ECU MINI COOPER 2014 Owner's Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2014, Model line: COOPER, Model: MINI COOPER 2014Pages: 230, PDF Size: 11.58 MB

Page 175 of 230

Run-flat tiresLabel

RSC label on the tire sidewall.

The wheels are composed of tires that are self-

supporting to a limited degree.

The support of the sidewall allows the tire to re‐

main drivable to a restricted degree in the

event of a pressure loss.

Continued driving with a damaged tire, refer to

page 99.

Continued driving with a damaged tire, refer to

page 96.

Changing run-flat tires

For your own safety, only use run-flat tires. No

spare tire is available in the case of a flat tire.

Your service center will be glad to advise you.

Repairing a flat tire Safety measures in case of a breakdown

Park the vehicle as far away as possible

from passing traffic and on solid ground.

Switch on the hazard warning system.

Turn the steering wheel until the front wheels

are in the straight-ahead position and engage

the steering wheel lock.

Secure the vehicle against rolling away by set‐

ting the parking brake.

Have all vehicle occupants get out of the vehi‐

cle and ensure that they remain outside the im‐

mediate area in a safe place, such as behind a

guardrail.

If necessary, set up a warning triangle at an ap‐

propriate distance.

Comply with all safety guidelines and regula‐

tions. ◀

Mobility System

The concept

With the Mobility System, minor tire damage

can be sealed quickly to enable continued travel. To accomplish this, sealant is pumped

into the tires, which seals the damage from the

inside.

The compressor can be used to check the tire

inflation pressure.

Hints▷Follow the instructions on using the Mobi‐

lity System found on the compressor and

sealant bottle.▷Use of the Mobility System may be ineffec‐

tive if the tire puncture measures approx.

1/8 in/4 mm or more.▷Contact the nearest service center if the tire

cannot be made drivable.▷If possible, do not remove foreign bodies

that have penetrated the tire.▷Pull the speed limit sticker off the sealant

bottle and apply it to the steering wheel.▷The use of a tire sealant can damage the

TPM wheel electronics. In this case, have

the electronics checked at the next oppor‐

tunity and have them replaced if necessary.

Storage

The Mobility System is located under the cargo

floor panel in the cargo area.

