change time MINI Clubman 2011 (Mini Connected) Owner's Guide

[x] Cancel search | Manufacturer: MINI, Model Year: 2011, Model line: Clubman, Model: MINI Clubman 2011Pages: 256, PDF Size: 3.75 MB

Page 212 of 256

MOBILITYReplacing components

210

Xenon lamps*

The service life of these bulbs is very long and

the probability of failure very low, provided that

they are not switched on and off an excessive

number of times. If a xenon lamp fails neverthe-

less, switch on the fog lamps and continue the

journey with great care, provided that local leg-

islation does not prohibit this.

Have any work on the xenon lamp system,

including bulb replacement, carried out

only by a MINI dealer or a workshop that has

specially trained personnel working in accor-

dance with the specifications of the MINI manu-

facturer. Due to high voltage, there is a risk of

fatal injury if work on the xenon lamps is carried

out improperly.<

Halogen low beams and high beams

H13 bulb, 60/55 watts

The H13 bulb is pressurized. Therefore,

wear safety glasses and protective gloves.

Otherwise, there is a risk of injury if the bulb is

damaged. <

Be careful when insta lling the cover; oth-

erwise, leaks could occur and cause dam-

age to the headlamp system. <

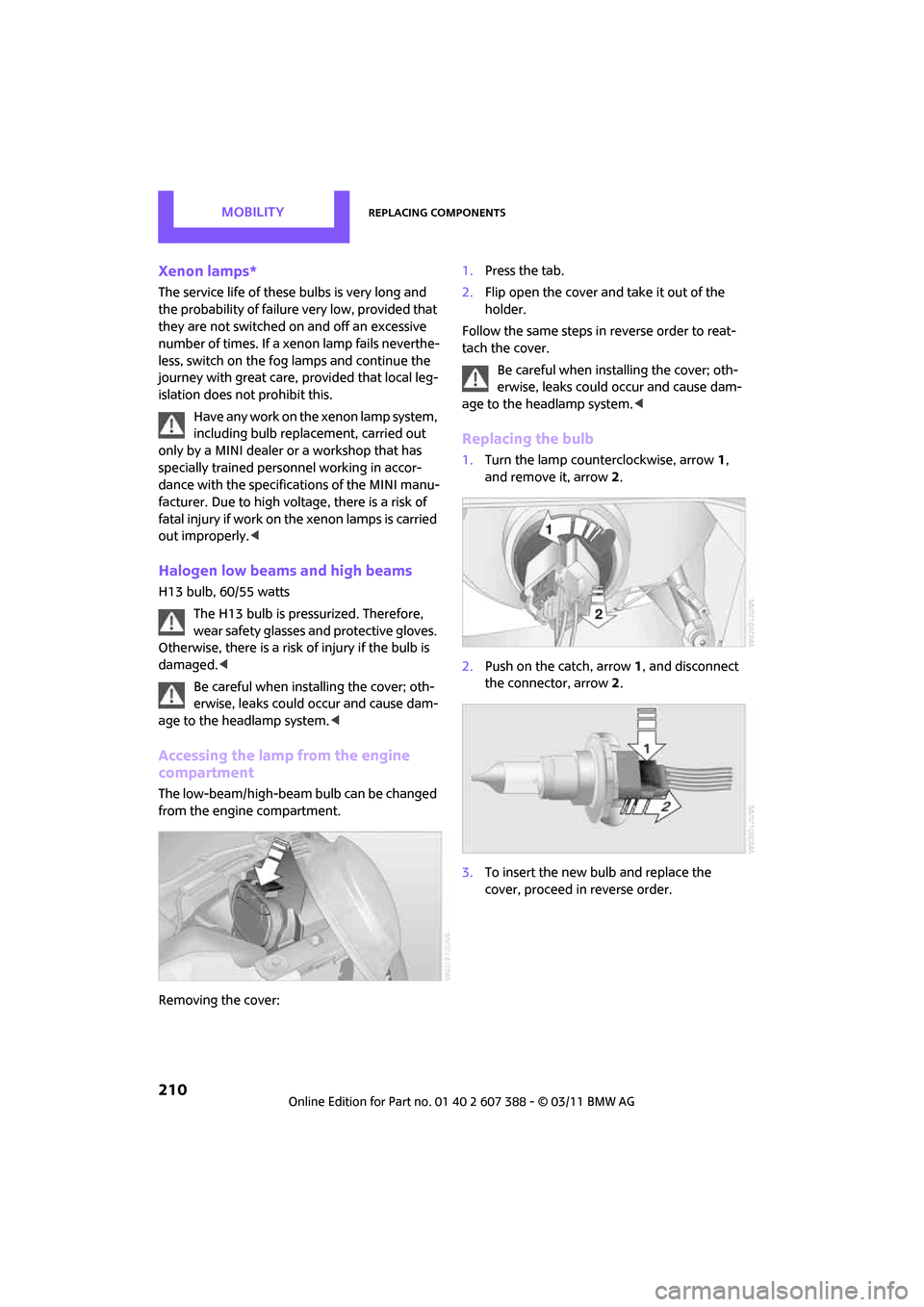

Accessing the lamp from the engine

compartment

The low-beam/high-beam bulb can be changed

from the engine compartment.

Removing the cover: 1.

Press the tab.

2. Flip open the cover and take it out of the

holder.

Follow the same steps in reverse order to reat-

tach the cover. Be careful when insta lling the cover; oth-

erwise, leaks could occur and cause dam-

age to the headlamp system. <

Replacing the bulb

1.Turn the lamp counterclockwise, arrow 1,

and remove it, arrow 2.

2. Push on the catch, arrow 1, and disconnect

the connector, arrow 2.

