check engine MINI Countryman 2015 (Mini Connected) User Guide

[x] Cancel search | Manufacturer: MINI, Model Year: 2015, Model line: Countryman, Model: MINI Countryman 2015Pages: 283, PDF Size: 6.76 MB

Page 130 of 283

Saving fuelVehicle equipment

This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series. Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

When using the features and systems described

here, adhere to local regulations.

General information

Your vehicle contains advanced technology for

the reduction of fuel consumption and emis‐

sions.

Fuel consumption depends on a number of dif‐

ferent factors. The implementation of certain measures, driving style and regular mainte‐nance can have an influence on fuel consump‐

tion and on the environmental impact.

Remove unnecessary cargo Additional weight increases fuel consumption.

Remove attached parts following use Remove unneeded auxiliary mirrors, roof or

rear luggage racks after use.

Attached parts on the vehicle impair the aero‐

dynamics and increase the fuel consumption.

Close both windows Open windows causes higher air resistance and

thus increases fuel consumption.Check the tire inflation pressure

regularly

Check and, if necessary, correct the tire infla‐

tion pressure, refer to page 216, at least twice

a month and before starting on a long trip.

Low tire inflation pressure increases rolling re‐

sistance and thus raises fuel consumption and

tire wear.

Drive away without delay

Do not wait for the engine to warm-up while

the vehicle remains stationary. Start driving

right away, but at moderate engine speeds.

This is the fastest way for the cold engine to

reach its operating temperature.

Look well ahead when drivingAvoid unnecessary acceleration and braking. To

achieve this, maintain a suitable distance to the

vehicle driving ahead of you.

Driving smoothly and looking ahead reduces

fuel consumption.

Avoid high engine speeds Use 1st gear to get the vehicle in motion. Be‐

ginning with 2nd gear, accelerate rapidly. When

accelerating, shift up before reaching high en‐

gine speeds.

When you reach the desired speed, shift into

the highest applicable gear and drive with the

engine speed as low as possible and at a con‐

stant speed.

As a rule: driving at low engine speeds lowers

fuel consumption and reduces wear.

Use coasting conditions

When approaching a red light, take your foot

off the accelerator and coast to a halt in the

highest applicable gear.Seite 128DRIVING TIPSSaving fuel128

Online Edition for Part no. 01 40 2 961 110 - II/15

Page 228 of 283

3.Insert the sealant bottle into the compres‐

sor housing in a vertical position.4.Unscrew the dust cap off of the valve of the

defective wheel and screw the filling hose 2

of the sealant bottle onto the valve.5.Ensure that the compressor is switched off.6.Insert connector 5 into the lighter socket/

socket in the passenger compartment, refer

to page 110.7.When the engine is running:

Switch on the compressor and let it run for

approx. 3 to 8 minutes to fill sealant into

the tire and achieve a tire inflation pressure

of approx. 1.8 bar/26 psi.

While sealant is being filled, the inflation

pressure may intermittently rise to approx.

5 bar/73 psi. Do not switch off the com‐

pressor in this phase.8.Switch off the compressor.

Do not allow the compressor to run too

long

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged. ◀

If an air pressure of 1.8 bar/26 psi is not

reached:

1.Unscrew the filling hose 2 from the wheel

and drive forward and back approx.

33 ft/10 m to evenly distribute the sealant

in the tire.2.Inflate the tire again using the compressor.If the inflation pressure of 1.8 bar/26 psi is still

not reached, the tire is too heavily damaged.

Contact the nearest service center.

Stowing the Mobility System1.Unscrew the filling hose 2 of the sealant

bottle from the wheel.2.Unscrew the compressor connection hose 6

from the sealant bottle.3.Connect the filling hose 2 of the sealant

bottle with the free connector on the seal‐

ant bottle.

This prevents left-over sealant from escap‐

ing from the bottle.4.Wrap the empty sealant bottle in suitable

material to avoid dirtying the cargo area.5.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Drive approx. 3.1 miles/5 km to evenly distrib‐

ute the sealant.

