tow MINI Clubman 2009 User Guide

[x] Cancel search | Manufacturer: MINI, Model Year: 2009, Model line: Clubman, Model: MINI Clubman 2009Pages: 158, PDF Size: 2.51 MB

Page 101 of 158

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

99

RSC – Run-Flat Tires

You will recognize Run-Flat Tires by a circular

symbol containing the letters RSC on the side of

the tire, page100.

M+S

Winter and all-season tires.

These have better winter properties than sum-

mer tires.

XL

Designation for specially reinforced tires.

Tire condition

Inspect your tires regularly for tread wear, signs

of damage and for foreign objects lodged in the

tread. Check the tread depth.

Tread depth

The tread depth should not drop below 1/8 in/

3 mm, although, for example, European legisla-

tion only specifies a minimum tread depth of

1/16 in/1.6 mm. At tread depths below 1/8 in/

3 mm there is an increased risk of high-speed

hydroplaning, even when only small amounts of

water are present on the road surface.

Winter tires

When winter tires wear down past a tread depth

of 1/6 in/4 mm, they become perceptibly less

suitable for winter conditions. In the interest of

safety, new tires should be installed.

Minimum tread depth

Wear indicators in the base of the tread groove

are distributed around the tire's circumference; the letters TWI, for Tread Wear Indicator, on the

tire's sidewalls identify tires that incorporate

these wear indicators. When tire tread is worn

down to the level of the wear indicators, the

remaining tread depth is 1/16 in/1.6 mm.

Tire damage

Please note that low-profile tires cause wheels,

tires and suspension parts to be more suscepti-

ble to road hazard and consequential damages.

Unusual vibrations encountered during normal

vehicle operation can indicate tire failure or

some other vehicle defect. This can, for exam-

ple, be caused by driving over curbs. The same

applies to any other abnormal road behavior,

such as pulling severely to the right or left.

In these cases, reduce speed immediately

and have wheels and tires thoroughly

checked. To do so, drive carefully to the nearest

MINI Dealer or tire shop that works according to

MINI repair procedures with correspondingly

trained personnel. If necessary, have the vehicle

towed there.

Otherwise tire damage can be extremely dan-

gerous for vehicle occupants and other road

users.<

Tire age

The manufacturing date of tires is contained in

the tire coding:

DOT ... 0309 means that the tire was manufac-

tured in week 3 of 2009.

For various reasons, such as the development

of brittleness, the manufacturer of your MINI

recommends tire replacement after no more

than 6 years, regardless of the actual wear of

the tires.

Page 105 of 158

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

103

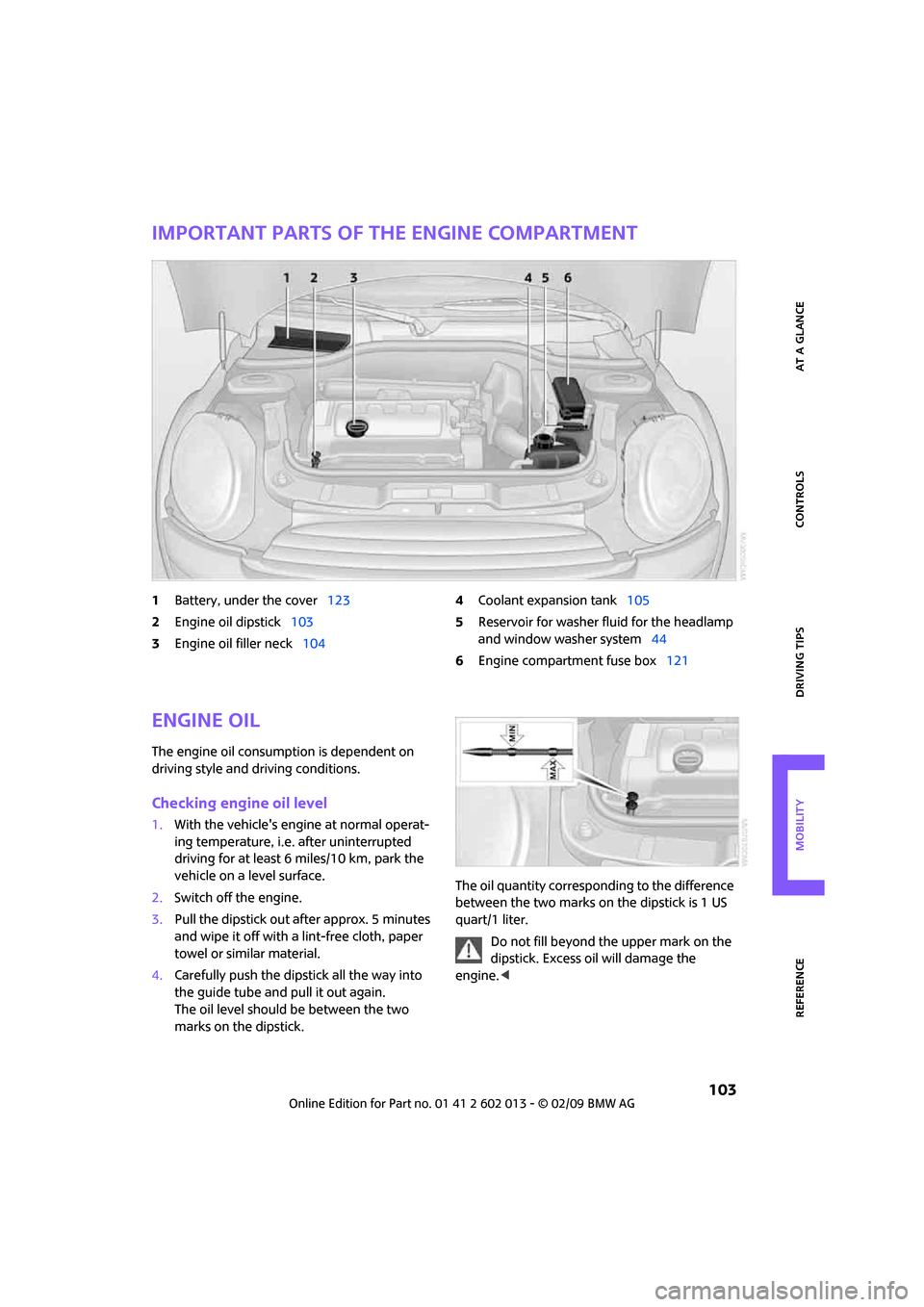

Important parts of the engine compartment

1Battery, under the cover123

2Engine oil dipstick103

3Engine oil filler neck1044Coolant expansion tank105

5Reservoir for washer fluid for the headlamp

and window washer system44

6Engine compartment fuse box121

Engine oil

The engine oil consumption is dependent on

driving style and driving conditions.

