MINI Coupe 2013 Owner's Manual

Manufacturer: MINI, Model Year: 2013, Model line: Coupe, Model: MINI Coupe 2013Pages: 292, PDF Size: 7.02 MB

Page 231 of 292

Changing wheels and

tires

Mounting Information on mounting tires

Have mounting and balancing performed

only by a service center or tire specialist.

If this work is not carried out properly, there is

the danger of subsequent damage and related

safety hazards. ◀

Wheel and tire combination Information on the right wheel and tire combi‐

nation and rim version for your vehicle can be

obtained from the service center.

Incorrect wheel and tire combinations impair

the function of a variety of systems such as ABS

or DSC.

To maintain good handling and vehicle re‐

sponse, use only tires with a single tread con‐

figuration from a single manufacturer.

Following tire damage, have the original wheel

and tire combination remounted on the vehicle

as soon as possible.

Approved wheels and tires

The manufacturer of your vehicle recom‐

mends that you use only wheels and tires that

have been approved for your particular vehicle

model.

For example, despite having the same official

size ratings, variations can lead to body contact

and with it, the risk of severe accidents.

The manufacturer of your vehicle cannot evalu‐

ate non-approved wheels and tires to deter‐

mine if they are suited for use, and therefore

cannot ensure the operating safety of the vehi‐

cle if they are mounted. ◀Wheels with electronics for TPM Tire

Pressure Monitor

When mounting new tires or changing from

summer to winter tires or vice versa, only use

wheels with TPM electronics; otherwise, the

Tire Pressure Monitor will not be able to detect

a flat tire, refer to page 95. Your service center

will be glad to advise you.

Recommended tire brands

For each tire size, the manufacturer of your ve‐

hicle recommends certain tire brands. These

are indicated by the clearly visible marking on

the tire sidewall.

With proper use, these tires meet the highest

standards for safety and handling.

Retreaded tires

The manufacturer of your vehicle does not rec‐

ommend the use of retreaded tires.

Retreaded tires

Possibly substantial variations in the de‐

sign and age of the tire casing structures can

limit service life and have a negative impact on

road safety. ◀

Winter tires The manufacturer of your vehicle recommends

winter tires for winter roads or at temperatures

below +45 ℉/+7 ℃.

Although so-called all-season M+S tires do pro‐

vide better winter traction than summer tires,

they do not provide the same level of perform‐

ance as winter tires.

Seite 231Wheels and tiresMobility231

Online Edition for Part no. 01 40 2 919 017 - II/13

Page 232 of 292

Maximum speed of winter tires

If the maximum speed of the vehicle is higher

than the permissible speed for the winter tires,

then display a corresponding sign in the field of

vision. You can obtain this sign from the tire

specialist or from your service center.

Maximum speed for winter tires

Do not exceed the maximum speed for

the winter tires; otherwise, tire damage and ac‐

cidents can occur. ◀

Run-flat tires When mounting new tires or changing fromsummer to winter tires or vice versa, use run-

flat tires for your own safety. Also, a compact

wheel is not available in case of a flat tire. Your

service center will be glad to advise you.

Rotating wheels between axles

Different wear patterns occur on the front and

rear axles, depending on the individual condi‐

tions of use.

To ensure even wear on the tires, the wheels

can be rotated between the axles. Your service

center will be glad to advise you.

After changing the tires, check the tire inflation

pressure and correct it if necessary.

Storage Store wheels and tires in a cool, dry place with

as little exposure to light as possible.

Always protect tires against all contact with oil,

grease and fuels.

Do not exceed the maximum tire inflation pres‐

sure indicated on the side wall of the tire.Run-flat tires

Label

The symbol identifying run-flat tires is a circle

with the letters RSC on the sidewall.

Run-flat tires are tires with special rims that

support themselves for a limited period of time.

The sidewall reinforcement ensures that the

tire can continue to be used to a limited extent

if it has lost pressure and even if it has become

completely depressurized.

For continued driving in the event of a flat tire,

refer to page 94.

