engine MINI COUPE ROADSTER CONVERTIBLE 2012 Workshop Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2012, Model line: COUPE ROADSTER CONVERTIBLE, Model: MINI COUPE ROADSTER CONVERTIBLE 2012Pages: 283, PDF Size: 9.38 MB

Page 227 of 283

MOBILITYMaintenance

226

Socket for On-Board

Diagnosis OBD

The primary components that make up the

emissions can be checked by a device via the

OBD socket.

Emissions

The warning lamps come on. The vehicle

is producing higher emissions. You can

continue your journey, but moderate

your speed and exercise due caution.

Have the car checked as soon as possible.

Under certain circumstances, one of the lamps

will flash or light up cont inuously. This indicates

excessive misfiring or a malfunction in the

engine. If this happens, reduce your speed and

visit the nearest MINI dealer as soon as possible.

Severe misfiring can quickly lead to serious

damage of emissions-related components,

especially the catalytic converter. In addition,

mechanical engine components can become

damaged.

If the fuel cap is not properly tightened,

the OBD system may conclude that fuel

vapors are escaping, causing an indica-

tor to light up. If the fuel cap is then tightened,

the indicator should go out within a few days.

Data memory

Your vehicle displays data about the operation,

malfunctions, and user settings. These data are

stored in the vehicle and can be partly stored in

the remote control; the data can be read by suit-

able devices, in particul ar at your MINI dealer.

The data read out are used for supporting the

service processes and repair or for optimization

and development of vehicle functions.

00320051004F004C00510048000300280047004C0057004C005200510003

Page 229 of 283

MOBILITYCare

228

Automatic transmission

Before driving into the car wash, make sure that

the vehicle can roll:

1.Place the remote control, even with Comfort

Access, in the ignition lock.

2. Move the selector lever to position N.

3. Release the parking brake.

4. Switch off the engine.

5. Insert the remote control in the ignition lock

so that the vehicle can roll.

Steam jets/high-pressure washers

When using steam jets or high-pressure

washers, make sure that you maintain

sufficient distance from the vehicle and do not

exceed a maximum temperature of 140 7/

60 6 .

If the distance is too close, the pressure too high,

or the temperature too high, parts of the vehicle

can be damaged, or water can penetrate.

Observe the operating instructions for high-

pressure washers. <

Do not spray sensors, such as the Park Dis-

tance Control, with high-pressure washers

for a long time or at a distance of less than 1 ft/

30 cm. <

Manual washing

Use a great deal of water and, if necessary, car

shampoo when washing your car by hand. Clean

the vehicle with a sponge or a washing brush

applying a slight amount of pressure.

Before cleaning the windshield, deacti-

vate the rain sensor or turn off the ignition

to prevent unintentional wiping. <

Observe local regulations regarding wash-

ing vehicles by hand. <

Headlamps

Do not wipe dry and do not use abrasive or

corrosive cleaning agen ts. Remove dirt and

contamination, such as in sects, by soaking with

shampoo and then washing with plenty of

water.

Do not remove accumulated ice and snow with

an ice scraper; use window deicers instead.

Windows

Clean the outside and inside of the windows and

mirrors with a window cleaner.

Do not clean the mirrors with cleaners

containing quartz. <

Wiper blades

Clean with soapy water and change regularly to

prevent the formation of streaks.

Wax, preservatives and dirt on the win-

dows cause streaks wh en the windshield

wipers are on, and can cause premature wear

of the wiper blades and interfere with the rain

sensor. <

Care of the convertible top

The appearance and service life of the convert-

ible top largely depends on its proper care and

operation.

Please follow these instructions:

>Never attempt to fold and stow the convert-

ible top in the convertible compartment

when the top is wet or frozen. Otherwise,

water stains, mildew, and chafe marks may

occur.

> If water spots occur on the inside headliner

despite precautions, remove them using a

microfiber cloth and interior cleaner.

> If the vehicle is parked in an enclosed area

for a longer period of time, make sure that

there is sufficient ventilation.

> Remove any bird droppings immediately,

since they have corrosive properties which

will corrode the conver tible top and damage

the rubber seals.

00320051004F004C00510048000300280047004C0057004C005200510003

Page 234 of 283

Replacing componentsMOBILITY

233

Light-emitting diodes LEDs

Light-emitting diodes installed behind translu-

cent lenses serve as the light sources for many of

the controls and displays in your vehicle. These

light-emitting diodes are related to conven-

tional laser diodes, and legislation defines them

as Class 1 light-emitting diodes.

Do not remove the covers or expose the

eyes directly to the unfiltered light source

for several hours; otherw ise, this could cause

irritation of the retina. <

Headlamp glass lens

In cool or humid weather, condensation may

occur on the interiors of the headlamps. The

condensation disappears a short time after the

light is switched on. The headlamps do not need

to be changed.

Do not remove the condensation from head-

lamps, despite driving with lights on, and if

condensation increases, e.g., because of water

droplets, have this checked by your MINI dealer.

Xenon lamps

The service life of these bulbs is very long and

the probability of failure very low, provided that

they are not switched on and off an excessive

number of times. If a xenon lamp fails neverthe-

less, switch on the fog lamps and continue the

journey with great care, provided that local leg-

islation does not prohibit this.

Work on the xenon lighting system,

including lamp replacem ent, is only to be

carried out only by your MINI dealer. Due to high

voltage, there is a risk of fatal injury if work on

the xenon lamps is carried out improperly. <

Halogen low beams and high beams

H13 bulb, 60/5 watts

The H13 bulb is pressurized. Therefore,

wear safety glasses an d protective gloves.