Checking engine oil level

1.With the vehicle's engine at normal operat-

ing temperature, i.e. after uninterrupted

driving for at least 6 miles/10 km, park the

vehicle on a level surface.

2.Switch off the engine.

3.Pull the dipstick out after approx. 5 minutes

and wipe it off with a lint-free cloth, paper

towel or similar material.

4.Carefully push the dipstick all the way into

the guide tube and pull it out again.

The oil level should be between the two

marks on the dipstick.The oil quantity corresponding to the difference

between the two marks on the dipstick is 1 US

quart/1 liter.

Do not fill beyond the upper mark on the

dipstick. Excess oil will damage the

engine.<

Page 114 of 158

Replacing components

112

Replacing components

Onboard tool kit

Your vehicle comes with an onboard tool kit that

varies with the equipment version; it is stored

underneath the level load floor.

>Mobility System with onboard tool kit and

tire change set

*116

>Tire change set with onboard tool kit for

space-saver spare tire118

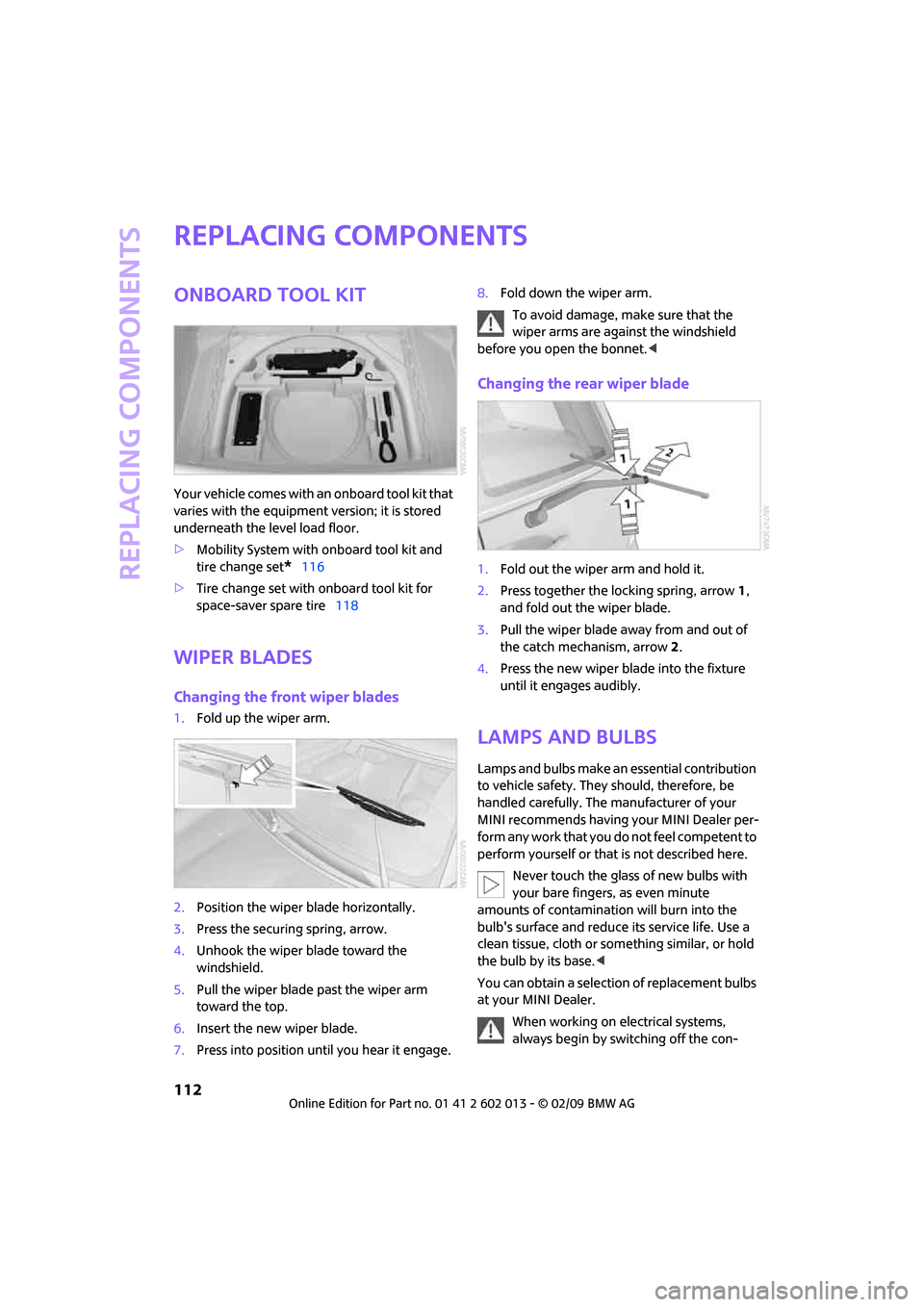

Wiper blades

Changing the front wiper blades

1.Fold up the wiper arm.

2.Position the wiper blade horizontally.

3.Press the securing spring, arrow.

4.Unhook the wiper blade toward the

windshield.

5.Pull the wiper blade past the wiper arm

toward the top.

6.Insert the new wiper blade.

7.Press into position until you hear it engage.8.Fold down the wiper arm.

To avoid damage, make sure that the

wiper arms are against the windshield

before you open the bonnet.<

Changing the rear wiper blade

1.Fold out the wiper arm and hold it.