Seite 175Wheels and tiresMOBILITY175

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 181 of 230

Never reach into the engine compart‐

ment

Never reach into the intermediate spaces or

gaps in the engine compartment. Otherwise,

there is risk of injury, e.g., from rotating or hot

parts. ◀

Fold down wiper arm

Before opening the hood, ensure that the

wiper arms are against the windshield, or this

may result in damage. ◀

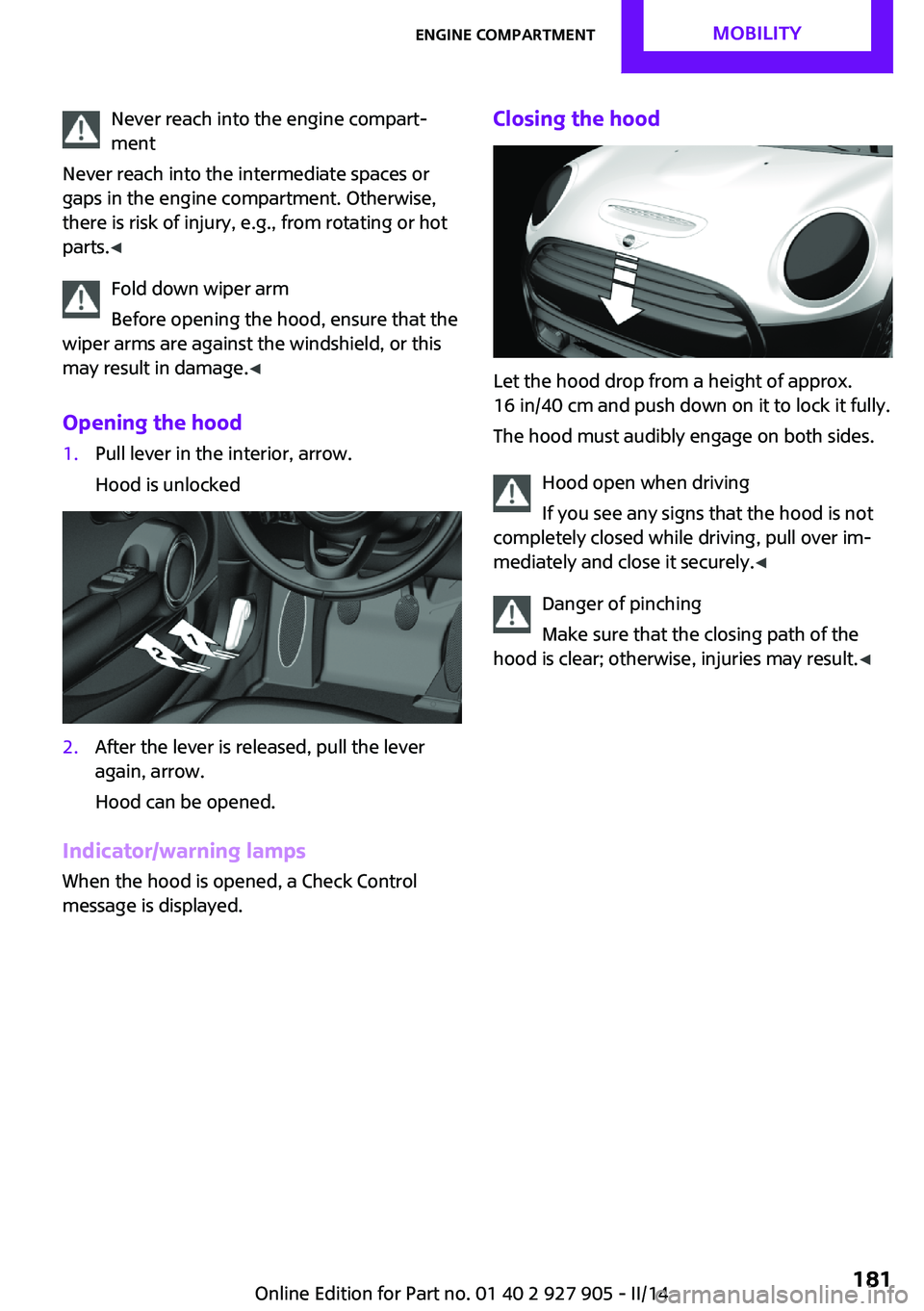

Opening the hood1.Pull lever in the interior, arrow.

Hood is unlocked2.After the lever is released, pull the lever

again, arrow.

Hood can be opened.

Indicator/warning lamps When the hood is opened, a Check Control

message is displayed.

Closing the hood

Let the hood drop from a height of approx.

16 in/40 cm and push down on it to lock it fully.

The hood must audibly engage on both sides.

Hood open when driving

If you see any signs that the hood is not

completely closed while driving, pull over im‐

mediately and close it securely. ◀

Danger of pinching

Make sure that the closing path of the

hood is clear; otherwise, injuries may result. ◀

Seite 181Engine compartmentMOBILITY181

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 197 of 230

Use the vehicle jack only for changing

wheels

Use the vehicle jack only for changing wheels

Do not attempt to use it to jack up a different

type of vehicle or loads of any kind; otherwise,

this could cause material damage and personal

injury. ◀

Removing compact wheel The compact wheel is housed in a well on the

underbody of the vehicle. The screw connec‐

tion of the compact wheel is located in the

cargo area under the floor mat, on the floor of

the storage compartment for the wheel chang‐

ing set.1.Loosen the nut from the wheel change set

using the wheel wrench.2.Remove the retaining plate.3.Screw the wheel wrench on the threads

and loosen the lock clockwise rotation.

Compact wheel releases and must be held

with the wheel wrench.4.Lower the compact wheel with the wheel

wrench.5.Unscrewing the wheel wrench6.Pull out the well with compact wheel under

the vehicle toward the rear.7.Remove the spacer and compact wheel of

the well.8.Stow the well and spacer in the vehicle.

Prepare wheel change

1.Follow the Safety instructions, refer to

page 196.2.With the wheel chock from the wheel

change set, also secure the vehicle against

rolling away at the front wheel of the oppo‐

site side.3.Loosen the wheel lug bolts a half turn.

Lug bolt lock, refer to page 198

Jacking up the vehicle

1.Place the vehicle jack at the jacking point

closest to the wheel such that the vehicle

jack foot is vertically beneath the vehicle

jacking point with the entire surface on the

ground.2.Insert the vehicle jack head in the rectan‐

gular recess of the jacking point for crank‐

ing it up.3.Crank it up until the wheel in question lifts

off of the ground.Seite 197Replacing componentsMOBILITY197

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 198 of 230

Wheel mounting1.Unscrew the wheel lug bolts and remove

the wheel.2.Put the new wheel or compact wheel on

and screw in at least two bolts.

If original MINI light alloy wheels are not

mounted, any accompanying lug bolts also

have to be used.3.Screw in the remaining the lug bolts and

tighten all bolts well in a crosswise pattern.4.Lower the vehicle and remove the vehicle

jack.

After the wheel change

1.Tighten the lug bolts crosswise. The tight‐

ening torque is 101 lb ft/140 Nm.

