engine MINI COOPER 2014 Workshop Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2014, Model line: COOPER, Model: MINI COOPER 2014Pages: 230, PDF Size: 11.58 MB

Page 166 of 230

FuelVehicle equipmentAll standard, country-specific and optional

equipment that is offered in the model series is

described in this chapter. Therefore, equipment

is also described that is not available in a vehi‐

cle, e. g., because of the selected optional

equipment or country variant. This also applies

for safety-related functions and systems.

Fuel recommendation Note General fuel quality

Even fuels that conform to the specifica‐

tions can be of low quality. This may cause en‐

gine problems, for instance poor engine start‐

ing behavior, poor handling and/or

performance. Switch gas stations or use a

brand name fuel with a higher octane rating. ◀

Gasoline For the best fuel economy, the gasoline should

be sulfur-free or very low in sulfur content.

Fuels that are marked on the gas pump as con‐

taining metal must not be used.

Refuel only with unleaded gasoline with‐

out metallic additives.

Do not refuel with any leaded gasoline or gaso‐

line with metallic additives, e. g. manganese or

iron, or permanent damage to the catalytic

converter and other components. ◀

Fuels with a maximum ethanol content of

25 %, i. e. E10 or E25, may be used for refuel‐

ing.

Ethanol should satisfy the following quality

standards:

US: ASTM 4806–xxCAN: CGSB-3.511–xx

xx: comply with the current standard in each

case.

Do not use a fuel with a higher percent‐

age of ethanol

Do not use a fuel with a higher ethanol per‐

centage than recommended or one with other

types of alcohol, i.e. no Flex Fuel, otherwise this

could damage the engine and fuel supply sys‐

tem. ◀

Recommended fuel grade

MINI recommends AKI 91.

Minimum fuel grade MINI recommends AKI 89.

Minimum fuel grade

Do not use any gasoline below the mini‐

mum fuel grade as this may impair engine per‐

formance. ◀

If you use gasoline with this minimum AKI Rat‐

ing, the engine may produce knocking sounds

when starting at high outside temperatures.

This has no effect on the engine life.

Fuel quality

The use of poor-quality fuels may result in

harmful engine deposits or damage. Addition‐

ally, problems relating to drivability, starting

and stalling, especially under certain environ‐

mental conditions such as high ambient tem‐

perature and high altitude, may occur.

