MINI Paceman 2014 Owner's Manual (Mini Connected)

Manufacturer: MINI, Model Year: 2014, Model line: Paceman, Model: MINI Paceman 2014Pages: 282, PDF Size: 6.76 MB

Page 221 of 282

MINI Countryman:

MINI Paceman:

Do not exceed the maximum permissible

speed

The maximum permissible speed for these tire

pressures is 100 mph/160 km/h. Do not exceed

this speed; otherwise, tire damage and acci‐

dents may occur. ◀

Tire inflation pressures for driving

above 100 mph or 160 km/h

Adjust the tire inflation pressures

To drive at maximum speeds in excess of

100 mph/160 km/h, adjust pressures to the re‐

spective tire inflation pressures listed on the

following pages in the column for traveling

speeds including those exceeding 100 mph or

160 km/h. Otherwise, tire damage and acci‐

dents could occur. ◀

Observe all national and local maximum speed limits; otherwise, violations of the laws could

occur.

Tire inflation pressures for MINI Countryman Cooper

Tire sizePressure specifications in bar/PSITraveling speeds of up to

100 mph/160 km/hTraveling speeds above

100 mph/160 km/All pressure specifications in the table are indicated in bar/PSI with cold

tires.

Cold = ambient temperature195/60 R 16 89 H M+S Std

205/55 R 17 91 H M+S RSC

205/55 R 17 91 H M+S A/S RSC

205/55 R 17 91 V RSC

225/45 R 18 91 V RSC

225/40 R 19 89 V RSC2.2/322.2/322.4/352.4/35More details on the permissible load and weights, refer to page 261.Seite 221Wheels and tiresMobility221

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 222 of 282

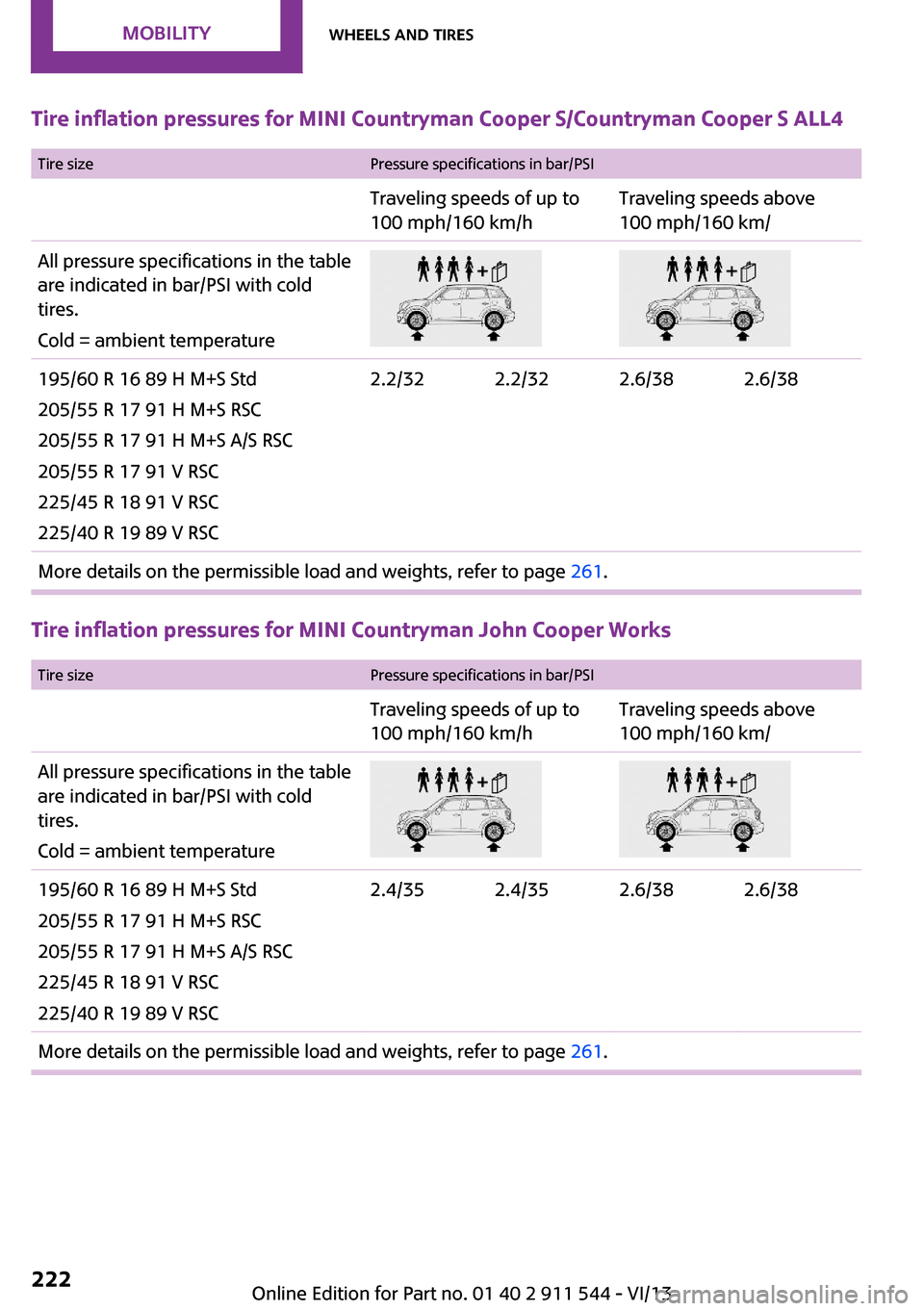

Tire inflation pressures for MINI Countryman Cooper S/Countryman Cooper S ALL4

Tire sizePressure specifications in bar/PSITraveling speeds of up to

100 mph/160 km/hTraveling speeds above

100 mph/160 km/All pressure specifications in the table are indicated in bar/PSI with cold

tires.

