wheel MINI COOPER 2014 Workshop Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2014, Model line: COOPER, Model: MINI COOPER 2014Pages: 230, PDF Size: 11.58 MB

Page 174 of 230

Recommended tire brands

For each tire size, the manufacturer of your ve‐

hicle recommends certain tire brands. These

can be identified by a star on the tire sidewall.

With proper use, these tires meet the highest

standards for safety and handling.

New tires

Due to technical factors associated with their

manufacture, tires do not achieve their full trac‐

tion potential until after an initial breaking-in

period.

Drive conservatively for the first

200 miles/300 km.

Retreaded tires The manufacturer of your vehicle does not rec‐

ommend the use of retreaded tires.

Retreaded tires

Possibly substantial variations in the de‐

sign and age of the tire casing structures can

limit service life and have a negative impact on

road safety. ◀

Winter tires

Winter tires are recommended for operating on

winter roads.

Although so-called all-season M+S tires do pro‐

vide better winter traction than summer tires, they do not provide the same level of perform‐

ance as winter tires.

Maximum speed of winter tires

If the maximum speed of the vehicle is higher

than the permissible speed for the winter tires,

then display a corresponding sign in the field of

vision. You can obtain this sign from the tire

specialist or from your service center.

Maximum speed for winter tires

Do not exceed the maximum speed for

the respective winter tires; otherwise, tire dam‐

age and accidents can occur. ◀

Run-flat tires If you are already using run-flat tires, for your

own safety you should replace them only with

the same kind. No spare tire is available in the

case of a flat tire. Your service center will be

glad to advise you.

Rotating wheels between axles

Different wear patterns can occur on the front

and rear axles depending on individual driving

conditions.

The tires can be rotated between the axles to

achieve even wear. Your service center will be

glad to advise you.

After rotating, check the tire pressure and cor‐

rect if necessary.

Storage

Store wheels and tires in a cool, dry place with

as little exposure to light as possible.

Always protect tires against all contact with oil,

grease and fuels.