If drivability problems are encountered, we rec‐

ommend switching to a high quality gasoline

brand and a higher octane grade — AKI num‐

ber — for a few tank fills. To avoid harmful en‐

gine deposits, it is highly recommended to pur‐

chase gasoline from BP or Top Tier retailers.Seite 166MOBILITYFuel166

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 177 of 230

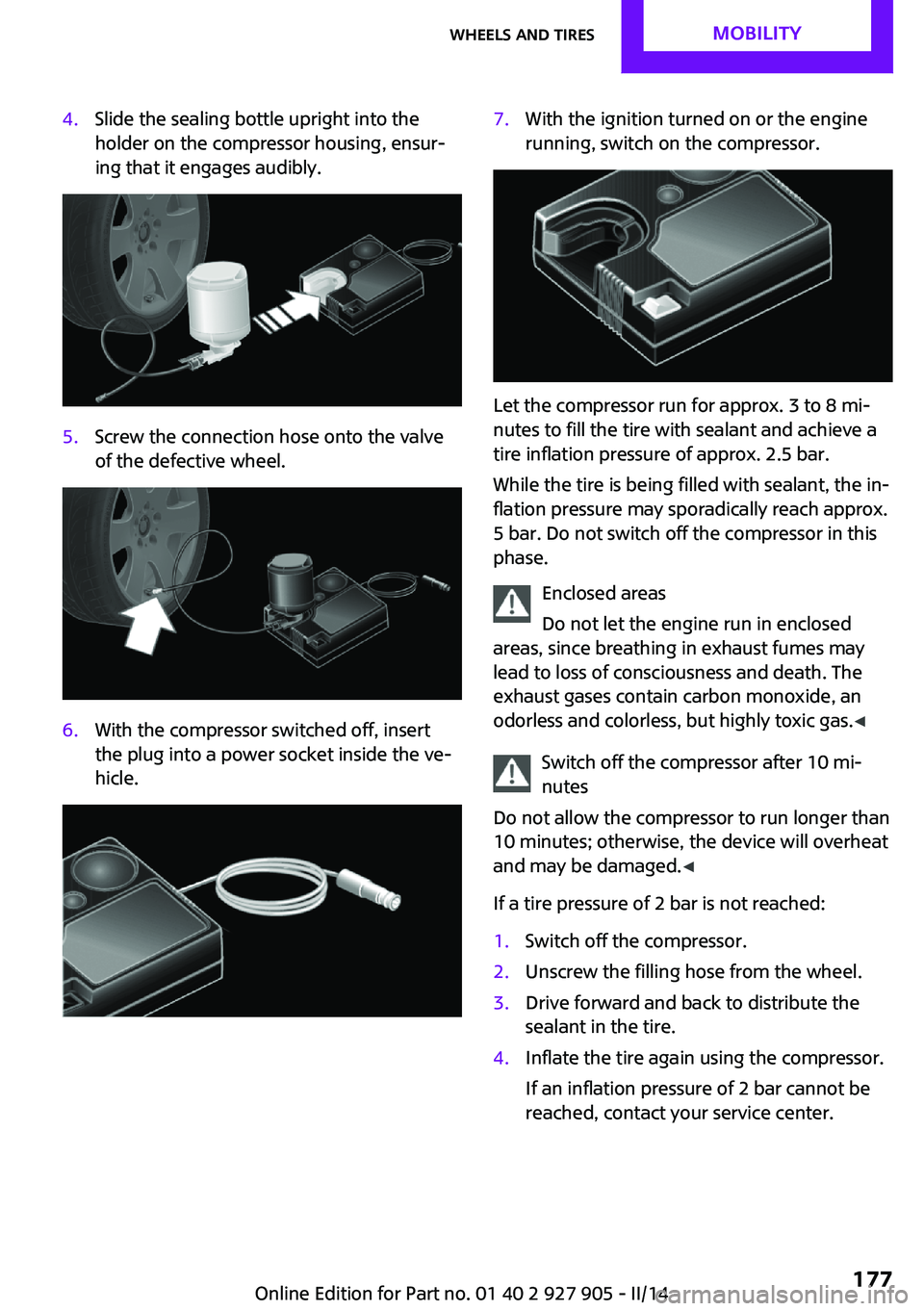

4.Slide the sealing bottle upright into the

holder on the compressor housing, ensur‐

ing that it engages audibly.5.Screw the connection hose onto the valve

of the defective wheel.6.With the compressor switched off, insert

the plug into a power socket inside the ve‐

hicle.7.With the ignition turned on or the engine

running, switch on the compressor.

Let the compressor run for approx. 3 to 8 mi‐

nutes to fill the tire with sealant and achieve a

tire inflation pressure of approx. 2.5 bar.

While the tire is being filled with sealant, the in‐

flation pressure may sporadically reach approx.

5 bar. Do not switch off the compressor in this

phase.

Enclosed areas

Do not let the engine run in enclosed

areas, since breathing in exhaust fumes may

lead to loss of consciousness and death. The

exhaust gases contain carbon monoxide, an

odorless and colorless, but highly toxic gas. ◀

Switch off the compressor after 10 mi‐

nutes

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged. ◀

If a tire pressure of 2 bar is not reached:

1.Switch off the compressor.2.Unscrew the filling hose from the wheel.3.Drive forward and back to distribute the

sealant in the tire.4.Inflate the tire again using the compressor.

If an inflation pressure of 2 bar cannot be

reached, contact your service center.Seite 177Wheels and tiresMOBILITY177

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 178 of 230

Stowing the Mobility System1.Disconnect the connection hose of the seal‐

ant bottle from the wheel.2.Disconnect the connection hose from the

sealant bottle.3.Wrap the empty sealant bottle and connec‐

tion hose in suitable material to avoid dirty‐

ing the cargo area.4.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Immediately drive to ensure that the sealant is

evenly distributed in the tire.

Do not exceed a speed of .

Do not drop below if possible.

