Mercury Villager 2001 Owner's Manuals

Manufacturer: MERCURY, Model Year: 2001, Model line: Villager, Model: Mercury Villager 2001Pages: 256, PDF Size: 2.35 MB

Page 171 of 256

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment

Fuse Panel Description

Cigar

Lighter20A Cigar Lighter

Hazard 10A Hazard Warning Flasher Switch, Anti-Theft

Indicator

RR Pwr

Plug20A Rear Powerpoint

Rear Blower 15A

Rear Blower Motor Relay, Rear Blower Motor

Front Wiper 20A Front Wiper/Washer Assembly

Rear Blower 15A

Rear Blower Motor Relay, Rear Blower Motor

Rear Wiper 10A Rear Wiper/Washer Assembly

O2 Sensor 7.5A Oxygen Sensor

Audio/Video 15A Radio/Video System

Turn 10A Hazard Warning Flasher Switch

Audio Amp 20A Subwoofer Amplifier

Front

Blower20A Front Blower Motor, Front Blower Motor/

Speed Controller

Eng Cont 7.5A Powertrain Control Module, Lighting

Control Module

Relays 10A Speed Control, Instrument Cluster, Rear

Blower Motor, Data Link Connector #2,

Cooling Fans

A/C Cont 7.5A Electronic Automatic Temperature Control

(EATC) Module, A/C Relay, Front Climate

Control Panel

Electron 10A Transmission Control, Lighting Control

Module, ABS Control Module, Smart Entry

Control (SEC)/Timer Module

Rear Defog 20A Rear Window Defrost

Front

Blower20A Front Blower Motor, Front Blower

Motor/Speed Controller

Rear Defog 20A Rear Window Defrost

Ð Ð Not Used

Heated

Mirror10A Rear Window Defrost Switch, Power/Heated

Mirrors

Roadside emergencies

171

Page 172 of 256

Power distribution box

The power distribution box is

located in the engine compartment.

The power distribution box contains

high-current fuses that protect your

vehicle's main electrical systems

from overloads.

Always disconnect the battery before servicing high current

fuses.

Always replace the cover to the Power Distribution Box before

reconnecting the battery or refilling fluid reservoirs.

If the battery has been disconnected and reconnected, refer to the

Batterysection of theMaintenance and carechapter.

USE SPECIFIED FUSES OR FUSIBLE LINKS ONLY

ALT

100A

MAIN140A

ALT65A

FR

BLW

45A

RR

DEF75A

RAD

FA N

JOINT CONN. RAD FAN

H1RAD FAN

H2RAD FAN

LO 30A

IGN

SW20A

RAD

FA N

LO 30A

PWR

WND40A

ABS20A

ABS

15A

HORN7.5A

SEC7.5A

LAMP

15A

H/L

LH15A

H/L

RH10A

ALT10A

ECCS10A

INJ 15A

FUEL

PUMP 7.5A

RAD

FRONT

FOG

Roadside emergencies

172

Page 173 of 256

The high-current fuses are coded as follows.

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box Description

Fog Lamp 7.5A* Fog Lamps

FUEL PUMP15A* Fuel Pump Relay

INJ 10A* Powertrain Control Module (PCM),

Injectors

SEC 7.5A* Anti-Theft Relay, Smart Entry Control

(SEC)/Timer Module

RAD 7.5A* Radiator Fan Sensing

ECCS 10A* Data Link Connector (DLC) #1, PCM

Power Relay

Ð Ð Not Used

Ð Ð Not Used

ALT 10A* Generator

ABS 20A* ABS Control Module

Ð Ð Not Used

H/L RH 15A* Lighting Control Module

HORN 15A* Horn Relay

Ð Ð Not Used

H/L LH 15A* Lighting Control Module

Ð Ð Not Used

Ð Ð Not Used

ABS 40A** ABS Control Module

Ð Ð Not Used

PWR WND 30A** Power Window Relay, Smart Entry Control

(SEC)/Timer Module, Power Seats

RAD FAN

LO20A** Low Speed Fan Control Relay

Ð Ð Not Used

IGN SW 30A** Ignition Switch

Ð Ð Not Used

RAD FAN 75A** High Speed Fan Control Relay

FR BLW 65A** Front Blower Motor Relays

Roadside emergencies

173

Page 174 of 256

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box Description

RR DEF 45A** Rear Window Defroster Relay

ALT 140A** Accessory Relay, Ignition Relay, Tail Lamp

Relay, Fuse Junction Panel

MAIN 100A** Generator

* Mini Fuses ** Maxi Fuses

Relay box

The relay box is located in the

engine compartment in front of the

battery.