3. To insert the new bulb and replace the

cover, proceed in reverse order.

Page 218 of 256

MOBILITYReplacing components

216

1.Fold up the floor mat.

2. Unscrew the nut, arrow, and remove the

space-saver spare tire.

Driving with the space-saver spare tire

Drive cautiously and do not exceed a

speed of 50 mph/80 km/h. Changes may

occur in vehicle handling such as lower track sta-

bility during br aking, longer braking distances

and changes in self-steering properties when

close to the handling limit. These properties are

more noticeable with winter tires. <

Only one space-saver spare tire may be

mounted at one time. Mount a wheel and

tire of the original size as soon as possible, to

avoid any safety risks. <

Check the tire inflation pressure at the ear-

liest opportunity and correct it if neces-

sary. Replace the defective tire as soon as possi-

ble and have the new wheel/tire assembly

balanced. <

Preparing for a tire change

Observe the safety precautions regarding

flat tires on page 213.<

Additional safety measures when chang-

ing tires:

Only change the tire wh en parked on a surface

that is level, firm and not slippery.

The vehicle or the jack could slip sideways on

soft or slippery support surfaces, such as snow,

ice, flagstones, etc.

Do not use a wooden block or similar object as a

support base for the jack, as this would prevent

it from extending to its full support height and

reduce its load-carrying capacity. Do not lie under the vehicle or start the engine

when the vehicle is supported by the jack; other-

wise, there is a risk of fatal injury.

<

1. Place the foldable chock

* behind the front

wheel on the other side of the vehicle or in

front of the wheel if the vehicle is on an

incline. If the wheel is changed on a surface

with a more severe sl ope, take additional

precautions to secure the vehicle from roll-

ing.