Otherwise, there is a risk of injury if the bulb is

damaged. < Be careful when inst

alling the cover;

otherwise, leaks could occur and cause

damage to the headlamp system. <

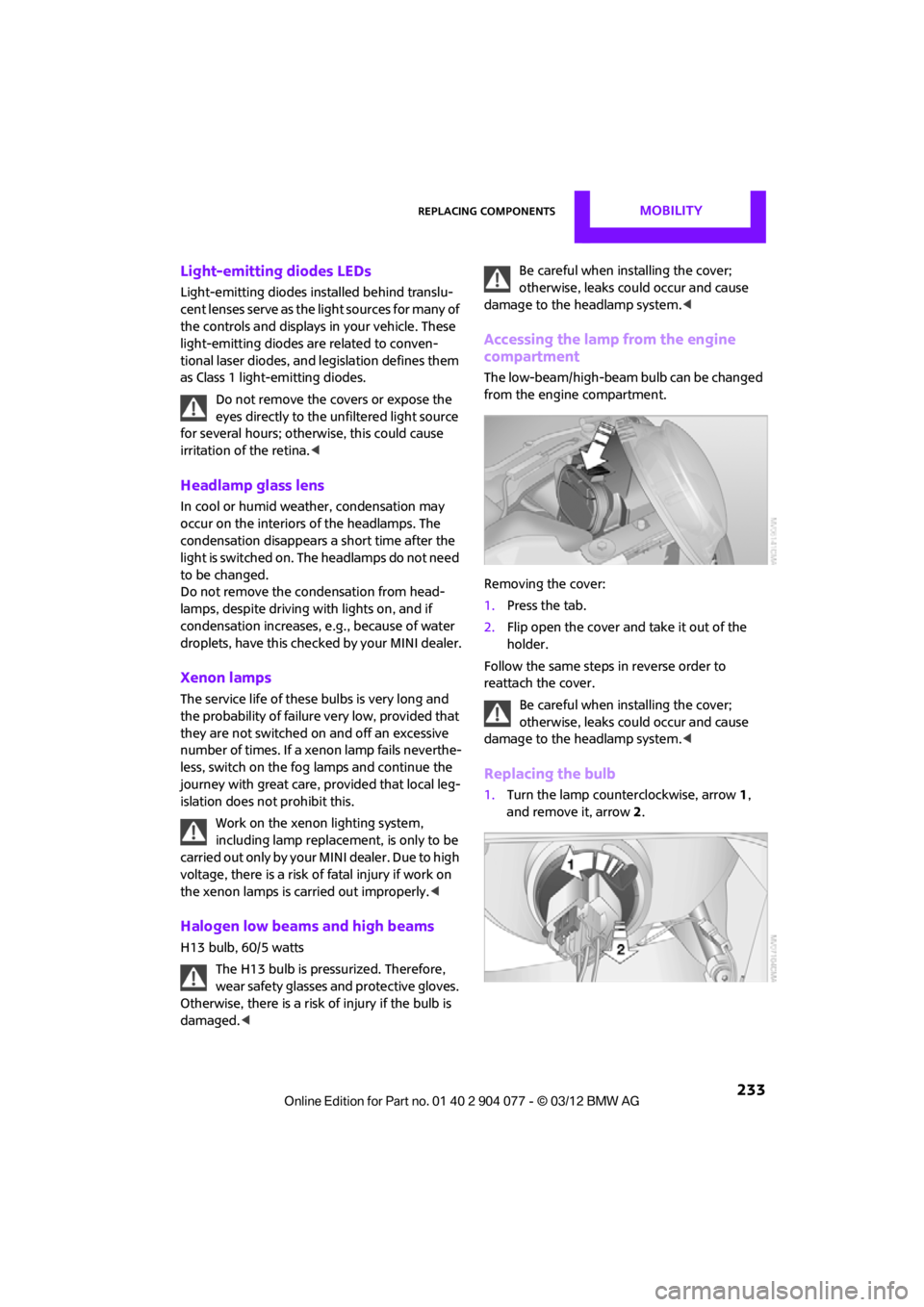

Accessing the lamp from the engine

compartment

The low-beam/high-beam bulb can be changed

from the engine compartment.

Removing the cover:

1.Press the tab.

2. Flip open the cover and take it out of the

holder.

Follow the same steps in reverse order to

reattach the cover.

Be careful when inst alling the cover;

otherwise, leaks could occur and cause

damage to the headlamp system. <

Replacing the bulb

1.Turn the lamp counterclockwise, arrow 1,

and remove it, arrow 2.

