MINI Hardtop 2 Door 2015 Owner's Manual (Mini Connected)

Manufacturer: MINI, Model Year: 2015, Model line: Hardtop 2 Door, Model: MINI Hardtop 2 Door 2015Pages: 244, PDF Size: 11.11 MB

Page 201 of 244

Replacing componentsVehicle features and op‐

tions

This chapter describes all standard, country-

specific and optional features offered with the

series. It also describes features that are not

necessarily available in your car, e. g., due to

the selected options or country versions. This

also applies to safety-related functions and sys‐

tems. The respectively applicable country provi‐

sions must be observed when using the respec‐

tive features and systems.

Onboard vehicle tool kit

The onboard vehicle tool kit is located in the

trough under the cargo area floor.

The warning triangle is located in the tailgate

trim.

Wiper blade replacement

Hints Do not fold down the wipers without

wiper blades

Do not fold down the wipers if wiper blades

have not been installed; this may damage the

windshield. ◀

Folding down wipers before opening the

hood

Before opening the hood, ensure that the wiper

arms with the wiper blades are against the

windshield to prevent damage. ◀

Replacing the wiper blades1.Fold up and hold the wiper arm firmly.2.Open the wiper blade lock, arrow.3.Pull the wiper blade down first out of the

holder on the wiper arm, arrow 1.

