MINI COOPER CONVERTIBLE 2007 Owners Manual

Manufacturer: MINI, Model Year: 2007, Model line: COOPER CONVERTIBLE, Model: MINI COOPER CONVERTIBLE 2007Pages: 172, PDF Size: 1.9 MB

Page 131 of 172

129

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

WIPER BLADES LAMPS AND BULBSRear window wiper*1. Rotate the wiper arm completely out

2. Turn the wiper blade as far as it will go

to the rear

3. Press the wiper blade against the limit

and thus out of the mounting

4. Press the new wiper blade into the

mounting.

Lamps and bulbs are an important compo-

nent of vehicle safety. Therefore, proceed

carefully when handling bulbs.

To replace bulbs which are not described

here, please contact a MINI Dealer or a

workshop that has specially trained per-

sonnel working in accordance with the

specifications of the MINI manufacturer.

Do not touch the glass portion of a

new bulb with your bare hands since

even small amounts of impurities burn into

the surface and reduce the service life of

the bulb. Use a clean cloth, paper napkin, or

similar material, or hold the bulb by its

metallic base.<

A replacement bulb set can be obtained at

your MINI Dealer.

Whenever working on the electrical

system, switch off the electrical

accessory you are working on or disconnect

the cable from the negative terminal of the

battery. Failure to do this could result in

short circuits.

To prevent injuries and damage, comply

with any instructions provided by the bulb

manufacturer.<

Page 132 of 172

130

LAMPS AND BULBS1 Low beamsH7 bulb, 55 watts2High beams H7 bulb, 55 watts

The H7 bulb is pressurized. Therefore,

wear safety glasses and protective

gloves. If the lamp is damaged there is a

risk of injury.<

For checking and adjusting headlamp

aim, please contact your MINI

Dealer.

1. Gently pull the retaining wire of the

headlamp cover and guide it outwards

2. Fold down the headlamp cover

3. Disconnect the cable connector from the

bulb socket and pull out the bulb

4. Place the bulb holder on the lower edge

of the mounting and press it in until it

engages in the bulb socket

5. Reconnect the cable connector and

install the headlamp cover again.Xenon lamps*The service life of these bulbs is very long

and the probability of a failure is very low,

provided that they are not switched on and

off an unusual number of times. If one of

these bulbs should nevertheless fail, it is

possible to continue driving with great cau-

tion using the fog lamps, provided traffic

laws in your area do not prohibit this.

Have any work on the xenon lamp

system, including bulb replacement,

carried out only by a MINI Dealer or a work-

shop that has specially trained personnel

working in accordance with the specifica-

tions of the MINI manufacturer. Due to

high voltage, there is a risk of fatal injury if

work on the xenon lamps is carried out

improperly.<

Turn signal indicators, front 21 watt bulb

1. Open the bonnet

2. Reach into the opening for the turn sig-

nal indicators from above

3. Apply gentle pressure to the bulb holder

while turning it to the left

4. Remove and replace the bulb.Parking lamps and standing lamps5watt bulb

The parking lamps and standing lamps are

integrated in the lamp housing of the turn

signal indicator.

1. Turn the bulb holder to the left and pull

out

2. Remove and replace the bulb.

Page 133 of 172

131

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

LAMPS AND BULBSSide turn signal indicators5watt bulb

1. Slide the lamp toward the rear of the

vehicle and remove

2. Remove and replace the bulb.

Tail lampsTurn signal lamp 1: 21 watts

Rear lamp 2: 21/5 watt bulb

Backup lamp 3: 16 watts

1 Turn signal indicator yellow

2 Rear lamp/Brake lamp red

3 Backup lamp white

Replacing bulbsTo access the bulb holder, remove the cover

on the side panel in the luggage compart-

ment for MINI and MINI Convertible.

1. Unplug the power supply, arrow 1

2. Squeeze the retaining clips together, see

arrows 2, and remove the bulb holder

3. Apply gentle pressure to the bulb while

turning it to the left

4. Remove and replace the bulb

5. Press the bulb holder into position until

you hear it engage

6. Plug in the power supply.

Page 134 of 172

132

LAMPS AND BULBSRear fog lamp*With the space-saver spare tire option:

Access to the lamp via the back or under-

side of the bumper.

1. Press the clips together

2. Push the lamp out of the bumper

3. Apply gentle pressure to the bulb while

turning it to the left

4. Remove and replace the bulb.

Other equipment:

In the event of a malfunction, please

contact your MINI Dealer or a work-

shop that has specially trained personnel

working in accordance with the specifica-

tions of your MINI manufacturer.<

License plate lamps 5watt bulb

As an example, the illustration shows the

license plate lamp of the MINI.