Do not exceed a speed of 50 mph/80 km/h. If

possible, do not drop below a speed of

10 mph/20 km/h.

Correcting the tire inflation pressure

1.After driving approx. 3.1 miles/5 km, or

about 10 minutes, stop in a suitable loca‐

tion.2.Screw the connection hose 6 of the com‐

pressor directly onto the tire valve.3.Insert the connector 5 into the power

socket in the passenger compartment.4.Correct the tire inflation pressure to

1.8 bar/26 psi. When the engine is running:▷To increase the inflation pressure:

switch on the compressor. To check the

currently set inflation pressure, switch

off the compressor.▷To reduce the inflation pressure: press

the release button 9.Seite 226MOBILITYWheels and tires226

Online Edition for Part no. 01 40 2 961 110 - II/15

Page 232 of 283

Engine oilEngine oil

Vehicle equipment This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series. Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

When using the features and systems described

here, adhere to local regulations.

General information

Engine oil consumption depends on the driving

style and the conditions of use. A highly sporty

driving style, for example, results in considera‐

bly higher engine oil consumption.

Therefore, regularly check the engine oil level

after refueling.

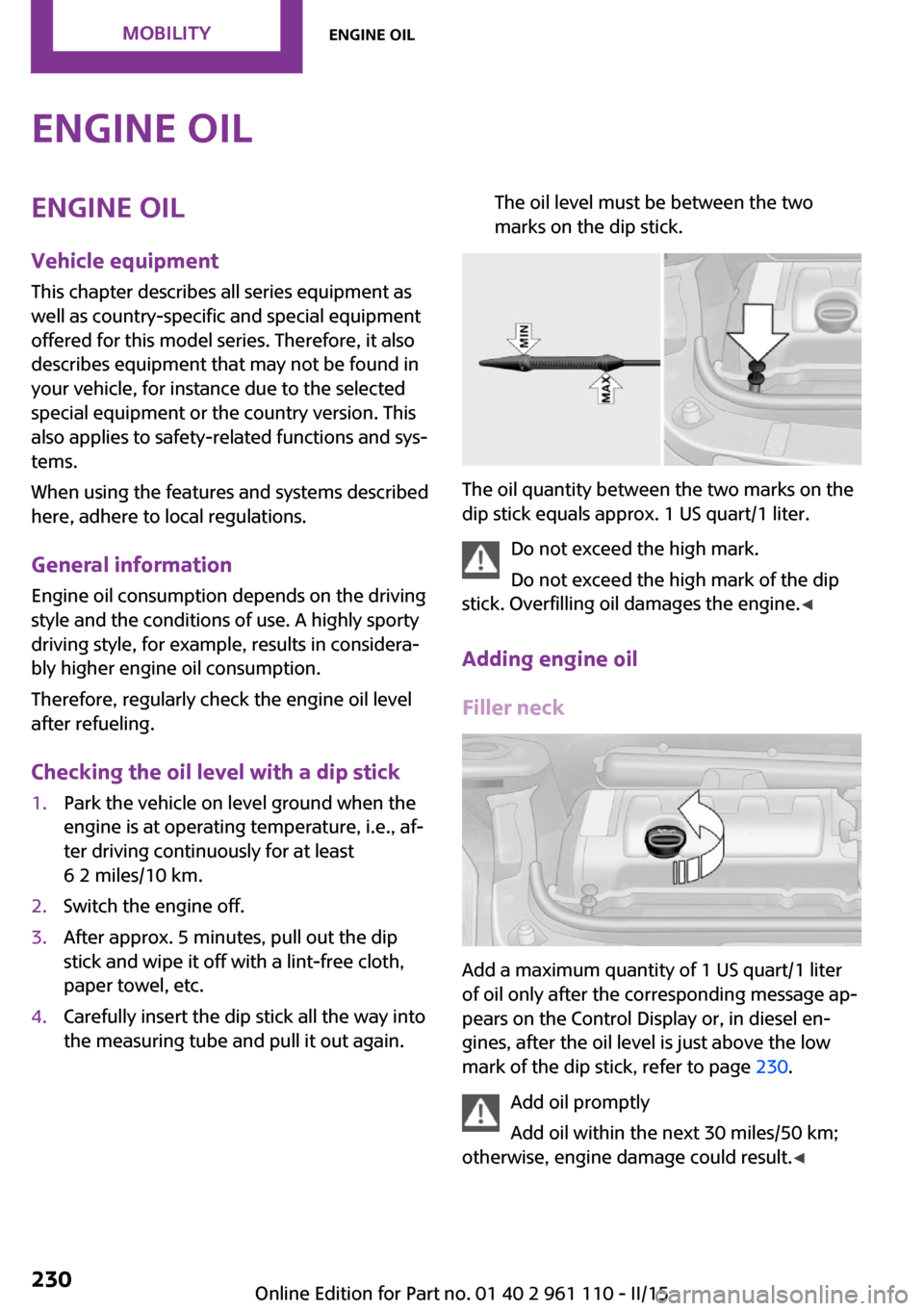

Checking the oil level with a dip stick1.Park the vehicle on level ground when the

engine is at operating temperature, i.e., af‐

ter driving continuously for at least

6 2 miles/10 km.2.Switch the engine off.3.After approx. 5 minutes, pull out the dip

stick and wipe it off with a lint-free cloth,

paper towel, etc.4.Carefully insert the dip stick all the way into

the measuring tube and pull it out again.The oil level must be between the two

marks on the dip stick.

The oil quantity between the two marks on the

dip stick equals approx. 1 US quart/1 liter.

Do not exceed the high mark.