Then pull the wiper blade free from the

holder of the wiper arm, arrow 2.4.Insert and latch a new wiper blade in re‐

verse order.5.Fold down the wipers.Seite 197Replacing componentsMOBILITY197

Online Edition for Part no. 01 40 2 961 168 - II/15

Page 202 of 244

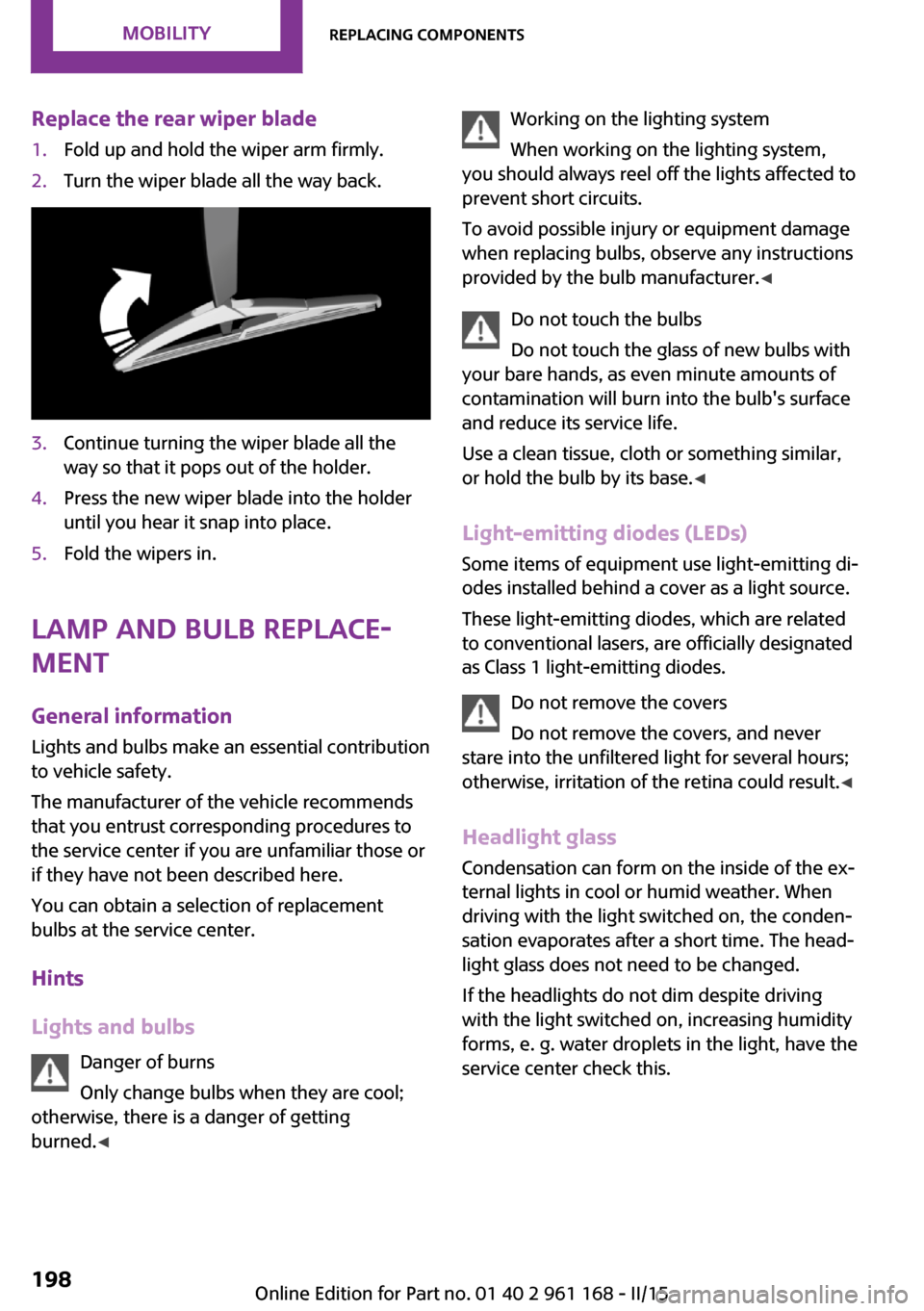

Replace the rear wiper blade1.Fold up and hold the wiper arm firmly.2.Turn the wiper blade all the way back.3.Continue turning the wiper blade all the

way so that it pops out of the holder.4.Press the new wiper blade into the holder

until you hear it snap into place.5.Fold the wipers in.

Lamp and bulb replace‐

ment

General information Lights and bulbs make an essential contribution

to vehicle safety.

The manufacturer of the vehicle recommends

that you entrust corresponding procedures to

the service center if you are unfamiliar those or

if they have not been described here.

You can obtain a selection of replacement

bulbs at the service center.

Hints

Lights and bulbs Danger of burns

Only change bulbs when they are cool;

otherwise, there is a danger of getting

burned. ◀

Working on the lighting system

When working on the lighting system,

you should always reel off the lights affected to

prevent short circuits.

To avoid possible injury or equipment damage

when replacing bulbs, observe any instructions

provided by the bulb manufacturer. ◀

Do not touch the bulbs

Do not touch the glass of new bulbs with

your bare hands, as even minute amounts of

contamination will burn into the bulb's surface

and reduce its service life.

Use a clean tissue, cloth or something similar,

or hold the bulb by its base. ◀

Light-emitting diodes (LEDs)

Some items of equipment use light-emitting di‐

odes installed behind a cover as a light source.

These light-emitting diodes, which are related

to conventional lasers, are officially designated as Class 1 light-emitting diodes.

Do not remove the covers

Do not remove the covers, and never

stare into the unfiltered light for several hours;

otherwise, irritation of the retina could result. ◀

Headlight glass Condensation can form on the inside of the ex‐

ternal lights in cool or humid weather. When

driving with the light switched on, the conden‐

sation evaporates after a short time. The head‐ light glass does not need to be changed.

If the headlights do not dim despite driving

with the light switched on, increasing humidity

forms, e. g. water droplets in the light, have the

service center check this.Seite 198MOBILITYReplacing components198

Online Edition for Part no. 01 40 2 961 168 - II/15

Page 203 of 244

Front lights, bulb replacement

Overview

Halogen headlights1Low beams/high beams2Turn signal

LED headlights

1Daytime running lights2Low beams/high beams3Turn signalBug light1Parking lights2Daytime running lights3Fog lights

LED bug light

1Parking lights2Fog lights

LED low beams/LED high beams Follow the general instructions on lights and

bulbs, refer to page 198.

The lights feature LED technology. Contact your

service center in the event of a malfunction.

halogen low beams/halogen high

beams

Follow the general instructions on lights and

bulbs, refer to page 198.