Check for secure seating of the lug

bolts

For safety reasons, have the secure seating

of the lug bolts checked with a calibrated

torque wrench; otherwise, a safety hazard

results from incorrectly tightened lug

bolts. ◀2.Stow the defective wheel in the cargo area.

The defective wheel cannot be stored in the

compact wheel bracket because of its size.3.Check tire inflation pressure at the next op‐

portunity and correct as needed.4.Reinitialize the Flat Tire Monitor, refer to

page 98.

Reinitialize the Tire Pressure Monitor, refer

to page 95.5.Replace the damaged tires as soon as pos‐

sible.

Driving with the compact wheel

Watch the speed when driving with the

compact wheel

Drive conservatively and do not exceed a speed

of 50 mph/80 km/h; otherwise, changed driving

characteristics such as reduced lane stability

while braking, extended braking distance and

changed self-steering properties in the limit

area. ◀

Mounting only one compact wheel

Only a single compact wheel may be

mounted. Reinstall wheels and tires of the orig‐

inal size as quickly as possible; otherwise, there

is a safety risk. ◀

Lug bolt lock

The adapter of the lug bolt lock is located in the

onboard vehicle tool kit, refer to page 188.▷Lug bolt, arrow 1.▷Adapter, arrow 2.

Removing

1.Attach the adapter to the wheel lug.2.Unscrew the lug bolt.

Remove the adapter after screwing the lug bolt

back on.

Vehicle battery

Maintenance

The battery is maintenance-free, i.e., the elec‐

trolyte will last for the life of the battery.

Your service center will be glad to advise you

on questions regarding the battery.

Seite 198MOBILITYReplacing components198

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 199 of 230

Battery replacementUse approved vehicle batteries only

Only use vehicle batteries that have been

approved for your vehicle by the manufacturer;

otherwise, the vehicle could be damaged and

systems or functions may not be fully availa‐

ble. ◀

After a battery replacement, have the battery

registered on the vehicle by your service center

to ensure that all comfort functions are fully

available and that any Check Control messages

are no longer displayed.

Charging the battery

Note Do not connect charging devices to the

12 volt socket in the vehicle

Do not connect battery chargers to the factory-

installed 12 volt sockets in the vehicle as this

may damage the vehicle battery due to an in‐

creased power consumption. ◀

General information Make sure that the battery is always sufficiently

charged to guarantee that the battery remains

usable for its full service life.

The battery may need to be charged in the fol‐

lowing cases:▷When making frequent short-distance

drives.▷If the vehicle is not used for prolonged peri‐

ods, longer than a month.▷Automatic transmission: when parked for

long periods of time in selector lever posi‐

tion D, R or N.

Starting aid terminals

In the vehicle, only charge the battery via the

starting aid terminals, refer to page 202, in the

engine compartment with the engine off.

Power failure

After a temporary power loss, some equipment

needs to be reinitialized.

Individual settings need to be reprogrammed:▷Time: update.▷Date: update.

Disposing of old batteries Have old batteries disposed of by your

service center or bring them to a recy‐

cling center.

Maintain the battery in an upright position for

transport and storage. Secure the battery so

that it does not tip over during transport.