2.Press together the locking spring, arrow 1,

and fold out the wiper blade.

3.Pull the wiper blade away from and out of

the catch mechanism, arrow 2.

4.Press the new wiper blade into the fixture

until it engages audibly.

Lamps and bulbs

Lamps and bulbs make an essential contribution

to vehicle safety. They should, therefore, be

handled carefully. The manufacturer of your

MINI recommends having your MINI Dealer per-

form any work that you do not feel competent to

perform yourself or that is not described here.

Never touch the glass of new bulbs with

your bare fingers, as even minute

amounts of contamination will burn into the

bulb's surface and reduce its service life. Use a

clean tissue, cloth or something similar, or hold

the bulb by its base.<

You can obtain a selection of replacement bulbs

at your MINI Dealer.

When working on electrical systems,

always begin by switching off the con-

Page 117 of 158

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

115

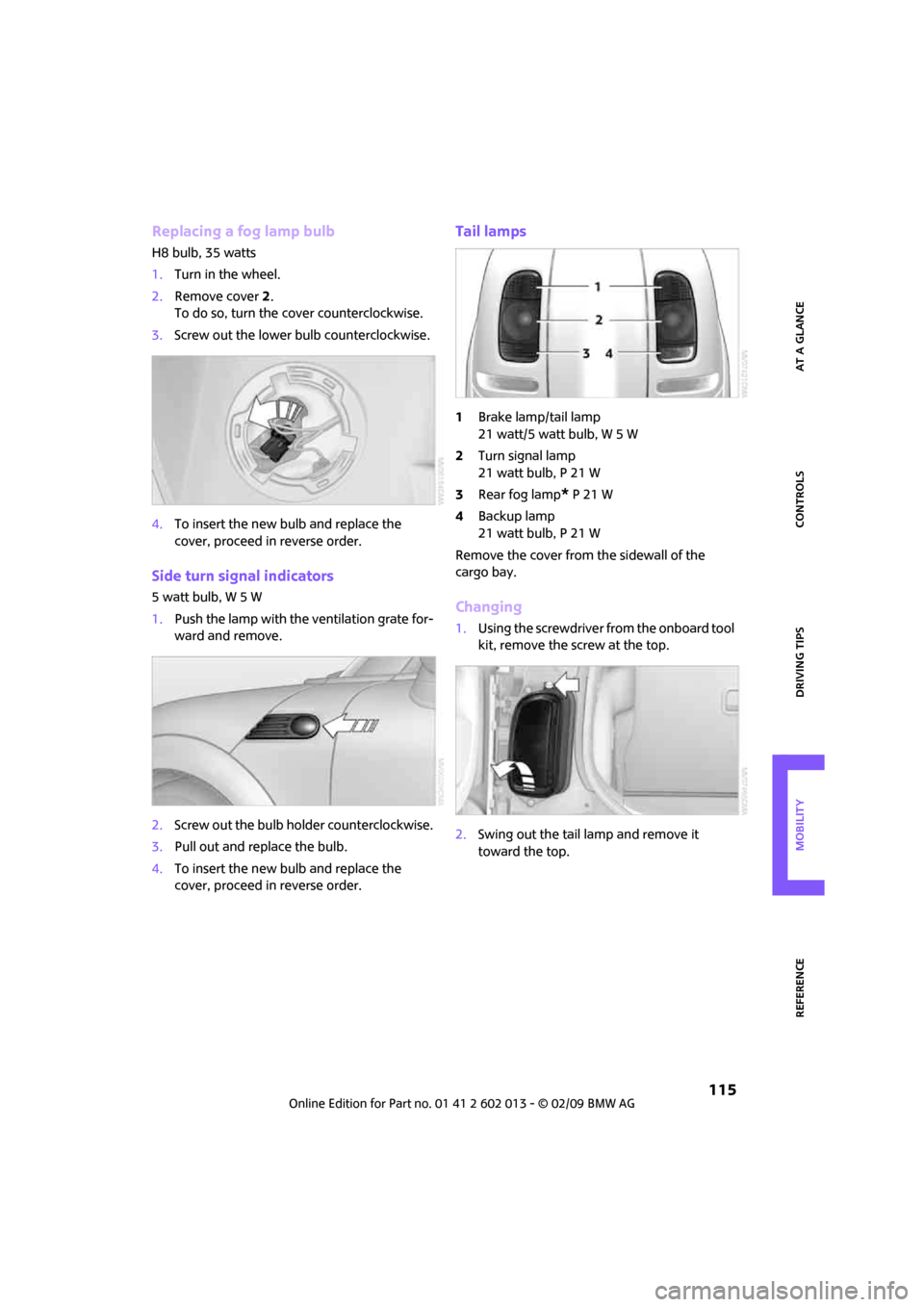

Replacing a fog lamp bulb

H8 bulb, 35 watts

1.Turn in the wheel.

2.Remove cover 2.

To do so, turn the cover counterclockwise.

3.Screw out the lower bulb counterclockwise.

4.To insert the new bulb and replace the

cover, proceed in reverse order.

Side turn signal indicators

5 watt bulb, W 5 W

1.Push the lamp with the ventilation grate for-

ward and remove.

2.Screw out the bulb holder counterclockwise.

3.Pull out and replace the bulb.

4.To insert the new bulb and replace the

cover, proceed in reverse order.

Tail lamps

1Brake lamp/tail lamp

21 watt/5 watt bulb, W 5 W

2Turn signal lamp

21 watt bulb, P 21 W

3Rear fog lamp

* P 21 W

4Backup lamp

21 watt bulb, P 21 W

Remove the cover from the sidewall of the

cargo bay.

Changing

1.Using the screwdriver from the onboard tool

kit, remove the screw at the top.

2.Swing out the tail lamp and remove it

toward the top.