00320051004F004C00510048000300280047004C0057004C005200510003

Page 239 of 283

MOBILITYReplacing components

238

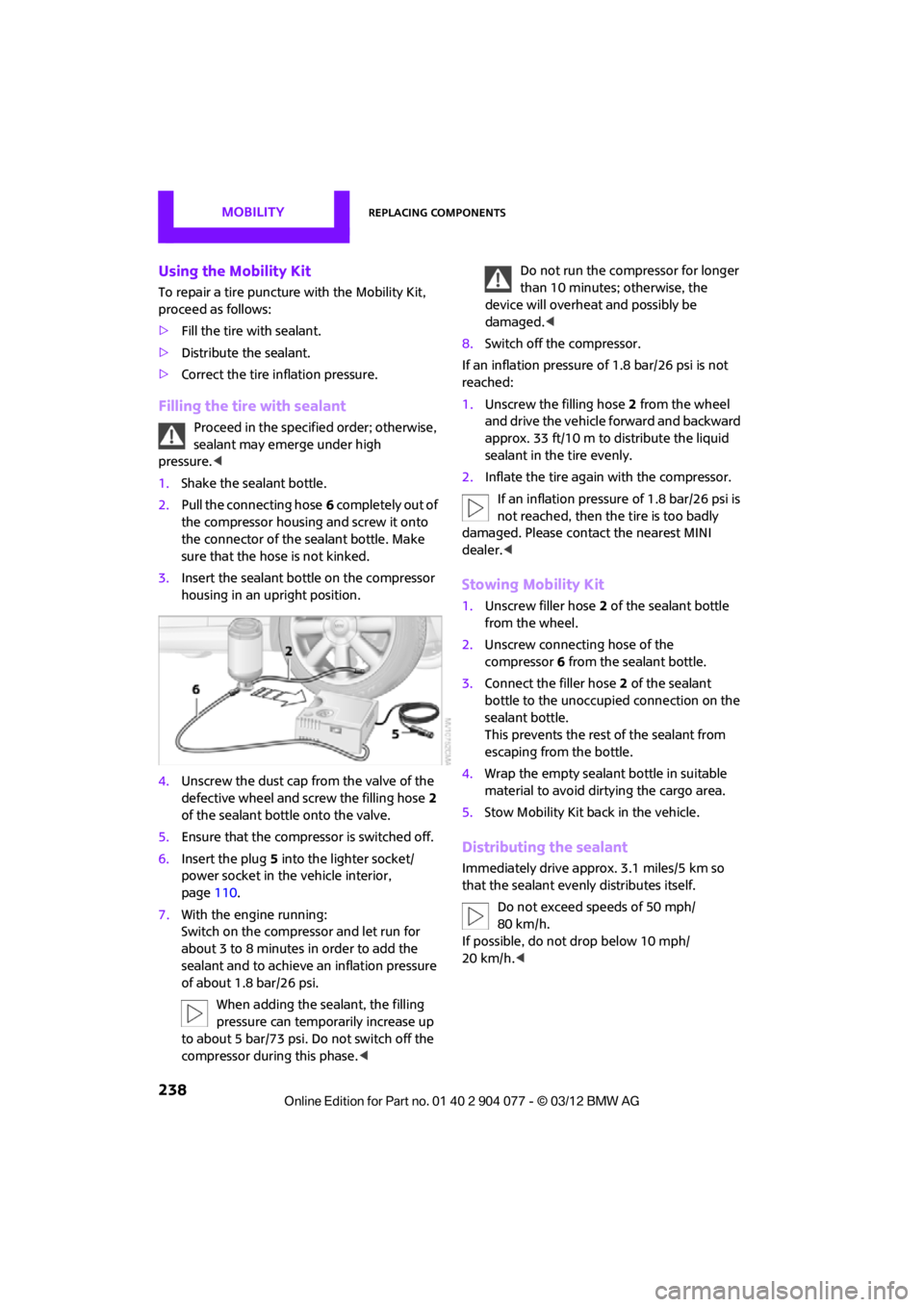

Using the Mobility Kit

To repair a tire puncture with the Mobility Kit,

proceed as follows:

>Fill the tire with sealant.

> Distribute the sealant.

> Correct the tire inflation pressure.

Filling the tire with sealant

Proceed in the specified order; otherwise,

sealant may emerge under high

pressure. <

1. Shake the sealant bottle.

2. Pull the connecting hose 6 completely out of

the compressor housing and screw it onto

the connector of the sealant bottle. Make

sure that the hose is not kinked.

3. Insert the sealant bo ttle on the compressor

housing in an upright position.

4. Unscrew the dust cap from the valve of the

defective wheel and screw the filling hose 2

of the sealant bottle onto the valve.

5. Ensure that the compressor is switched off.

6. Insert the plug 5 into the lighter socket/

power socket in the vehicle interior,

page 110.

7. With the engine running:

Switch on the compressor and let run for

about 3 to 8 minutes in order to add the

sealant and to achieve an inflation pressure

of about 1.8 bar/26 psi.

When adding the sealant, the filling

pressure can temporarily increase up

to about 5 bar/73 psi. Do not switch off the

compressor during this phase.

device will overheat and possibly be

damaged. <

8. Switch off the compressor.

If an inflation pressure of 1.8 bar/26 psi is not

reached:

1. Unscrew the filling hose 2 from the wheel

and drive the vehicle forward and backward

approx. 33 ft/10 m to distribute the liquid

sealant in the tire evenly.

2. Inflate the tire again with the compressor.

If an inflation pressure of 1.8 bar/26 psi is

not reached, then the tire is too badly

damaged. Please contact the nearest MINI

dealer. <

Stowing Mobility Kit

1.Unscrew filler hose 2 of the sealant bottle

from the wheel.

2. Unscrew connecting hose of the

compressor 6 from the sealant bottle.

3. Connect the filler hose 2 of the sealant

bottle to the unoccupied connection on the

sealant bottle.

This prevents the rest of the sealant from

escaping from the bottle.

4. Wrap the empty sealant bottle in suitable

material to avoid dirtying the cargo area.

5. Stow Mobility Kit back in the vehicle.

Distributing the sealant

Immediately drive appr ox. 3.1 miles/5 km so

that the sealant evenly distributes itself.

Do not exceed speeds of 50 mph/

80 km/h.

If possible, do not drop below 10 mph/

20 km/h. <

00320051004F004C00510048000300280047004C0057004C005200510003

Page 240 of 283

Replacing componentsMOBILITY

239

Adjusting the tire pressure

1.After driving approx. 3.1 miles/5 km or

10 minutes, stop at a suitable location.

2. Screw the connection hose 6 of the

compressor directly onto the tire valve.

3. Insert the plug 5 into the power socket in

the vehicle interior.

4. Adjust tire pressure to 1.8 bar/26 psi. With

the engine running:

> To increase the inflatio n pressure: switch on

the compressor. To check the current infla-

tion pressure, switch off the compressor.

Do not run the compressor for longer

than 10 minutes; otherwise, the

device will overheat and possibly be

damaged. <

> To decrease the inflation pressure: press the

release button 9.

If the tire cannot ma intain the inflation

pressure, drive the vehicle again, refer to

Distributing the sealan t. Then repeat steps

1to4.

If an inflation pressure of 1.8 bar/26 psi still

cannot be reached, then the tire is too heavily

damaged. Contact your nearest MINI dealer. <

Driving on

Do not exceed the permitted maximum

speed of 50 mph/80 km/h; doing so may

result in an accident. <

Replace the defective tire as soon as possible

and have the new wheel/tire assembly

balanced.

Have the Mobility Kit refilled.

Changing wheels

Run-flat tires

Tire change for run-flat tires:

> Prepare for tire change, page 240

> Jack up vehicle, page 241

> Tighten lug bolts, page 241

Space-saver spare tire

Tire change with space-saver spare tire:

>Remove the space-saver spare tire,

page 239

> Prepare for tire change, page 240

> Jack up vehicle, page 241

> Mount space-saver spare tire, page 241

> Tighten lug bolts, page 241

> Drive with space-saver spare tire, page 240

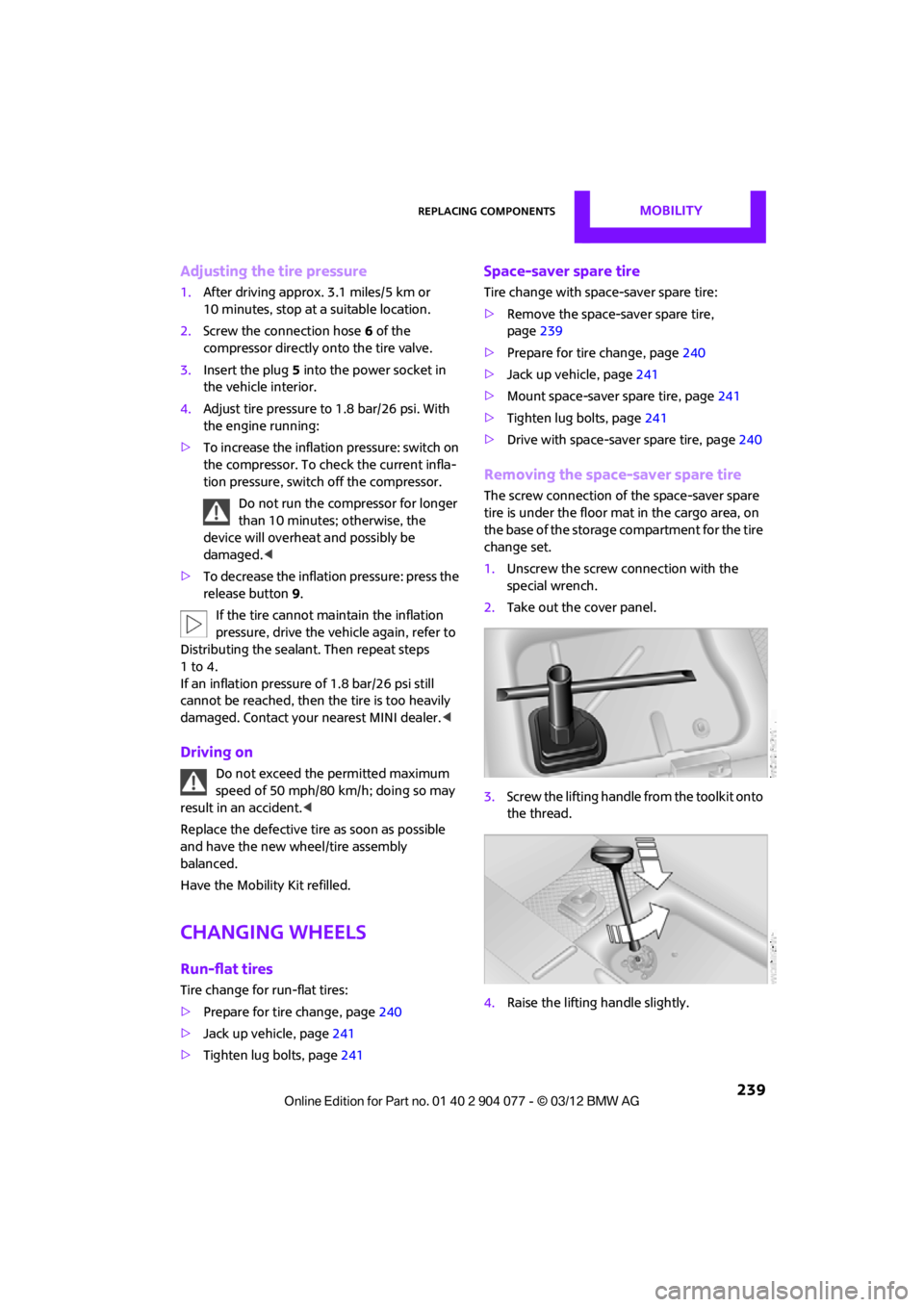

Removing the space-saver spare tire

The screw connection of the space-saver spare

tire is under the floor mat in the cargo area, on

the base of the storage compartment for the tire

change set.

1. Unscrew the screw connection with the

special wrench.

2. Take out the cover panel.

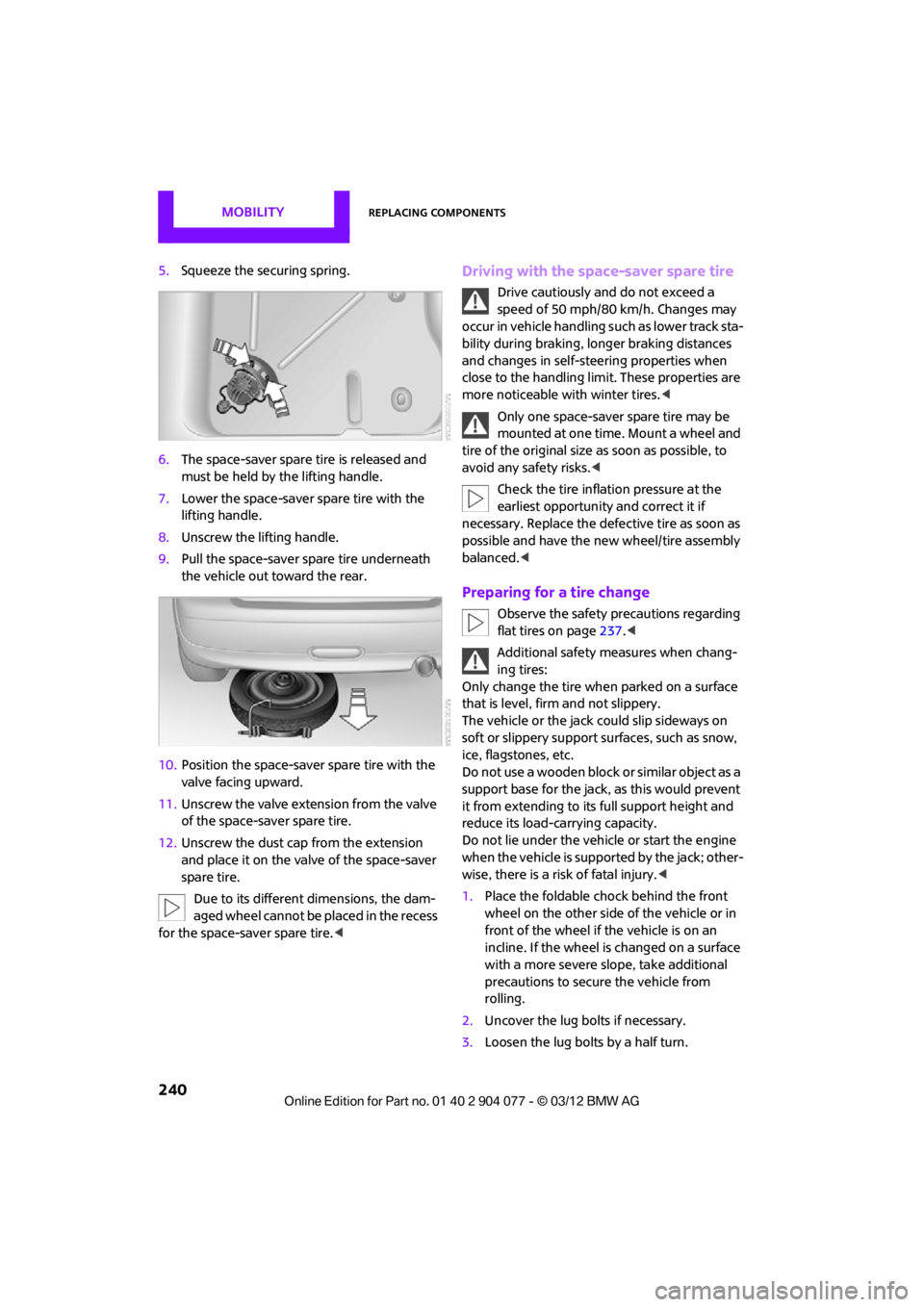

3. Screw the lifting handle from the toolkit onto

the thread.

