engine MINI Paceman 2014 Service Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2014, Model line: Paceman, Model: MINI Paceman 2014Pages: 218, PDF Size: 5.5 MB

Page 150 of 218

FuelVehicle equipmentThis chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series.Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

Fuel recommendation GasolineFor the best fuel economy, the gasoline should

be sulfur-free or very low in sulfur content.

Do not use fuels that are labeled at the fuel

pump as containing metals.

Only refuel with lead-free gasoline with‐

out metal additives

Do not refuel with leaded gasoline or gasoline

with metal additives, e. g., manganese or iron;

otherwise, the catalytic converter and other components will be permanently damaged. ◀

Fuels with a maximum ethanol content of

10 %, i.e., E10, may be used for refueling.

The ethanol should fulfill the following quality standards:

US: ASTM 4806–xx

CAN: CGSB-3.511–xx

xx: always adhere to the currently applicable

standard.

Do not refuel with ethanol E85

Do not refuel with E85, i.e., fuel with an

ethanol content of 85 %, or with Flex Fuel, as

this would damage the engine and fuel supply system. ◀The engine is knock controlled. Therefore, you

can refuel with different gasoline qualities.

Gasoline quality

The manufacturer of your MINI recommends:▷AKI 91.▷John Cooper Works AKI 93.

Minimum fuel grade

The manufacturer of your MINI recommends

AKI 89.

Minimum fuel grade

Do not fill up with fuel below the speci‐

fied minimum quality; otherwise, the engine

may not run properly. ◀

If you use gasoline with this minimum AKI rat‐

ing, the engine may produce knocking sounds

when starting at high outside temperatures.

This has no effect on the engine life.

Minimum fuel grade

The use of poor-quality fuels may result in

harmful engine deposits or damage. Addition‐

ally, problems relating to drivability, starting

and stalling, especially under certain environ‐

mental conditions such as high ambient tem‐

perature and high altitude, may occur.

If drivability problems are encountered, we rec‐

ommend switching to a high quality gasoline

brand and a higher octane grade — AKI num‐

ber — for a few tank fills. To avoid harmful en‐

gine deposits, it is highly recommended to pur‐

chase gasoline from BP or Top Tier retailers.