Correcting a flat tire Safety measures in case of a breakdown

▷Park the vehicle as far as possible

from passing traffic and on solid

ground. Switch on the hazard warn‐

ing system.▷Let the steering wheel lock engage with the

wheels in the straight-ahead position, set

the handbrake, and engage first gear or re‐

verse, or engage selector lever position P.▷Have all vehicle occupants get out of the

vehicle and ensure that they remain out‐

side the immediate area in a safe place,

such as behind a guardrail.Seite 232MobilityWheels and tires232

Online Edition for Part no. 01 40 2 919 017 - II/13

Page 233 of 292

▷If a warning triangle or portable hazard

warning lamp is required, set it up on the

roadside at an appropriate distance from

the rear of the vehicle. Comply with all

safety guidelines and regulations. ◀

The procedure to correct a flat tire depends on

the equipment in the vehicle:

▷Run-flat tires, refer to page 232.▷MINI Mobility System, refer to page 233.▷Wheel change with a compact wheel, refer

to page 249.

MINI Mobility System

Notes

▷Follow the instructions on using the Mobi‐

lity System found on the compressor and

sealant bottle.▷Use of the Mobility System may be ineffec‐

tive if tire damage is greater than approx.

1/8 in/4 mm in size.▷Contact the nearest service center if the tire

cannot be made drivable.▷If possible, do not remove foreign bodies

that have penetrated the tire.▷Pull the speed limit sticker off the sealant

bottle and apply it to the steering wheel.