Fuses Hints Replacing fuses

Never attempt to repair a blown fuse and

do not replace a defective fuse with a substi‐

tute of another color or amperage rating; this

could lead to a circuit overload, ultimately re‐

sulting in a fire in the vehicle. ◀

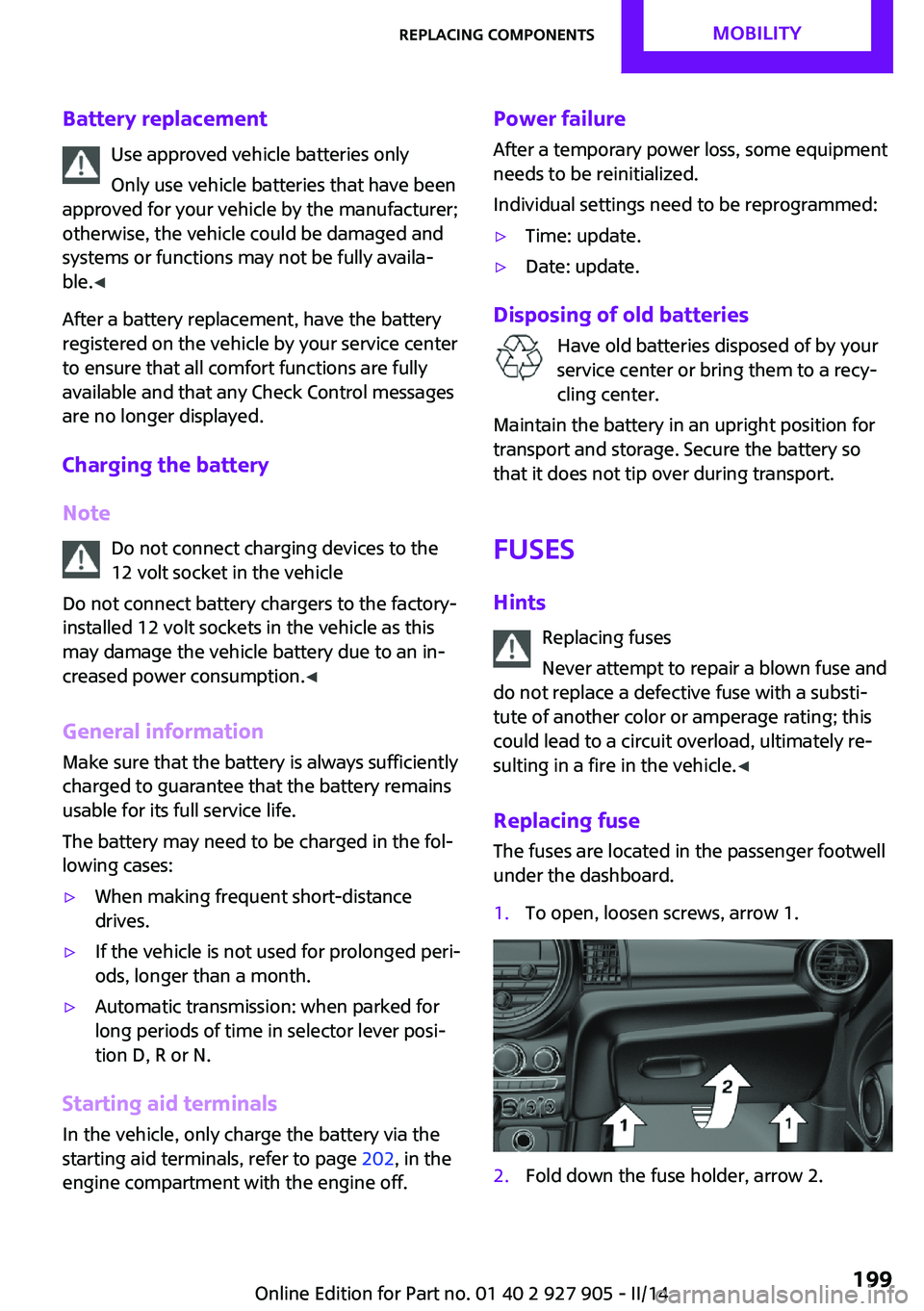

Replacing fuse

The fuses are located in the passenger footwell

under the dashboard.

1.To open, loosen screws, arrow 1.2.Fold down the fuse holder, arrow 2.Seite 199Replacing componentsMOBILITY199

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 205 of 230

Towing other vehicles

General information Light towing vehicle

The towing vehicle must not be lighter

than the vehicle being towed; otherwise, it will

not be possible to control the vehicle re‐

sponse. ◀

Attaching the tow bar/tow rope correctly

Attach the tow bar or tow rope to the tow

fitting; connecting it to other vehicle parts may

cause damage. ◀▷Switch on the hazard warning system, de‐

pending on local regulations.▷If the electrical system has failed, clearly

identify the vehicle being towed by placing

a sign or a warning triangle in the rear win‐

dow.

Tow bar

The tow fittings used should be on the same

side on both vehicles.

Should it prove impossible to avoid mounting

the tow bar at an offset angle, please observe

the following:

▷Maneuvering capability is limited during

cornering.▷The tow bar will generate lateral forces if it

is secured with an offset.

Tow rope

When starting to tow the vehicle, make sure

that the tow rope is taut.

To avoid jerking and the associated stresses on

the vehicle components when towing, always

use nylon ropes or nylon straps.

Attaching the tow rope correctly

Only secure the tow rope on the tow fit‐

ting; otherwise, damage can occur when it is

secured on other parts of the vehicle. ◀

Tow fitting

The screw-in tow fitting should always be car‐

ried in the vehicle. It can be screwed in at the

front or rear of the MINI. It is located in the

cargo area under the cargo floor panel in the

onboard vehicle tool kit, refer to page 188.

Tow fitting, information on use

▷Use only the tow fitting provided with

the vehicle and screw it all the way in.▷Use the tow fitting for towing on paved

roads only.▷Avoid lateral loading of the tow fitting, e.g.,

do not lift the vehicle by the tow fitting.