4. Raise the lifting handle slightly.

00320051004F004C00510048000300280047004C0057004C005200510003

Page 241 of 283

MOBILITYReplacing components

240

5.Squeeze the securing spring.

6. The space-saver spare tire is released and

must be held by the lifting handle.

7. Lower the space-saver spare tire with the

lifting handle.

8. Unscrew the lifting handle.

9. Pull the space-saver spare tire underneath

the vehicle out toward the rear.

10. Position the space-save r spare tire with the

valve facing upward.

11. Unscrew the valve extension from the valve

of the space-saver spare tire.

12. Unscrew the dust cap from the extension

and place it on the valve of the space-saver

spare tire.

Due to its different dimensions, the dam-

aged wheel cannot be placed in the recess

for the space-saver spare tire.

speed of 50 mph/80 km/h. Changes may

occur in vehicle handling such as lower track sta-

bility during braking, longer braking distances

and changes in self-steering properties when

close to the handling limit. These properties are

more noticeable with winter tires. <

Only one space-saver spare tire may be

mounted at one time. Mount a wheel and

tire of the original size as soon as possible, to

avoid any safety risks. <

Check the tire inflation pressure at the

earliest opportunity and correct it if

necessary. Replace the defe ctive tire as soon as

possible and have the ne w wheel/tire assembly

balanced. <

Preparing for a tire change

Observe the safety precautions regarding

flat tires on page 237.<

Additional safety measures when chang-

ing tires:

Only change the tire wh en parked on a surface

that is level, firm and not slippery.

The vehicle or the jack could slip sideways on

soft or slippery support surfaces, such as snow,

ice, flagstones, etc.

Do not use a wooden block or similar object as a

support base for the jack, as this would prevent

it from extending to its full support height and

reduce its load-carrying capacity.

Do not lie under the vehicle or start the engine

when the vehicle is supported by the jack; other-

wise, there is a risk of fatal injury. <

1. Place the foldable chock behind the front

wheel on the other side of the vehicle or in

front of the wheel if the vehicle is on an

incline. If the wheel is changed on a surface

with a more severe sl ope, take additional

precautions to secure the vehicle from

rolling.

2. Uncover the lug bolts if necessary.

3. Loosen the lug bolts by a half turn.

00320051004F004C00510048000300280047004C0057004C005200510003

Page 243 of 283

MOBILITYReplacing components

242

Starting-aid terminals

Only charge the battery in the vehicle when the

engine is off. Connections, refer to Jump-start-

ing on page 243.

Charger

The use of a charger ensures that the battery has

a sufficient charge even when it is used for fre-

quent short-distance driv es, for example. Charg-

ers that have been developed especially for the

vehicle and adapted to the vehicle electrical

system are available at your MINI dealer.

Disposal

After replacing old batteries, return the

used batteries to your MINI dealer or to a

recycling center. Maintain the battery in an

upright position for transport and storage.

Always secure the battery against tipping over

during transport. <

Power failure

After a temporary power loss, some equipment

may not be fully functional and may require

initialization. Individual se ttings are also lost and

must be reprogrammed:

> Time and date

These values must be updated, page 76.

> Onboard monitor

Operability must be waited for, page124.

Indicator and warning lamps

Lights up in red:

Battery is no longer being charged.

Alternator malfunction.

Switch off all unnecessary electrical consumers.

Have the battery checked without delay. Lights up in yellow:

Battery charge level very low, battery

aged, or battery not securely con-

nected.

Charge it by taking a long er drive or by using an

external charger. If the display appears again,

have the battery checked as soon as possible.