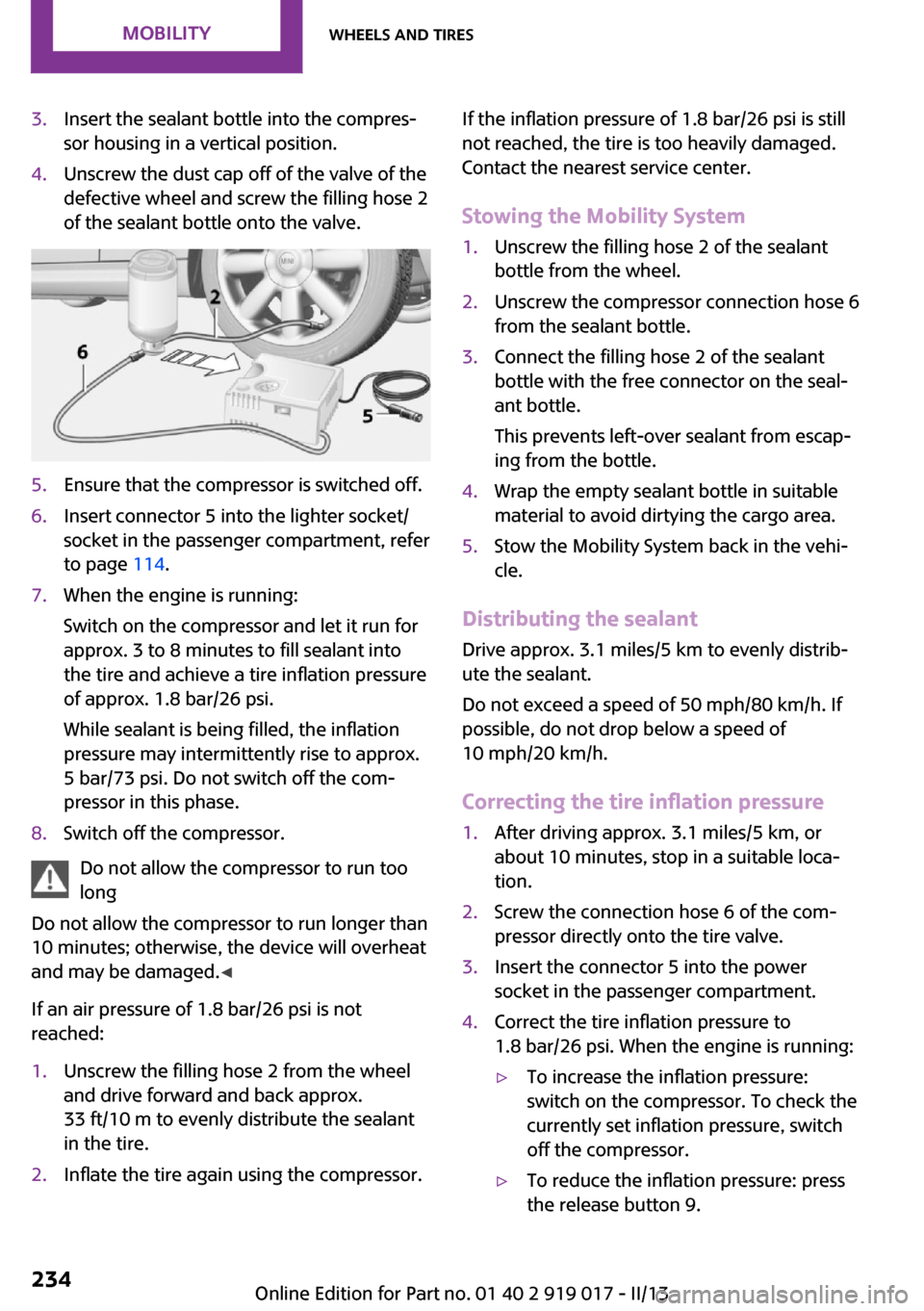

Sealant and compressor

1Sealant bottle and speed limit sticker2Filling hose

Note the use-by date on the sealant bottle.3Holder for the sealant bottle4Compressor5Connector and cable for the lighter socket/

socket in passenger compartment 114.6Connection hose for connecting the com‐

pressor and sealant bottle or the compres‐

sor and wheel7On/off switch8Pressure gauge for displaying the tire infla‐

tion pressure9Release button for reducing the tire infla‐

tion pressure

The connector, cable, and connecting hose are

stowed in the compressor housing.

Using the Mobility System

To repair a flat tire with the Mobility System,

proceed as follows:

▷Filling the tire with sealant▷Distributing the sealant▷Correcting the tire inflation pressure

Filling the tire with sealant

Adhere to the specified sequence

Adhere to the specified sequence of the

steps; otherwise, sealant may escape under

high pressure. ◀

1.Shake the sealant bottle.2.Pull the connection hose 6 fully out of the

compressor housing and screw it onto the

sealant bottle connection. Ensure that the

connection hose is not kinked.Seite 233Wheels and tiresMobility233

Online Edition for Part no. 01 40 2 919 017 - II/13

Page 234 of 292

3.Insert the sealant bottle into the compres‐

sor housing in a vertical position.4.Unscrew the dust cap off of the valve of the

defective wheel and screw the filling hose 2

of the sealant bottle onto the valve.5.Ensure that the compressor is switched off.6.Insert connector 5 into the lighter socket/

socket in the passenger compartment, refer

to page 114.7.When the engine is running:

Switch on the compressor and let it run for

approx. 3 to 8 minutes to fill sealant into

the tire and achieve a tire inflation pressure

of approx. 1.8 bar/26 psi.

While sealant is being filled, the inflation

pressure may intermittently rise to approx.

5 bar/73 psi. Do not switch off the com‐

pressor in this phase.8.Switch off the compressor.

Do not allow the compressor to run too

long

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged. ◀

If an air pressure of 1.8 bar/26 psi is not

reached:

1.Unscrew the filling hose 2 from the wheel

and drive forward and back approx.

33 ft/10 m to evenly distribute the sealant

in the tire.2.Inflate the tire again using the compressor.If the inflation pressure of 1.8 bar/26 psi is still

not reached, the tire is too heavily damaged.

Contact the nearest service center.

Stowing the Mobility System1.Unscrew the filling hose 2 of the sealant

bottle from the wheel.2.Unscrew the compressor connection hose 6

from the sealant bottle.3.Connect the filling hose 2 of the sealant

bottle with the free connector on the seal‐

ant bottle.