Otherwise, damage to the tow fitting and the

vehicle can occur. ◀

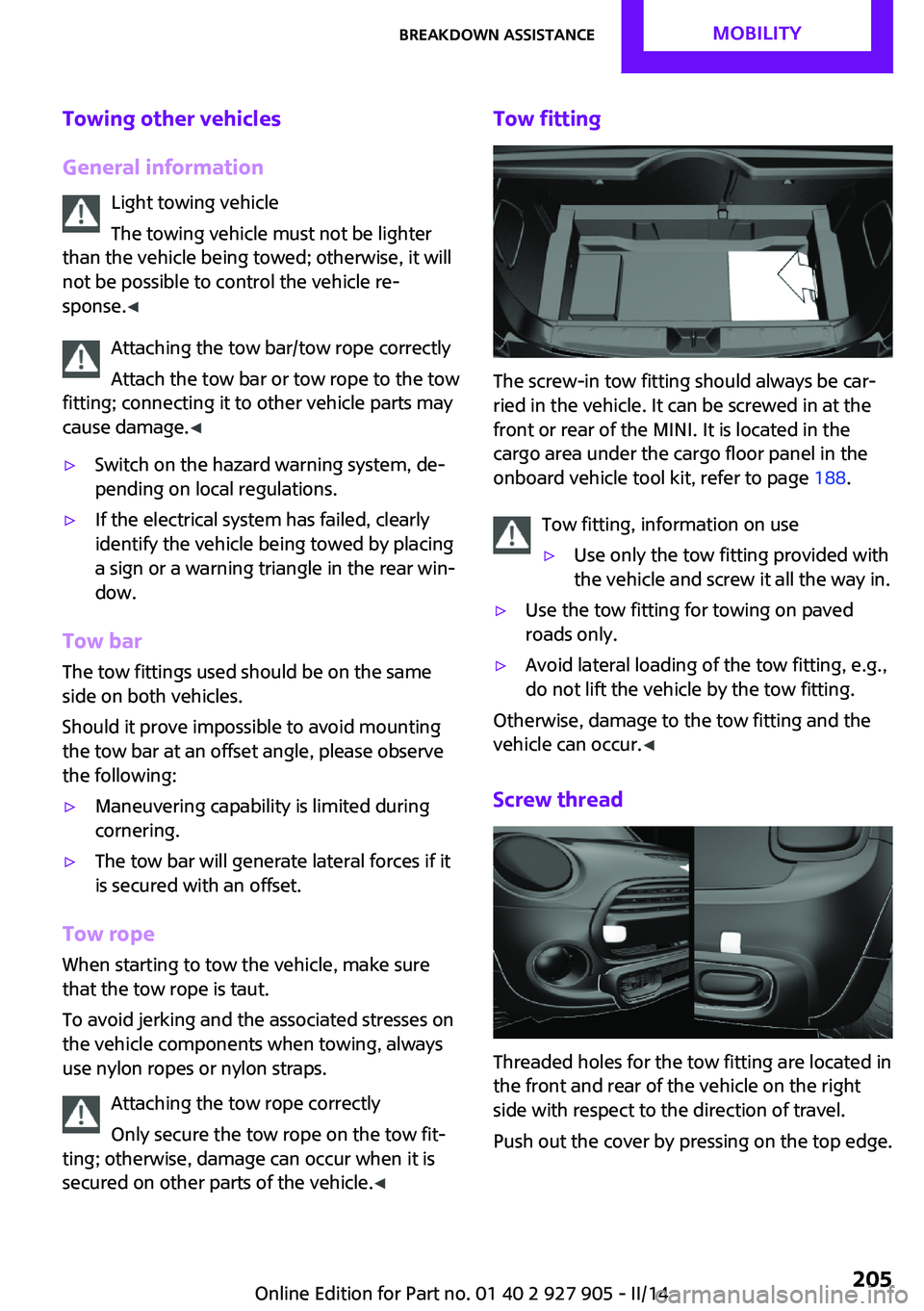

Screw thread

Threaded holes for the tow fitting are located in

the front and rear of the vehicle on the right

side with respect to the direction of travel.

Push out the cover by pressing on the top edge.

Seite 205Breakdown assistanceMOBILITY205

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 210 of 230

Carpets and floor matsNo objects in the area around the pedals

Keep floor mats, carpets, and any other

objects out of the area of motion of the pedals;

otherwise, the function of the pedals could be

impeded while driving and create the risk of an

accident.

Do not place additional floor mats over existing

mats or other objects.

Only use floor mats that have been approved

for the vehicle and can be properly fixed in

place.

Ensure that the floor mats are securely fastened

again after they were removed for cleaning, for

example. ◀

Floor mats can be removed from the passenger

compartment for cleaning.