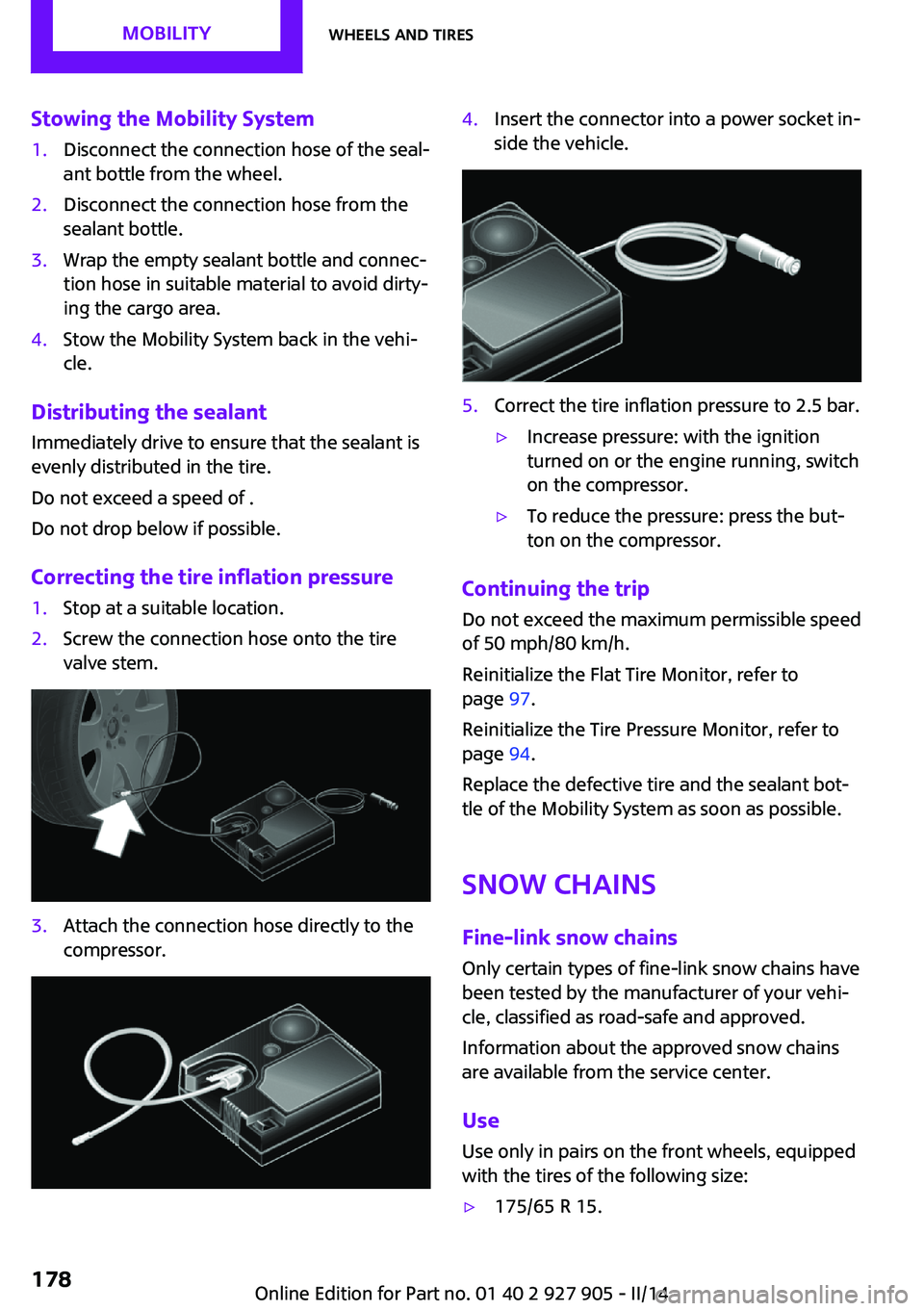

Correcting the tire inflation pressure

1.Stop at a suitable location.2.Screw the connection hose onto the tire

valve stem.3.Attach the connection hose directly to the

compressor.4.Insert the connector into a power socket in‐

side the vehicle.5.Correct the tire inflation pressure to 2.5 bar.▷Increase pressure: with the ignition

turned on or the engine running, switch

on the compressor.▷To reduce the pressure: press the but‐

ton on the compressor.

Continuing the trip

Do not exceed the maximum permissible speed

of 50 mph/80 km/h.

Reinitialize the Flat Tire Monitor, refer to

page 97.

Reinitialize the Tire Pressure Monitor, refer to

page 94.

Replace the defective tire and the sealant bot‐

tle of the Mobility System as soon as possible.

Snow chains

Fine-link snow chains Only certain types of fine-link snow chains have

been tested by the manufacturer of your vehi‐

cle, classified as road-safe and approved.

Information about the approved snow chains

are available from the service center.

