tires MINI COOPER 2016 Owner's Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2016, Model line: COOPER, Model: MINI COOPER 2016Pages: 251, PDF Size: 8.4 MB

Page 187 of 251

New tires

Tire traction is not optimal due to manufactur‐

ing circumstances when tires are brand-new;

they achieve their full traction potential after a

break-in time.

Drive conservatively for the first

200 miles/300 km.

Retreaded tires The manufacturer of your vehicle does not rec‐

ommend the use of retreaded tires.

WARNING

Retreated tires can have different tire

casing structures. With advanced age the serv‐

ice life can be limited. There is risk of an acci‐

dent. Do not use retreated tires. ◀

Winter tires

Winter tires are recommended for operating on

winter roads.

Although so-called all-season M+S tires provide

better winter traction than summer tires, they

do not provide the same level of performance

as winter tires.

Maximum speed of winter tiresIf the maximum speed of the vehicle is higher

than the permissible speed for the winter tires,

then a respective symbol is displayed in your

field of vision. The plate is available from a

dealer’s service center or another qualified

service center or repair shop.

With mounted winter tires, observe and adhere

to the permissible maximum speed.

Run-flat tires If you are already using run-flat tires, for your

own safety you should replace them only with

the same kind. No spare tire is available in the

case of a flat tire. A dealer’s service center or

another qualified service center or repair shop

will be glad to answer additional questions at

any time.Rotating wheels between axles

Different wear patterns can occur on the front

and rear axles depending on individual driving

conditions.

The tires can be rotated between the axles to

achieve even wear. A dealer’s service center or

another qualified service center or repair shop

will be glad to answer additional questions at

any time.

After rotating, check the tire pressure and cor‐

rect if needed.

Storage Store wheels and tires in a cool, dry place with

as little exposure to light as possible.

Always protect tires against all contact with oil,

grease and fuels.

Do not exceed the maximum tire inflation pres‐

sure indicated on the side wall of the tire.