Page 119 of 158

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

117

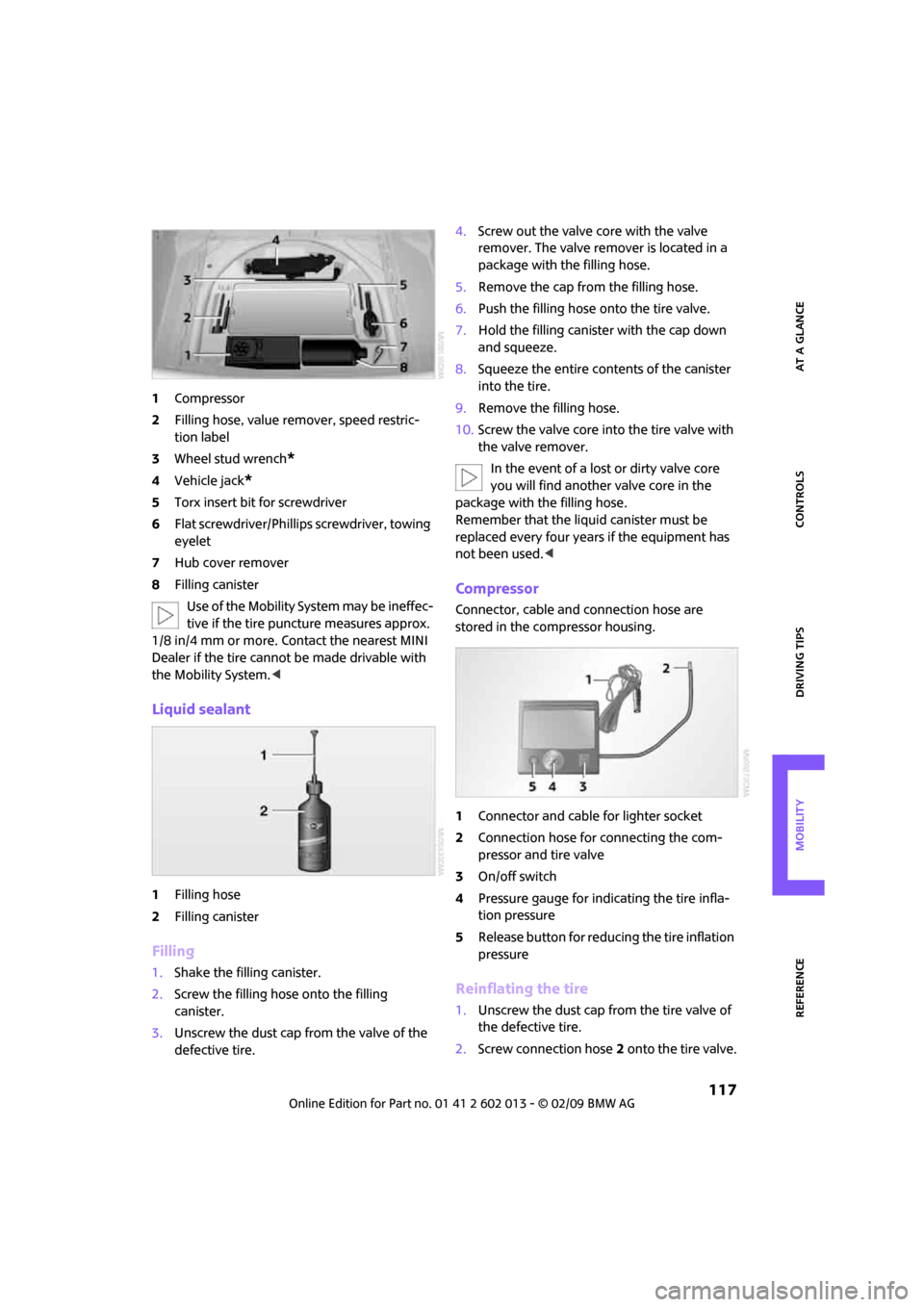

1Compressor

2Filling hose, value remover, speed restric-

tion label

3Wheel stud wrench

*

4Vehicle jack*

5Torx insert bit for screwdriver

6Flat screwdriver/Phillips screwdriver, towing

eyelet

7Hub cover remover

8Filling canister

Use of the Mobility System may be ineffec-

tive if the tire puncture measures approx.

1/8 in/4 mm or more. Contact the nearest MINI

Dealer if the tire cannot be made drivable with

the Mobility System.<

Liquid sealant

1Filling hose

2Filling canister

Filling

1.Shake the filling canister.

2.Screw the filling hose onto the filling

canister.

3.Unscrew the dust cap from the valve of the

defective tire.4.Screw out the valve core with the valve

remover. The valve remover is located in a

package with the filling hose.

5.Remove the cap from the filling hose.

6.Push the filling hose onto the tire valve.

7.Hold the filling canister with the cap down

and squeeze.

8.Squeeze the entire contents of the canister

into the tire.

9.Remove the filling hose.

10.Screw the valve core into the tire valve with

the valve remover.

In the event of a lost or dirty valve core

you will find another valve core in the

package with the filling hose.

Remember that the liquid canister must be

replaced every four years if the equipment has

not been used.<

Compressor

Connector, cable and connection hose are

stored in the compressor housing.

1Connector and cable for lighter socket

2Connection hose for connecting the com-

pressor and tire valve

3On/off switch

4Pressure gauge for indicating the tire infla-

tion pressure

5Release button for reducing the tire inflation

pressure

Reinflating the tire

1.Unscrew the dust cap from the tire valve of

the defective tire.

2.Screw connection hose2 onto the tire valve.

Page 121 of 158

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

119

located beneath the floor mat or level load floor

in the cargo bay.

1Folding chock and cover for defective wheel

2Vehicle jack

3Wheel stud wrench

4Hub cover remover

5Flat screwdriver/Phillips screwdriver

6Torx insert bit for screwdriver

7Towing eyelet

The onboard tool kit includes a pouch with

a plastic bag in which you can place the dam-

aged wheel.

Removing the space-saver spare tire

The space-saver spare tire is located under the

tire change set in the cargo bay.

1.Fold up the floor mat.

2.Unscrew the nut, arrow, and remove the

space-saver spare tire.