The relays are coded as follows:

Relay location Description

1 Start Inhibit Relay

2 Fuel Pump Relay

3 Bulb Check Relay

4 Fog Lamp

5 Anti-theft Relay

6 Horn Relay

7 A/C Relay

1234

56 7

Roadside emergencies

174

Page 175 of 256

CHANGING THE TIRES

If you get a flat tire while driving, do not apply the brake heavily.

Instead, gradually decrease your speed. Hold the steering wheel firmly

and slowly move to a safe place on the side of the road.

Temporary spare tire information

Your vehicle may have a temporary or conventional size spare tire. The

temporary spare tire for your vehicle is labeled as such. It is smaller than

a regular tire and is designed for emergency use only. Replace this tire

with a full-size tire as soon as possible.

If you use the temporary spare tire continuously or do not follow

these precautions, the tire could fail, causing you to lose control

of the vehicle, possibly injuring yourself or others.

When driving with the temporary spare tiredo not:

²exceed 80 km/h (50 mph) under any circumstances

²load the vehicle beyond maximum vehicle load rating listed on the

Certification Label

²tow a trailer

²use tire chains

²drive through an automatic car wash, because of the vehicle's reduced

ground clearance

²try to repair the temporary spare tire or remove it from its wheel

²use the wheel for any other type of vehicle

Location of the spare tire and tools

The spare tire and tools for your vehicle are stowed in the following

locations:

Item Location

Spare tire Under the vehicle, just forward of the rear bumper

Jack assembly Under the third row bench seat in the tool bag

Removing the jack and tools

1. Lift the 3rd row seat cushion.

2. Remove the jack assembly from the bag under the seat.

Roadside emergencies

175

Page 176 of 256

Removing the spare tire

1. Open the liftgate, locate the U-shaped slits in the carpet, and flip up

the piece of carpet to expose the hex nut.

2. Insert the lug nut wrench on the

hex nut in cargo floor.

3. Turn the wrench

counterclockwise until tire is

lowered to the ground and the cable

is slightly slack.

4. Remove the retainer from the

spare tire. It may be necessary to

lift one end of the tire to disengage

the retainer.

Roadside emergencies

176

Page 177 of 256

Stowing the spare tire

1. Lay the tire on the ground with the interior side facing up.

2. Install the retainer through the

wheel center and slide the wheel

under the vehicle.

3. Turn the wrench clockwise until

the tire is raised to its original

position underneath the vehicle. The

hex nut ratchets when the tire is

raised to the stowed position. It will

not allow you to overtighten.

4. Check seating position of tire for

looseness against the underbody

supports and retighten if necessary.

Ensure the position of the

tire is not too far forward to

avoid contact with the axle.

Tire change procedure

When one of the front wheels is off the ground, the transaxle

alone will not prevent the vehicle from moving or slipping off the

jack, even if the vehicle is in P (Park).

To prevent the vehicle from moving when you change a tire, be

sure the parking brake is set, then block (in both directions) the

wheel that is diagonally opposite (other side and end of the vehicle) to

the tire being changed.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

All occupants should be out of the vehicle while it is on the jack.

Roadside emergencies

177

Page 178 of 256

1. Park on a level surface, activate

hazard flashers and set parking

brake.

2. Place gearshift lever in P (Park),

turn engine OFF, and block the

diagonally opposite wheel.

3. Remove the spare tire and jack

assembly.

4. Remove the center ornament or

wheel cover from the wheel with the tapered end of the jack handle that

came with your vehicle. Insert and twist the handle, then pry against the

wheel.

5. Loosen each wheel lug nut

one-half turn counterclockwise but

do not remove them until the wheel

is raised off the ground.

Jacking notches are located

approximately six inches rearward

of the front wheels and twelve

inches foward of the rear wheels.

6. Locate the jack notch closest to

the tire you are changing, then

place the jack on the frame rail

directly behind the notch.

PUSH

TO

RELEASE

Roadside emergencies

178

Page 179 of 256

7. Turn the jack handle clockwise until the wheel is completely off the

ground.

To lessen the risk of personal injury, do not put any part of your

body under the vehicle while changing a tire. Do not start the

engine when your vehicle is on the jack. The jack is only meant for

changing the tire.

8. Remove the lug nuts with the lug wrench.

9. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall lug nuts until the wheel is snug against the hub.

Do not fully tighten the lug nuts until the wheel has been lowered.