Use

Use only in pairs on the front wheels, equipped

with the tires of the following size:

▷175/65 R 15.Seite 178MOBILITYWheels and tires178

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 180 of 230

Engine compartmentVehicle equipment

All standard, country-specific and optional

equipment that is offered in the model series is

described in this chapter. Therefore, equipmentis also described that is not available in a vehi‐

cle, e. g., because of the selected optional

equipment or country variant. This also applies

for safety-related functions and systems.

Important features in the engine compartment

1Washer fluid reservoir2Vehicle identification number3Oil filler neck4Jump-starting, positive terminal5Jump-starting, negative terminal6Coolant reservoirHood

Hints Working in the engine compartment

Never attempt to perform any service or

repair operations on your vehicle without the

necessary professional technical training.If you are unfamiliar with the statutory guide‐

lines, have any work on the vehicle performed

only by a service center.

If this work is not carried out properly, there is

the danger of subsequent damage and related

safety hazards. ◀Seite 180MOBILITYEngine compartment180

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 181 of 230

Never reach into the engine compart‐

ment

Never reach into the intermediate spaces or

gaps in the engine compartment. Otherwise,

there is risk of injury, e.g., from rotating or hot

parts. ◀

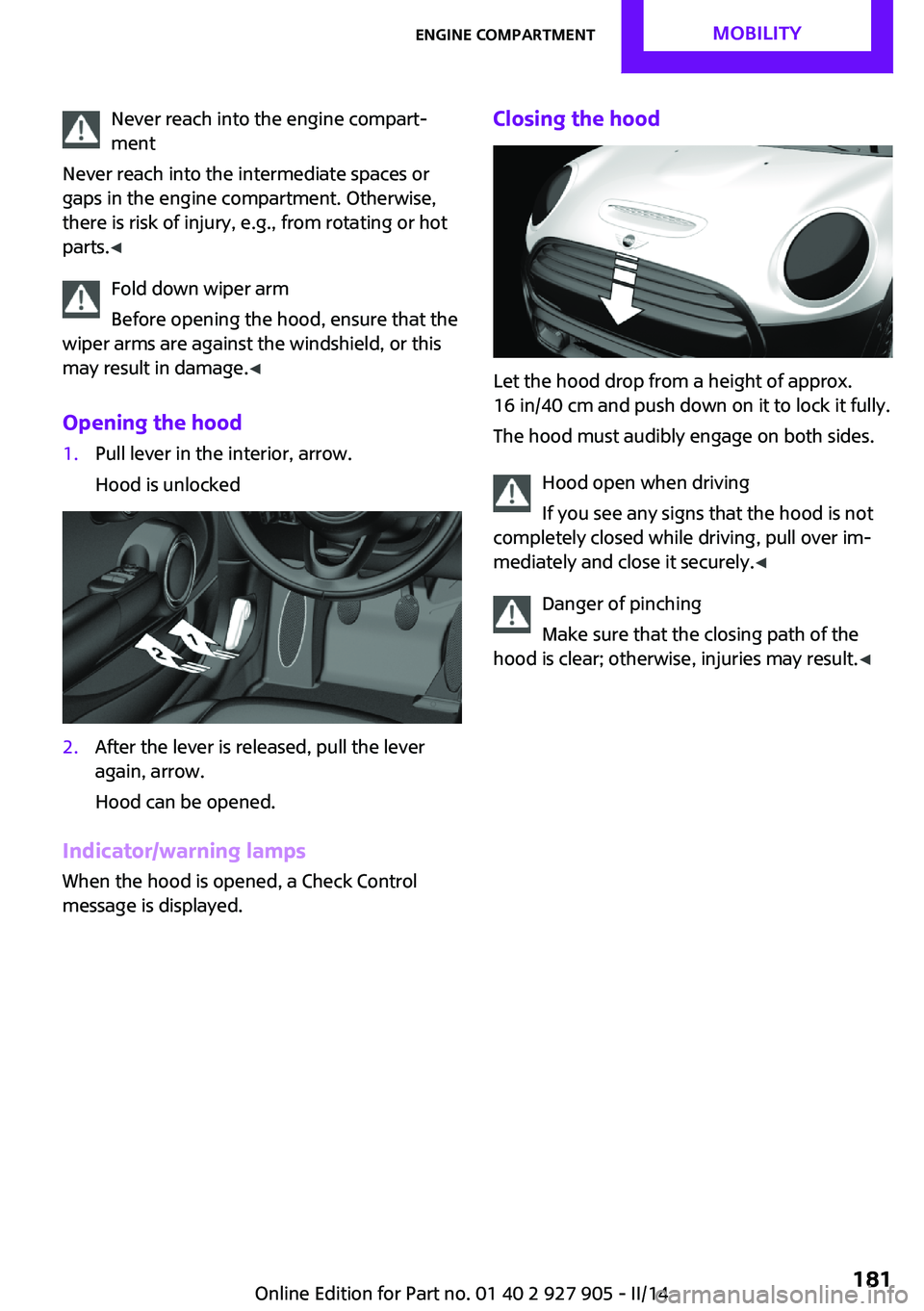

Fold down wiper arm

Before opening the hood, ensure that the

wiper arms are against the windshield, or this

may result in damage. ◀

Opening the hood1.Pull lever in the interior, arrow.

Hood is unlocked2.After the lever is released, pull the lever

again, arrow.

Hood can be opened.

Indicator/warning lamps When the hood is opened, a Check Control

message is displayed.

Closing the hood

Let the hood drop from a height of approx.

16 in/40 cm and push down on it to lock it fully.

The hood must audibly engage on both sides.

Hood open when driving

If you see any signs that the hood is not

completely closed while driving, pull over im‐

mediately and close it securely. ◀

Danger of pinching

Make sure that the closing path of the

hood is clear; otherwise, injuries may result. ◀

Seite 181Engine compartmentMOBILITY181

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 182 of 230

Engine oilVehicle equipment

All standard, country-specific and optional

equipment that is offered in the model series is

described in this chapter. Therefore, equipment

is also described that is not available in a vehi‐

cle, e. g., because of the selected optional