Driving with the space-saver spare tire

Drive cautiously and do not exceed a

speed of 50 mph/80 km/h. Changes may

occur in vehicle handling such as lower track sta-

bility during braking, longer braking distances

and changes in self-steering properties when

close to the handling limit. These properties are

more noticeable with winter tires.<

Only one space-saver spare tire may be

mounted at one time. Mount a wheel and

tire of the original size as soon as possible, to

avoid any safety risks.<

Check the tire inflation pressure at the ear-

liest opportunity and correct it if neces-

sary. Replace the defective tire as soon as possi-ble and have the new wheel/tire assembly

balanced.<

Preparing for a tire change

Observe the safety precautions regarding

flat tires on page116.<

Additional safety measures when chang-

ing tires:

Only change the tire when parked on a surface

that is level, firm and not slippery.

The vehicle or the jack could slip sideways on

soft or slippery support surfaces, such as snow,

ice, flagstones, etc.

Do not use a wooden block or similar object as a

support base for the jack, as this would prevent

it from extending to its full support height and

reduce its load-carrying capacity.

Do not lie under the vehicle or start the engine

when the vehicle is supported by the jack; other-

wise there is a risk of fatal injury.<

1.Place the foldable chock

* behind the front

wheel on the other side of the vehicle or in

front of the wheel if the vehicle is on an in-

cline. If the wheel is changed on a surface

with a more severe slope, take additional

precautions to secure the vehicle from

rolling.

2.Uncover the lug bolts if necessary.

If the wheel is equipped with a hub cover,

pry it off using the screwdriver from the tire

change kit.

3.Loosen the lug bolts by a half turn.

Jacking up the vehicle

The vehicle jack is designed for changing

wheels only. Do not attempt to raise

another vehicle model with it or to raise any load

Page 125 of 158

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

123

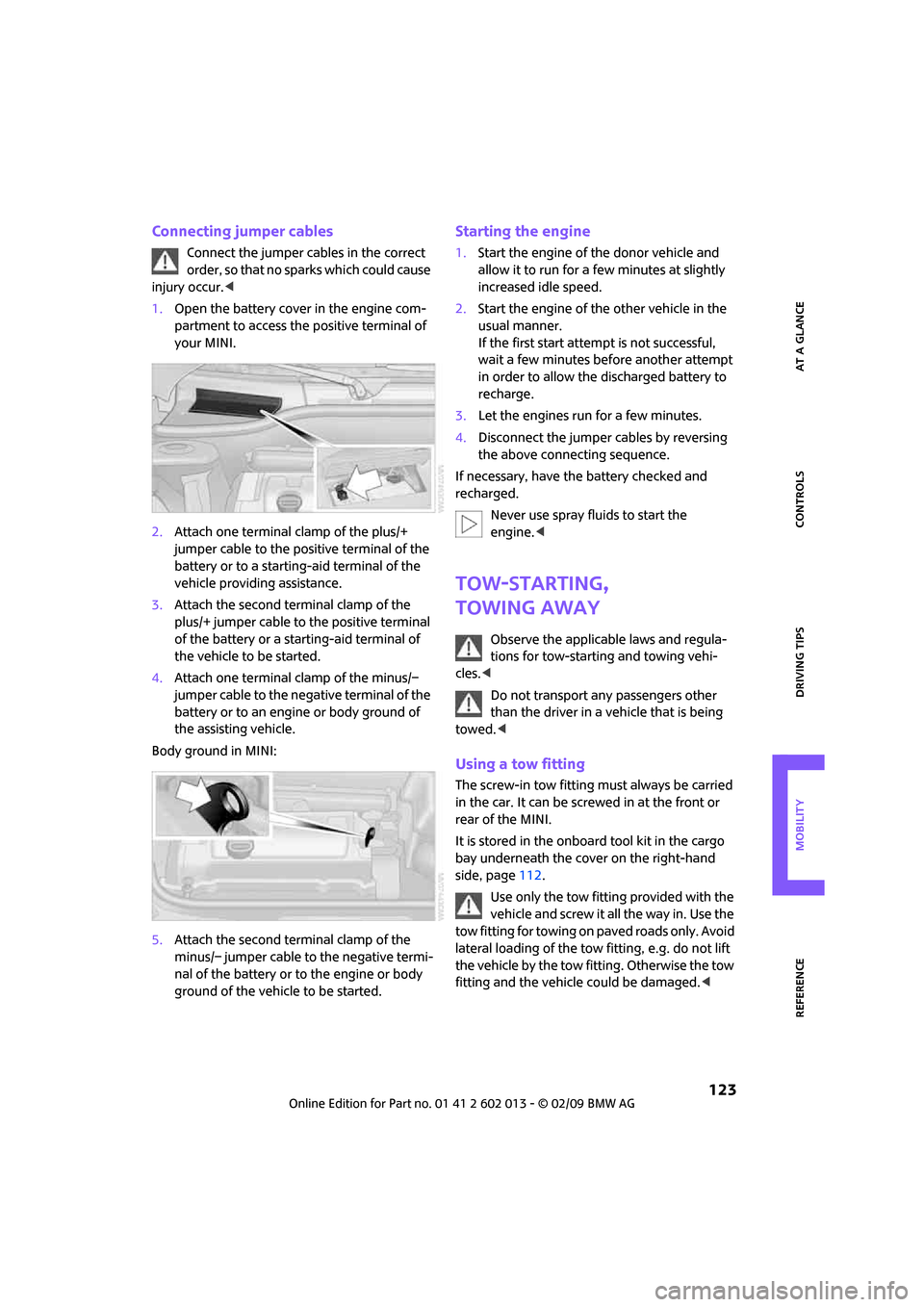

Connecting jumper cables

Connect the jumper cables in the correct

order, so that no sparks which could cause

injury occur.<

1.Open the battery cover in the engine com-

partment to access the positive terminal of

your MINI.

2.Attach one terminal clamp of the plus/+

jumper cable to the positive terminal of the

battery or to a starting-aid terminal of the

vehicle providing assistance.

3.Attach the second terminal clamp of the

plus/+ jumper cable to the positive terminal

of the battery or a starting-aid terminal of

the vehicle to be started.