Cold = ambient temperature195/60 R 16 89 H M+S Std

205/55 R 17 91 H M+S RSC

205/55 R 17 91 H M+S A/S RSC

205/55 R 17 91 V RSC

225/45 R 18 91 V RSC

225/40 R 19 89 V RSC2.2/322.2/322.6/382.6/38More details on the permissible load and weights, refer to page 261.

Tire inflation pressures for MINI Countryman John Cooper Works

Tire sizePressure specifications in bar/PSITraveling speeds of up to

100 mph/160 km/hTraveling speeds above

100 mph/160 km/All pressure specifications in the table are indicated in bar/PSI with cold

tires.

Cold = ambient temperature195/60 R 16 89 H M+S Std

205/55 R 17 91 H M+S RSC

205/55 R 17 91 H M+S A/S RSC

225/45 R 18 91 V RSC

225/40 R 19 89 V RSC2.4/352.4/352.6/382.6/38More details on the permissible load and weights, refer to page 261.Seite 222MobilityWheels and tires222

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 223 of 282

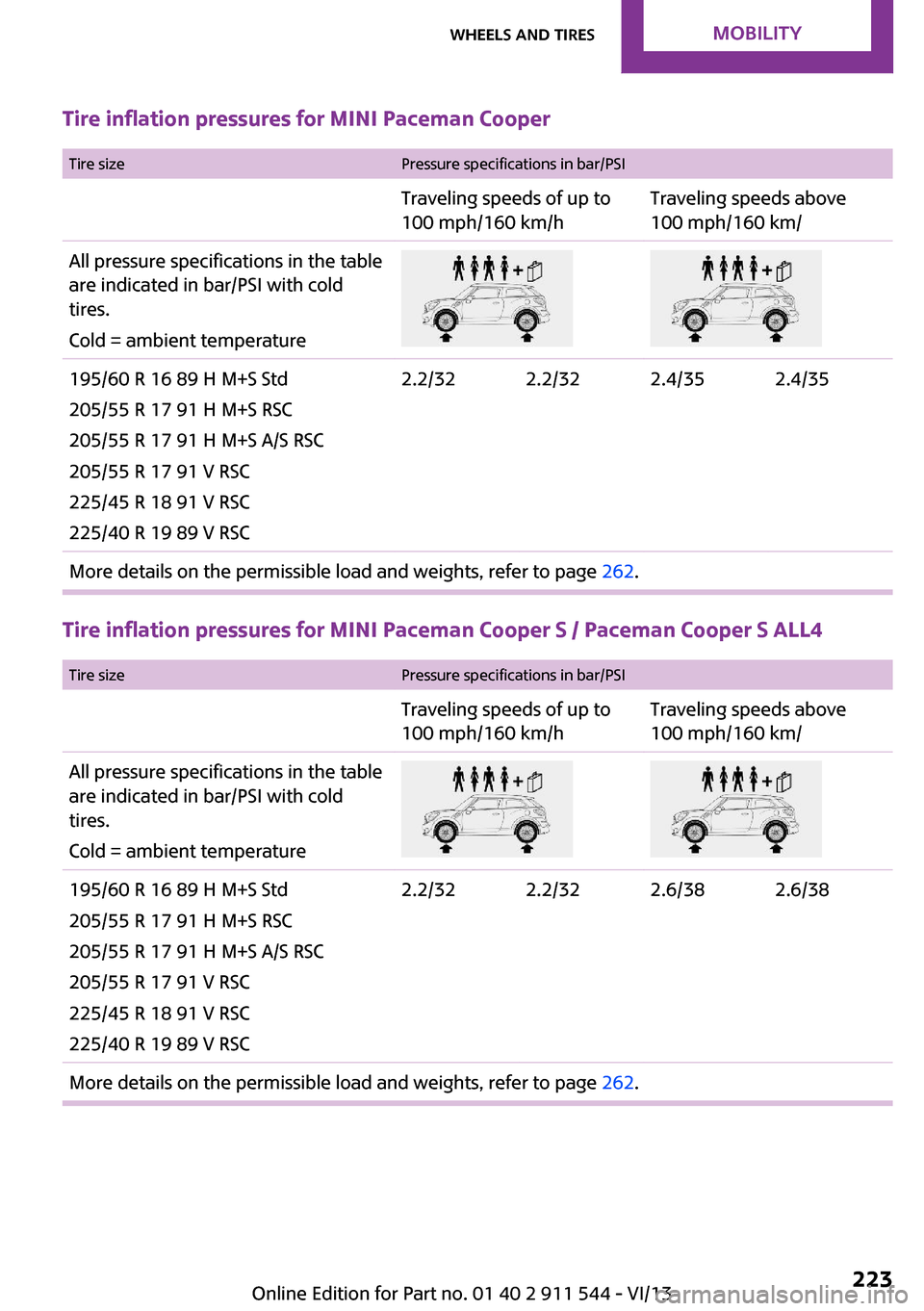

Tire inflation pressures for MINI Paceman Cooper

Tire sizePressure specifications in bar/PSITraveling speeds of up to

100 mph/160 km/hTraveling speeds above

100 mph/160 km/All pressure specifications in the table are indicated in bar/PSI with cold

tires.