Do not exceed the maximum tire inflation pres‐

sure indicated on the side wall of the tire.Seite 174MOBILITYWheels and tires174

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 175 of 230

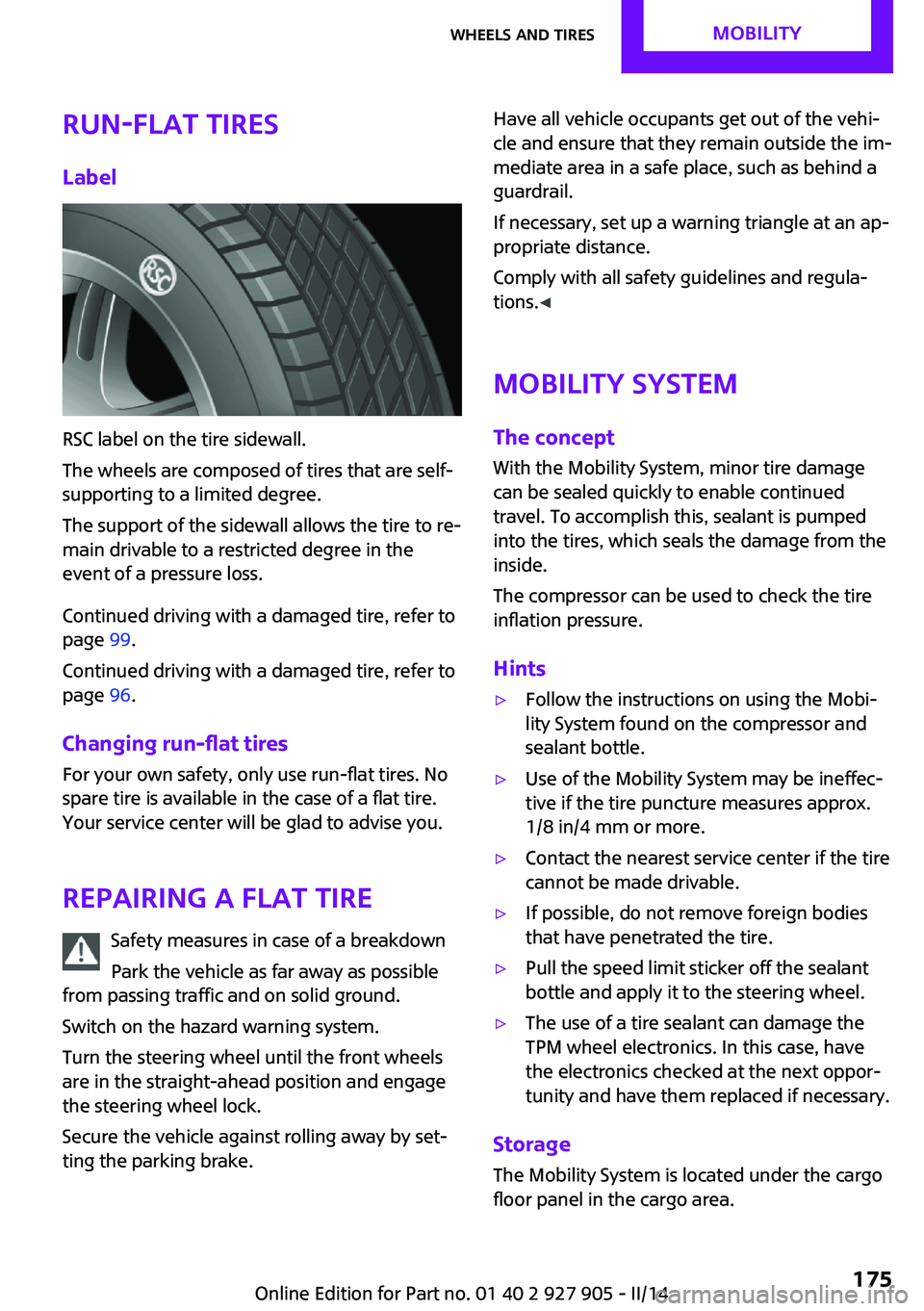

Run-flat tiresLabel

RSC label on the tire sidewall.

The wheels are composed of tires that are self-

supporting to a limited degree.

The support of the sidewall allows the tire to re‐

main drivable to a restricted degree in the

event of a pressure loss.

Continued driving with a damaged tire, refer to

page 99.

Continued driving with a damaged tire, refer to

page 96.

Changing run-flat tires

For your own safety, only use run-flat tires. No

spare tire is available in the case of a flat tire.

Your service center will be glad to advise you.

Repairing a flat tire Safety measures in case of a breakdown

Park the vehicle as far away as possible

from passing traffic and on solid ground.

Switch on the hazard warning system.

Turn the steering wheel until the front wheels

are in the straight-ahead position and engage

the steering wheel lock.

Secure the vehicle against rolling away by set‐

ting the parking brake.

Have all vehicle occupants get out of the vehi‐

cle and ensure that they remain outside the im‐

mediate area in a safe place, such as behind a

guardrail.

If necessary, set up a warning triangle at an ap‐

propriate distance.

Comply with all safety guidelines and regula‐

tions. ◀

Mobility System

The concept

With the Mobility System, minor tire damage

can be sealed quickly to enable continued travel. To accomplish this, sealant is pumped

into the tires, which seals the damage from the

inside.

The compressor can be used to check the tire

inflation pressure.

Hints▷Follow the instructions on using the Mobi‐

lity System found on the compressor and

sealant bottle.▷Use of the Mobility System may be ineffec‐

tive if the tire puncture measures approx.

1/8 in/4 mm or more.▷Contact the nearest service center if the tire

cannot be made drivable.▷If possible, do not remove foreign bodies

that have penetrated the tire.▷Pull the speed limit sticker off the sealant

bottle and apply it to the steering wheel.▷The use of a tire sealant can damage the

TPM wheel electronics. In this case, have

the electronics checked at the next oppor‐

tunity and have them replaced if necessary.

Storage

The Mobility System is located under the cargo

floor panel in the cargo area.