1. Apply a screwdriver to the recess and

lever out the lamp cover

2. Replace the bulb.Light-emitting diodes (LEDs)Light-emitting diodes installed behind

translucent lenses serve as the light

sources for many of the controls and dis-

plays in your vehicle. These light-emitting

diodes are related to conventional lasers,

and legislation defines them as light-emit-

ting diodes, Class 1.

Do not remove the protective lenses

and avoid staring directly at the unfil-

tered beam for several hours, as inflamma-

tion of the retina could result.<

Page 135 of 172

133

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

REPAIRING A FLAT TIRE SPACE-SAVER SPARE TIRE

*

Safety measures in the event of a

flat:

Park the vehicle as far away from flowing

traffic as possible, and switch on the haz-

ard warning flashers.

Turn the steering wheel to the straight-

ahead wheel position and engage the

steering lock. Engage the parking brake and

shift into 1st or reverse gear – selector lever

in P.

All passengers should be outside the vehi-

cle and well away from your immediate

working area – behind a guardrail, for

instance.

If a portable hazard warning lamp is avail-

able, set it up on the roadside at an appro-

priate distance from the rear of the vehicle.

Comply with all safety guidelines and regu-

lations.<

In the event of a flat tire, different proce-

dures should be followed depending on the

equipment included in your vehicle:

>Vehicles with Run-Flat Tires, refer to

page111

>Vehicles with a space-saver spare tire,

refer to the following section

>Vehicles with MINI Mobility System,

refer to page137.

To change a space-saver spare tire, proceed

as follows:

>Remove space-saver spare tire, refer to

the section after the next one

>Prepare for tire change, refer to page135

>Jack up the vehicle, refer to page136

>Mount the space-saver spare tire, refer

to page136

>Tighten the lug bolts, refer to page136

>Drive with space-saver spare tire, refer to

page135.

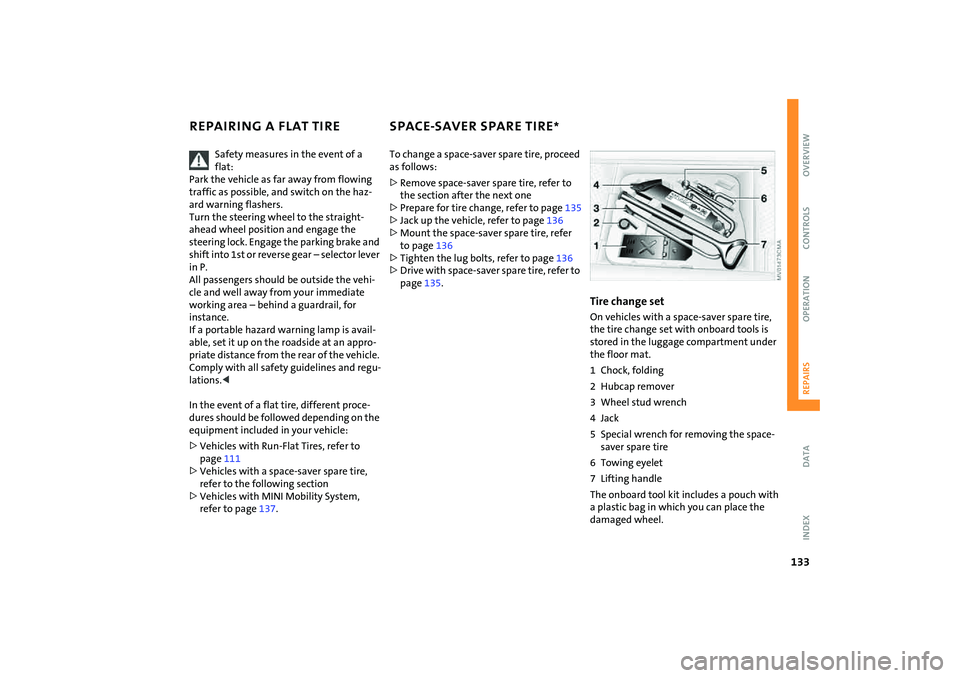

Tire change setOn vehicles with a space-saver spare tire,

the tire change set with onboard tools is

stored in the luggage compartment under

the floor mat.