Cold = ambient temperature195/60 R 16 89 H M+S Std

205/55 R 17 91 H M+S RSC

205/55 R 17 91 H M+S A/S RSC

205/55 R 17 91 V RSC

225/45 R 18 91 V RSC

225/40 R 19 89 V RSC2.2/322.2/322.4/352.4/35More details on the permissible load and weights, refer to page 262.

Tire inflation pressures for MINI Paceman Cooper S / Paceman Cooper S ALL4

Tire sizePressure specifications in bar/PSITraveling speeds of up to

100 mph/160 km/hTraveling speeds above

100 mph/160 km/All pressure specifications in the table are indicated in bar/PSI with cold

tires.

Cold = ambient temperature195/60 R 16 89 H M+S Std

205/55 R 17 91 H M+S RSC

205/55 R 17 91 H M+S A/S RSC

205/55 R 17 91 V RSC

225/45 R 18 91 V RSC

225/40 R 19 89 V RSC2.2/322.2/322.6/382.6/38More details on the permissible load and weights, refer to page 262.Seite 223Wheels and tiresMobility223

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 224 of 282

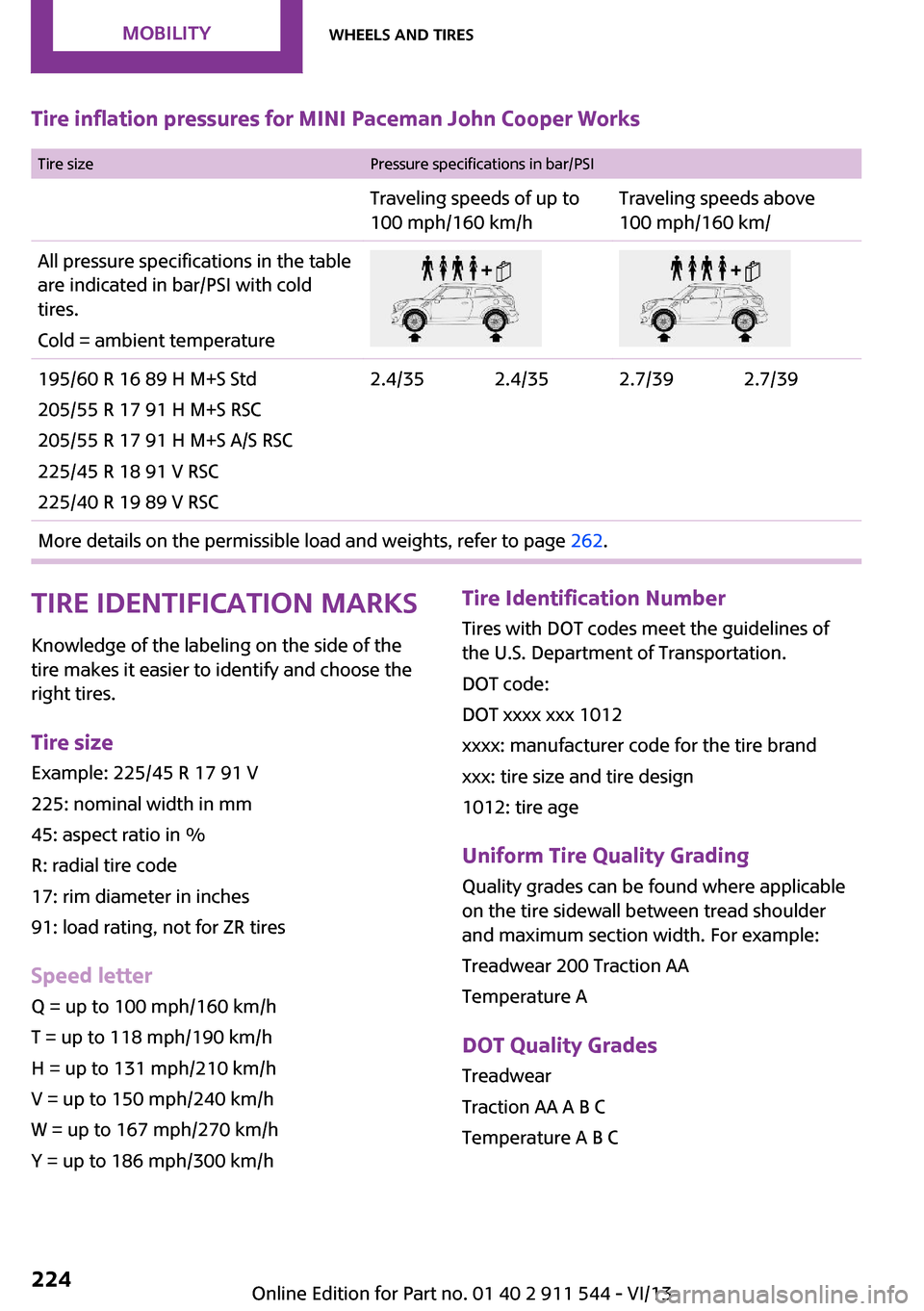

Tire inflation pressures for MINI Paceman John Cooper Works Tire sizePressure specifications in bar/PSITraveling speeds of up to

100 mph/160 km/hTraveling speeds above

100 mph/160 km/All pressure specifications in the table are indicated in bar/PSI with cold

tires.