Do not exceed the high mark of the dip

stick. Overfilling oil damages the engine. ◀

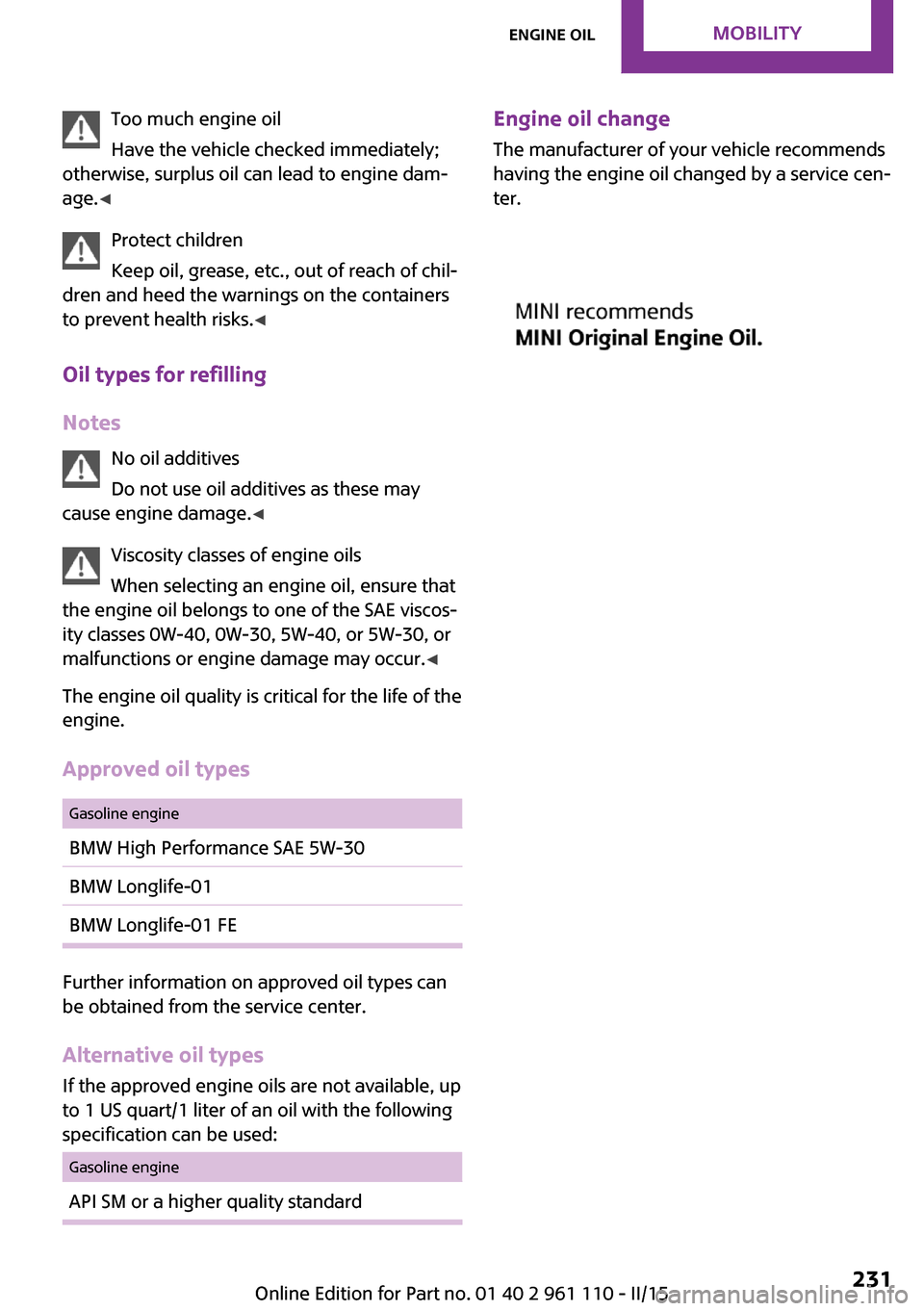

Adding engine oil

Filler neck

Add a maximum quantity of 1 US quart/1 liter

of oil only after the corresponding message ap‐

pears on the Control Display or, in diesel en‐

gines, after the oil level is just above the low

mark of the dip stick, refer to page 230.

Add oil promptly

Add oil within the next 30 miles/50 km;

otherwise, engine damage could result. ◀

Seite 230MOBILITYEngine oil230

Online Edition for Part no. 01 40 2 961 110 - II/15

Page 233 of 283

Too much engine oil

Have the vehicle checked immediately;

otherwise, surplus oil can lead to engine dam‐

age. ◀

Protect children

Keep oil, grease, etc., out of reach of chil‐

dren and heed the warnings on the containers

to prevent health risks. ◀

Oil types for refilling

Notes No oil additives

Do not use oil additives as these may

cause engine damage. ◀

Viscosity classes of engine oils

When selecting an engine oil, ensure that

the engine oil belongs to one of the SAE viscos‐

ity classes 0W-40, 0W-30, 5W-40, or 5W-30, or

malfunctions or engine damage may occur. ◀

The engine oil quality is critical for the life of the

engine.

Approved oil typesGasoline engineBMW High Performance SAE 5W-30BMW Longlife-01BMW Longlife-01 FE

Further information on approved oil types can

be obtained from the service center.

Alternative oil types

If the approved engine oils are not available, up

to 1 US quart/1 liter of an oil with the following

specification can be used:

Gasoline engineAPI SM or a higher quality standardEngine oil change

The manufacturer of your vehicle recommends

having the engine oil changed by a service cen‐

ter.Seite 231Engine oilMOBILITY231

Online Edition for Part no. 01 40 2 961 110 - II/15

Page 234 of 283

CoolantVehicle equipment

This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series. Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

When using the features and systems described

here, adhere to local regulations.

General information Danger of burns from hot engine

Do not open the cooling system while the

engine is hot; otherwise, escaping coolant may

cause burns. ◀

Suitable additives

Only use suitable additives; otherwise,

engine damage may occur. The additives are

harmful to your health. ◀

Coolant consists of water and additives.

Not all commercially available additives are

suitable for your MINI vehicle. Ask your service

center for suitable additives.