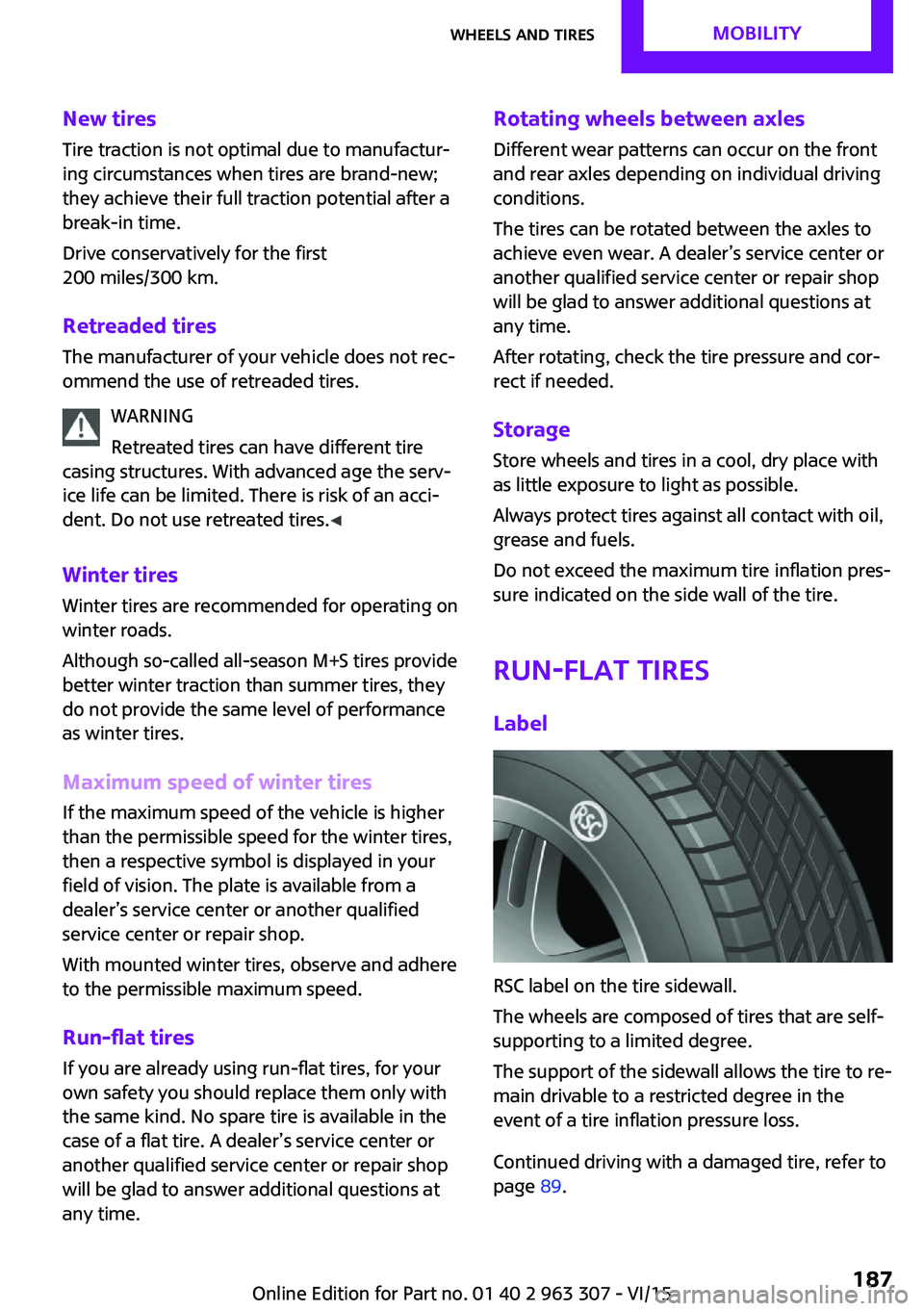

Run-flat tires

Label

RSC label on the tire sidewall.

The wheels are composed of tires that are self-

supporting to a limited degree.

The support of the sidewall allows the tire to re‐

main drivable to a restricted degree in the

event of a tire inflation pressure loss.

Continued driving with a damaged tire, refer to

page 89.

Seite 187Wheels and tiresMOBILITY187

Online Edition for Part no. 01 40 2 963 307 - VI/15

Page 188 of 251

Continued driving with a damaged tire, refer to

page 86.

Changing run-flat tires

For your own safety, only use run-flat tires. No

spare tire is available in the case of a flat tire. A

dealer’s service center or another qualified

service center or repair shop will be glad to an‐

swer additional questions at any time.

Repairing a flat tireSafety measures▷Park the vehicle as far away as possible

from passing traffic and on solid ground.▷Switch on the hazard warning system.▷Secure the vehicle against rolling away by

setting the parking brake.▷Turn the steering wheel until the front

wheels are in the straight-ahead position

and engage the steering wheel lock.▷Have all vehicle occupants get out of the

vehicle and ensure that they remain out‐

side the immediate area in a safe place,

such as behind a guardrail.▷If necessary, set up a warning triangle at an

appropriate distance.

Mobility System

The concept

With the Mobility System, minor tire damage

can be sealed quickly to enable continued

travel. To accomplish this, sealant is pumped

into the tires, which seals the damage from the

inside.

The compressor can be used to check the tire

inflation pressure.

Information▷Follow the instructions on using the Mobi‐

lity System found on the compressor and

sealant container.▷Use of the Mobility System may be ineffec‐

tive if the tire puncture measures approx.

1/8 in/4 mm or more.▷Contact a dealer’s service center or another

qualified service center or repair shop if the

tire cannot be made drivable.▷If possible, do not remove foreign bodies

that have penetrated the tire.▷Pull the speed limit sticker off the sealant

container and apply it to the steering

wheel.▷The use of a sealant can damage the TPM

wheel electronics. In this case, have the

electronics checked at the next opportunity

and have them replaced if needed.

DANGER

If the exhaust pipe is blocked or ventila‐

tion is insufficient, harmful exhaust gases can

enter into the vehicle. The exhaust gases con‐

tain carbon monoxide, an odorless and color‐

less but highly toxic gas. In enclosed areas, ex‐

haust gases can also accumulate outside of the

vehicle. There is danger to life. Keep the ex‐

haust pipe free and ensure sufficient ventila‐

tion. ◀

Storage

The Mobility System is located under the cargo

floor panel.