Cold = ambient temperature195/60 R 16 89 H M+S Std

205/55 R 17 91 H M+S RSC

205/55 R 17 91 H M+S A/S RSC

225/45 R 18 91 V RSC

225/40 R 19 89 V RSC2.4/352.4/352.7/392.7/39More details on the permissible load and weights, refer to page 262.Tire identification marks

Knowledge of the labeling on the side of the tire makes it easier to identify and choose the

right tires.

Tire size Example: 225/45 R 17 91 V

225: nominal width in mm

45: aspect ratio in %

R: radial tire code

17: rim diameter in inches

91: load rating, not for ZR tires

Speed letter Q = up to 100 mph/160 km/h

T = up to 118 mph/190 km/h

H = up to 131 mph/210 km/h

V = up to 150 mph/240 km/h

W = up to 167 mph/270 km/h

Y = up to 186 mph/300 km/hTire Identification Number Tires with DOT codes meet the guidelines of

the U.S. Department of Transportation.

DOT code:

DOT xxxx xxx 1012

xxxx: manufacturer code for the tire brand

xxx: tire size and tire design

1012: tire age

Uniform Tire Quality Grading Quality grades can be found where applicable

on the tire sidewall between tread shoulder

and maximum section width. For example:

Treadwear 200 Traction AA

Temperature A

DOT Quality Grades

Treadwear

Traction AA A B C

Temperature A B CSeite 224MobilityWheels and tires224

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 225 of 282

Conform to Federal Safety Requirements

All passenger car tires must conform to

Federal Safety Requirements in addition to

these grades. ◀

Treadwear

The treadwear grade is a comparative rating based on the wear rate of the tire when tested

under controlled conditions on a specified gov‐

ernment test course. For example, a tire graded

150 would wear one and one-half (1 1/2) times

as well on the government course as a tire graded 100. The relative performance of tires

depends upon the actual conditions of their

use, however, and may depart significantly

from the norm due to variations in driving hab‐

its, service practices and differences in road

characteristics and climate.

TractionThe traction grades, from highest to lowest, are

AA, A, B, and C.

Those grades represent the tire’s ability to stop

on wet pavement as measured under control‐

led conditions on specified government test

surfaces of asphalt and concrete. A tire marked

C may have poor traction performance.

The traction grade assigned to this tire is based

on straight-ahead braking traction tests, and

does not include acceleration, cornering, hy‐

droplaning, or peak traction characteristics.

Temperature

The temperature grades are A, the highest, B,

and C, representing the tire’s resistance to the

generation of heat and its ability to dissipate

heat when tested under controlled conditions

on a specified indoor laboratory test wheel.

Sustained high temperature can cause the ma‐

terial of the tire to degenerate and reduce tire

life, and excessive temperature can lead to

sudden tire failure. The grade C corresponds to

a level of performance which all passenger car

tires must meet under the Federal Motor Vehi‐cle Safety Standard No. 109. Grades B and A

represent higher levels of performance on the

laboratory test wheel than the minimum re‐

quired by law.

Temperature grade for this tire

The temperature grade for this tire is es‐

tablished for a tire that is properly inflated and

not overloaded. Excessive speed, underinfla‐

tion, or excessive loading, either separately or

in combination, can cause heat buildup and

possible tire failure. ◀

RSC – Run-flat tires

The symbol identifying run-flat tires is a circle

with the letters RSC on the sidewall, refer to

page 228.

M+S

Winter and all-season tires.

These have better winter properties than

summer tires.

XL

Designation for specially reinforced tires.

Tire treadSummer tiresThe tread depth should not be less than

0.12 in/3 mm, although European legislation,

for example, requires a minimum tread depth

of only 0.063 in/1.6 mm. At tread depths less

than 0.12 in/3 mm, there is a great danger of

hydroplaning even in low water depths and at

raised speeds.

Winter tires

The suitability of winter tires for winter driving

is reduced noticeably when their tread depth

becomes less than 0.16 in/4 mm.Seite 225Wheels and tiresMobility225

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 226 of 282

Minimum tread depth

Wear indicators in the tread base are distrib‐

uted around the circumference of the tire and

are marked on the tire sidewall with TWI, Tread

Wear Indicator. When the tire tread has been

worn down to the wear indicators, a tread has

reached a depth of 0.063 in/1.6 mm.

Tire damage

General information Inspect your tires often for damage, foreign ob‐

jects lodged in the tread, and tread wear.

Notes

Driving over rough or damaged road surfaces,

as well as debris, curbs and other obstacles can

cause serious damage to wheels, tires and sus‐

pension parts. This is more likely to occur with

low-profile tires, which provide less cushioning

between the wheel and the road. Be careful to

avoid road hazards and reduce your speed, es‐

pecially if your vehicle is equipped with low-

profile tires.

Indications of tire damage or other vehicle de‐

fects:

▷Unusual vibrations during driving.▷Unusual handling such as a strong ten‐

dency to pull to the left or right.