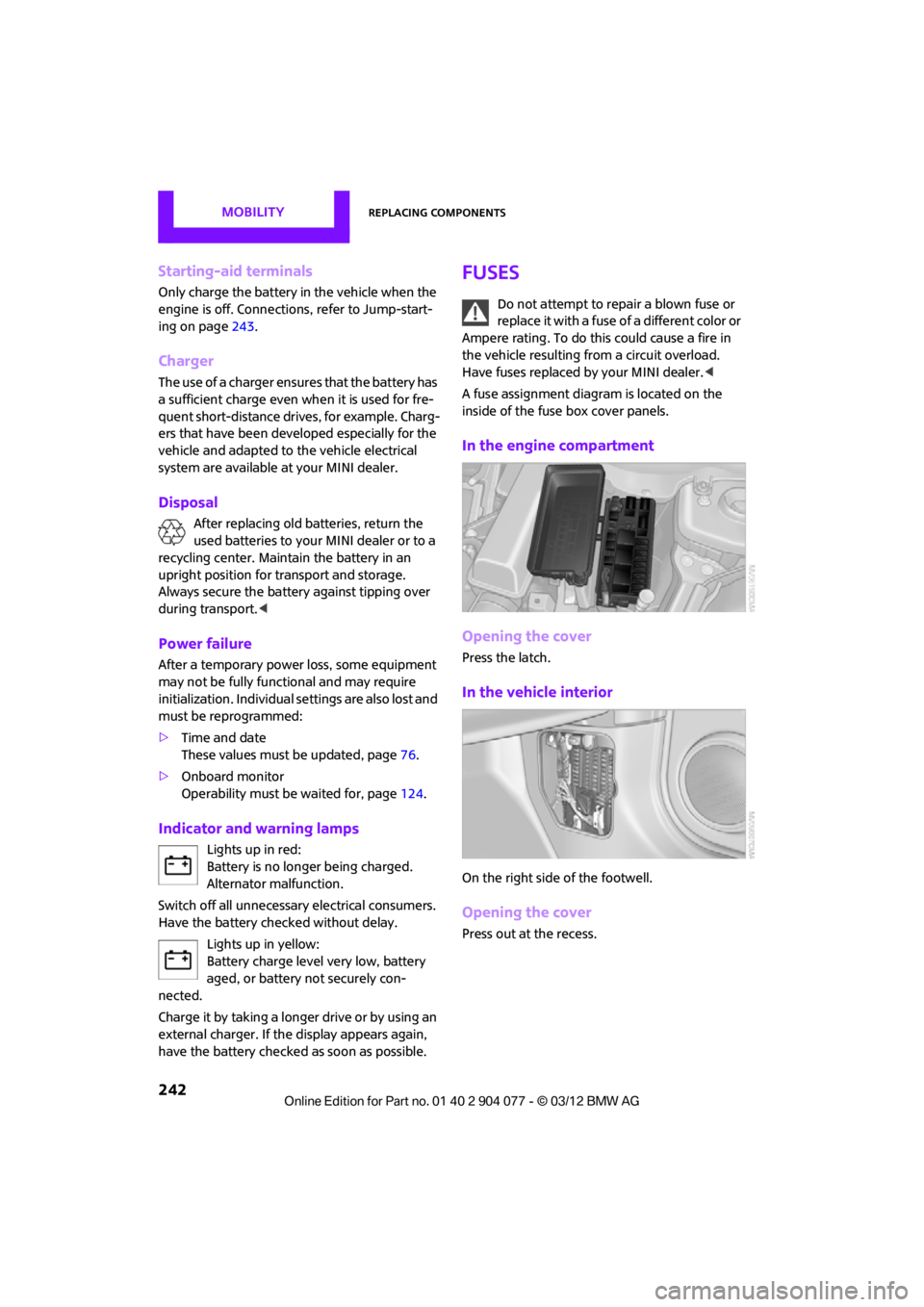

Fuses

Do not attempt to repair a blown fuse or

replace it with a fuse of a different color or

Ampere rating. To do this could cause a fire in

the vehicle resulting from a circuit overload.

Have fuses replaced by your MINI dealer. <

A fuse assignment diag ram is located on the

inside of the fuse box cover panels.

In the engine compartment

Opening the cover

Press the latch.

In the vehicle interior

On the right side of the footwell.

Opening the cover

Press out at the recess.

00320051004F004C00510048000300280047004C0057004C005200510003

Page 244 of 283

Giving and receiving assistanceMOBILITY

243

Giving and receiving assistance

Vehicle equipment

In this chapter, all production, country, and

optional equipment that is offered in the model

range is described. Equipment is also described

that is not available because of, for example,

selected options or count ry version. This also

applies to safety related functions and systems.

Roadside Assistance

Roadside Assistance is available by phone

24 hours a day in many countries. You can

receive assistance there in the event of an

emergency.

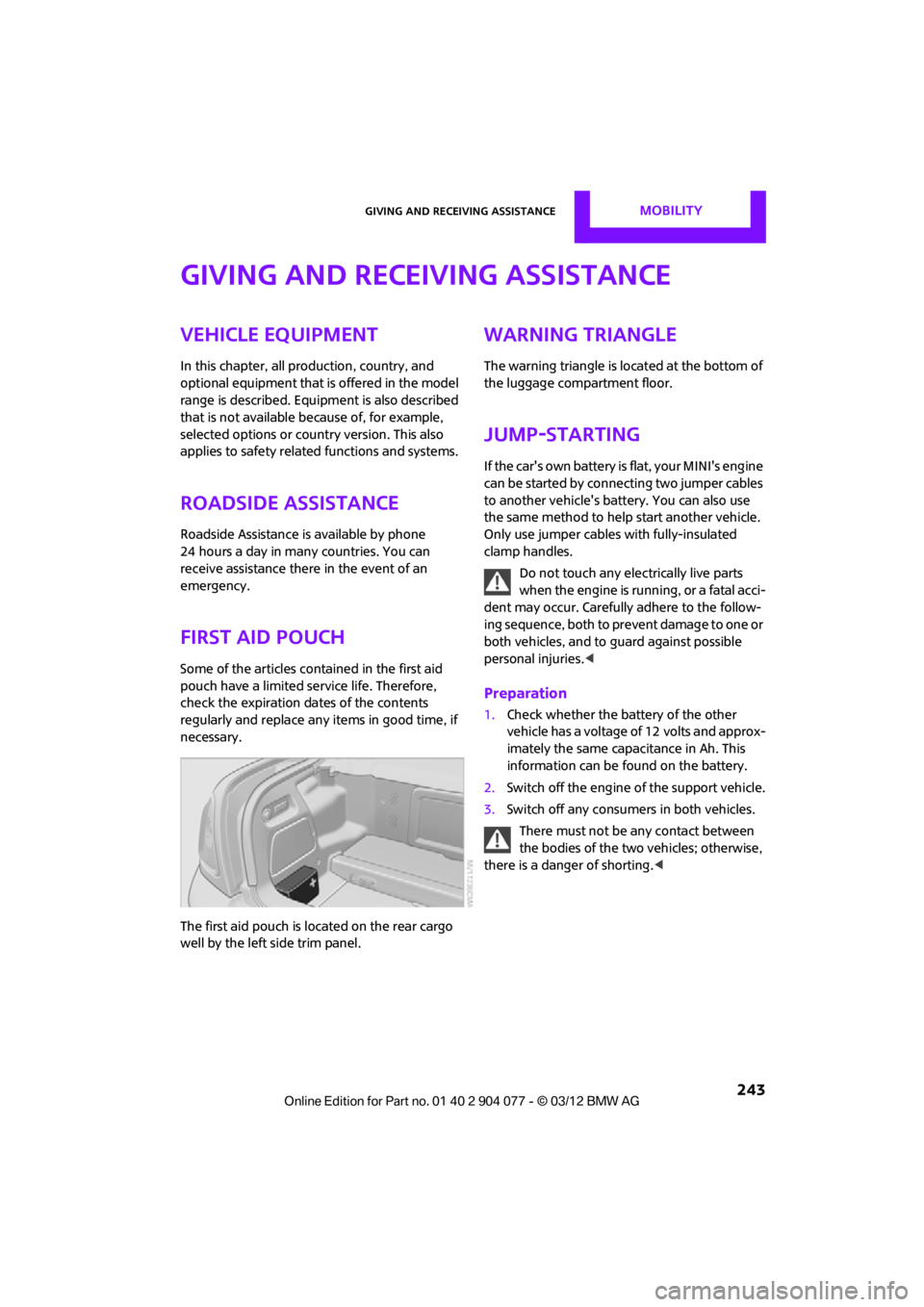

First aid pouch

Some of the articles co ntained in the first aid

pouch have a limited se rvice life. Therefore,

check the expiration dates of the contents

regularly and replace any items in good time, if

necessary.