Seite 188MOBILITYWheels and tires188

Online Edition for Part no. 01 40 2 963 307 - VI/15

Page 189 of 251

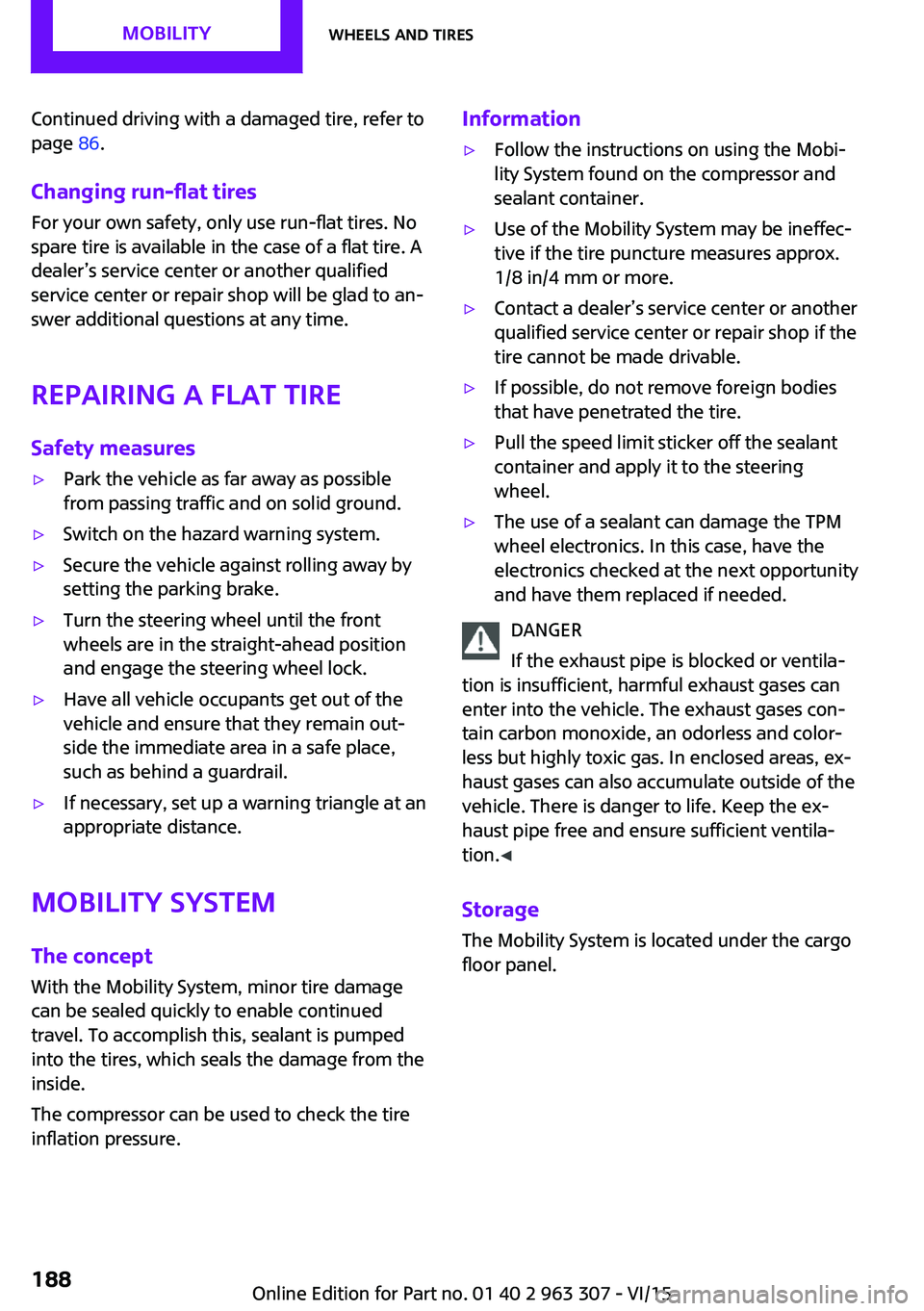

Sealant container▷Sealant container, arrow 1.▷Filling hose, arrow 2.

Observe use-by date on the sealant container.

Compressor

1On/off switch2Holder for bottle3Reduce inflation pressure4Inflation pressure dial5Compressor6Connector/cable for socket7Connection hose — stowed in the bottom