Coolant temperature

If the coolant and therefore the engine over‐

heat, a warning lamp lights up. A message ap‐

pears on the Control Display.Coolant level

Checking1.Do not open the hood until the engine has

cooled down.2.Turn the expansion tank cap counterclock‐

wise slightly to allow any accumulated

pressure to escape; then continue turning

to open.3.The coolant level is correct if it is between

the markings. The markings are located on

the side of the coolant reservoir.

Refilling

1.Do not open the hood until the engine has

cooled down.2.Turn the expansion tank cap counterclock‐

wise slightly to allow any accumulated

pressure to escape, then continue turning

to open.3.If the coolant level is low, slowly add cool‐

ant up to the specified level; do not overfill.4.Twist the cap closed.5.Have the cause of the coolant loss elimi‐

nated as soon as possible.

Disposal

Comply with the appropriate environ‐mental protection regulations when dis‐

posing of coolant additives.

Seite 232MOBILITYCoolant232

Online Edition for Part no. 01 40 2 961 110 - II/15

Page 236 of 283

Socket for OBD Onboard

Diagnosis

Socket for Onboard Diagnosis

The socket for Onboard Diagnosis may

only be used by the service center, by work‐

shops that operate according to the specifica‐

tions of the vehicle manufacturer with appro‐

priately trained personnel, and by other

authorized persons. Otherwise, its use may

lead to vehicle malfunctions. ◀

Primary components in the vehicle emissions

can be checked via the OBD socket using a de‐

vice.

Emissions The warning lamps light up. The vehicle

is producing higher emissions. You can

continue your journey, but moderate

your speed and exercise due caution. Have the

vehicle checked as soon as possible.

Under certain circumstances, one of the lamps

flashes or lights up continuously. This indicates

that there is excessive misfiring or a malfunc‐

tion in the engine. If this happens, reduce the

vehicle speed and drive to the next service cen‐

ter promptly. Serious engine misfiring within a

brief period can seriously damage emission

control components, in particular the catalytic

converter. In addition, the mechanical engine

components may become damaged.