Seite 199Replacing componentsMOBILITY199

Online Edition for Part no. 01 40 2 961 168 - II/15

Page 204 of 244

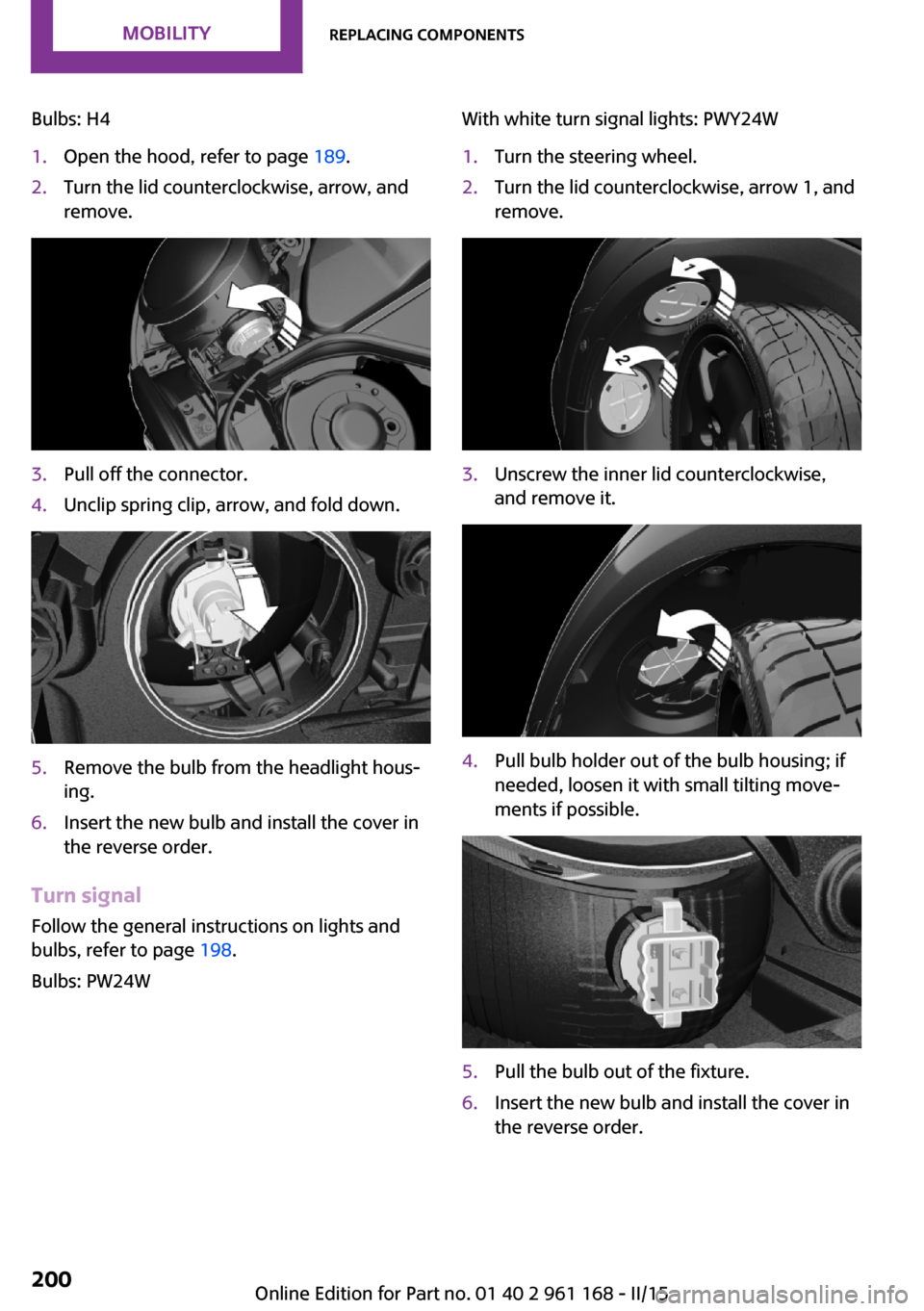

Bulbs: H41.Open the hood, refer to page 189.2.Turn the lid counterclockwise, arrow, and

remove.3.Pull off the connector.4.Unclip spring clip, arrow, and fold down.5.Remove the bulb from the headlight hous‐

ing.6.Insert the new bulb and install the cover in

the reverse order.

Turn signal

Follow the general instructions on lights and

bulbs, refer to page 198.

Bulbs: PW24W

With white turn signal lights: PWY24W1.Turn the steering wheel.2.Turn the lid counterclockwise, arrow 1, and

remove.3.Unscrew the inner lid counterclockwise,

and remove it.4.Pull bulb holder out of the bulb housing; if

needed, loosen it with small tilting move‐

ments if possible.5.Pull the bulb out of the fixture.6.Insert the new bulb and install the cover in

the reverse order.Seite 200MOBILITYReplacing components200

Online Edition for Part no. 01 40 2 961 168 - II/15

Page 205 of 244

LED parking lights/LED fog lightsFollow the general instructions on lights and

bulbs, refer to page 198.