equipment or country variant. This also applies

for safety-related functions and systems.

General information

Engine oil consumption depends on driving

style and driving conditions, e.g., if your driving

style is very sporty engine oil consumption will

be considerably greater.

Therefore, regularly check the engine oil level

after refueling.

The vehicle is equipped with electronic oil

measurement.

The electronic oil measurement has two meas‐

uring principles.▷Status display▷Detailed measurement

Checking the oil level

electronically

Status display

The concept

The oil level is monitored electronically during

driving and shown on the Control Display.

If the oil level reaches the minimum level, a

check control message is displayed.

Requirements

A current measured value is available after ap‐

prox. 30 minutes of driving. During a shorter

trip, the status of the last, sufficiently long trip is

displayed.

With frequent short-distance trips, perform a

detailed measurement.

Displaying the oil level1."Vehicle Info"2."Vehicle status"3. "Engine oil level"

Oil level display messages Different messages appear on the display de‐

pending on the oil level. Pay attention to these

messages.

If the engine oil level is too low, within the next

125 miles/200 km add oil, refer to page 183.

Engine oil level too low

Add oil immediately; otherwise, an insuf‐

ficient amount of engine oil could result in en‐

gine damage. ◀

Take care not to add too much engine oil. Too much engine oil

Have the vehicle checked immediately;

otherwise, surplus oil can lead to engine dam‐

age. ◀

Detailed measurement

The concept

In the detailed measurement the oil level is

checked and displayed via a scale.

If the oil level reaches the minimum level or an

overfilling is detected, a check control message

is displayed.

Seite 182MOBILITYEngine oil182

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 183 of 230

During the measurement, the idle speed is in‐

creased somewhat.

Requirements▷Vehicle is on level road.▷Manual transmission: shift lever in neutral

position, clutch and accelerator pedals not

depressed.▷Automatic transmission: selector lever in

transmission position N or P and accelera‐

tor pedal not depressed.▷Engine is running and is at operating tem‐

perature.

Performing a detailed measurement

In order to perform a detailed measurement of

the engine oil level:

1."Vehicle Info"2."Vehicle status"3. "Measure engine oil level"4."Start measurement"

The oil level is checked and displayed via a

scale.

Duration: approx. 1 minute.

Adding engine oilGeneral information

Switch off the ignition and safely park the vehi‐

cle before engine oil is added.