Damage can be caused by driving over curbs,

road damage and similar situations.

In case of tire damage

If there are indications of tire damage, re‐

duce your speed immediately and have the

wheels and tires checked right away; other‐

wise, there is the increased risk of an accident.

Drive carefully to the next service center or tire

shop.

If necessary, have the vehicle towed.

Otherwise, tire damage can present a life-

threatening hazard to vehicle occupants and

other road users. ◀

Repair of tire damage

For safety reasons, the manufacturer of

your vehicle recommends that you do not have

damaged tires repaired; they should be re‐

placed. Otherwise, damage can occur as a re‐

sult. ◀

Tire age RecommendationFor several reasons, among other things be‐

cause of beginning brittleness, the manufac‐

turer of your MINI recommends mounting new

tires at the latest after six years, regardless of

the actual wear.

Manufacture date The date of manufacture of the tires is specified

in the tire label:

DOT … 2313: the tire was manufactured in

week 23 of 2013.Seite 226MobilityWheels and tires226

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 227 of 282

Changing wheels and

tires

Mounting Information on mounting tires

Have mounting and balancing performed

only by a service center or tire specialist.

If this work is not carried out properly, there is

the danger of subsequent damage and related

safety hazards. ◀

Wheel and tire combination Information on the right wheel and tire combi‐

nation and rim version for your vehicle can be

obtained from the service center.

Incorrect wheel and tire combinations impair

the function of a variety of systems such as ABS

or DSC.

To maintain good handling and vehicle re‐

sponse, use only tires with a single tread con‐

figuration from a single manufacturer.

Following tire damage, have the original wheel

and tire combination remounted on the vehicle

as soon as possible.

Approved wheels and tires

The manufacturer of your vehicle recom‐

mends that you use only wheels and tires that

have been approved for your particular vehicle

model.

For example, despite having the same official

size ratings, variations can lead to body contact

and with it, the risk of severe accidents.

The manufacturer of your vehicle cannot evalu‐

ate non-approved wheels and tires to deter‐

mine if they are suited for use, and therefore

cannot ensure the operating safety of the vehi‐

cle if they are mounted. ◀Wheels with electronics for TPM Tire

Pressure Monitor

When mounting new tires or changing from

summer to winter tires or vice versa, only use

wheels with TPM electronics; otherwise, the

Tire Pressure Monitor will not be able to detect

a flat tire, refer to page 87. Your service center

will be glad to advise you.

Recommended tire brands

For each tire size, the manufacturer of your ve‐

hicle recommends certain tire brands. These

are indicated by the clearly visible marking on

the tire sidewall.

With proper use, these tires meet the highest

standards for safety and handling.

Retreaded tires

The manufacturer of your vehicle does not rec‐

ommend the use of retreaded tires.

Retreaded tires

Possibly substantial variations in the de‐

sign and age of the tire casing structures can

limit service life and have a negative impact on

road safety. ◀

Winter tires The manufacturer of your vehicle recommends

winter tires for winter roads or at temperatures

below +45 ℉/+7 ℃.

Although so-called all-season M+S tires do pro‐

vide better winter traction than summer tires,

they do not provide the same level of perform‐

ance as winter tires.

Seite 227Wheels and tiresMobility227

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 228 of 282

Maximum speed of winter tires

If the maximum speed of the vehicle is higher

than the permissible speed for the winter tires,

then display a corresponding sign in the field of

vision. You can obtain this sign from the tire

specialist or from your service center.

Maximum speed for winter tires

Do not exceed the maximum speed for

the winter tires; otherwise, tire damage and ac‐

cidents can occur. ◀

Run-flat tires When mounting new tires or changing fromsummer to winter tires or vice versa, use run-

flat tires for your own safety. Also, a compact

wheel is not available in case of a flat tire. Your

service center will be glad to advise you.

Rotating wheels between axles

Different wear patterns occur on the front and

rear axles, depending on the individual condi‐

tions of use.

To ensure even wear on the tires, the wheels

can be rotated between the axles. Your service

center will be glad to advise you.

After changing the tires, check the tire inflation

pressure and correct it if necessary.

Storage Store wheels and tires in a cool, dry place with

as little exposure to light as possible.

Always protect tires against all contact with oil,

grease and fuels.