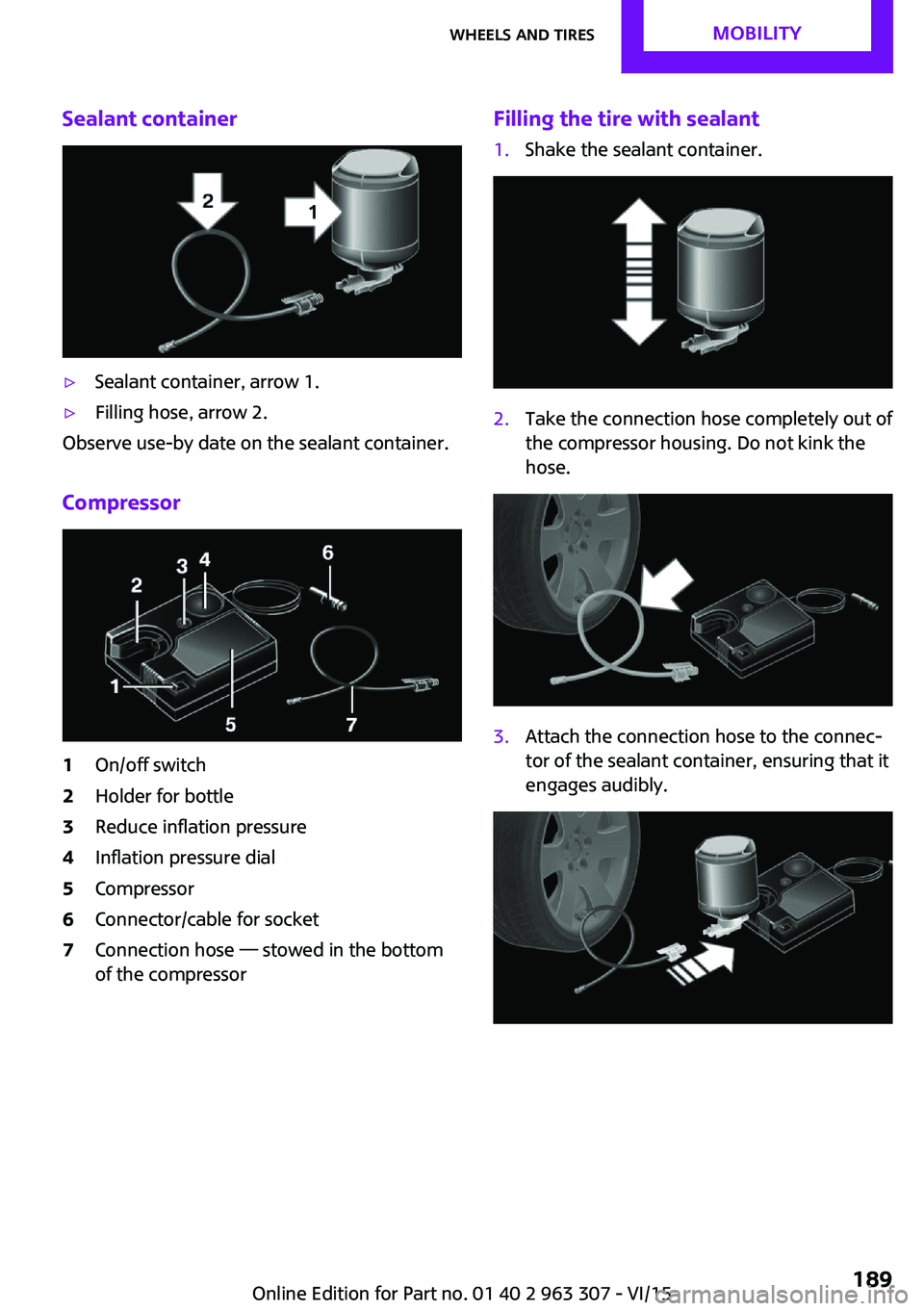

of the compressorFilling the tire with sealant1.Shake the sealant container.2.Take the connection hose completely out of