If the floor carpets are very dirty, clean with a

microfiber cloth and water or a textile cleaner.

To prevent matting of the carpet, rub back and

forth in the direction of travel only.

Sensors/cameras To clean sensors and cameras, use a cloth

moistened with a small amount of glass

cleaner.

Displays/Screens/Projection lenses Cleaning displays and screens

Do not use any chemical or household

cleaning agents; otherwise, surfaces can be af‐

fected. ◀

Keeping out moisture

Keep all fluids and moisture away from

the unit; otherwise, electrical components can

be damaged. ◀

Avoid pressure

Avoid pressing too hard when cleaning

and do not use abrasive materials; otherwise,

damage can result. ◀Clean with a clean, antistatic microfiber cloth.

For stubborn soiling on the projection lens of

the Head-up Display, dampen the microfiber

cloth with alcohol. Extending projection lens,

refer to page 84.

Long-term vehicle storage

When the vehicle is shut down for longer than

three months, special measures must be taken.

Additional information is available from the

service center.Seite 210MOBILITYCare210

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 221 of 230

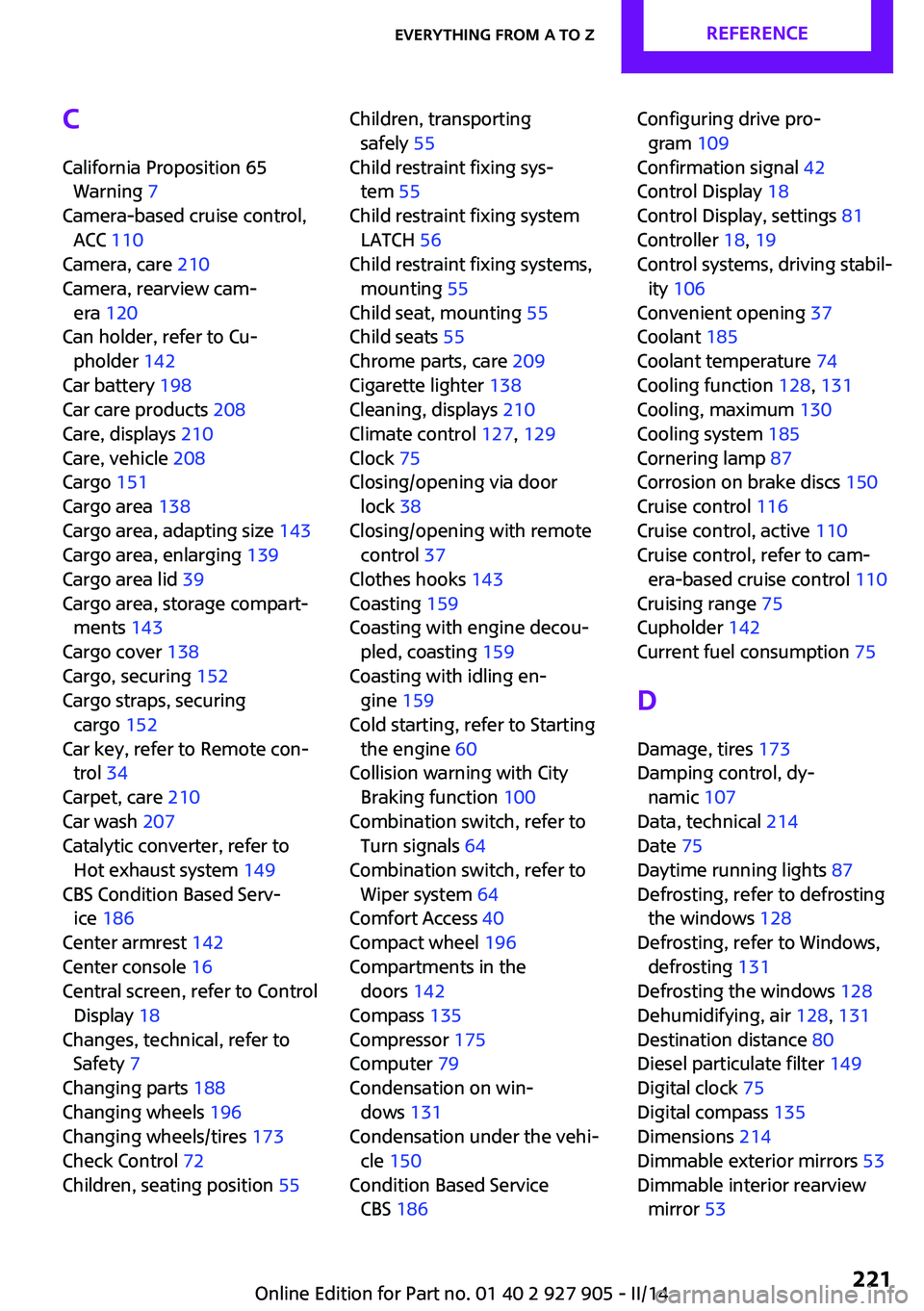

C

California Proposition 65 Warning 7

Camera-based cruise control, ACC 110

Camera, care 210

Camera, rearview cam‐ era 120

Can holder, refer to Cu‐ pholder 142

Car battery 198

Car care products 208

Care, displays 210

Care, vehicle 208

Cargo 151

Cargo area 138

Cargo area, adapting size 143

Cargo area, enlarging 139

Cargo area lid 39

Cargo area, storage compart‐ ments 143

Cargo cover 138

Cargo, securing 152

Cargo straps, securing cargo 152

Car key, refer to Remote con‐ trol 34

Carpet, care 210

Car wash 207

Catalytic converter, refer to Hot exhaust system 149

CBS Condition Based Serv‐ ice 186

Center armrest 142

Center console 16

Central screen, refer to Control Display 18

Changes, technical, refer to Safety 7

Changing parts 188

Changing wheels 196

Changing wheels/tires 173

Check Control 72

Children, seating position 55 Children, transporting

safely 55

Child restraint fixing sys‐ tem 55

Child restraint fixing system LATCH 56

Child restraint fixing systems, mounting 55

Child seat, mounting 55

Child seats 55

Chrome parts, care 209

Cigarette lighter 138

Cleaning, displays 210

Climate control 127, 129

Clock 75

Closing/opening via door lock 38

Closing/opening with remote control 37

Clothes hooks 143

Coasting 159

Coasting with engine decou‐ pled, coasting 159

Coasting with idling en‐ gine 159

Cold starting, refer to Starting the engine 60

Collision warning with City Braking function 100

Combination switch, refer to Turn signals 64

Combination switch, refer to Wiper system 64

Comfort Access 40

Compact wheel 196

Compartments in the doors 142

Compass 135

Compressor 175

Computer 79

Condensation on win‐ dows 131

Condensation under the vehi‐ cle 150

Condition Based Service CBS 186 Configuring drive pro‐

gram 109

Confirmation signal 42

Control Display 18

Control Display, settings 81

Controller 18, 19

Control systems, driving stabil‐ ity 106

Convenient opening 37

Coolant 185