1 Chock, folding

2 Hubcap remover

3 Wheel stud wrench

4Jack

5 Special wrench for removing the space-

saver spare tire

6 Towing eyelet

7 Lifting handle

The onboard tool kit includes a pouch with

a plastic bag in which you can place the

damaged wheel.

Page 136 of 172

134

SPACE-SAVER SPARE TIRE

*

Removing the space-saver spare tire

The screw connection of the space-saver

spare tire is in the luggage compartment

under the floor mat, on the base of the

storage compartment for the tire change

set.

1. Loosen the screw connection using the

special wrench

2. Take out the cover panel

3. Screw the lifting handle from the

onboard tool kit onto the thread

4. Raise the lifting handle slightly

5. Squeeze the securing spring

6. The space-saver spare tire is released

and must be held by the lifting handle

7. Lower the space-saver spare tire with

the lifting handle

8. Unscrew the lifting handle

Page 137 of 172

135

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

SPACE-SAVER SPARE TIRE

*

CHANGING TIRES

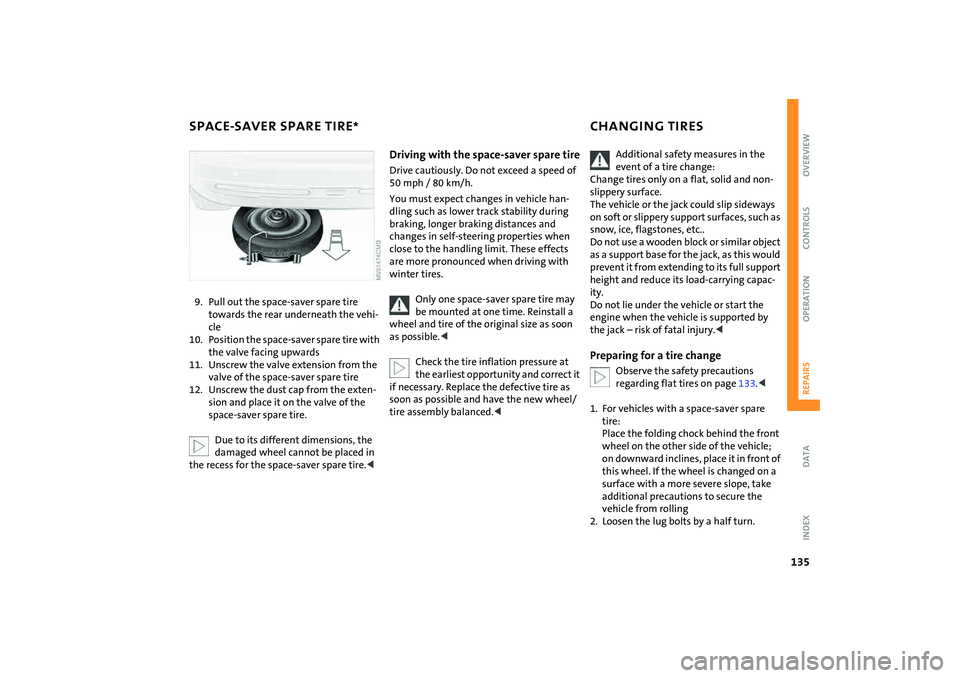

9. Pull out the space-saver spare tire

towards the rear underneath the vehi-

cle

10. Position the space-saver spare tire with

the valve facing upwards

11. Unscrew the valve extension from the

valve of the space-saver spare tire

12. Unscrew the dust cap from the exten-

sion and place it on the valve of the

space-saver spare tire.

Due to its different dimensions, the

damaged wheel cannot be placed in

the recess for the space-saver spare tire.<

Driving with the space-saver spare tireDrive cautiously. Do not exceed a speed of

50 mph / 80 km/h.

You must expect changes in vehicle han-

dling such as lower track stability during

braking, longer braking distances and

changes in self-steering properties when

close to the handling limit. These effects

are more pronounced when driving with

winter tires.

Only one space-saver spare tire may

be mounted at one time. Reinstall a

wheel and tire of the original size as soon

as possible.<

Check the tire inflation pressure at

the earliest opportunity and correct it

if necessary. Replace the defective tire as

soon as possible and have the new wheel/

tire assembly balanced.<

Additional safety measures in the

event of a tire change:

Change tires only on a flat, solid and non-

slippery surface.

The vehicle or the jack could slip sideways

on soft or slippery support surfaces, such as

snow, ice, flagstones, etc..

Do not use a wooden block or similar object

as a support base for the jack, as this would

prevent it from extending to its full support

height and reduce its load-carrying capac-

ity.