the compressor housing. Do not kink the

hose.3.Attach the connection hose to the connec‐

tor of the sealant container, ensuring that it

engages audibly.Seite 189Wheels and tiresMOBILITY189

Online Edition for Part no. 01 40 2 963 307 - VI/15

Page 190 of 251

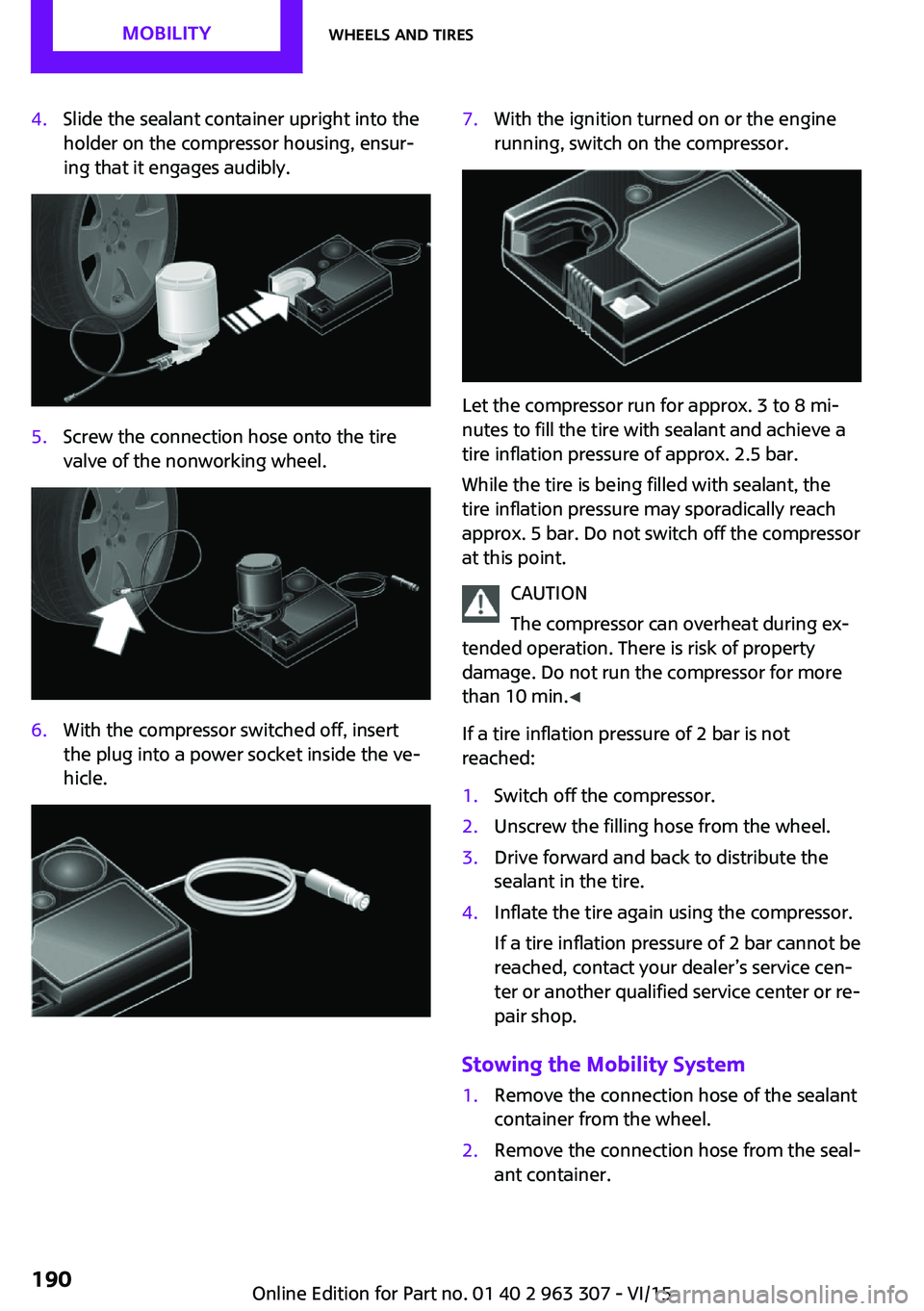

4.Slide the sealant container upright into the

holder on the compressor housing, ensur‐

ing that it engages audibly.5.Screw the connection hose onto the tire

valve of the nonworking wheel.6.With the compressor switched off, insert

the plug into a power socket inside the ve‐

hicle.7.With the ignition turned on or the engine

running, switch on the compressor.

Let the compressor run for approx. 3 to 8 mi‐

nutes to fill the tire with sealant and achieve a

tire inflation pressure of approx. 2.5 bar.

While the tire is being filled with sealant, the

tire inflation pressure may sporadically reach

approx. 5 bar. Do not switch off the compressor

at this point.

CAUTION

The compressor can overheat during ex‐

tended operation. There is risk of property

damage. Do not run the compressor for more

than 10 min. ◀

If a tire inflation pressure of 2 bar is not

reached:

1.Switch off the compressor.2.Unscrew the filling hose from the wheel.3.Drive forward and back to distribute the

sealant in the tire.4.Inflate the tire again using the compressor.

If a tire inflation pressure of 2 bar cannot be

reached, contact your dealer’s service cen‐

ter or another qualified service center or re‐

pair shop.

Stowing the Mobility System

1.Remove the connection hose of the sealant

container from the wheel.2.Remove the connection hose from the seal‐

ant container.Seite 190MOBILITYWheels and tires190

Online Edition for Part no. 01 40 2 963 307 - VI/15

Page 191 of 251

3.Wrap the empty sealant container and con‐

nection hose in suitable material to avoid

dirtying the trunk.4.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Immediately drive approx. 5 mls/10 km/h to

ensure that the sealant is evenly distributed in the tire.

Do not exceed a speed of 50 mph/80 km/h.

If possible, do not drive at speeds less than

12 mph/20 km/h.