2. Uncover the lug bolts if necessary.

3. Loosen the lug bolts by a half turn.

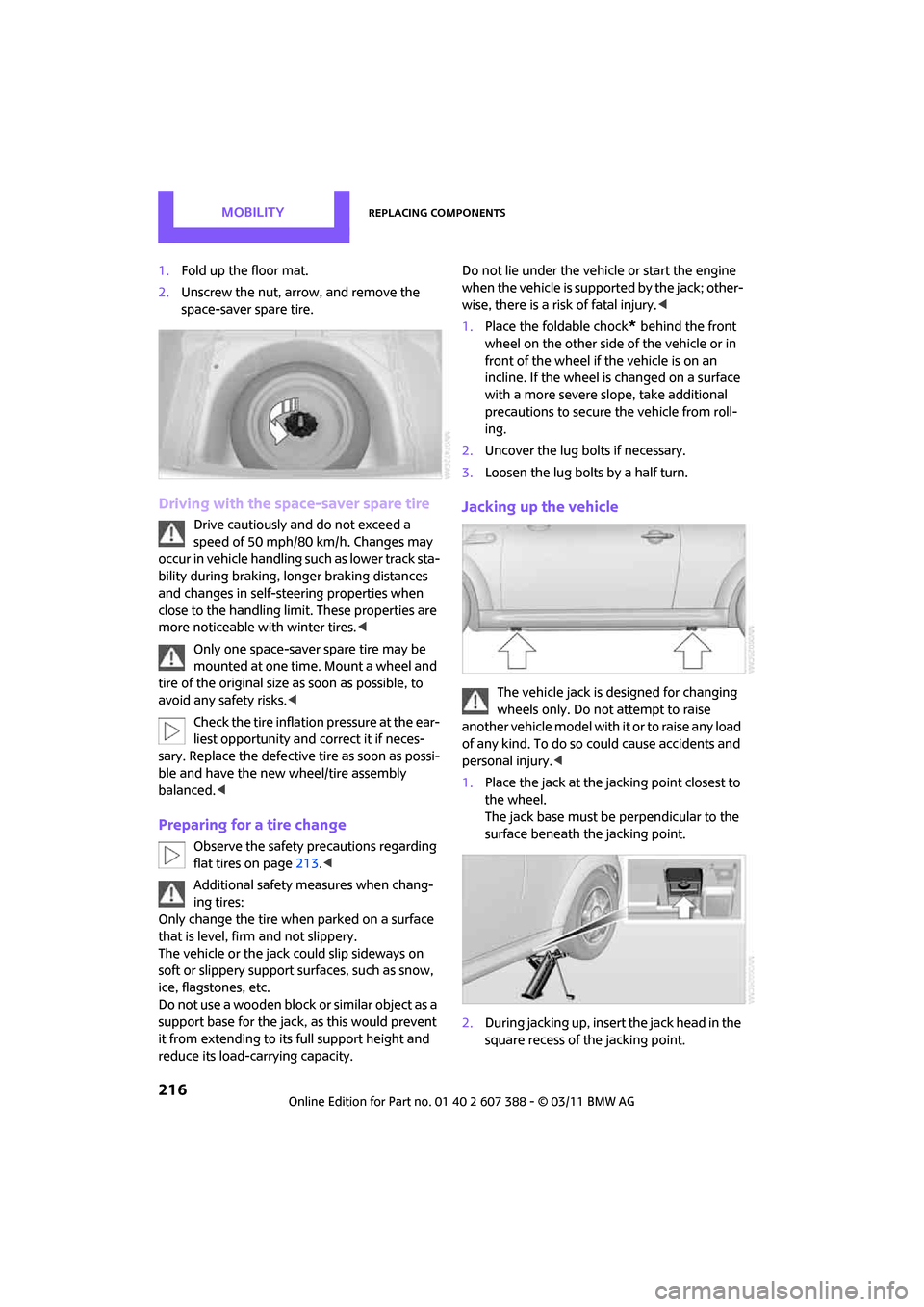

Jacking up the vehicle

The vehicle jack is designed for changing

wheels only. Do not attempt to raise

another vehicle model with it or to raise any load

of any kind. To do so could cause accidents and

personal injury. <

1. Place the jack at the jacking point closest to

the wheel.

The jack base must be perpendicular to the

surface beneath the jacking point.

2. During jacking up, insert the jack head in the

square recess of the jacking point.