Do not exceed the maximum tire inflation pres‐

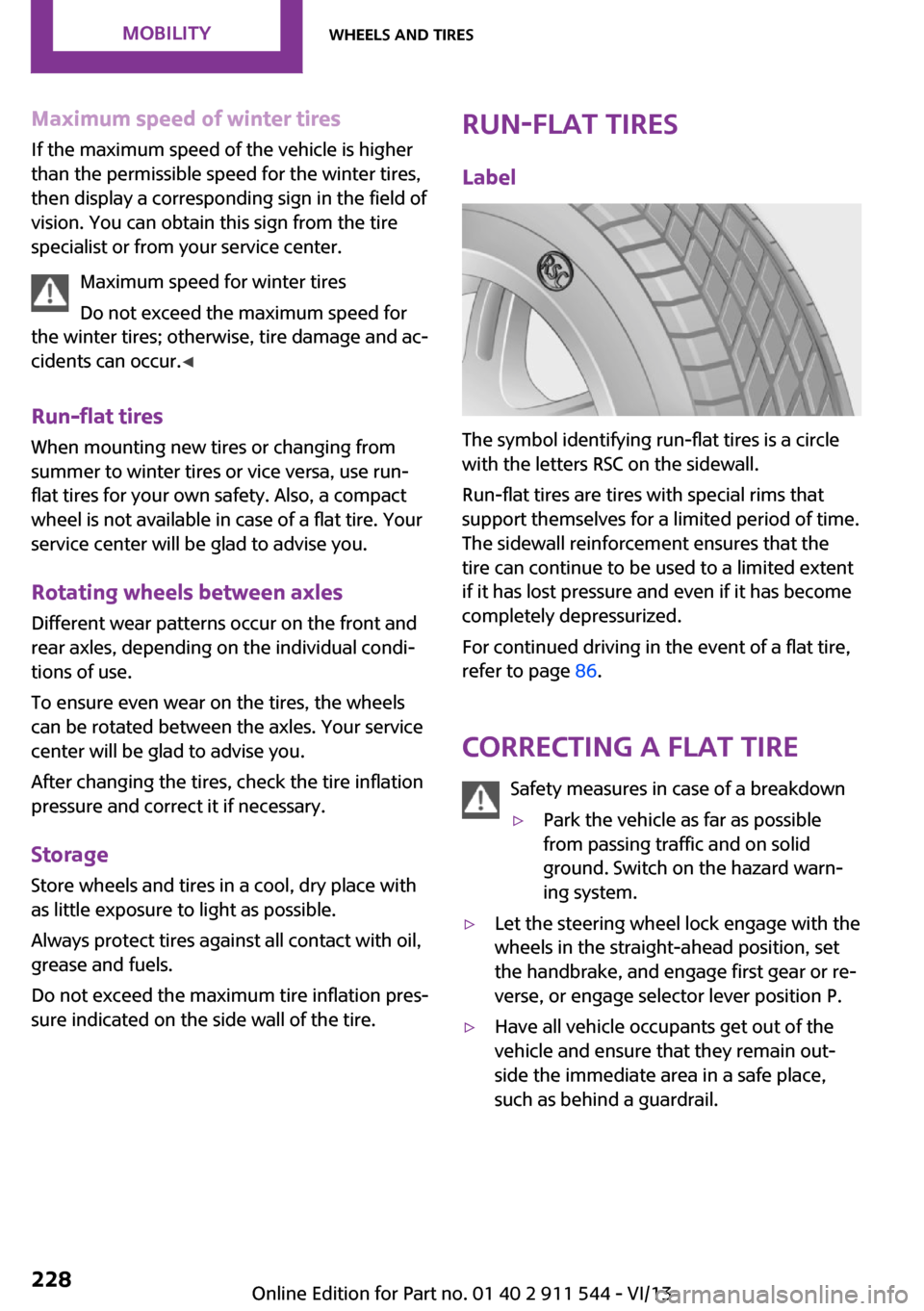

sure indicated on the side wall of the tire.Run-flat tires

Label

The symbol identifying run-flat tires is a circle

with the letters RSC on the sidewall.

Run-flat tires are tires with special rims that

support themselves for a limited period of time.

The sidewall reinforcement ensures that the

tire can continue to be used to a limited extent

if it has lost pressure and even if it has become

completely depressurized.

For continued driving in the event of a flat tire,

refer to page 86.

Correcting a flat tire Safety measures in case of a breakdown

▷Park the vehicle as far as possible

from passing traffic and on solid

ground. Switch on the hazard warn‐

ing system.▷Let the steering wheel lock engage with the

wheels in the straight-ahead position, set

the handbrake, and engage first gear or re‐

verse, or engage selector lever position P.▷Have all vehicle occupants get out of the

vehicle and ensure that they remain out‐

side the immediate area in a safe place,

such as behind a guardrail.Seite 228MobilityWheels and tires228

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 229 of 282

▷If a warning triangle or portable hazard

warning lamp is required, set it up on the

roadside at an appropriate distance from

the rear of the vehicle. Comply with all

safety guidelines and regulations. ◀

The procedure to correct a flat tire depends on

the equipment in the vehicle:

▷Run-flat tires, refer to page 228.▷MINI Mobility System, refer to page 229.

MINI Mobility System

Notes

▷Follow the instructions on using the Mobi‐

lity System found on the compressor and

sealant bottle.▷Use of the Mobility System may be ineffec‐

tive if tire damage is greater than approx.

1/8 in/4 mm in size.▷Contact the nearest service center if the tire

cannot be made drivable.▷If possible, do not remove foreign bodies

that have penetrated the tire.▷Pull the speed limit sticker off the sealant

bottle and apply it to the steering wheel.