If the fuel filler cap is not properly tight‐

ened, the OBD system may conclude

that fuel vapor is escaping; this will cause a dis‐

play to light up. If the filler cap is then tight‐

ened, the display should go out in a few days.Seite 234MOBILITYMaintenance234

Online Edition for Part no. 01 40 2 961 110 - II/15

Page 245 of 283

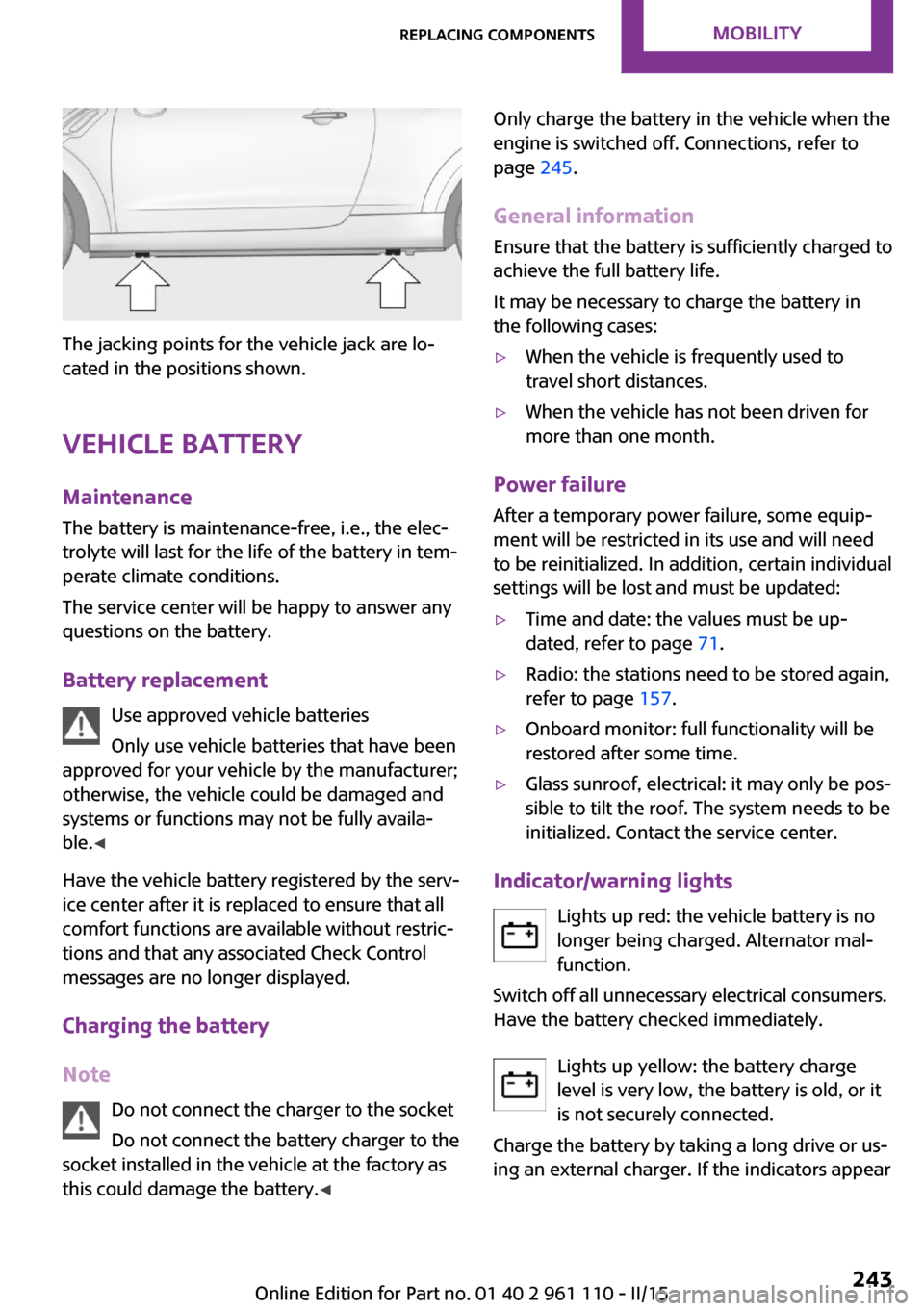

The jacking points for the vehicle jack are lo‐

cated in the positions shown.

Vehicle battery Maintenance

The battery is maintenance-free, i.e., the elec‐

trolyte will last for the life of the battery in tem‐

perate climate conditions.

The service center will be happy to answer any

questions on the battery.

Battery replacement Use approved vehicle batteries

Only use vehicle batteries that have been

approved for your vehicle by the manufacturer;

otherwise, the vehicle could be damaged and

systems or functions may not be fully availa‐

ble. ◀

Have the vehicle battery registered by the serv‐

ice center after it is replaced to ensure that all

comfort functions are available without restric‐

tions and that any associated Check Control

messages are no longer displayed.

Charging the battery

Note Do not connect the charger to the socket

Do not connect the battery charger to the

socket installed in the vehicle at the factory as this could damage the battery. ◀

Only charge the battery in the vehicle when the

engine is switched off. Connections, refer to

page 245.

General information Ensure that the battery is sufficiently charged to

achieve the full battery life.

It may be necessary to charge the battery in

the following cases:▷When the vehicle is frequently used to

travel short distances.▷When the vehicle has not been driven for

more than one month.

Power failure

After a temporary power failure, some equip‐

ment will be restricted in its use and will need

to be reinitialized. In addition, certain individual

settings will be lost and must be updated:

▷Time and date: the values must be up‐

dated, refer to page 71.▷Radio: the stations need to be stored again,

refer to page 157.▷Onboard monitor: full functionality will be

restored after some time.▷Glass sunroof, electrical: it may only be pos‐

sible to tilt the roof. The system needs to be

initialized. Contact the service center.