The lights feature LED technology. Contact your

service center in the event of a malfunction.

Parking lights/fog lights/daytime

running lights

Follow the general instructions on lights and

bulbs, refer to page 198.

Bulbs:▷Parking lights for halogen headlights: W5W

Parking lights for LED headlights: W5W NBV▷Daytime running light: PSX24W▷Fog lamp: H81.Turn the steering wheel.2.Turn the lid counterclockwise, arrow 2, and

remove.3.Remove the corresponding connector.4.▷Remove bulb holder of the parking

lamp, arrow 1, by turning it counter‐

clockwise.

Pull the bulb out of the fixture.▷Remove the bulb holder of the daytime

running lights, arrow 2, by pressing to‐

gether the top and bottom latch mech‐

anism.

For better accessibility, if needed, re‐

move the bulb of the fog lamp before‐

hand.▷Turn the bulb holder of the fog lamp

counterclockwise, arrow 3, and re‐

move.5.Insert the new bulbs and install the cover in

the reverse order.

When installing the daytime running lights,

audibly latch the bulb holder first at the

bottom, then at the top.

Tail lights, bulb replacement

Overview

Vehicles with a rear fog lamp

1Side tail lights2Rear fog lamp3License plate lamp4Third brake lampSeite 201Replacing componentsMOBILITY201

Online Edition for Part no. 01 40 2 961 168 - II/15

Page 206 of 244

Vehicle with two rear fog lights1Side tail lights2Rear fog lights3License plate lamp4Third brake lamp

Side tail lights

1Brake lights/tail lights2Turn signal3Reversing lights

Side LED tail lights

1Tail lights2Turn signal3Brake light4Reversing lights

Side tail lights

Follow the general instructions on lights and

bulbs, refer to page 198.

Bulbs: P21W

1.Open the tailgate, refer to page 40.2.Remove left or right cover.3.Through the opening, loosen the plug con‐

nector, arrow 2 on the bulb holder.

Press the latches together, arrows 1, and

remove the bulb holder.4.Remove the bulb holder from the opening.5.Press the defective bulb gently into the

socket, turn counterclockwise and remove.▷Arrow 1: brake lights/tail lights▷Arrow 2: turn signalSeite 202MOBILITYReplacing components202

Online Edition for Part no. 01 40 2 961 168 - II/15

Page 207 of 244

▷Arrow 3: reversing light6.Proceed in the reverse order to insert the

new bulb and attach the bulb holder. Make

sure that the bulb holder engages in all fas‐

teners.

Central brake lamp and license plate

lamp

Follow the general instructions on lights and

bulbs, refer to page 198.

The lights feature LED technology. Contact your

service center in the event of a malfunction.

Vehicles with a rear fog lamp Follow the general instructions on lights and

bulbs, refer to page 198.

Bulbs: W16W

1.On vehicles with heat shield:

Loosen 3 screws, arrow.2.Push the heat shield forward and the

bumper back in order to be able to reach

the fog lamp.3.Turn the bulb socket counterclockwise and

remove.The wire is long enough to guide the socket

down and through between any heat shield

that may be installed and the bumper.4.Replace defective bulb.5.To install the new bulb, proceed in reverse

order of removal.

Vehicle with two rear fog lights

Follow the general instructions on lights and

bulbs, refer to page 198.

Bulbs: W16W

Left rear fog lamp:

1.On vehicles with heat shield:

Loosen 3 screws, arrow.2.Push the heat shield forward and the

bumper back in order to be able to reach

the fog lamp.3.Turn the bulb socket counterclockwise and

remove.Seite 203Replacing componentsMOBILITY203

Online Edition for Part no. 01 40 2 961 168 - II/15

Page 208 of 244

The wire is long enough to guide the socket

down and through between any heat shield

that may be installed and the bumper.4.Replace defective bulb.5.To install the new bulb, proceed in reverse

order of removal.

Right fog lamp:

1.Turn the bulb socket counterclockwise and

remove.

The wire is long enough to guide the socket

down and through between any heat shield

that may be installed and the bumper.2.Replace defective bulb.3.To install the new bulb, proceed in reverse

order of removal.

Side turn signal, bulb replacement

Follow the general instructions on lights and

bulbs, refer to page 198.