Seite 175Wheels and tiresMOBILITY175

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 176 of 230

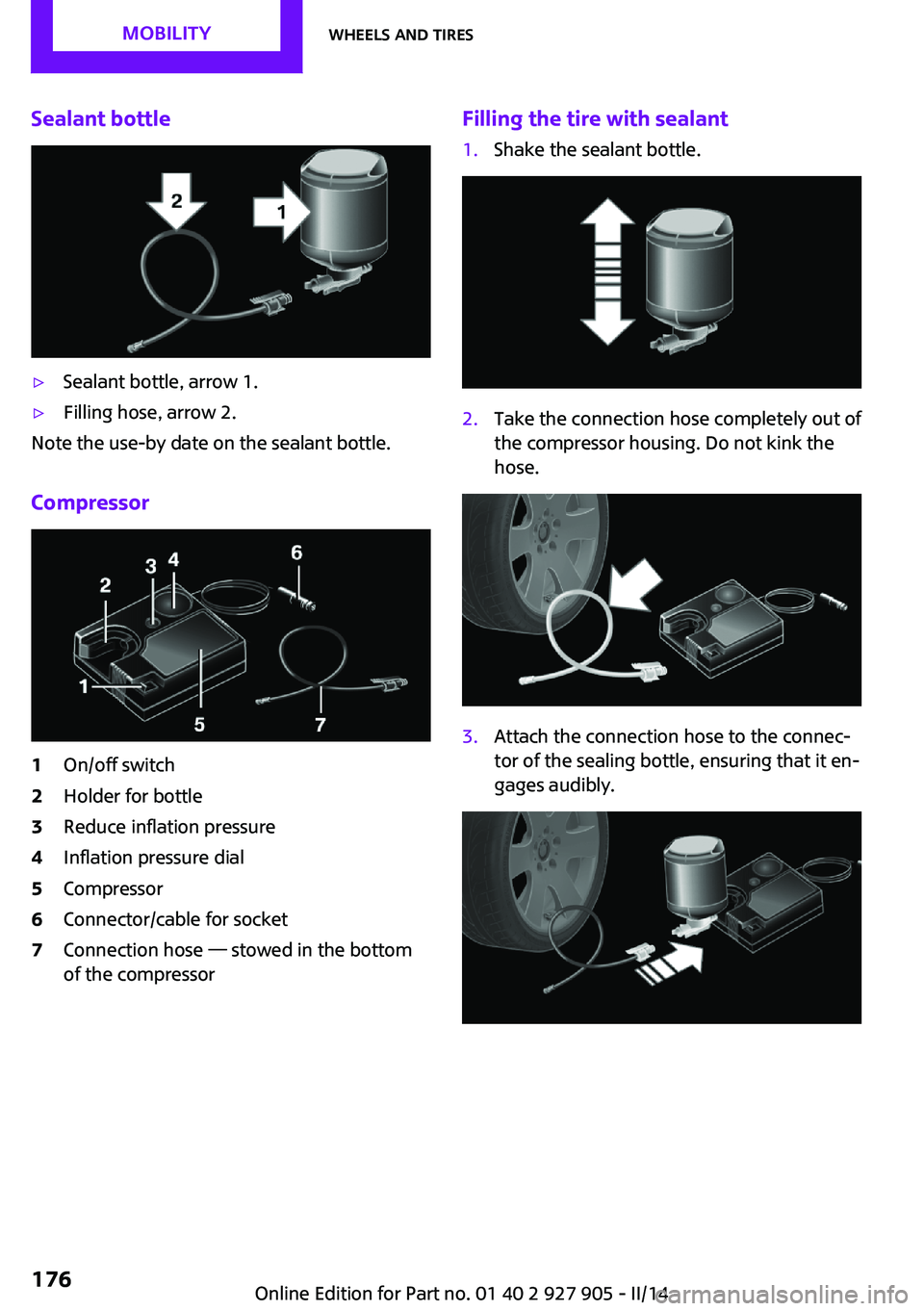

Sealant bottle▷Sealant bottle, arrow 1.▷Filling hose, arrow 2.

Note the use-by date on the sealant bottle.

Compressor

1On/off switch2Holder for bottle3Reduce inflation pressure4Inflation pressure dial5Compressor6Connector/cable for socket7Connection hose — stowed in the bottom

of the compressorFilling the tire with sealant1.Shake the sealant bottle.2.Take the connection hose completely out of