4.Attach one terminal clamp of the minus/–

jumper cable to the negative terminal of the

battery or to an engine or body ground of

the assisting vehicle.

Body ground in MINI:

5.Attach the second terminal clamp of the

minus/– jumper cable to the negative termi-

nal of the battery or to the engine or body

ground of the vehicle to be started.

Starting the engine

1.Start the engine of the donor vehicle and

allow it to run for a few minutes at slightly

increased idle speed.

2.Start the engine of the other vehicle in the

usual manner.

If the first start attempt is not successful,

wait a few minutes before another attempt

in order to allow the discharged battery to

recharge.

3.Let the engines run for a few minutes.

4.Disconnect the jumper cables by reversing

the above connecting sequence.

If necessary, have the battery checked and

recharged.

Never use spray fluids to start the

engine.<

Tow-starting,

towing away

Observe the applicable laws and regula-

tions for tow-starting and towing vehi-

cles.<

Do not transport any passengers other

than the driver in a vehicle that is being

towed.<

Using a tow fitting

The screw-in tow fitting must always be carried

in the car. It can be screwed in at the front or

rear of the MINI.

It is stored in the onboard tool kit in the cargo

bay underneath the cover on the right-hand

side, page112.

Use only the tow fitting provided with the

vehicle and screw it all the way in. Use the

tow fitting for towing on paved roads only. Avoid

lateral loading of the tow fitting, e.g. do not lift

the vehicle by the tow fitting. Otherwise the tow

fitting and the vehicle could be damaged.<

Page 126 of 158

Giving and receiving assistance

124

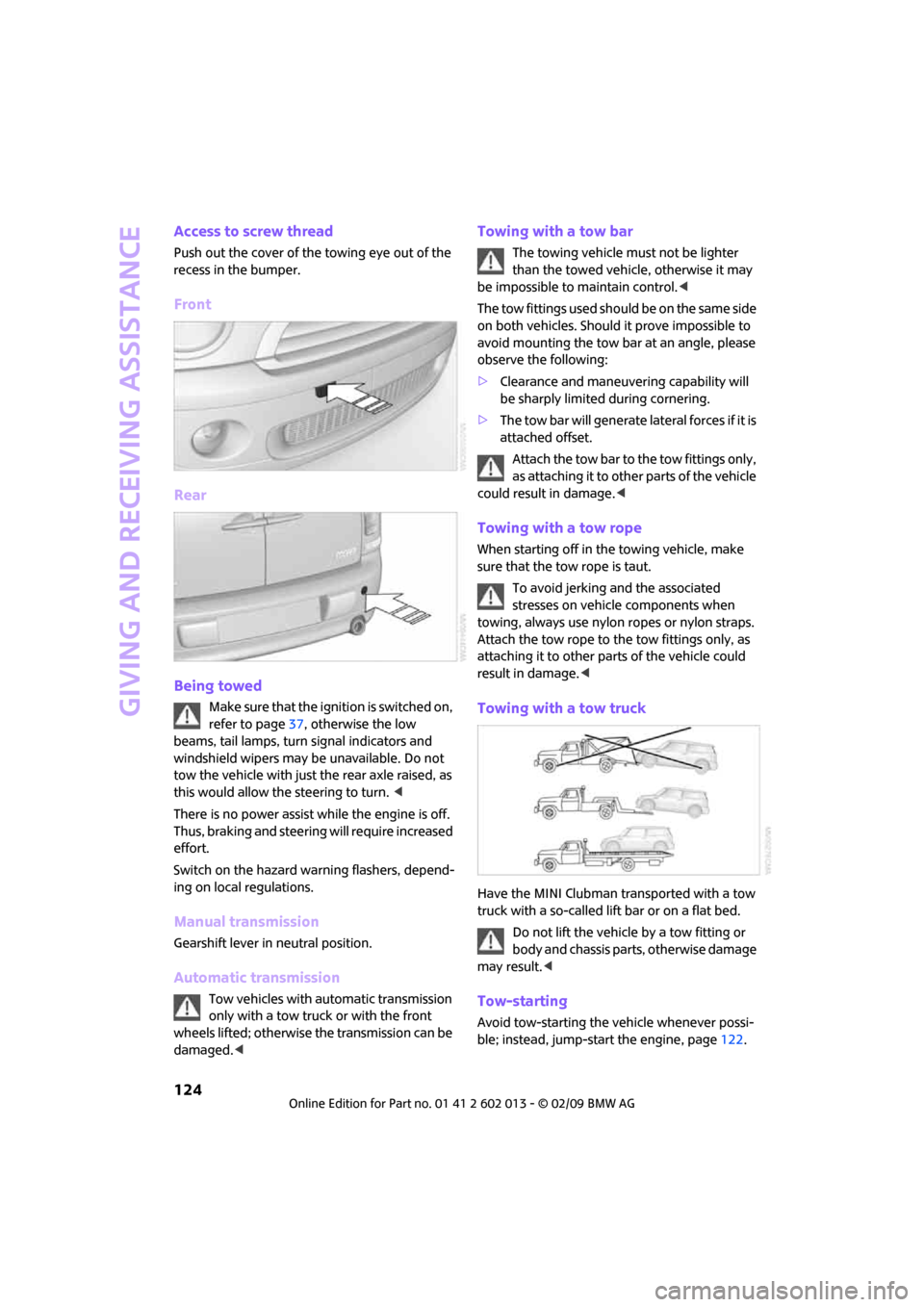

Access to screw thread

Push out the cover of the towing eye out of the

recess in the bumper.

Front

Rear

Being towed

Make sure that the ignition is switched on,

refer to page37, otherwise the low

beams, tail lamps, turn signal indicators and

windshield wipers may be unavailable. Do not

tow the vehicle with just the rear axle raised, as

this would allow the steering to turn. <

There is no power assist while the engine is off.

Thus, braking and steering will require increased

effort.

Switch on the hazard warning flashers, depend-

ing on local regulations.

Manual transmission

Gearshift lever in neutral position.