Indicator/warning lights

Lights up red: the vehicle battery is nolonger being charged. Alternator mal‐function.

Switch off all unnecessary electrical consumers.

Have the battery checked immediately.

Lights up yellow: the battery charge

level is very low, the battery is old, or it

is not securely connected.

Charge the battery by taking a long drive or us‐

ing an external charger. If the indicators appear

Seite 243Replacing componentsMOBILITY243

Online Edition for Part no. 01 40 2 961 110 - II/15

Page 246 of 283

again, have the battery checked as soon as

possible.

Disposing of old batteries Have used batteries disposed of by the

service center after they are replaced or

take them to a recycling center.

Maintain the battery in an upright position for

transport and storage. Secure the battery so

that it does not tip over during transport.

Fuses Replacing fuses

Never attempt to repair a blown fuse and

do not replace a defective fuse with a substi‐

tute of another color or amperage rating; this

could lead to a circuit overload, ultimately re‐

sulting in a fire in the vehicle. ◀

Fuses should be replaced by the service center.

Information on the fuses can be found on the

inside of the covers.

In the engine compartment

Opening the cover

Press the snap lock.

In interior

On the right side of the footwell.

Opening the cover

Push out at the recess.

Seite 244MOBILITYReplacing components244

Online Edition for Part no. 01 40 2 961 110 - II/15

Page 247 of 283

Breakdown assistanceVehicle equipment

This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series. Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

When using the features and systems described

here, adhere to local regulations.

Hazard warning flash‐

ers

The button is located on the speedometer.

Warning triangle

Under the loading edge in the cargo area.

To remove, open the two fasteners.

First aid kit Some of the articles contained in the first aid kit

have a limited service life. Therefore, check the

use-by dates of the contents regularly and re‐

place the items before they expire.

The first aid kit is located in the left side trim on

the cargo area floor or under the loading floor.

Roadside Assistance Service availability

Roadside Assistance can be reached around the

clock in many countries. You can obtain assis‐

tance there in the event of a vehicle break‐

down.

Jump-starting

Notes If the battery is discharged, the engine can be

started using the battery of another vehicle and

two jumper cables. In the same way, you can

help jump-start another vehicle. Only use

jumper cables with fully insulated clamp han‐

dles.

Seite 245Breakdown assistanceMOBILITY245

Online Edition for Part no. 01 40 2 961 110 - II/15

Page 248 of 283

To prevent personal injury or damage to both

vehicles, adhere strictly to the following proce‐

dure.

Do not touch live parts

To avoid the risk of potentially fatal injury,

always avoid all contact with electrical compo‐

nents while the engine is running. ◀

Preparation1.Check whether the battery of the other ve‐

hicle has a voltage of 12 volts and approxi‐

mately the same capacitance in Ah. This in‐

formation can be found on the battery.2.Switch off the engine of the assisting vehi‐

cle.3.Switch off any electronic systems/power

consumers in both vehicles.

Bodywork contact between vehicles

There must not be any contact between

the bodies of the two vehicles, otherwise there

is a danger of shorting. ◀

Connecting jumper cables

Connecting order

Connect the jumper cables in the correct

order; otherwise, there is the danger of injury

from sparking. ◀1.Open the battery cover in the engine com‐

partment to access the positive terminal.2.Unlock the tabs of the positive terminal

cover on the left and right, arrows 1, and

raise the cover, arrow 2.3.Attach one terminal clamp of the positive

jumper cable to the positive terminal of the

battery or to a starting aid terminal of the

vehicle providing assistance.4.Attach the second clamp of the positive

jumper cable to the positive terminal of the

battery of the vehicle to be started.5.Attach one terminal clamp of the negative

jumper cable to the negative terminal of

the battery, or to the corresponding engine

or body ground of the vehicle providing as‐

sistance.6.Attach the second clamp of the negative

jumper cable to the negative terminal ofSeite 246MOBILITYBreakdown assistance246

Online Edition for Part no. 01 40 2 961 110 - II/15