This prevents left-over sealant from escap‐

ing from the bottle.4.Wrap the empty sealant bottle in suitable

material to avoid dirtying the cargo area.5.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Drive approx. 3.1 miles/5 km to evenly distrib‐

ute the sealant.

Do not exceed a speed of 50 mph/80 km/h. If

possible, do not drop below a speed of

10 mph/20 km/h.

Correcting the tire inflation pressure

1.After driving approx. 3.1 miles/5 km, or

about 10 minutes, stop in a suitable loca‐

tion.2.Screw the connection hose 6 of the com‐

pressor directly onto the tire valve.3.Insert the connector 5 into the power

socket in the passenger compartment.4.Correct the tire inflation pressure to

1.8 bar/26 psi. When the engine is running:▷To increase the inflation pressure:

switch on the compressor. To check the

currently set inflation pressure, switch

off the compressor.▷To reduce the inflation pressure: press

the release button 9.Seite 234MobilityWheels and tires234

Online Edition for Part no. 01 40 2 919 017 - II/13

Page 235 of 292

Do not allow the compressor to run too

long

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged. ◀

If the inflation pressure is not maintained, take

the vehicle on another drive, distributing the

sealant, refer to page 234. Then repeat steps

1 to 4 once.

If the inflation pressure of 1.8 bar/26 psi is still

not reached, the tire is too heavily damaged.

Contact the nearest service center.

Continuing the trip Note the maximum speed

Do not exceed the maximum speed of

50 mph/80 km/h; otherwise, accidents can oc‐

cur. ◀

Replace the defective tire as soon as possible

and have the wheel balanced.

Have the Mobility System refilled.

Snow chains

Only certain fine-link snow chains have been

tested by MINI, classified as safe for use, and

recommended. Consult your service center for more information.

Use only in pairs on the front wheels, equipped

with tires of the following size:▷175/65 R 15 M+S▷175/60 R 16 M+S

John Cooper Works:

▷185/50 R 17 86 H M+S XL RSC

Observe the manufacturer's instructions when

mounting snow chains. Do not exceed a speed

of 30 mph or 50 km/h when using snow chains.

Do not initialize the Flat Tire Monitor if snow

chains are mounted; otherwise, the instrument

might issue an incorrect reading. When driving

with snow chains, it may be useful to tempora‐

rily deactivate DSC or activate DTC, refer to

page 101.Seite 235Wheels and tiresMobility235

Online Edition for Part no. 01 40 2 919 017 - II/13

Page 236 of 292

Engine compartmentVehicle equipment

This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series.Therefore, it alsodescribes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

Important features in the engine compartment

1Vehicle identification number2Battery, under the cover 2523Dip stick for engine oil 2384Engine oil filler neck 2385Coolant expansion tank 2406Reservoir for washer fluid for the headlamp

and window washer system 697Engine compartment fuse box 253Hood

Notes Working in the engine compartment

Never attempt to perform any service or

repair operations on your vehicle without the

necessary professional technical training.If you are unfamiliar with the statutory guide‐

lines, have any work on the vehicle performed

only by a service center.

If this work is not carried out properly, there is

the danger of subsequent damage and related

safety hazards. ◀Seite 236MobilityEngine compartment236

Online Edition for Part no. 01 40 2 919 017 - II/13

Page 237 of 292

To avoid damage, make sure that the

wiper arms are resting against the wind‐

shield before you open the engine compart‐

ment. Do not open the engine hood before the

engine has cooled down; otherwise, injuries

may result. ◀

Unlocking and opening the hood1.Pull the lever.2.Lift the hood all the way.3.Press the release handle and open the

hood.

Danger of injury when the hood is open

There is a danger of injury from protrud‐

ing parts when the hood is open. ◀

Closing the hood

Close the hood from a height of ap‐

prox. 16 in/40 cm with momentum. It must be

clearly heard to engage.