Do not lie under the vehicle or start the

engine when the vehicle is supported by

the jack – risk of fatal injury.<

Preparing for a tire change

Observe the safety precautions

regarding flat tires on page133.<

1. For vehicles with a space-saver spare

tire:

Place the folding chock behind the front

wheel on the other side of the vehicle;

on downward inclines, place it in front of

this wheel. If the wheel is changed on a

surface with a more severe slope, take

additional precautions to secure the

vehicle from rolling

2. Loosen the lug bolts by a half turn.

Page 138 of 172

136

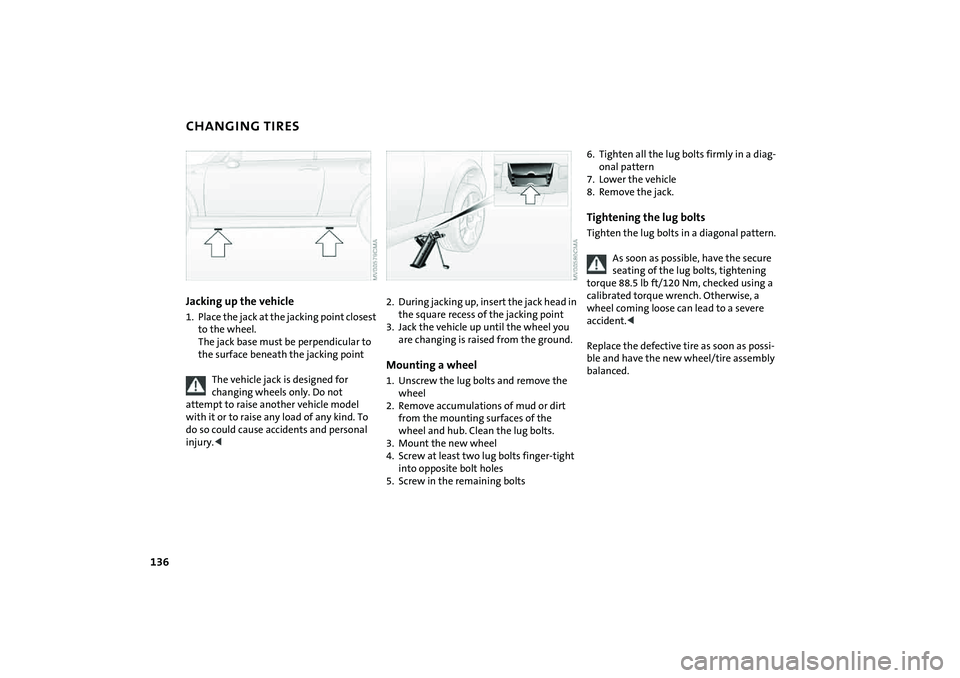

CHANGING TIRESJacking up the vehicle1. Place the jack at the jacking point closest

to the wheel.

The jack base must be perpendicular to

the surface beneath the jacking point

The vehicle jack is designed for

changing wheels only. Do not

attempt to raise another vehicle model

with it or to raise any load of any kind. To

do so could cause accidents and personal

injury.<

2. During jacking up, insert the jack head in

the square recess of the jacking point

3. Jack the vehicle up until the wheel you

are changing is raised from the ground.Mounting a wheel1. Unscrew the lug bolts and remove the

wheel

2. Remove accumulations of mud or dirt

from the mounting surfaces of the

wheel and hub. Clean the lug bolts.

3. Mount the new wheel

4. Screw at least two lug bolts finger-tight

into opposite bolt holes

5. Screw in the remaining bolts

6. Tighten all the lug bolts firmly in a diag-

onal pattern

7. Lower the vehicle

8. Remove the jack.Tightening the lug boltsTighten the lug bolts in a diagonal pattern.

As soon as possible, have the secure

seating of the lug bolts, tightening

torque 88.5 lb ft/120 Nm, checked using a

calibrated torque wrench. Otherwise, a

wheel coming loose can lead to a severe

accident.<

Replace the defective tire as soon as possi-

ble and have the new wheel/tire assembly

balanced.

Page 139 of 172

137

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

MINI MOBILITY SYSTEM

*

MINI Mobility System

The MINI Mobility System is provided to

help you repair a flat tire. With the help of

this system you can apply a liquid sealant

on the inside of the tire, which seals the

damaged area and enables you to continue

to drive.Preparing for tire repair

Before using the MINI Mobility Sys-

tem read the warning and danger

precautions on the equipment.<

If possible, leave objects in which have

been forced into the tire.