Automatic transmission

Tow vehicles with automatic transmission

only with a tow truck or with the front

wheels lifted; otherwise the transmission can be

damaged.<

Towing with a tow bar

The towing vehicle must not be lighter

than the towed vehicle, otherwise it may

be impossible to maintain control.<

The tow fittings used should be on the same side

on both vehicles. Should it prove impossible to

avoid mounting the tow bar at an angle, please

observe the following:

>Clearance and maneuvering capability will

be sharply limited during cornering.

>The tow bar will generate lateral forces if it is

attached offset.

Attach the tow bar to the tow fittings only,

as attaching it to other parts of the vehicle

could result in damage.<

Towing with a tow rope

When starting off in the towing vehicle, make

sure that the tow rope is taut.

To avoid jerking and the associated

stresses on vehicle components when

towing, always use nylon ropes or nylon straps.

Attach the tow rope to the tow fittings only, as

attaching it to other parts of the vehicle could

result in damage.<

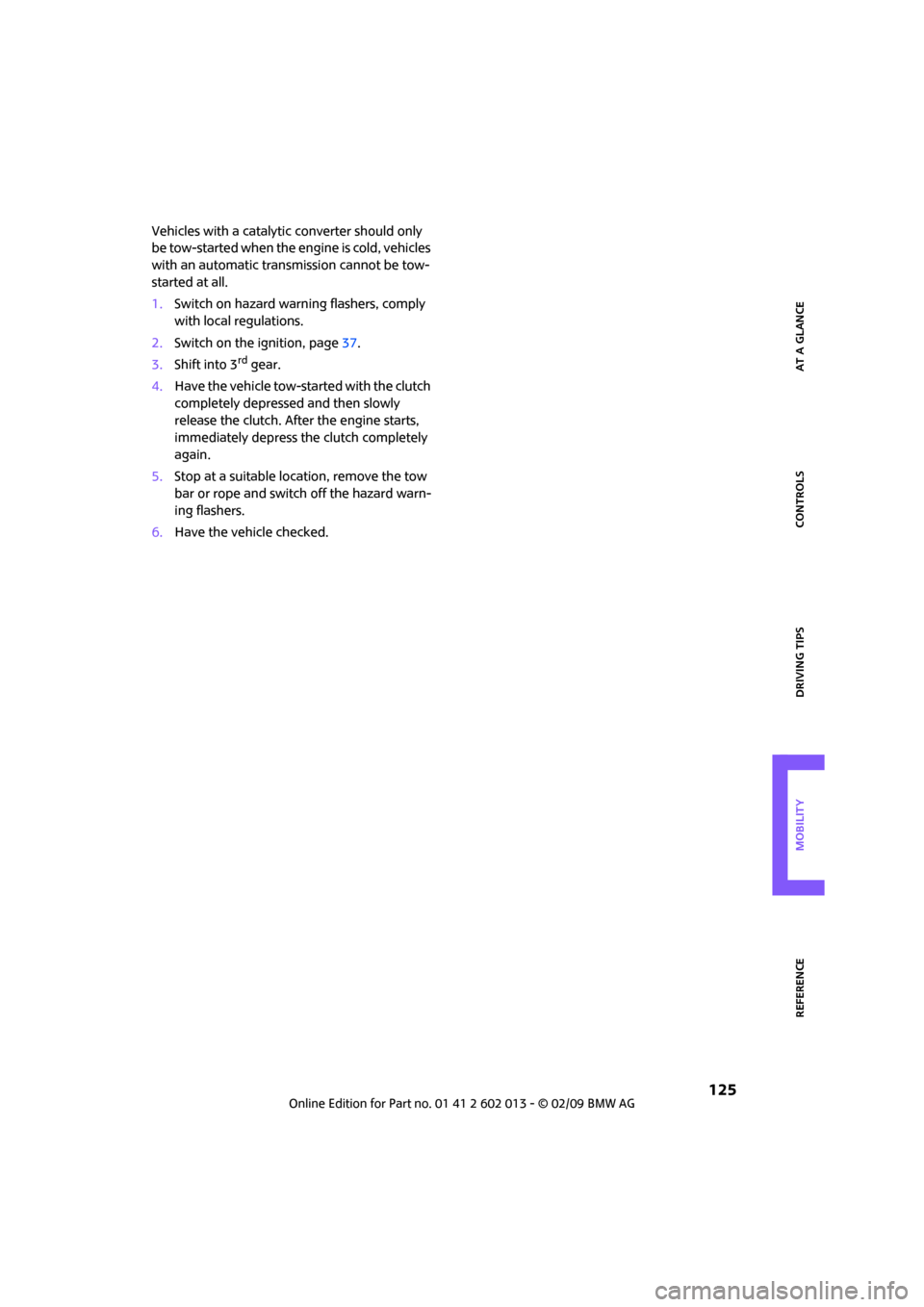

Towing with a tow truck

Have the MINI Clubman transported with a tow

truck with a so-called lift bar or on a flat bed.

Do not lift the vehicle by a tow fitting or

body and chassis parts, otherwise damage

may result.<

Tow-starting

Avoid tow-starting the vehicle whenever possi-

ble; instead, jump-start the engine, page122.

Page 127 of 158

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

125

Vehicles with a catalytic converter should only

be tow-started when the engine is cold, vehicles

with an automatic transmission cannot be tow-

started at all.

1.Switch on hazard warning flashers, comply

with local regulations.

2.Switch on the ignition, page37.

3.Shift into 3

rd gear.

4.Have the vehicle tow-started with the clutch

completely depressed and then slowly

release the clutch. After the engine starts,

immediately depress the clutch completely

again.

5.Stop at a suitable location, remove the tow

bar or rope and switch off the hazard warn-

ing flashers.

6.Have the vehicle checked.