Hood open when driving

If you see any signs that the hood is not

completely closed while driving, pull over im‐

mediately and close it securely. ◀

Danger of pinching

Make sure that the closing path of the

hood is clear; otherwise, injuries may result. ◀

Seite 237Engine compartmentMobility237

Online Edition for Part no. 01 40 2 919 017 - II/13

Page 238 of 292

Engine oilVehicle equipment

This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series.Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

Engine oil General information

Engine oil consumption depends on the driving

style and the conditions of use. A highly sporty

driving style, for example, results in considera‐

bly higher engine oil consumption.

Therefore, regularly check the engine oil level

after refueling.

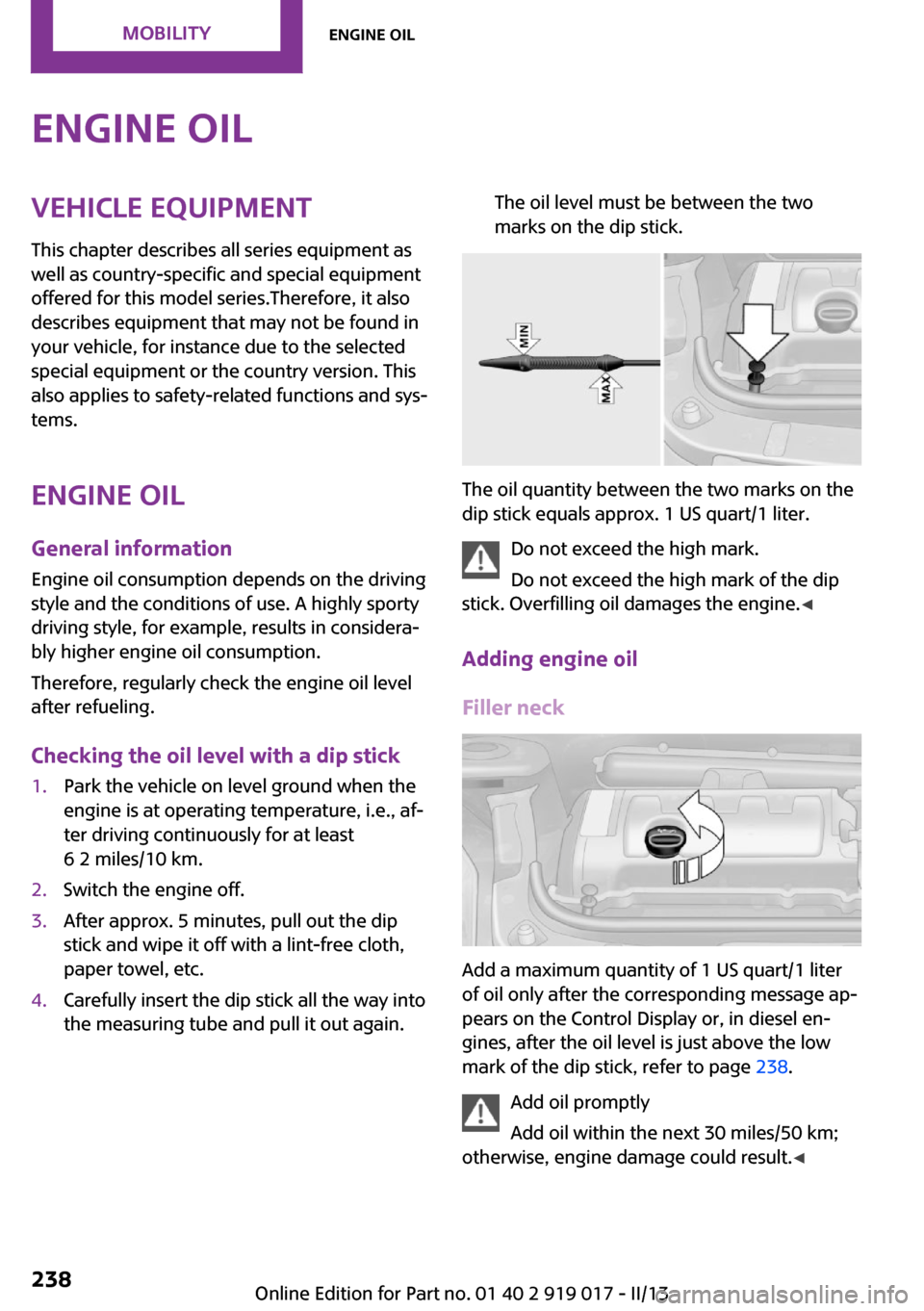

Checking the oil level with a dip stick1.Park the vehicle on level ground when the