Coolant temperature 74

Cooling function 128, 131

Cooling, maximum 130

Cooling system 185

Cornering lamp 87

Corrosion on brake discs 150

Cruise control 116

Cruise control, active 110

Cruise control, refer to cam‐ era-based cruise control 110

Cruising range 75

Cupholder 142

Current fuel consumption 75

D

Damage, tires 173

Damping control, dy‐ namic 107

Data, technical 214

Date 75

Daytime running lights 87

Defrosting, refer to defrosting the windows 128

Defrosting, refer to Windows, defrosting 131

Defrosting the windows 128

Dehumidifying, air 128, 131

Destination distance 80

Diesel particulate filter 149

Digital clock 75

Digital compass 135

Dimensions 214

Dimmable exterior mirrors 53

Dimmable interior rearview mirror 53 Seite 221Everything from A to ZREFERENCE221

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 222 of 230

Direction indicator, refer toTurn signals 64

Display, electronic, instrument cluster 72

Display lighting, refer to In‐ strument lighting 89

Displays 71

Displays, cleaning 210

Disposal, coolant 185

Disposal, vehicle battery 199

Distance control, refer to PDC 118

Distance to destination 80

Divided screen view, split screen 23

Door lock, refer to Remote control 34

Drive mode, GREEN mode 156

Drive-off assistant 109

Drive-off assistant, refer to DSC 106

Driving Dynamics Control 108

Driving Excitement, SPORT 80

Driving instruction, GREEN mode 158

Driving instructions, breaking in 148

Driving mode 108

Driving notes, general 148

Driving stability control sys‐ tems 106

Driving style analysis 160

Driving tips 148

DSC Dynamic Stability Con‐ trol 106

DTC Dynamic Traction Con‐ trol 107

Dynamic Damping Con‐ trol 107

Dynamic Stability Control DSC 106

Dynamic Traction Control DTC 107 E

Electronic displays, instrument cluster 72

Electronic Stability Program ESP, refer to DSC 106

Emergency detection, remote control 35

Emergency release, fuel filler flap 164

Emergency Request 201

Emergency service, refer to Roadside Assistance 202

Emergency start function, en‐ gine start 35

Emergency unlocking, door lock 39

Energy Control 75

Engine, automatic Start/Stop function 61

Engine, automatic switch- off 61

Engine compartment 180

Engine compartment, working in 180

Engine coolant 185

Engine idling when driving, coasting 159

Engine oil 182

Engine oil, adding 183

Engine oil additives 183

Engine oil change 184

Engine oil filler neck 183

Engine oil temperature 74

Engine oil types, alterna‐ tive 184

Engine oil types, ap‐ proved 184

Engine start during malfunc‐ tion 35

Engine start, jump-start‐ ing 202

Engine start, refer to Starting the engine 60

Engine stop 60

Engine temperature 74 Entering a car wash 207

Equipment, interior 133

ESP Electronic Stability Pro‐ gram, refer to DSC 106

Exchanging wheels/tires 173

Exhaust system 149

Exterior mirror, automatic dimming feature 53

Exterior mirrors 52

External start 202

External temperature dis‐ play 75

External temperature warn‐ ing 75

Eyes for securing cargo 152

F

Failure message, refer to Check Control 72

False alarm, refer to Uninten‐ tional alarm 43

Fan, refer to Air flow 128, 130

Fault displays, refer to Check Control 72