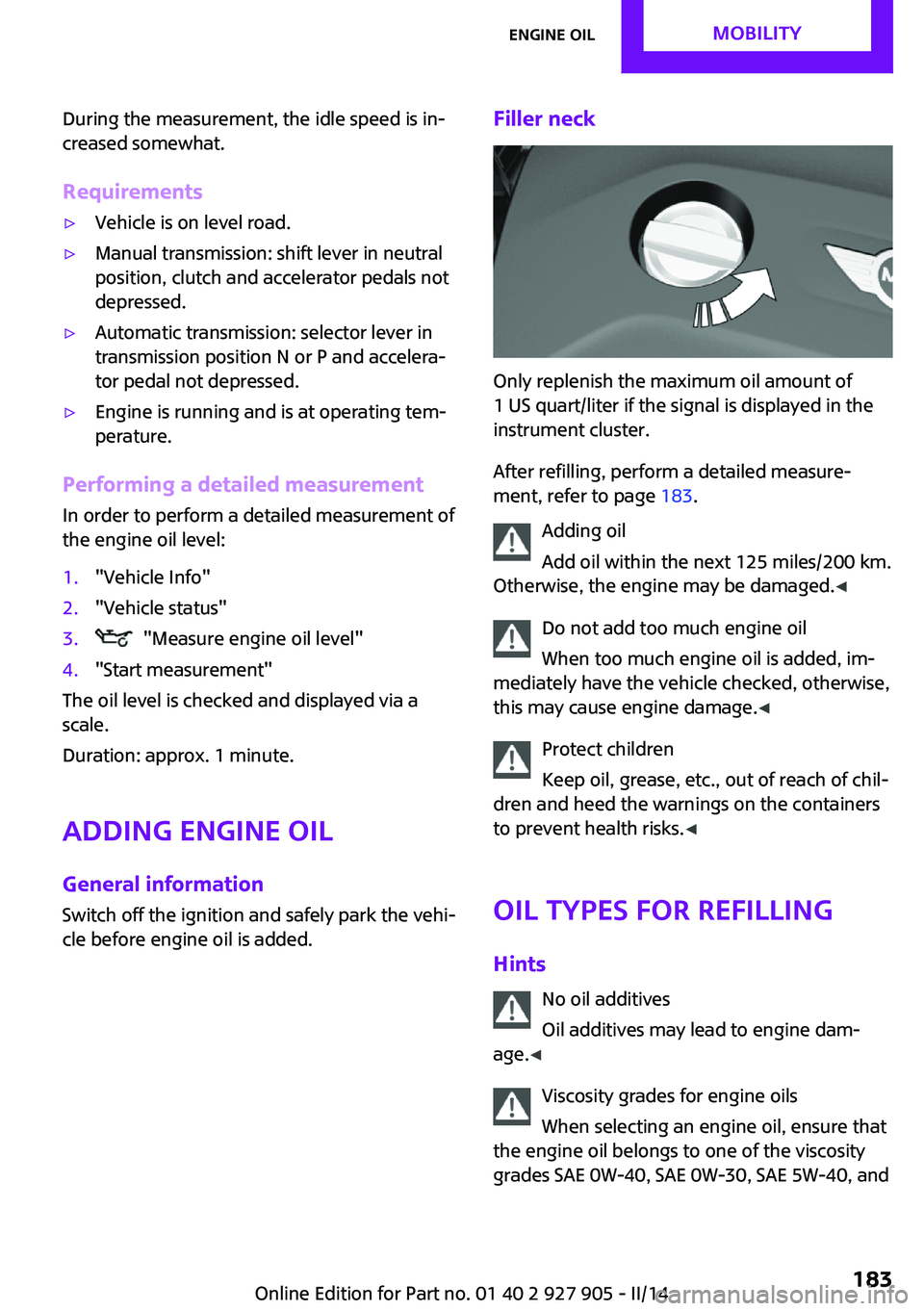

Filler neck

Only replenish the maximum oil amount of

1 US quart/liter if the signal is displayed in the

instrument cluster.

After refilling, perform a detailed measure‐

ment, refer to page 183.

Adding oil

Add oil within the next 125 miles/200 km.

Otherwise, the engine may be damaged. ◀

Do not add too much engine oil

When too much engine oil is added, im‐

mediately have the vehicle checked, otherwise,

this may cause engine damage. ◀

Protect children

Keep oil, grease, etc., out of reach of chil‐

dren and heed the warnings on the containers

to prevent health risks. ◀

Oil types for refilling

Hints No oil additives

Oil additives may lead to engine dam‐

age. ◀

Viscosity grades for engine oils

When selecting an engine oil, ensure that

the engine oil belongs to one of the viscosity

grades SAE 0W-40, SAE 0W-30, SAE 5W-40, and

Seite 183Engine oilMOBILITY183

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 184 of 230

SAE 5W-30 or malfunctions or engine damage

may occur. ◀

The engine oil quality is critical for the life of the

engine.