the compressor housing. Do not kink the

hose.3.Attach the connection hose to the connec‐

tor of the sealing bottle, ensuring that it en‐

gages audibly.Seite 176MOBILITYWheels and tires176

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 177 of 230

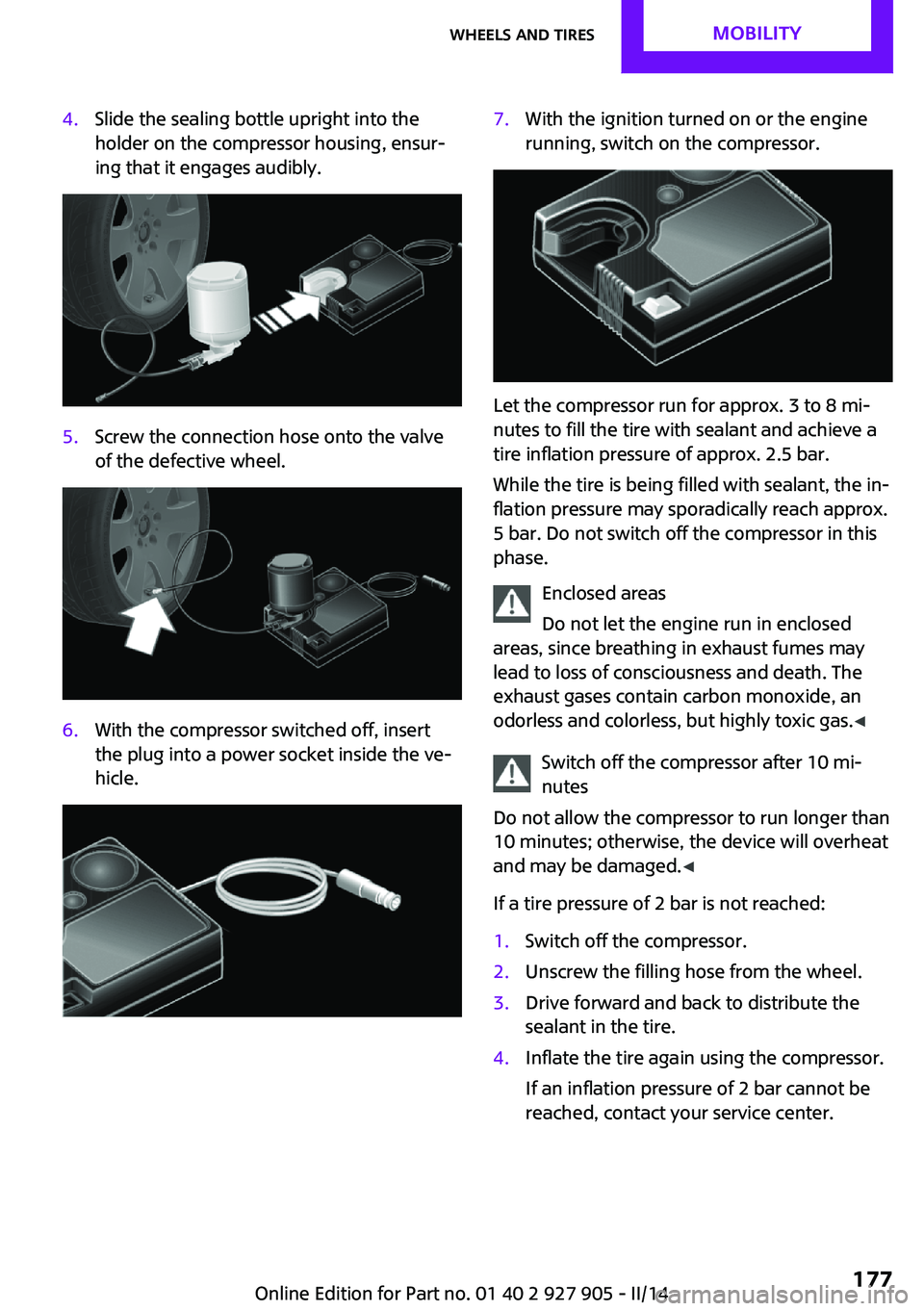

4.Slide the sealing bottle upright into the

holder on the compressor housing, ensur‐

ing that it engages audibly.5.Screw the connection hose onto the valve

of the defective wheel.6.With the compressor switched off, insert

the plug into a power socket inside the ve‐

hicle.7.With the ignition turned on or the engine

running, switch on the compressor.

Let the compressor run for approx. 3 to 8 mi‐

nutes to fill the tire with sealant and achieve a

tire inflation pressure of approx. 2.5 bar.

While the tire is being filled with sealant, the in‐

flation pressure may sporadically reach approx.

5 bar. Do not switch off the compressor in this

phase.

Enclosed areas

Do not let the engine run in enclosed

areas, since breathing in exhaust fumes may

lead to loss of consciousness and death. The

exhaust gases contain carbon monoxide, an

odorless and colorless, but highly toxic gas. ◀

Switch off the compressor after 10 mi‐

nutes

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged. ◀

If a tire pressure of 2 bar is not reached:

1.Switch off the compressor.2.Unscrew the filling hose from the wheel.3.Drive forward and back to distribute the

sealant in the tire.4.Inflate the tire again using the compressor.

If an inflation pressure of 2 bar cannot be

reached, contact your service center.Seite 177Wheels and tiresMOBILITY177

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 178 of 230

Stowing the Mobility System1.Disconnect the connection hose of the seal‐

ant bottle from the wheel.2.Disconnect the connection hose from the

sealant bottle.3.Wrap the empty sealant bottle and connec‐

tion hose in suitable material to avoid dirty‐

ing the cargo area.4.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Immediately drive to ensure that the sealant is

evenly distributed in the tire.

Do not exceed a speed of .

Do not drop below if possible.