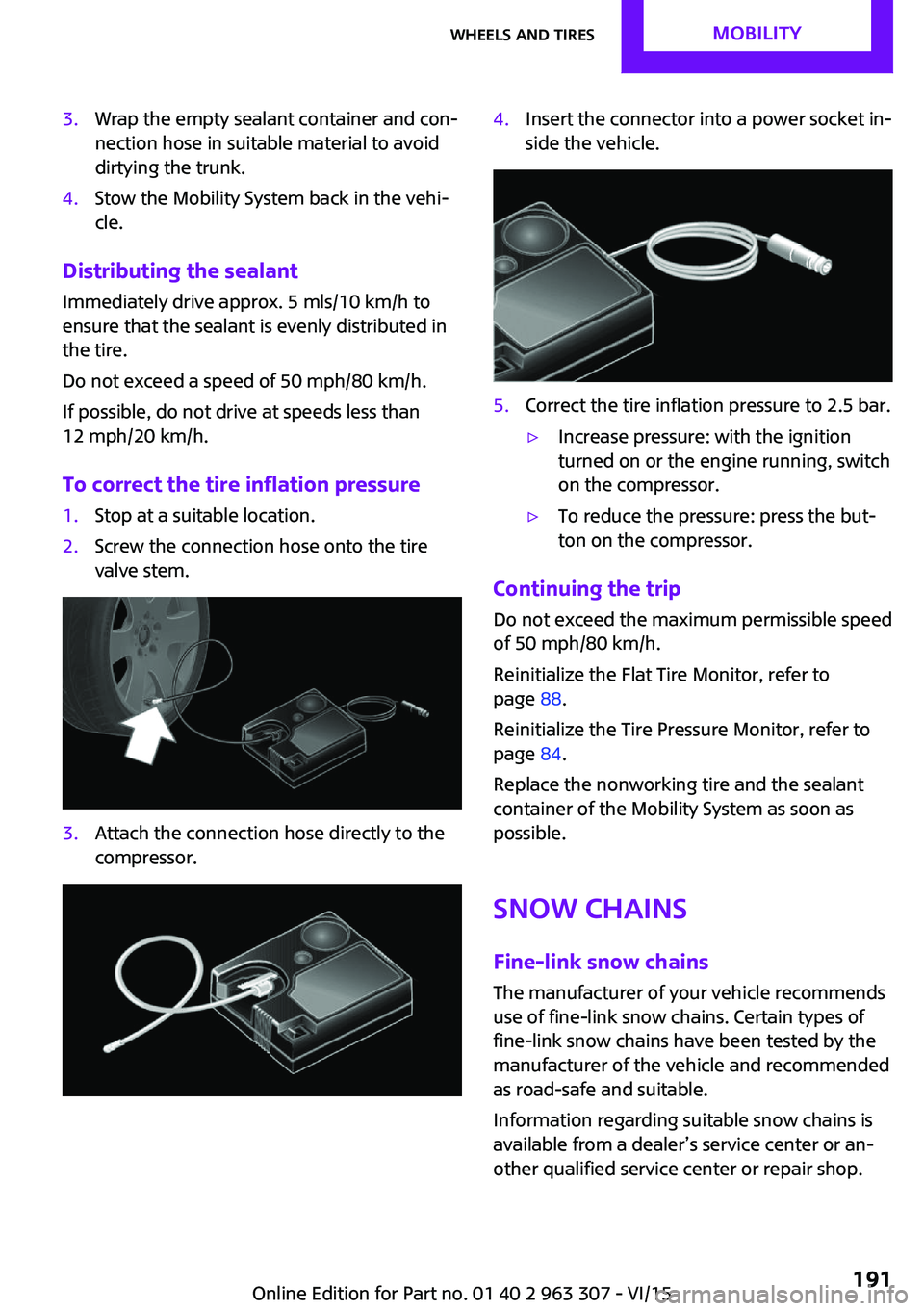

To correct the tire inflation pressure

1.Stop at a suitable location.2.Screw the connection hose onto the tire

valve stem.3.Attach the connection hose directly to the

compressor.4.Insert the connector into a power socket in‐

side the vehicle.5.Correct the tire inflation pressure to 2.5 bar.▷Increase pressure: with the ignition

turned on or the engine running, switch

on the compressor.▷To reduce the pressure: press the but‐

ton on the compressor.

Continuing the trip

Do not exceed the maximum permissible speed

of 50 mph/80 km/h.

Reinitialize the Flat Tire Monitor, refer to

page 88.

Reinitialize the Tire Pressure Monitor, refer to

page 84.

Replace the nonworking tire and the sealant

container of the Mobility System as soon as

possible.

Snow chains Fine-link snow chains

The manufacturer of your vehicle recommends use of fine-link snow chains. Certain types of

fine-link snow chains have been tested by the

manufacturer of the vehicle and recommended

as road-safe and suitable.

Information regarding suitable snow chains is

available from a dealer’s service center or an‐ other qualified service center or repair shop.