Approved oil types

You can add oils with the following specifica‐

tions:Gasoline engineBMW Longlife-01BMW Longlife-01 FE

Additional information about the approved

types of oils can be requested from the service

center.

Alternative oil types

If the approved engine oils are not available, up

to 1 US quart/liter of an oil with the following

specification can be added:

Gasoline engineAPI SM or superior grade specification

Engine oil change:

The vehicle manufacturer recommends that

you let the service center change the motor oil.

Seite 184MOBILITYEngine oil184

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 185 of 230

CoolantVehicle equipment

All standard, country-specific and optional

equipment that is offered in the model series is

described in this chapter. Therefore, equipment

is also described that is not available in a vehi‐

cle, e. g., because of the selected optional

equipment or country variant. This also applies

for safety-related functions and systems.

General information Danger of burns from hot engine

Do not open the cooling system while the

engine is hot; otherwise, escaping coolant may

cause burns. ◀

Suitable additives

Only use suitable additives; otherwise,

engine damage may occur. The additives are

harmful to your health. ◀

Coolant consists of water and additives.

Not all commercially available additives are

suitable for your vehicle. Ask your service cen‐

ter for suitable additives.

Coolant levelChecking

There are yellow Min and Max marks in the

coolant reservoir.1.Let the engine cool.2.Turn the coolant reservoir lid counterclock‐

wise to unscrew and open it.3.The coolant level is correct when it is be‐

tween these two marks.

Adding

1.Let the engine cool.2.Turn the coolant reservoir lid counterclock‐

wise to unscrew and open it.3.If the coolant is low, slowly add coolant up

to the specified level; do not overfill.4.Turn the cap.5.Have the cause of the coolant loss elimi‐

nated as soon as possible.

Disposal

Comply with the relevant environmen‐

tal protection regulations when dispos‐

ing of coolant and coolant additives.

Seite 185CoolantMOBILITY185

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 186 of 230

MaintenanceVehicle equipment

All standard, country-specific and optional

equipment that is offered in the model series is

described in this chapter. Therefore, equipment

is also described that is not available in a vehi‐

cle, e. g., because of the selected optional

equipment or country variant. This also applies

for safety-related functions and systems.

MINI maintenance system

The maintenance system indicates required

maintenance measures, and thereby provides

support in maintaining road safety and the op‐

erational reliability of the vehicle.

Condition Based Service

CBS

Sensors and special algorithms take into ac‐

count the driving conditions of your vehicle.

Based on this, Condition Based Service deter‐

mines the maintenance requirements.

The system makes it possible to adapt the

amount of maintenance you need to your user

profile.

Detailed information on service requirements,

refer to page 76, can be displayed on the Con‐

trol Display.

Service data in the remote control

Information on the required maintenance is

continuously stored in the remote control. Your

service center will read out this data and sug‐

gest the right array of service procedures for

your vehicle.

Therefore, hand your service specialist the re‐

mote control that you used most recently.Storage periods

Storage periods during which the vehicle bat‐

tery was disconnected are not taken into ac‐

count.

If this occurs, have a service center update the

time-dependent maintenance procedures, such

as checking brake fluid and, if necessary,

changing the engine oil and the microfilter/acti‐

vated-charcoal filter.

Service and Warranty In‐

formation Booklet for

US models and Warranty

and Service Guide Book‐

let for Canadian models

Please consult your Service and Warranty Infor‐

mation Booklet for US models and Warranty

and Service Guide Booklet for Canadian models

for additional information on service require‐

ments.

Maintenance and repair should be performed

by your service center. Make sure to have regu‐

lar maintenance procedures recorded in the ve‐

hicle's Service and Warranty Information Book‐

let for US models, and in the Warranty and

Service Guide Booklet for Canadian models.

These entries are proof of regular maintenance.

Socket for OBD Onboard

Diagnosis

Note Socket for Onboard Diagnosis

The socket for onboard diagnostics may

only be used by the service center or a work‐ shop that operates in accordance with theSeite 186MOBILITYMaintenance186

Online Edition for Part no. 01 40 2 927 905 - II/14