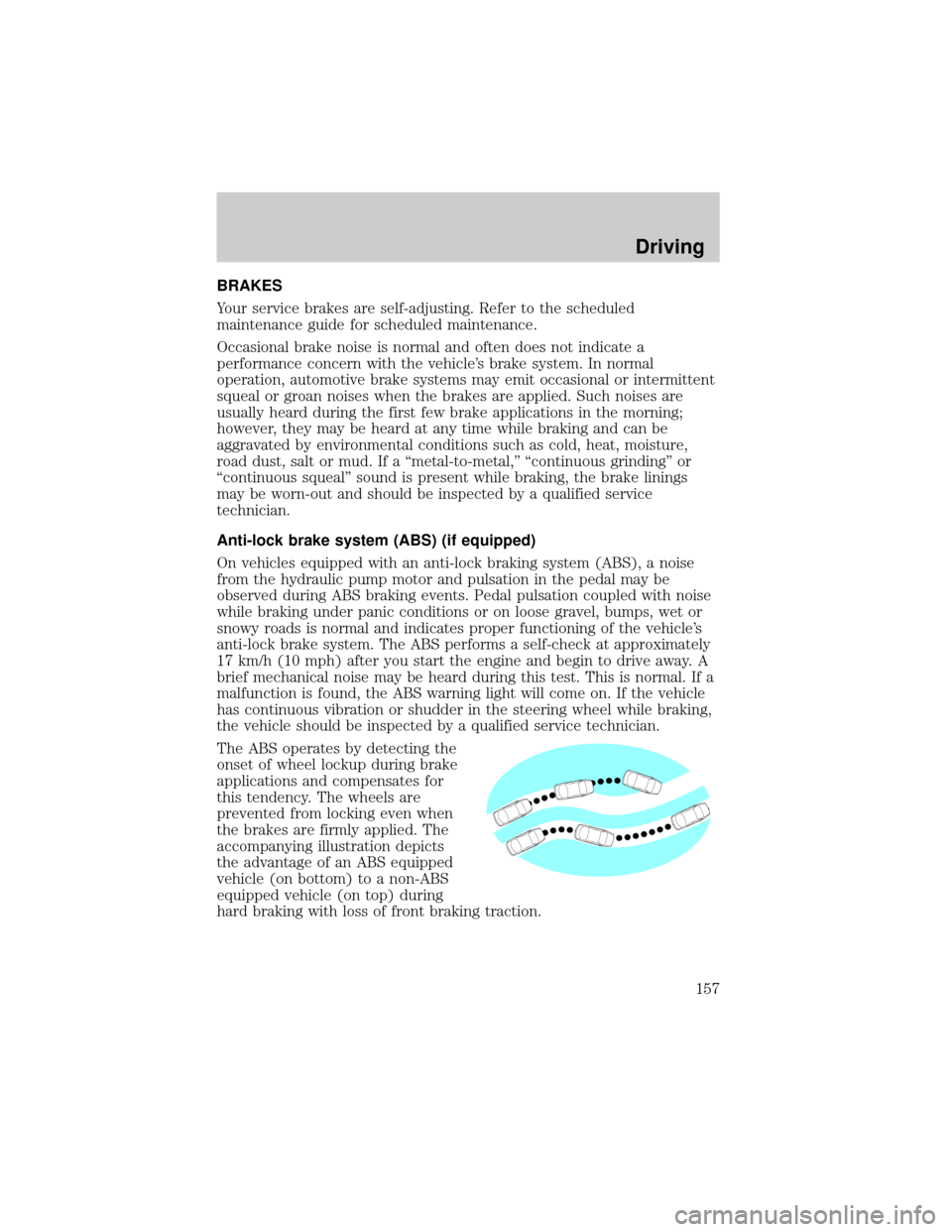

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during

hard braking with loss of front braking traction.

Driving

157

Page 158 of 264

ABS warning lamp

The

ABSwarning lamp in the instrument cluster momentarily illuminates

when the ignition is turned to the ON position. If the light does not

illuminate momentarily at start up, remains on or continues to flash, the

ABS needs to be serviced.

With the ABS light on, the anti-lock

brake system is disabled and normal

braking is still effective unless the

brake warning light also remains

illuminated with parking brake

released. (If your brake warning lamp illuminates, have your vehicle

serviced immediately).

Using ABS

²In an emergency or when maximum efficiency from the ABS is

required, apply continuous full force on the brake. The ABS will be

activated immediately, thus allowing you to retain full steering control

of your vehicle and, providing there is sufficient space, will enable you

to avoid obstacles and bring the vehicle to a controlled stop.

²The Anti-Lock system does not decrease the time necessary to apply

the brakes or always reduce stopping distance. Always leave enough

room between your vehicle and the vehicle in front of you to stop.

²We recommend that you familiarize yourself with this braking

technique. However, avoid taking any unnecessary risks.

Parking brake

Apply the parking brake whenever

the vehicle is parked. To set the

parking brake, press the parking

brake pedal down until the pedal

stops.

P!

BRAKE

FUSES

Driving

158

Page 160 of 264

²high crown in center of road

²high crosswinds

²wheels out of alignment

²loose or worn components in steering linkage

AUTOMATIC TRANSAXLE OPERATION

Brake-shift interlock

This vehicle is equipped with a brake-shift interlock feature that prevents

the gearshift lever from being moved from P (Park) unless the brake

pedal is depressed.

If you cannot move the gearshift lever out of P (Park) with the brake

pedal depressed:

1. Apply the parking brake, turn ignition key to OFF/LOCK, then remove

the key.

2. Insert the key and turn it to ACC. Apply the brake pedal and shift to

N (Neutral).

3. Start the vehicle.

Do not drive your vehicle until you verify that the brakelamps

are working.

If your vehicle gets stuck in mud or snow it may be rocked out by

shifting from forward and reverse gears, stopping between shifts, in a

steady pattern. Press lightly on the accelerator in each gear.

Do not rock the vehicle for more than a few minutes. The

transmission and tires may be damaged or the engine may

overheat.

Always set the parking brake fully and make sure the gearshift is

latched in P (Park). Turn off the ignition whenever you leave

your vehicle.

If the parking brake is fully released, but the brake warning lamp

remains illuminated, the brakes may not be working properly.

See your dealer or a qualified service technician.

Driving

160