The first aid pouch is located on the rear cargo

well by the left side trim panel.

Warning triangle

The warning triangle is located at the bottom of

the luggage compartment floor.

Jump-starting

If the car's own battery is flat, your MINI's engine

can be started by connecting two jumper cables

to another vehicle's battery. You can also use

the same method to help start another vehicle.

Only use jumper cables with fully-insulated

clamp handles.

Do not touch any electrically live parts

w hen the e ngin e is run ning, or a fatal acci-

dent may occur. Carefully adhere to the follow-

ing sequence, both to prevent damage to one or

both vehicles, and to guard against possible

personal injuries. <

Preparation

1.Check whether the battery of the other

vehicle has a voltage of 12 volts and approx-

imately the same capacitance in Ah. This

information can be found on the battery.

2. Switch off the engine of the support vehicle.

3. Switch off any consumers in both vehicles.

There must not be any contact between

the bodies of the two vehicles; otherwise,

there is a danger of shorting. <

00320051004F004C00510048000300280047004C0057004C005200510003

Page 245 of 283

MOBILITYGiving and receiving assistance

244

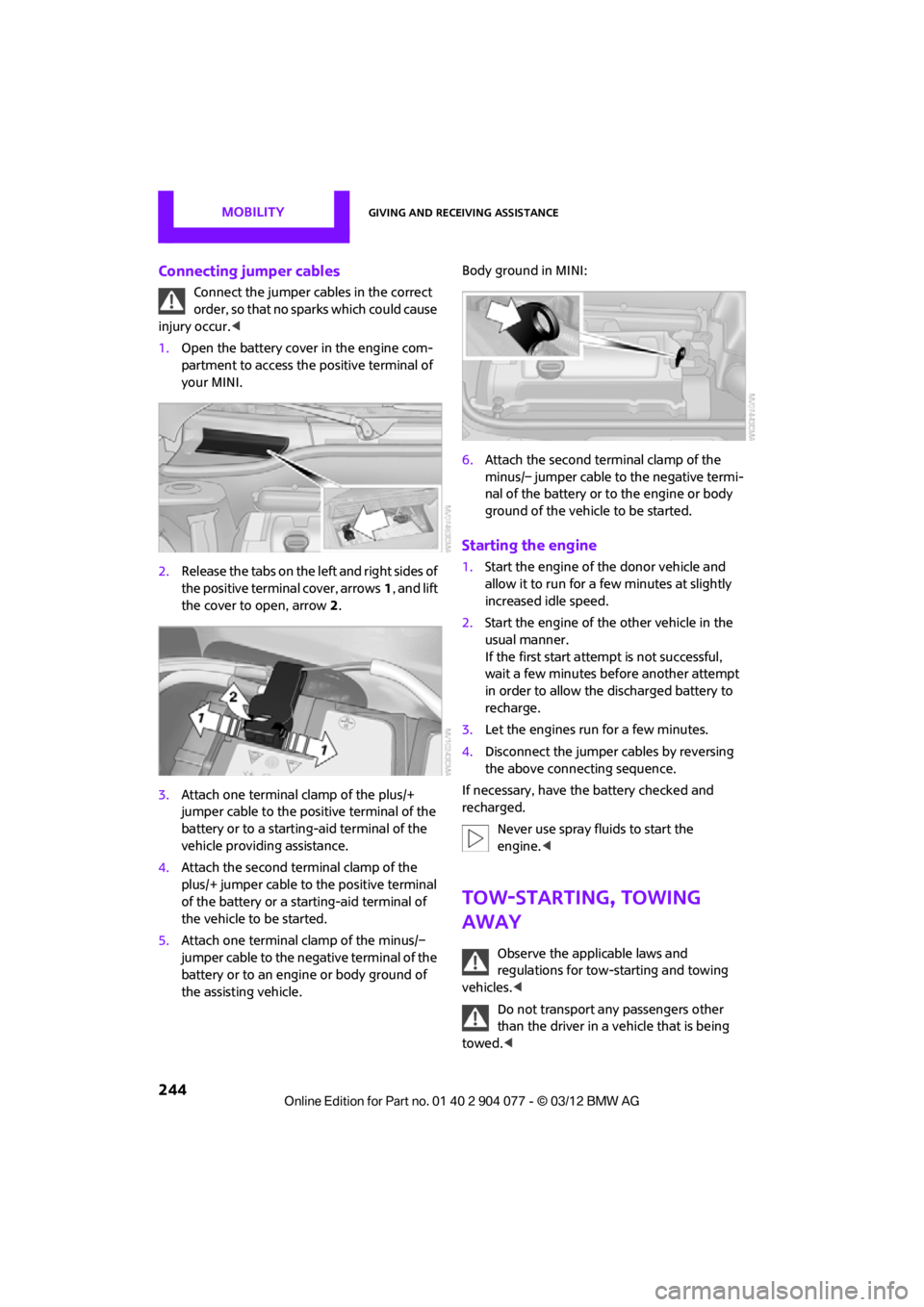

Connecting jumper cables

Connect the jumper cables in the correct

order, so that no sparks which could cause

injury occur.<

1. Open the battery cover in the engine com-

partment to access the positive terminal of

your MINI.

2. Release the tabs on the left and right sides of

the positive terminal cover, arrows 1, and lift

the cover to open, arrow 2.

3. Attach one terminal clamp of the plus/+

jumper cable to the positive terminal of the

battery or to a starting-aid terminal of the

vehicle providing assistance.

4. Attach the second terminal clamp of the

plus/+ jumper cable to the positive terminal

of the battery or a starting-aid terminal of

the vehicle to be started.

5. Attach one terminal clamp of the minus/–

jumper cable to the negative terminal of the

battery or to an engine or body ground of

the assisting vehicle. Body ground in MINI:

6.

Attach the second te rminal clamp of the

minus/– jumper cable to the negative termi-

nal of the battery or to the engine or body

ground of the vehicle to be started.

Starting the engine

1. Start the engine of the donor vehicle and

allow it to run for a few minutes at slightly

increased idle speed.