Favorites buttons, onboard monitor 24

Filler neck for engine oil 183

Fine wood, care 209

First aid kit 202

Fitting for towing, refer to Tow fitting 205

Flat tire, changing wheels 196

Flat Tire Monitor FTM 97

Flat tire, repairing 175

Flat tire, Tire Pressure Monitor TPM 94

Flat tire, warning lamp 95, 98

Flooding 149

Floor carpet, care 210

Floor mats, care 210

Fogged up windows 128

Fold-out position, windshield wipers 66

Foot brake 149

Front airbags 91 Seite 222REFERENCEEverything from A to Z222

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 224 of 230

Internet site 6

Interval display, service re‐ quirements 76

J

Jacking points for the vehicle jack 196

Joystick, automatic transmis‐ sion 68

Jump-starting 202

K Key/remote control 34

Keyless Go, refer to Comfort Access 40

Key Memory, refer to Personal Profile 35

Kickdown, automatic trans‐ mission 68

Knee airbag 91

L Lamp replacement 189

Lamp replacement, front 190

Lamp replacement, rear 192

Lamp replacement, side 195

Lamps and bulbs 189

Language on Control Dis‐ play 82

Lashing eyes, securing cargo 152

LATCH child restraint fixing system 56

Launch Control 70

Leather, care 208

LED bug light 190

LED headlamps 190

LED ring, central instrument cluster 82

LEDs, light-emitting di‐ odes 189

Left-hand traffic, lamp set‐ ting 89 Letters and numbers, enter‐

ing 24

Light 86

Light-alloy wheels, care 209

Light-emitting diodes, LEDs 189

Lighter 138

Lighting 86

Lighting via remote con‐ trol 37

Light switch 86

Load 152

Loading 151

Lock, door 38

Locking/unlocking via door lock 38

Locking/unlocking with re‐ mote control 37

Locking, automatic 42

Locking, settings 42

Low beams 86

Low beams, automatic, refer to High-beam Assistant 88

Lower back support, mechani‐ cal 48

Lug bolt lock 198

Luggage rack, refer to Roof- mounted luggage rack 152

Lumbar support, mechani‐ cal 48

M

Maintenance 186

Maintenance require‐ ments 186

Maintenance, service require‐ ments 76

Maintenance system, MINI 186

Malfunction displays, refer to Check Control 72

Manual air distribu‐ tion 128, 130

Manual air flow 128, 130 Manual mode, transmis‐

sion 68

Manual operation, door lock 38

Manual operation, exterior mirrors 52

Manual operation, fuel filler flap 164

Manual operation, Park Dis‐ tance Control PDC 119

Manual operation, rearview camera 121

Manual transmission 67

Manufacturer of the MINI 7

Marking on approved tires 174

Marking, run-flat tires 175

Master key, refer to Remote control 34

Maximum cooling 130

Maximum speed, display 77

Maximum speed, winter tires 174

Measure, units of 82

Medical kit 202

Menu in instrument cluster 78

Menus, refer to onboard mon‐ itor operating concept 20

Microfilter 129, 132

MID - program, driving dy‐ namics 108

MINI Connected, refer to Integrated Owner's Manual

MINI maintenance sys‐ tem 186

MINIMALISM Analyser 160

MINIMALISM info 159

Minimum tread, tires 172

Mirrors 52

Mobile communication devi‐ ces in the vehicle 149

Mobility System 175

Mode, GREEN Mode 156

Modifications, technical, refer to Safety 7

Moisture in headlamp 189 Seite 224REFERENCEEverything from A to Z224

Online Edition for Part no. 01 40 2 927 905 - II/14