engine is at operating temperature, i.e., af‐

ter driving continuously for at least

6 2 miles/10 km.2.Switch the engine off.3.After approx. 5 minutes, pull out the dip

stick and wipe it off with a lint-free cloth,

paper towel, etc.4.Carefully insert the dip stick all the way into

the measuring tube and pull it out again.The oil level must be between the two

marks on the dip stick.

The oil quantity between the two marks on the

dip stick equals approx. 1 US quart/1 liter.

Do not exceed the high mark.

Do not exceed the high mark of the dip

stick. Overfilling oil damages the engine. ◀

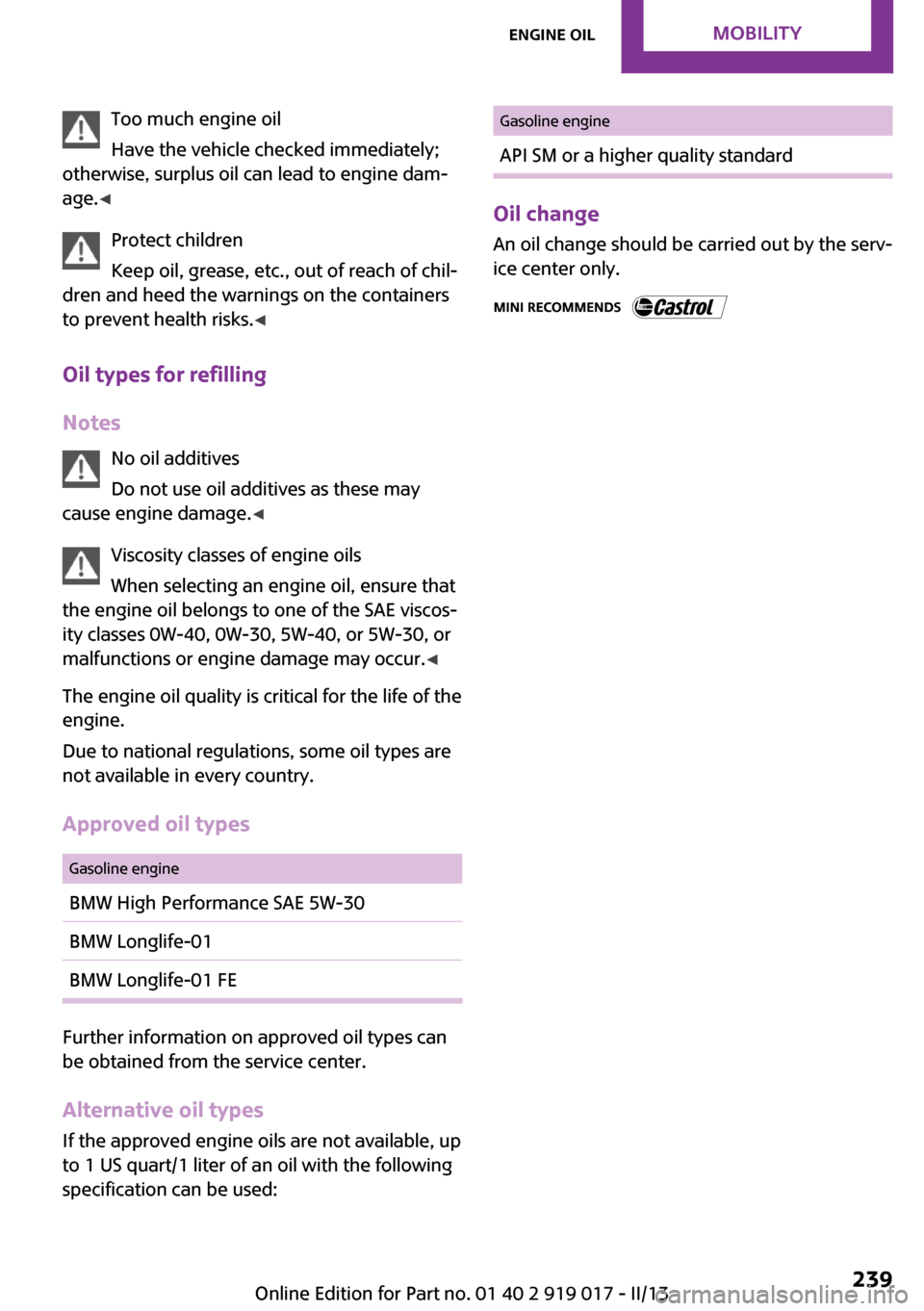

Adding engine oil

Filler neck

Add a maximum quantity of 1 US quart/1 liter

of oil only after the corresponding message ap‐

pears on the Control Display or, in diesel en‐

gines, after the oil level is just above the low

mark of the dip stick, refer to page 238.

Add oil promptly

Add oil within the next 30 miles/50 km;

otherwise, engine damage could result. ◀

Seite 238MobilityEngine oil238

Online Edition for Part no. 01 40 2 919 017 - II/13

Page 239 of 292

Too much engine oil

Have the vehicle checked immediately;

otherwise, surplus oil can lead to engine dam‐

age. ◀

Protect children

Keep oil, grease, etc., out of reach of chil‐

dren and heed the warnings on the containers

to prevent health risks. ◀

Oil types for refilling

Notes No oil additives

Do not use oil additives as these may

cause engine damage. ◀

Viscosity classes of engine oils

When selecting an engine oil, ensure that

the engine oil belongs to one of the SAE viscos‐

ity classes 0W-40, 0W-30, 5W-40, or 5W-30, or

malfunctions or engine damage may occur. ◀

The engine oil quality is critical for the life of the

engine.

Due to national regulations, some oil types are

not available in every country.

Approved oil typesGasoline engineBMW High Performance SAE 5W-30BMW Longlife-01BMW Longlife-01 FE

Further information on approved oil types can

be obtained from the service center.

Alternative oil types