2. Start the engine of the other vehicle in the

usual manner.

If the first start attempt is not successful,

wait a few minutes before another attempt

in order to allow the discharged battery to

recharge.

3. Let the engines run for a few minutes.

4. Disconnect the jumper cables by reversing

the above connecting sequence.

If necessary, have the battery checked and

recharged. Never use spray fluids to start the

engine. <

Tow-starting, towing

away

Observe the applicable laws and

regulations for tow-starting and towing

vehicles. <

Do not transport any passengers other

than the driver in a vehicle that is being

towed. <

00320051004F004C00510048000300280047004C0057004C005200510003

Page 246 of 283

Giving and receiving assistanceMOBILITY

245

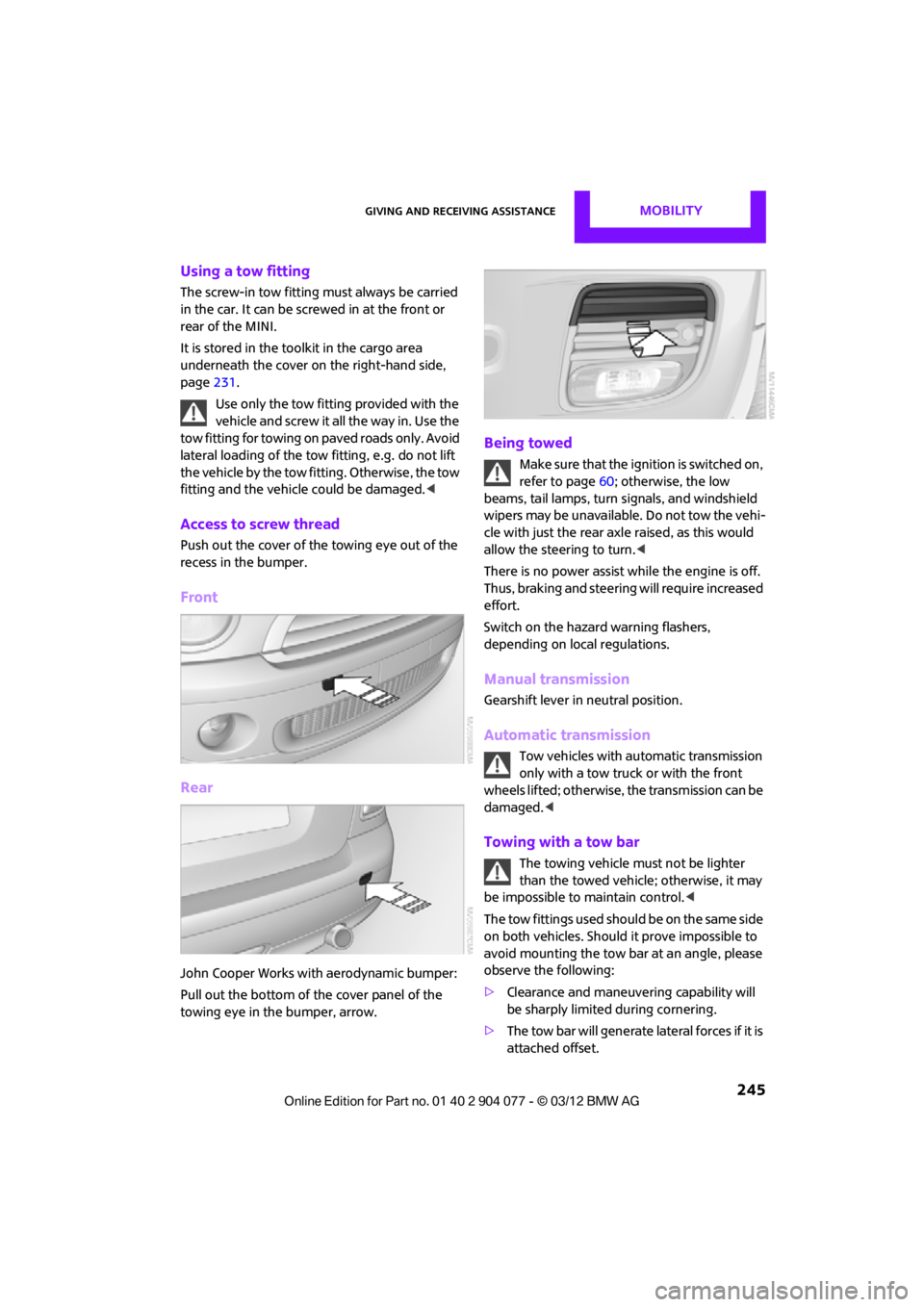

Using a tow fitting

The screw-in tow fitting must always be carried

in the car. It can be screwed in at the front or

rear of the MINI.

It is stored in the toolkit in the cargo area

underneath the cover on the right-hand side,

page231.

Use only the tow fitting provided with the

vehicle and screw it all the way in. Use the

tow fitting for towing on paved roads only. Avoid

lateral loading of the tow fitting, e.g. do not lift

the vehicle by the tow fitting. Otherwise, the tow

fitting and the vehicle could be damaged. <

Access to screw thread

Push out the cover of the towing eye out of the

recess in the bumper.

Front

Rear

John Cooper Works with aerodynamic bumper:

Pull out the bottom of the cover panel of the

towing eye in the bumper, arrow.

Being towed

Make sure that the ignition is switched on,

refer to page60; otherwise, the low

beams, tail lamps, turn signals, and windshield

wipers may be unavailable. Do not tow the vehi-

cle with just the rear ax le raised, as this would

allow the steering to turn. <

There is no power assist while the engine is off.

Thus, braking and steering will require increased

effort.

Switch on the hazard warning flashers,

depending on local regulations.

Manual transmission

Gearshift lever in neutral position.

Automatic transmission

Tow vehicles with automatic transmission

only with a tow truck or with the front

wheels lifted; otherwise, the transmission can be

damaged. <

Towing with a tow bar

The towing vehicle must not be lighter

than the towed vehicle; otherwise, it may

be impossible to maintain control. <

The tow fittings used should be on the same side

on both vehicles. Should it prove impossible to

avoid mounting the tow bar at an angle, please

observe the following:

> Clearance and maneuvering capability will

be sharply limited during cornering.

> The tow bar will generate lateral forces if it is

attached offset.

00320051004F004C00510048000300280047004C0057004C005200510003