Page 146 of 158

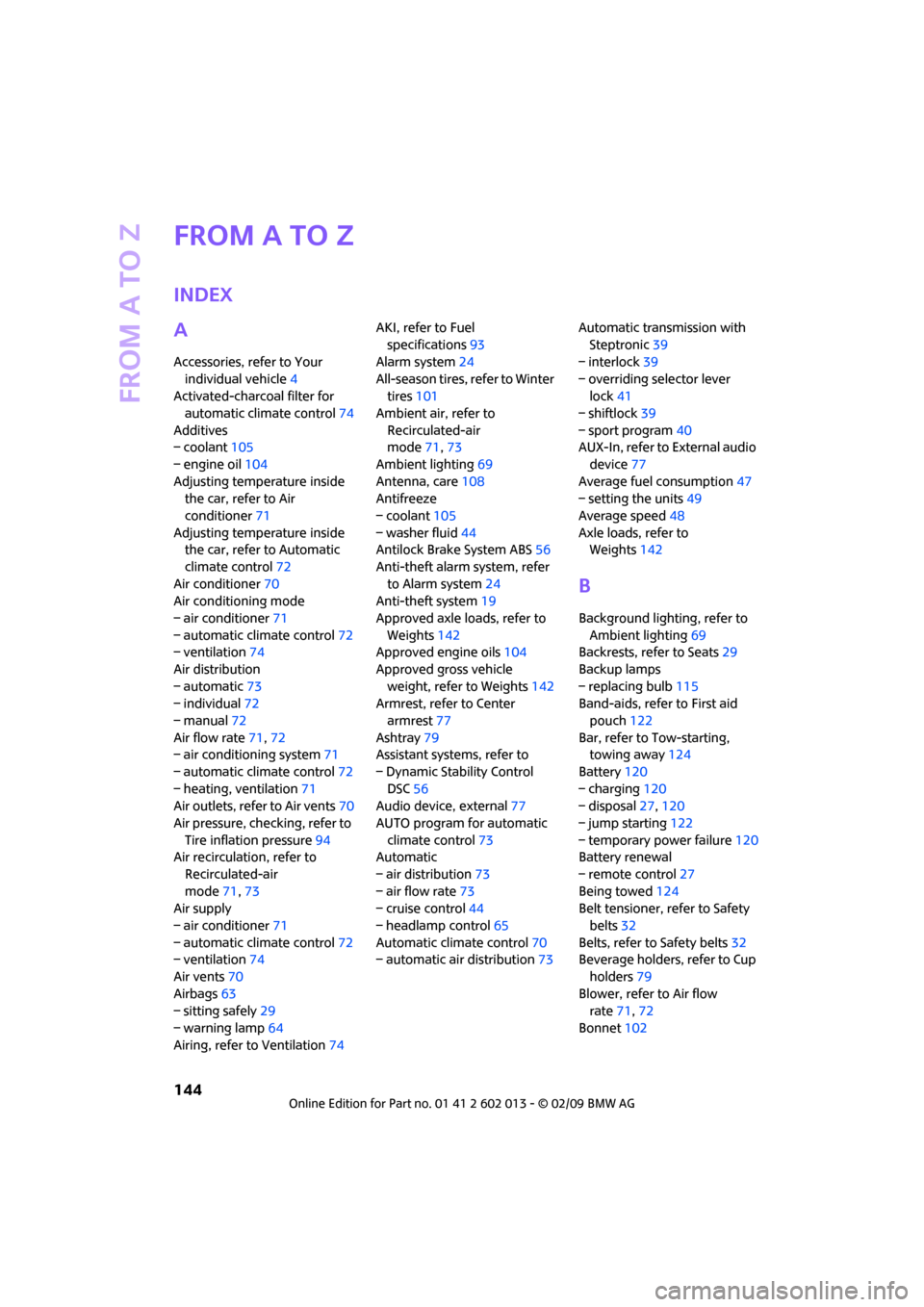

From A to Z

144

From A to Z

INDEX

A

Accessories, refer to Your

individual vehicle4

Activated-charcoal filter for

automatic climate control74

Additives

– coolant105

– engine oil104

Adjusting temperature inside

the car, refer to Air

conditioner71

Adjusting temperature inside

the car, refer to Automatic

climate control72

Air conditioner70

Air conditioning mode

– air conditioner71

– automatic climate control72

– ventilation74

Air distribution

– automatic73

– individual72

– manual72

Air flow rate71,72

– air conditioning system71

– automatic climate control72

– heating, ventilation71

Air outlets, refer to Air vents70

Air pressure, checking, refer to

Tire inflation pressure94

Air recirculation, refer to

Recirculated-air

mode71,73

Air supply

– air conditioner71

– automatic climate control72

– ventilation74

Air vents70

Airbags63

– sitting safely29

– warning lamp64

Airing, refer to Ventilation74AKI, refer to Fuel

specifications93

Alarm system24

All-season tires, refer to Winter

tires101

Ambient air, refer to

Recirculated-air

mode71,73

Ambient lighting69

Antenna, care108

Antifreeze

– coolant105

– washer fluid44

Antilock Brake System ABS56

Anti-theft alarm system, refer

to Alarm system24

Anti-theft system

19

Approved axle loads, refer to

Weights142

Approved engine oils104

Approved gross vehicle

weight, refer to Weights142

Armrest, refer to Center

armrest77

Ashtray79

Assistant systems, refer to

– Dynamic Stability Control

DSC56

Audio device, external77

AUTO program for automatic

climate control73

Automatic

– air distribution73

– air flow rate73

– cruise control44

– headlamp control65

Automatic climate control70

– automatic air distribution73Automatic transmission with

Steptronic39

– interlock39

– overriding selector lever

lock41

– shiftlock39

– sport program40

AUX-In, refer to External audio

device77

Average fuel consumption47

– setting the units49

Average speed48

Axle loads, refer to

Weights142B

Background lighting, refer to

Ambient lighting69

Backrests, refer to Seats29

Backup lamps

– replacing bulb115

Band-aids, refer to First aid

pouch122

Bar, refer to Tow-starting,

towing away124

Battery120

– charging120

– disposal27,120

– jump starting122

– temporary power failure120

Battery renewal

– remote control27

Being towed124

Belt tensioner, refer to Safety

belts32

Belts, refer to Safety belts32

Beverage holders, refer to Cup

holders79

Blower, refer to Air flow

rate71,72

Bonnet102