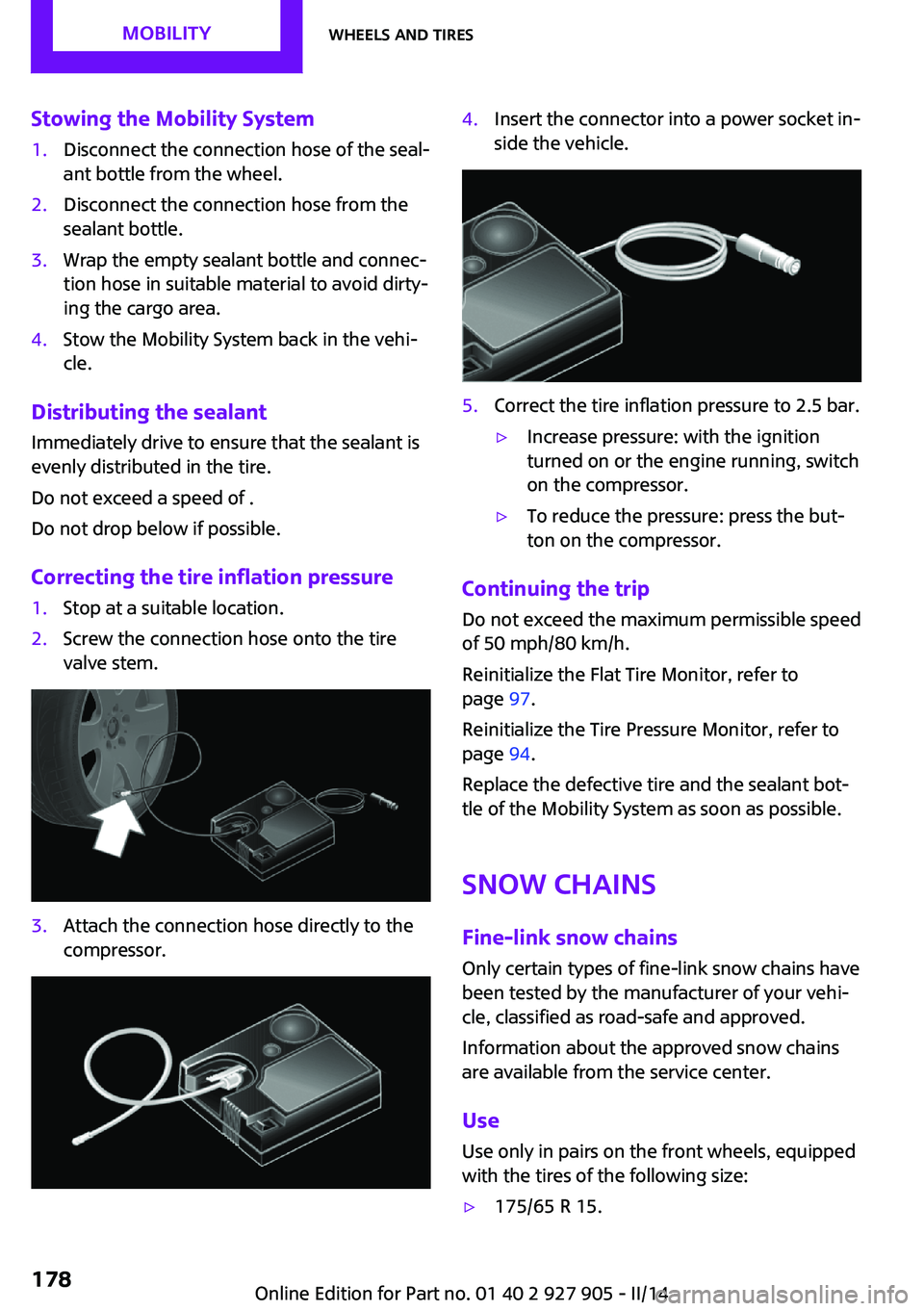

Correcting the tire inflation pressure

1.Stop at a suitable location.2.Screw the connection hose onto the tire

valve stem.3.Attach the connection hose directly to the

compressor.4.Insert the connector into a power socket in‐

side the vehicle.5.Correct the tire inflation pressure to 2.5 bar.▷Increase pressure: with the ignition

turned on or the engine running, switch

on the compressor.▷To reduce the pressure: press the but‐

ton on the compressor.

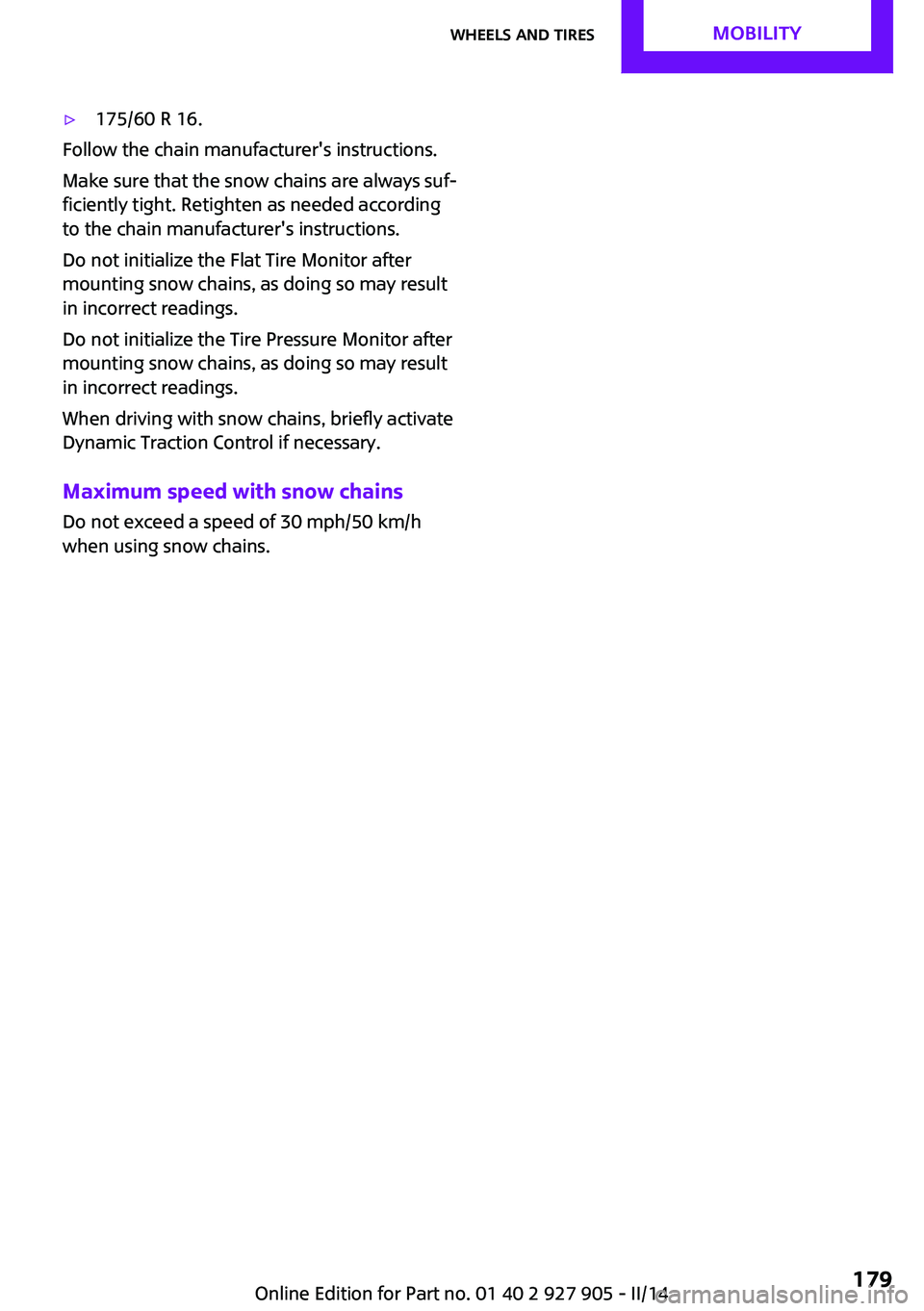

Continuing the trip

Do not exceed the maximum permissible speed

of 50 mph/80 km/h.