Seite 191Wheels and tiresMOBILITY191

Online Edition for Part no. 01 40 2 963 307 - VI/15

Page 192 of 251

UseUse only in pairs on the front wheels, equipped

with the tires of the following size:▷175/65 R 15.▷175/60 R 16.

John Cooper Works:

▷185/50 R 17.

Follow the chain manufacturer's instructions.

Make sure that the snow chains are always suf‐

ficiently tight. Retighten as needed according

to the chain manufacturer's instructions.

Do not initialize the Flat Tire Monitor after

mounting snow chains, as doing so may result

in incorrect readings.

Do not initialize the Tire Pressure Monitor after

mounting snow chains, as doing so may result

in incorrect readings.

When driving with snow chains, briefly activate

Dynamic Traction Control if needed.

Maximum speed with snow chains

Do not exceed a speed of 30 mph/50 km/h

when using snow chains.

Seite 192MOBILITYWheels and tires192

Online Edition for Part no. 01 40 2 963 307 - VI/15

Page 210 of 251

Changing wheelsInformation

When using run-flat tires or tire sealants, a tire

does not need to be changed immediately in

the event of pressure loss due to a flat tire.

Which is why no spare tire is available.

The tools for changing wheels are available as

accessories from your dealer’s service center or

another qualified service center or repair shop.

Jacking points for the vehicle jack

The jacking points for the vehicle jack are lo‐

cated at the positions shown.

Emergency wheel

Safety measures

▷Park the vehicle as far away as possible

from passing traffic and on solid ground.

Switch on the hazard warning system.▷Set the parking brake and engage lever in

position P P.▷Have all vehicle occupants get out of the

vehicle and ensure that they remain out‐

side the immediate area in a safe place,

such as behind a guardrail.▷If necessary, set up a warning triangle or

portable hazard warning lamp at an appro‐

priate distance.▷Perform wheel change only on a flat, solid

and slip-resistant surface. On soft or slip‐

pery ground, e.g., snow, ice, tiles, etc., thevehicle or vehicle jack can slip away to the

side.▷Do not place wood blocks or similar items

under the vehicle jack; otherwise, it cannot

reach its carrying capacity because of the

restricted height.▷If the vehicle is raised, do not lie under the

vehicle and do not start the engine; other‐

wise, a fatal hazard exists.

Information

WARNING

The vehicle jack is optimized for lifting

the vehicle and for the jacking points on the ve‐

hicle only. There is risk of injuries. Do not lift

any other vehicle or cargo using the vehicle

jack. ◀

Removing the emergency wheel The emergency wheel is housed in a well on

the underbody of the vehicle. The screw con‐

nection of the emergency wheel is in the cargo

area underneath the floor mat, on the floor of

the storage compartment for the onboard vehi‐

cle tool kit.

1.Loosen the nut using the wheel wrench

from the onboard vehicle tool kit.2.Remove the retaining plate.Seite 210MOBILITYReplacing components210

Online Edition for Part no. 01 40 2 963 307 - VI/15

Page 212 of 251

3.Check tire inflation pressure at the next op‐

portunity and correct as needed.4.Reinitialize the Flat Tire Monitor, refer to

page 88.

Reinitialize the Tire Pressure Monitor, refer

to page 85.5.Check to make sure the lug bolts are tight

with a calibrated torque wrench.

Driving with emergency wheel

WARNING

The emergency wheel has particular di‐

mensions. When driving with an emergency wheel, changed driving properties may occur at

higher speeds, e.g. reduced lane stability when

braking, longer braking distance and changed

self-steering properties in the limit area. There

is risk of an accident. Drive moderately and do

not exceed a speed of 50 mph/80 km/h. ◀

After the trip with emergency wheel

Have the following work performed by a deal‐

er's service center or another qualified service

center or repair shop.

1.Replace the damaged tires as soon as pos‐

sible.2.Replace the emergency wheel with a new

wheel.3.Have the tray with the emergency wheel

installed.

Vehicle battery

Maintenance

The battery is maintenance-free.

The added amount of acid is sufficient for the

service life of the battery.

More information about the battery can be re‐

quested from a dealer’s service center or an‐

other qualified service center or repair shop.

Battery replacement

CAUTION

Vehicle batteries that are not compatible

can damage vehicle systems and impair vehicle

functions.There is risk of property damage. In‐ formation on the compatible vehicle batteries is

available at your dealer's service center. ◀

After a battery replacement, the manufacturer

of your vehicle recommends that the vehicle

battery be registered on the vehicle by a

dealer’s service center or another qualified

service center or repair shop to ensure that all

comfort features are fully available and that

any Check Control messages of these comfort

features are no longer displayed.