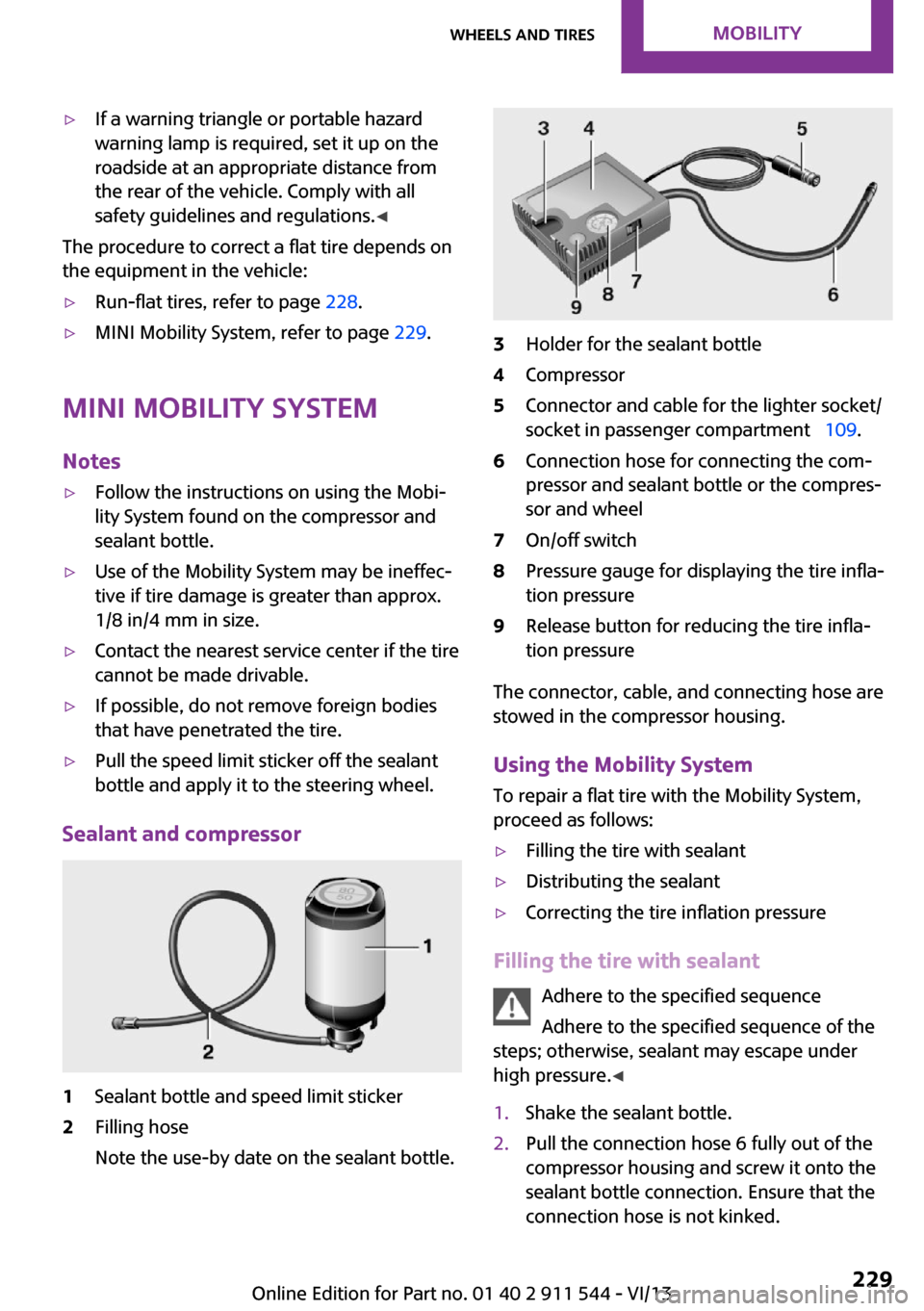

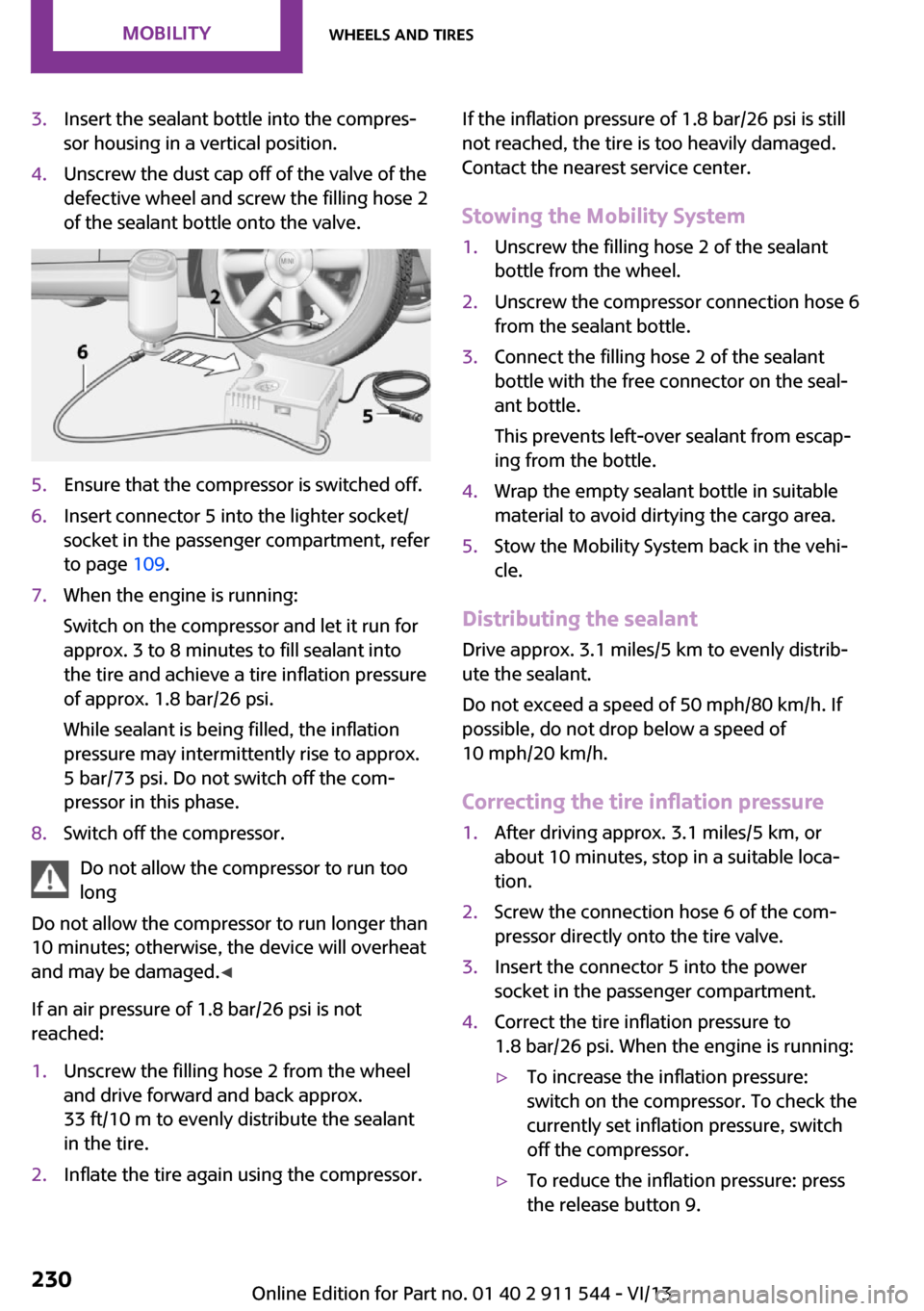

Sealant and compressor

1Sealant bottle and speed limit sticker2Filling hose

Note the use-by date on the sealant bottle.3Holder for the sealant bottle4Compressor5Connector and cable for the lighter socket/

socket in passenger compartment 109.6Connection hose for connecting the com‐

pressor and sealant bottle or the compres‐

sor and wheel7On/off switch8Pressure gauge for displaying the tire infla‐

tion pressure9Release button for reducing the tire infla‐

tion pressure

The connector, cable, and connecting hose are

stowed in the compressor housing.

Using the Mobility System

To repair a flat tire with the Mobility System,

proceed as follows:

▷Filling the tire with sealant▷Distributing the sealant▷Correcting the tire inflation pressure

Filling the tire with sealant

Adhere to the specified sequence

Adhere to the specified sequence of the

steps; otherwise, sealant may escape under

high pressure. ◀

1.Shake the sealant bottle.2.Pull the connection hose 6 fully out of the

compressor housing and screw it onto the

sealant bottle connection. Ensure that the

connection hose is not kinked.Seite 229Wheels and tiresMobility229

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 230 of 282

3.Insert the sealant bottle into the compres‐

sor housing in a vertical position.4.Unscrew the dust cap off of the valve of the

defective wheel and screw the filling hose 2

of the sealant bottle onto the valve.5.Ensure that the compressor is switched off.6.Insert connector 5 into the lighter socket/

socket in the passenger compartment, refer

to page 109.7.When the engine is running:

Switch on the compressor and let it run for

approx. 3 to 8 minutes to fill sealant into

the tire and achieve a tire inflation pressure

of approx. 1.8 bar/26 psi.

While sealant is being filled, the inflation