10. Lower the wheel by turning the jack handle counterclockwise.

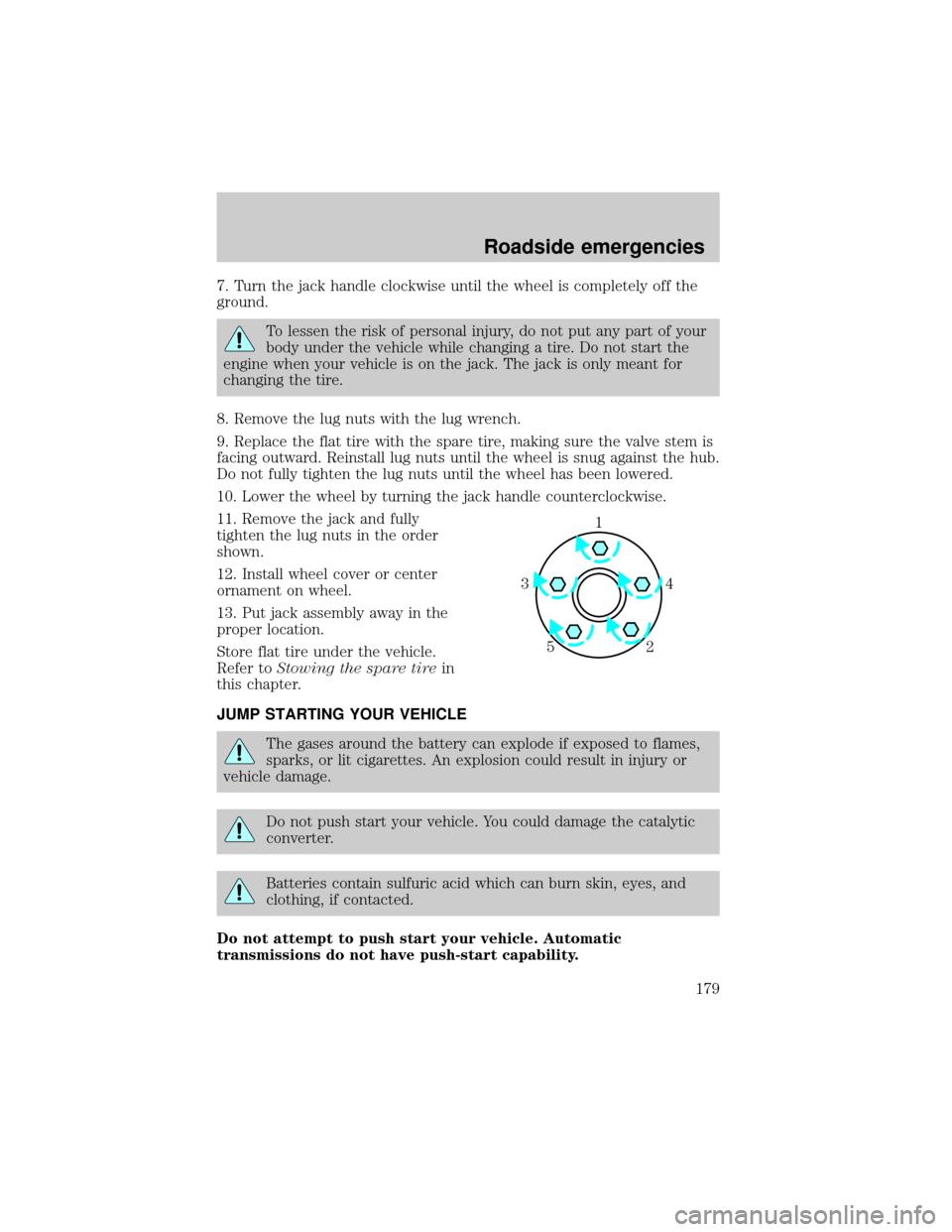

11. Remove the jack and fully

tighten the lug nuts in the order

shown.

12. Install wheel cover or center

ornament on wheel.

13. Put jack assembly away in the

proper location.

Store flat tire under the vehicle.

Refer toStowing the spare tirein

this chapter.

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Do not push start your vehicle. You could damage the catalytic

converter.

Batteries contain sulfuric acid which can burn skin, eyes, and

clothing, if contacted.

Do not attempt to push start your vehicle. Automatic

transmissions do not have push-start capability.

1

4 3

2 5

Roadside emergencies

179

Page 180 of 256

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

transmission must relearn its adaptive strategy. As a result of this, the

transmission may shift firmly. This operation is considered normal and

will not effect function or durability of the transmission. Over time, the

adaptive learning process will fully update transmission operation to its

optimum shift feel.

1.Use only a 12±volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle's electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

Connecting the jumper cables

1. Connect the positive (+) booster cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

+–+–

Roadside emergencies

180