Charging the battery

General information Make sure that the battery is always sufficiently

charged to guarantee that the battery remains

usable for its full service life.

The battery may need to be charged in the fol‐

lowing cases:▷When making frequent short-distance

drives.▷If the vehicle is not used for prolonged peri‐

ods, longer than a month.▷Steptronic transmission: when parked for

long periods of time in selector lever posi‐

tion D, R or N.

Information

CAUTION

Battery chargers for the vehicle battery

can work with high voltages and currents, which means that the 12V on-board network

can be overloaded or damaged. There is risk of

property damage. Only connect battery charg‐

ers for the vehicle battery to the starting aid

terminals in the engine compartment. ◀

Seite 212MOBILITYReplacing components212

Online Edition for Part no. 01 40 2 963 307 - VI/15

Page 220 of 251

CareVehicle features and op‐tions

This chapter describes all standard, country-

specific and optional features offered with the series. It also describes features that are not

necessarily available in your car, e. g., due to

the selected options or country versions. This

also applies to safety-related functions and sys‐

tems. The respectively applicable country provi‐

sions must be observed when using the respec‐

tive features and systems.

Car washes

General information Regularly remove foreign objects such as leaves

in the area below the windshield when the

hood is raised.

Wash your vehicle frequently, particularly in

winter. Intense soiling and road salt can dam‐

age the vehicle.

Steam jets or high-pressure washers

Information CAUTION

When cleaning with high-pressure wash‐

ers, components can be damaged due to the

pressure or temperatures being too high. There

is risk of property damage. Maintain sufficient

distance and do not spray too long continu‐

ously. Follow the user's manual for the high-

pressure washer. ◀

Distances and temperature▷Maximum temperature: 140 ℉/60 ℃.▷Minimum distance from sensors, cameras,

seals: 12 in/30 cm.▷Minimum distance from glass sunroof:

31.5 inches/80 cm.

Automatic car washes

Information

▷Give preference to cloth car washes or

those that use soft brushes in order to

avoid paint damage.▷Make sure that the wheels and tires are not

damaged by the transport mechanisms.▷Fold in the exterior mirrors; otherwise, they

may be damaged, depending on the width

of the vehicle.▷Unscrew the rod antenna.▷Deactivate the rain sensor, refer to

page 56, to avoid unintentional wiper acti‐

vation.▷In some cases, an unintentional alarm can

be triggered by the interior motion sensor

of the alarm system. Follow the instructions

on avoiding an unintentional alarm, refer to

page 31.

CAUTION

Too high guide rails in car washes can

damage body parts. There is risk of property

damage. Avoid car washes with guide rails

higher than 4 in/10 cm. ◀

Before driving into a car wash

In order to ensure that the vehicle can roll in a

car wash, take the following steps:

Manual transmission:

1.Drive into the car wash.2.Shift to neutral.3.Switch the engine off.4.Switch on the ignition.Seite 220MOBILITYCare220

Online Edition for Part no. 01 40 2 963 307 - VI/15

Page 226 of 251

Technical dataVehicle features and op‐

tions

This chapter describes all standard, country-

specific and optional features offered with the

series. It also describes features that are not

necessarily available in your car, e. g., due to

the selected options or country versions. This

also applies to safety-related functions and sys‐

tems. The respectively applicable country provi‐

sions must be observed when using the respec‐

tive features and systems.

Information

The technical data and specifications in this

Owner's Manual are used as guidance values.

The vehicle-specific data can deviate from this,

for example, due to the selected special equip‐

ment, country version or country-specific

measurement method. Detailed values can be

found in the approval documents, on labels on

the vehicle or can be obtained from a dealer’s

service center or another qualified service cen‐

ter or repair shop.

The information in the vehicle documents al‐

ways has priority.

Dimensions

The dimensions can vary depending on the

model version, equipment or country-specific

measurement method.

The specified heights do not take into account

attached parts, for example, a roof antenna,

roof racks or spoiler. The heights can deviate,

for example, due to the selected special equip‐

ment, tires, load and chassis version.

Seite 226REFERENCETechnical data226

Online Edition for Part no. 01 40 2 963 307 - VI/15

MINI 3-doorWidth with mirrorsinches/mm76.1/1,932Width without mirrorsinches/mm68.0/1,727Heightinches/mm55.7/1,414LengthCooperinches/mm151.1/3,837Cooper Sinches/mm151.9/3,858John Cooper Worksinches/mmWheelbaseinches/mm98.2/2,495Smallest turning radius diam.ft/m35.4/10.8152.5/3,874