pressure may intermittently rise to approx.

5 bar/73 psi. Do not switch off the com‐

pressor in this phase.8.Switch off the compressor.

Do not allow the compressor to run too

long

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged. ◀

If an air pressure of 1.8 bar/26 psi is not

reached:

1.Unscrew the filling hose 2 from the wheel

and drive forward and back approx.

33 ft/10 m to evenly distribute the sealant

in the tire.2.Inflate the tire again using the compressor.If the inflation pressure of 1.8 bar/26 psi is still

not reached, the tire is too heavily damaged.

Contact the nearest service center.

Stowing the Mobility System1.Unscrew the filling hose 2 of the sealant

bottle from the wheel.2.Unscrew the compressor connection hose 6

from the sealant bottle.3.Connect the filling hose 2 of the sealant

bottle with the free connector on the seal‐

ant bottle.

This prevents left-over sealant from escap‐

ing from the bottle.4.Wrap the empty sealant bottle in suitable

material to avoid dirtying the cargo area.5.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Drive approx. 3.1 miles/5 km to evenly distrib‐

ute the sealant.

Do not exceed a speed of 50 mph/80 km/h. If

possible, do not drop below a speed of

10 mph/20 km/h.

Correcting the tire inflation pressure

1.After driving approx. 3.1 miles/5 km, or

about 10 minutes, stop in a suitable loca‐

tion.2.Screw the connection hose 6 of the com‐

pressor directly onto the tire valve.3.Insert the connector 5 into the power

socket in the passenger compartment.4.Correct the tire inflation pressure to

1.8 bar/26 psi. When the engine is running:▷To increase the inflation pressure:

switch on the compressor. To check the

currently set inflation pressure, switch

off the compressor.▷To reduce the inflation pressure: press

the release button 9.Seite 230MobilityWheels and tires230

Online Edition for Part no. 01 40 2 911 544 - VI/13