If the approved engine oils are not available, up

to 1 US quart/1 liter of an oil with the following

specification can be used:

Gasoline engineAPI SM or a higher quality standard

Oil change

An oil change should be carried out by the serv‐

ice center only.

Seite 239Engine oilMobility239

Online Edition for Part no. 01 40 2 919 017 - II/13

Page 240 of 292

CoolantVehicle equipment

This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series.Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

General information Danger of burns from hot engine

Do not open the cooling system while the

engine is hot; otherwise, escaping coolant may

cause burns. ◀

Suitable additives

Only use suitable additives; otherwise,

engine damage may occur. The additives are

harmful to your health. ◀

Coolant consists of water and additives.

Not all commercially available additives are

suitable for your MINI vehicle. Ask your service

center for suitable additives.

Coolant temperature

If the coolant and therefore the engine over‐

heat, a warning lamp lights up. A message ap‐

pears on the Control Display.

Coolant level Checking1.Do not open the hood until the engine has

cooled down.2.Turn the expansion tank cap counterclock‐

wise slightly to allow any accumulated

pressure to escape; then continue turning

to open.3.The coolant level is correct if it is between

the markings. The markings are located on

the side of the coolant reservoir.

Refilling

1.Do not open the hood until the engine has

cooled down.2.Turn the expansion tank cap counterclock‐

wise slightly to allow any accumulated

pressure to escape, then continue turning

to open.3.If the coolant level is low, slowly add cool‐

ant up to the specified level; do not overfill.4.Twist the cap closed.5.Have the cause of the coolant loss elimi‐

nated as soon as possible.

Disposal

Comply with the appropriate environ‐mental protection regulations when dis‐

posing of coolant additives.

Seite 240MobilityCoolant240

Online Edition for Part no. 01 40 2 919 017 - II/13