Bulbs:

▷With orange lens: W5W▷With white lens: WY5W diadem1.Pull the turn signal housing at the top out

of the catch, then unhook it at the bottom.2.Turn the bulb socket counterclockwise and

remove.3.Replace the bulb.4.Proceed in the reverse order to insert the

new bulb and install the turn signal hous‐

ing.

First hook the turn signal housing to the

bottom, then at the top press it into the

latch.

Changing wheels

Hints

When using run-flat tires or tire sealants, a tire

does not need to be changed immediately in

the event of pressure loss due to a flat tire.

Which is why no spare tire is available.

The tools for changing wheels are available as

accessories from your service center.

Seite 204MOBILITYReplacing components204

Online Edition for Part no. 01 40 2 961 168 - II/15

Page 209 of 244

Jacking points for the vehicle jack

The jacking points for the vehicle jack are lo‐

cated at the positions shown.

Emergency wheel

Hints Safety measures in case of a breakdown

or a wheel change

▷Park the vehicle as far away as possible

from passing traffic and on solid ground.

Switch on the hazard warning system.▷Set the parking brake, and engage first gear

or selector lever position P.▷Have all vehicle occupants get out of the

vehicle and ensure that they remain out‐

side the immediate area in a safe place,

such as behind a guardrail.▷If necessary, set up a warning triangle or

portable hazard warning lamp at an appro‐

priate distance. Comply with all safety

guidelines and regulations.▷Perform wheel change only on a flat, solid

and slip-resistant surface. On soft or slip‐

pery ground, e.g., snow, ice, tiles, etc., the

vehicle or vehicle jack can slip away to the

side.▷Do not place wood blocks or similar items

under the vehicle jack; otherwise, it cannot

reach its carrying capacity because of the

restricted height.▷If the vehicle is raised, do not lie under the

vehicle and do not start the engine; other‐

wise, a fatal hazard exists. ◀Use the vehicle jack only for changing

wheels

Use the vehicle jack only for changing wheels.

Do not attempt to use it to jack up a different

type of vehicle or cargo of any kind; otherwise,

this could cause material damage and personal

injury. ◀

Removing the emergency wheel The emergency wheel is housed in a well on

the underbody of the vehicle. The screw con‐

nection of the emergency wheel is located in

the trunk under the floor mat, on the floor of

the storage compartment for the wheel chang‐

ing set.1.Loosen the nut from the wheel change set

using the wheel wrench.2.Remove the retaining plate.3.Screw wheel lug wrench onto the thread

and hold in place with one hand.Seite 205Replacing componentsMOBILITY205

Online Edition for Part no. 01 40 2 961 168 - II/15

Page 210 of 244

4.Unlock the locking hexagon of the emer‐

gency wheel well using the hexagon at‐

tached to retaining plate.5.Lower the emergency wheel with the wheel

wrench.6.Unscrewing the wheel wrench7.Pull out the well with emergency wheel un‐

der the vehicle toward the rear.8.Remove the spacer and emergency wheel

from the well.9.Stow the well and spacer in the vehicle.

Prepare wheel change

1.Follow the Safety instructions, refer to

page 205.2.With the wheel chock from the wheel

change set, also secure the vehicle against

rolling away at the front wheel of the oppo‐

site side.3.Loosen the wheel lug bolts a half turn.

Jacking up the vehicle

1.Place the vehicle jack at the jacking point

closest to the wheel such that the vehicle

jack foot is vertically beneath the vehiclejacking point with the entire surface on the

ground.2.Insert the vehicle jack head in the rectan‐

gular recess of the jacking point for crank‐

ing it up.3.Crank it up until the wheel in question lifts

off of the ground.

Wheel mounting

1.Unscrew the wheel lug bolts and remove

the wheel.2.Put the new wheel or emergency wheel on

and screw in at least two bolts.

If original MINI light alloy wheels are not

mounted, any accompanying lug bolts also

have to be used.3.Screw in the remaining the lug bolts and

tighten all bolts well in a crosswise pattern.4.Lower the vehicle and remove the vehicle

jack.

After the wheel change

1.Tighten the lug bolts crosswise. The tight‐

ening torque is 101 lb ft/140 Nm.

Check for secure seating of the lug

bolts

For safety reasons, have the secure seating

of the lug bolts checked with a calibrated

torque wrench; otherwise, a safety hazard

results from incorrectly tightened lug

bolts. ◀2.Stow the defective wheel in the trunk.Seite 206MOBILITYReplacing components206

Online Edition for Part no. 01 40 2 961 168 - II/15