Reinitialize the Flat Tire Monitor, refer to

page 97.

Reinitialize the Tire Pressure Monitor, refer to

page 94.

Replace the defective tire and the sealant bot‐

tle of the Mobility System as soon as possible.

Snow chains

Fine-link snow chains Only certain types of fine-link snow chains have

been tested by the manufacturer of your vehi‐

cle, classified as road-safe and approved.

Information about the approved snow chains

are available from the service center.

Use

Use only in pairs on the front wheels, equipped

with the tires of the following size:

▷175/65 R 15.Seite 178MOBILITYWheels and tires178

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 179 of 230

▷175/60 R 16.

Follow the chain manufacturer's instructions.

Make sure that the snow chains are always suf‐

ficiently tight. Retighten as needed according

to the chain manufacturer's instructions.

Do not initialize the Flat Tire Monitor after

mounting snow chains, as doing so may result

in incorrect readings.

Do not initialize the Tire Pressure Monitor after

mounting snow chains, as doing so may result

in incorrect readings.

When driving with snow chains, briefly activate

Dynamic Traction Control if necessary.

Maximum speed with snow chains Do not exceed a speed of 30 mph/50 km/h

when using snow chains.

Seite 179Wheels and tiresMOBILITY179

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 191 of 230

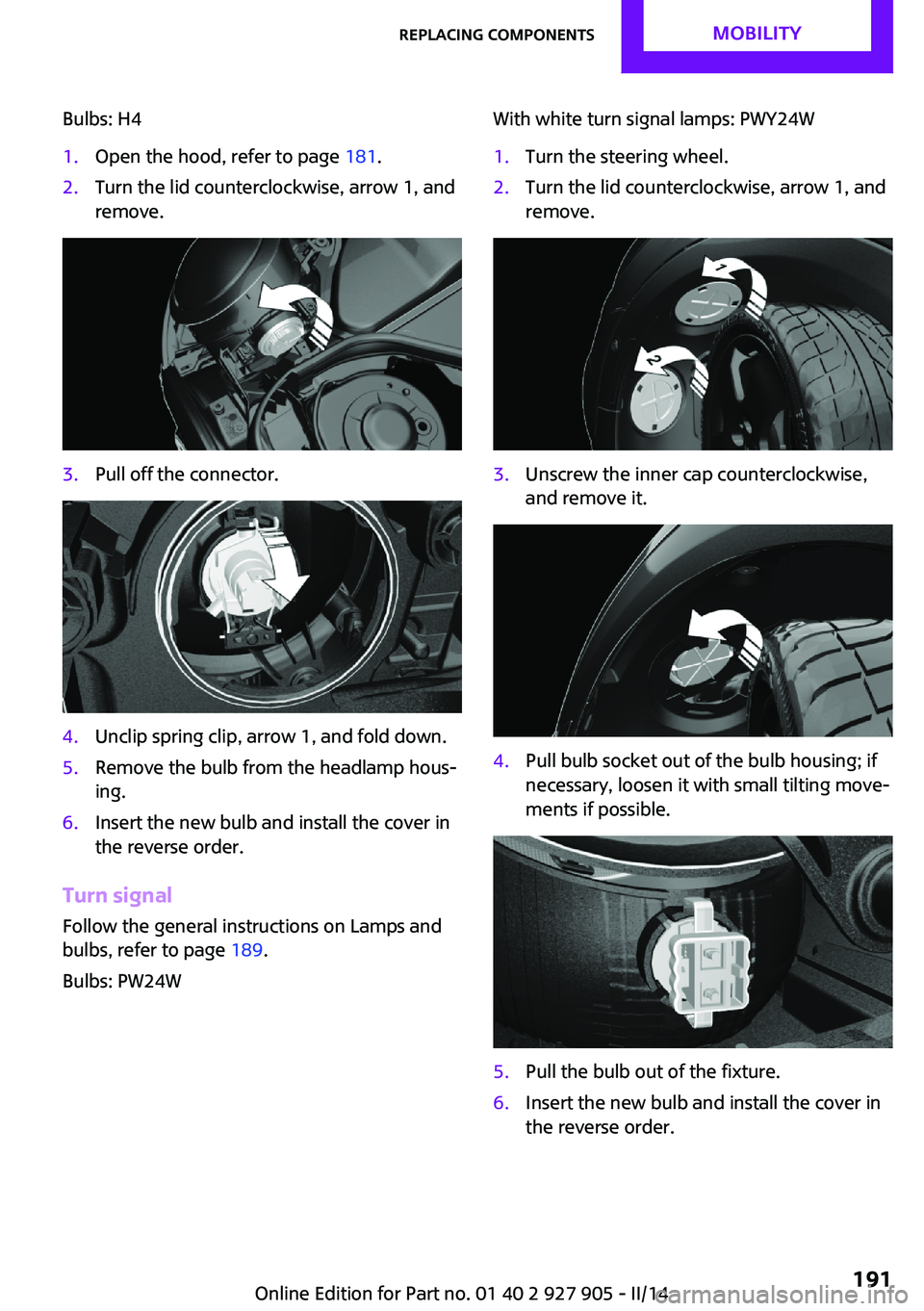

Bulbs: H41.Open the hood, refer to page 181.2.Turn the lid counterclockwise, arrow 1, and

remove.3.Pull off the connector.4.Unclip spring clip, arrow 1, and fold down.5.Remove the bulb from the headlamp hous‐

ing.6.Insert the new bulb and install the cover in

the reverse order.

Turn signal

Follow the general instructions on Lamps and

bulbs, refer to page 189.

Bulbs: PW24W

With white turn signal lamps: PWY24W1.Turn the steering wheel.2.Turn the lid counterclockwise, arrow 1, and

remove.3.Unscrew the inner cap counterclockwise,

and remove it.4.Pull bulb socket out of the bulb housing; if

necessary, loosen it with small tilting move‐

ments if possible.5.Pull the bulb out of the fixture.6.Insert the new bulb and install the cover in

the reverse order.Seite 191Replacing componentsMOBILITY191

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 192 of 230

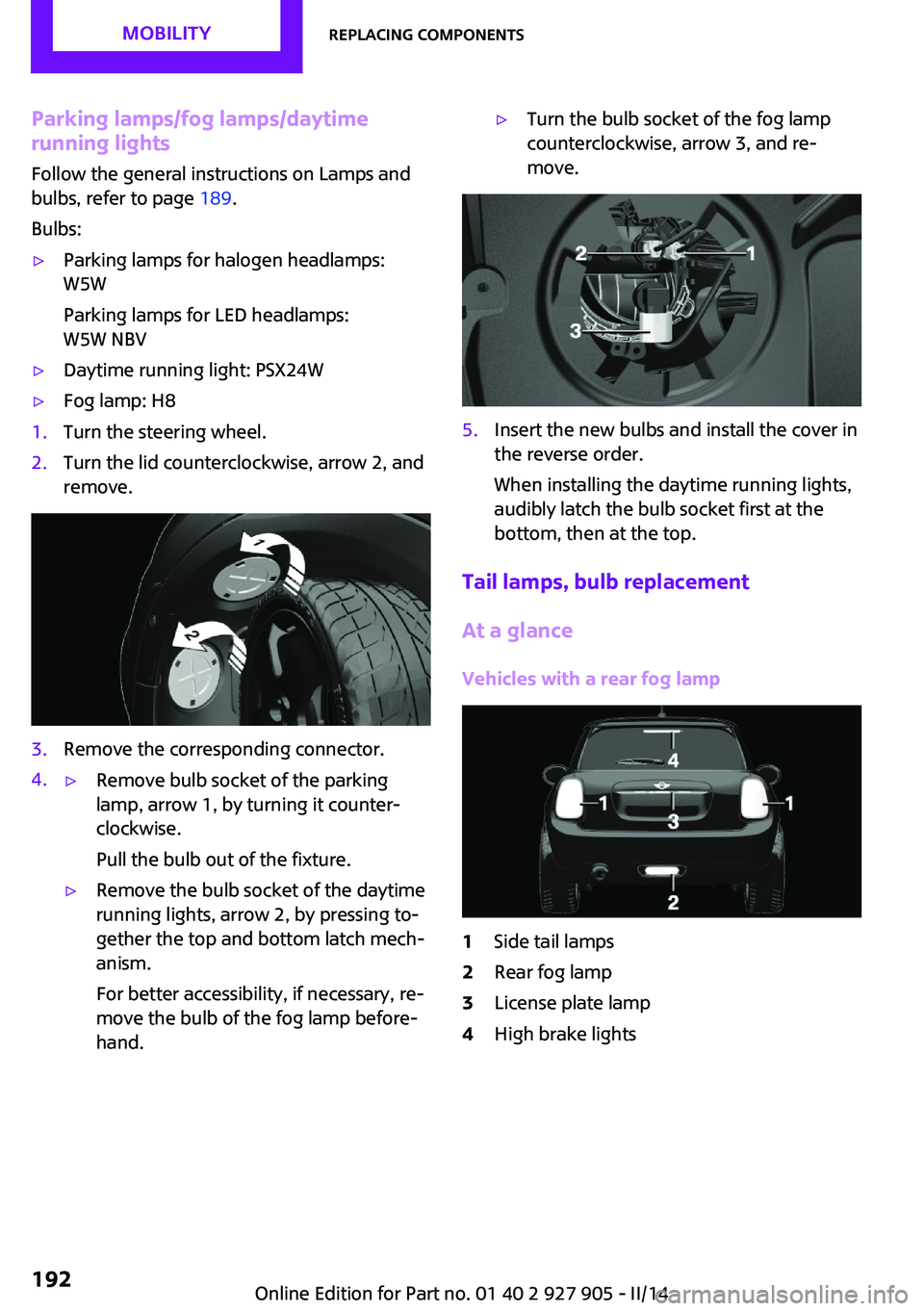

Parking lamps/fog lamps/daytime

running lights

Follow the general instructions on Lamps and

bulbs, refer to page 189.