Take off the tag regarding speed limits and

stick it onto the steering wheel.

Using the MINI Mobility SystemIn order to repair a flat tire with the MINI

Mobility System, proceed as follows:

>Pump in liquid sealant, refer to page138

>Reinflate the tire, refer to page138

>Distribute liquid sealant, refer to

page139

>Check tire inflation pressure, refer to

page139

>Drive on, refer to page139.

MINI Mobility System with onboard

tools The MINI Mobility System with tire change

set and onboard tools is located in the lug-

gage compartment under the floor mat:

1Jack

2 Wheel stud wrench

3 Hubcap remover

4 Wrench, screwdriver/Phillips screw-

driver, towing eyelet

5 Compressor, hose with manometer and

plug for cigarette lighter socket

6 Package with filling hose, valve remover

and valve core

7 Filling canister

8 Hex wrench/screwdriver

9 Adapter for wheel lug lock

Page 140 of 172

138

MINI MOBILITY SYSTEM

*

Pumping in liquid sealant

1. Shake the filling canister

2. Screw the filling hose onto the filling

canister

3. Unscrew the dust protection cap from

the valve of the defective tire

4. Screw out the valve core with the valve

remover. The valve remover is located in

a package with the filling hose.

Place the valve core and valve

remover only on clean surfaces.<

5. Remove the cap from the filling hose

6. Push the filling hose onto the tire valve

7. Hold the filling canister with the cap

down and squeeze.

Squeeze the entire contents of the canis-

ter into the tire

8. Remove filling hose

9. Screw valve core into the tire valve with

the valve remover.

In the event of a lost or dirty valve

core you will find another valve core

in a package with the filling hose.

Please remember that the liquid canister

must be replaced every four years if the

equipment has not been used.<

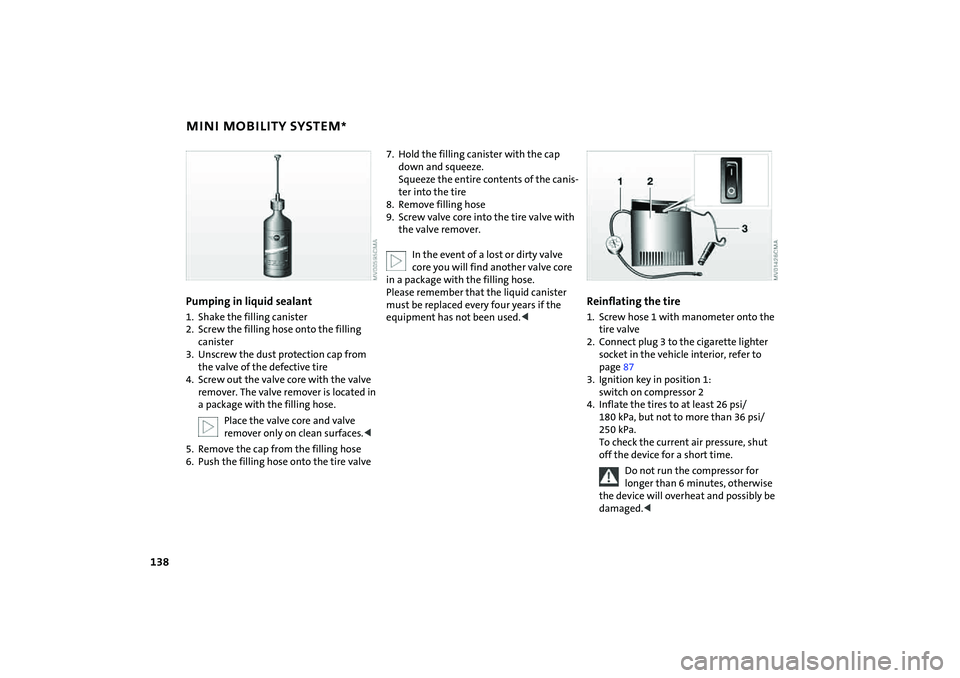

Reinflating the tire1. Screw hose 1 with manometer onto the

tire valve

2. Connect plug 3 to the cigarette lighter

socket in the vehicle interior, refer to

page87

3. Ignition key in position 1:

switch on compressor 2

4. Inflate the tires to at least 26 psi/

180 kPa, but not to more than 36 psi/

250 kPa.

To check the current air pressure, shut

off the device for a short time.

Do not run the compressor for

longer than 6 minutes, otherwise

the device will overheat and possibly be

damaged.<