Bulbs:▷Parking lamps for halogen headlamps:

W5W

Parking lamps for LED headlamps:

W5W NBV▷Daytime running light: PSX24W▷Fog lamp: H81.Turn the steering wheel.2.Turn the lid counterclockwise, arrow 2, and

remove.3.Remove the corresponding connector.4.▷Remove bulb socket of the parking

lamp, arrow 1, by turning it counter‐

clockwise.

Pull the bulb out of the fixture.▷Remove the bulb socket of the daytime

running lights, arrow 2, by pressing to‐

gether the top and bottom latch mech‐

anism.

For better accessibility, if necessary, re‐

move the bulb of the fog lamp before‐

hand.▷Turn the bulb socket of the fog lamp

counterclockwise, arrow 3, and re‐

move.5.Insert the new bulbs and install the cover in

the reverse order.

When installing the daytime running lights,

audibly latch the bulb socket first at the

bottom, then at the top.

Tail lamps, bulb replacement

At a glance

Vehicles with a rear fog lamp

1Side tail lamps2Rear fog lamp3License plate lamp4High brake lightsSeite 192MOBILITYReplacing components192

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 196 of 230

▷With white lens: WY5W diadem1.Push turn signal housing up and pull out at

the bottom.2.Turn the bulb socket counterclockwise and

remove.3.Replace the bulb.4.Proceed in the reverse order to insert the

new bulb and install the turn signal hous‐

ing.

First hook the turn signal housing to the

bottom, then at the top press it into the

latch.

Changing wheels

Hints

The vehicle equipment does not include a

spare tire.

When using run-flat tires or tire sealants, a tire

does not need to be changed immediately in

the event of pressure loss due to a flat tire.

The tools for changing wheels are available as

accessories from your service center.

Jacking points for the vehicle jack

The jacking points for the vehicle jack are lo‐

cated at the positions shown.

Compact wheel

Hints Safety measures in case of a breakdown

or a wheel change

▷Park the vehicle as far away as possible

from passing traffic and on solid ground.

Switch on the hazard warning system.▷Set the parking brake, and engage first gear

or transmission position P.▷Have all vehicle occupants get out of the

vehicle and ensure that they remain out‐

side the immediate area in a safe place,

such as behind a guardrail.▷If necessary, set up a warning triangle or

portable hazard warning lamp at an appro‐

priate distance. Comply with all safety

guidelines and regulations.▷Perform wheel change only on a flat, solid

and slip-resistant surface. On soft or slip‐

pery ground, e.g., snow, ice, tiles, etc., the

vehicle or vehicle jack can slip away to the

side.▷Do not place wood blocks or similar items

under the vehicle jack; otherwise, it cannot

reach its carrying capacity because of the

restricted height.▷If the vehicle is raised, do not lie under the

vehicle and do not start the engine; other‐

wise, a mortal hazard exists. ◀Seite 196MOBILITYReplacing components196

Online Edition for Part no. 01 40 2 927 905 - II/14

Page 197 of 230

Use the vehicle jack only for changing

wheels

Use the vehicle jack only for changing wheels

Do not attempt to use it to jack up a different

type of vehicle or loads of any kind; otherwise,

this could cause material damage and personal

injury. ◀

Removing compact wheel The compact wheel is housed in a well on the

underbody of the vehicle. The screw connec‐

tion of the compact wheel is located in the

cargo area under the floor mat, on the floor of

the storage compartment for the wheel chang‐

ing set.1.Loosen the nut from the wheel change set

using the wheel wrench.2.Remove the retaining plate.3.Screw the wheel wrench on the threads

and loosen the lock clockwise rotation.

Compact wheel releases and must be held

with the wheel wrench.4.Lower the compact wheel with the wheel

wrench.5.Unscrewing the wheel wrench6.Pull out the well with compact wheel under

the vehicle toward the rear.7.Remove the spacer and compact wheel of

the well.8.Stow the well and spacer in the vehicle.

Prepare wheel change

1.Follow the Safety instructions, refer to

page 196.2.With the wheel chock from the wheel

change set, also secure the vehicle against

rolling away at the front wheel of the oppo‐

site side.3.Loosen the wheel lug bolts a half turn.

Lug bolt lock, refer to page 198

Jacking up the vehicle

1.Place the vehicle jack at the jacking point

closest to the wheel such that the vehicle

jack foot is vertically beneath the vehicle

jacking point with the entire surface on the

ground.2.Insert the vehicle jack head in the rectan‐

gular recess of the jacking point for crank‐

ing it up.3.Crank it up until the wheel in question lifts

off of the ground.Seite 197Replacing componentsMOBILITY197

Online Edition for Part no. 01 40 2 927 905 - II/14