Failure to comply with these recommendations

may result in the need for unscheduled mainte‐

nance. ◀

Seite 150MobilityFuel150

Online Edition for Part no. 01 40 2 911 521 - VI/13

Page 162 of 218

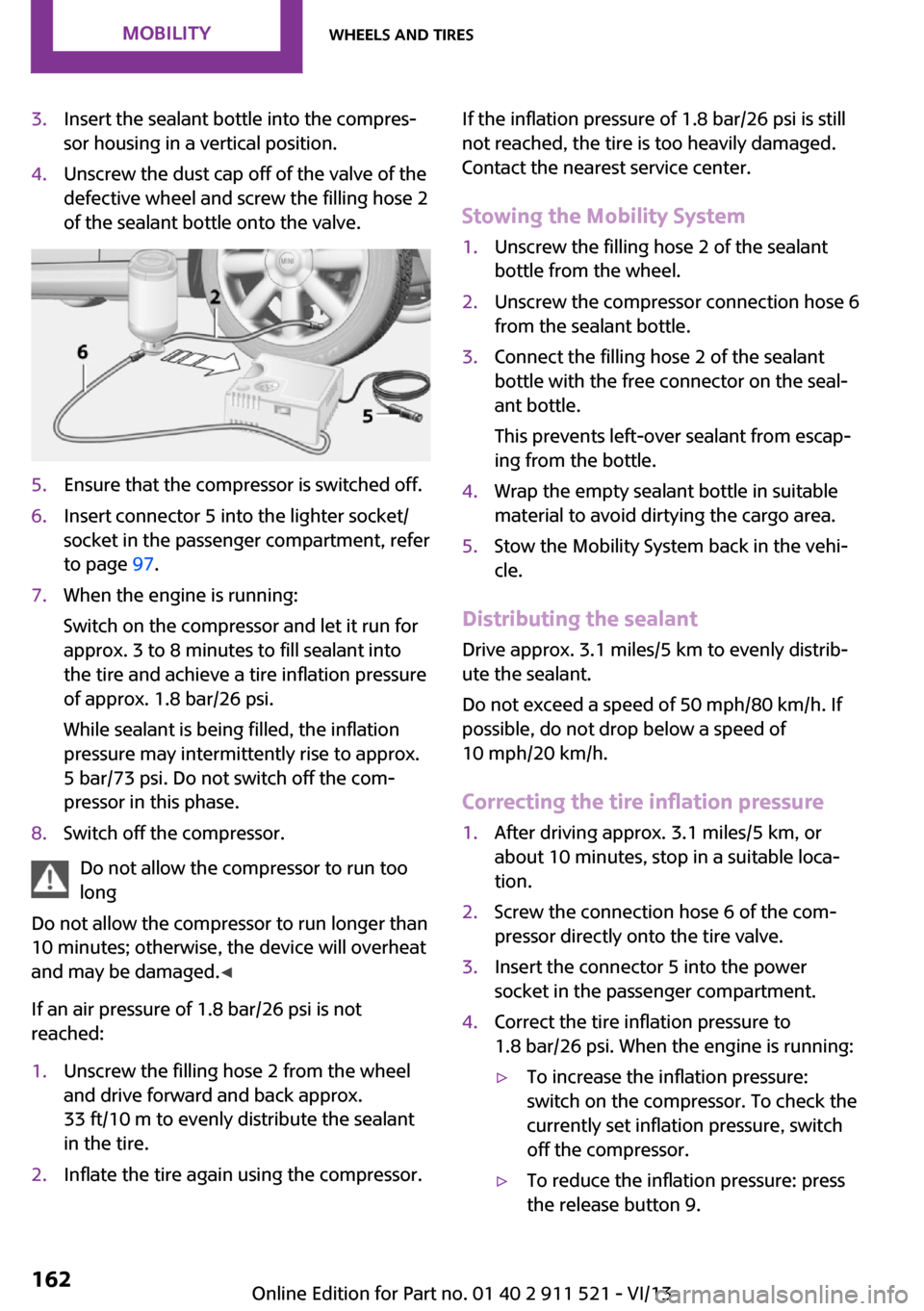

3.Insert the sealant bottle into the compres‐

sor housing in a vertical position.4.Unscrew the dust cap off of the valve of the

defective wheel and screw the filling hose 2

of the sealant bottle onto the valve.5.Ensure that the compressor is switched off.6.Insert connector 5 into the lighter socket/

socket in the passenger compartment, refer

to page 97.7.When the engine is running:

Switch on the compressor and let it run for

approx. 3 to 8 minutes to fill sealant into

the tire and achieve a tire inflation pressure

of approx. 1.8 bar/26 psi.

While sealant is being filled, the inflation

pressure may intermittently rise to approx.

5 bar/73 psi. Do not switch off the com‐

pressor in this phase.8.Switch off the compressor.

Do not allow the compressor to run too

long

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged. ◀

If an air pressure of 1.8 bar/26 psi is not

reached:

1.Unscrew the filling hose 2 from the wheel

and drive forward and back approx.

33 ft/10 m to evenly distribute the sealant

in the tire.2.Inflate the tire again using the compressor.If the inflation pressure of 1.8 bar/26 psi is still

not reached, the tire is too heavily damaged.

Contact the nearest service center.

Stowing the Mobility System1.Unscrew the filling hose 2 of the sealant

bottle from the wheel.2.Unscrew the compressor connection hose 6

from the sealant bottle.3.Connect the filling hose 2 of the sealant

bottle with the free connector on the seal‐

ant bottle.

This prevents left-over sealant from escap‐

ing from the bottle.4.Wrap the empty sealant bottle in suitable

material to avoid dirtying the cargo area.5.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Drive approx. 3.1 miles/5 km to evenly distrib‐

ute the sealant.

Do not exceed a speed of 50 mph/80 km/h. If

possible, do not drop below a speed of

10 mph/20 km/h.

Correcting the tire inflation pressure

1.After driving approx. 3.1 miles/5 km, or

about 10 minutes, stop in a suitable loca‐

tion.2.Screw the connection hose 6 of the com‐

pressor directly onto the tire valve.3.Insert the connector 5 into the power

socket in the passenger compartment.4.Correct the tire inflation pressure to

1.8 bar/26 psi. When the engine is running:▷To increase the inflation pressure:

switch on the compressor. To check the

currently set inflation pressure, switch

off the compressor.▷To reduce the inflation pressure: press

the release button 9.Seite 162MobilityWheels and tires162

Online Edition for Part no. 01 40 2 911 521 - VI/13

Page 164 of 218

Engine compartmentVehicle equipment

This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series.Therefore, it alsodescribes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

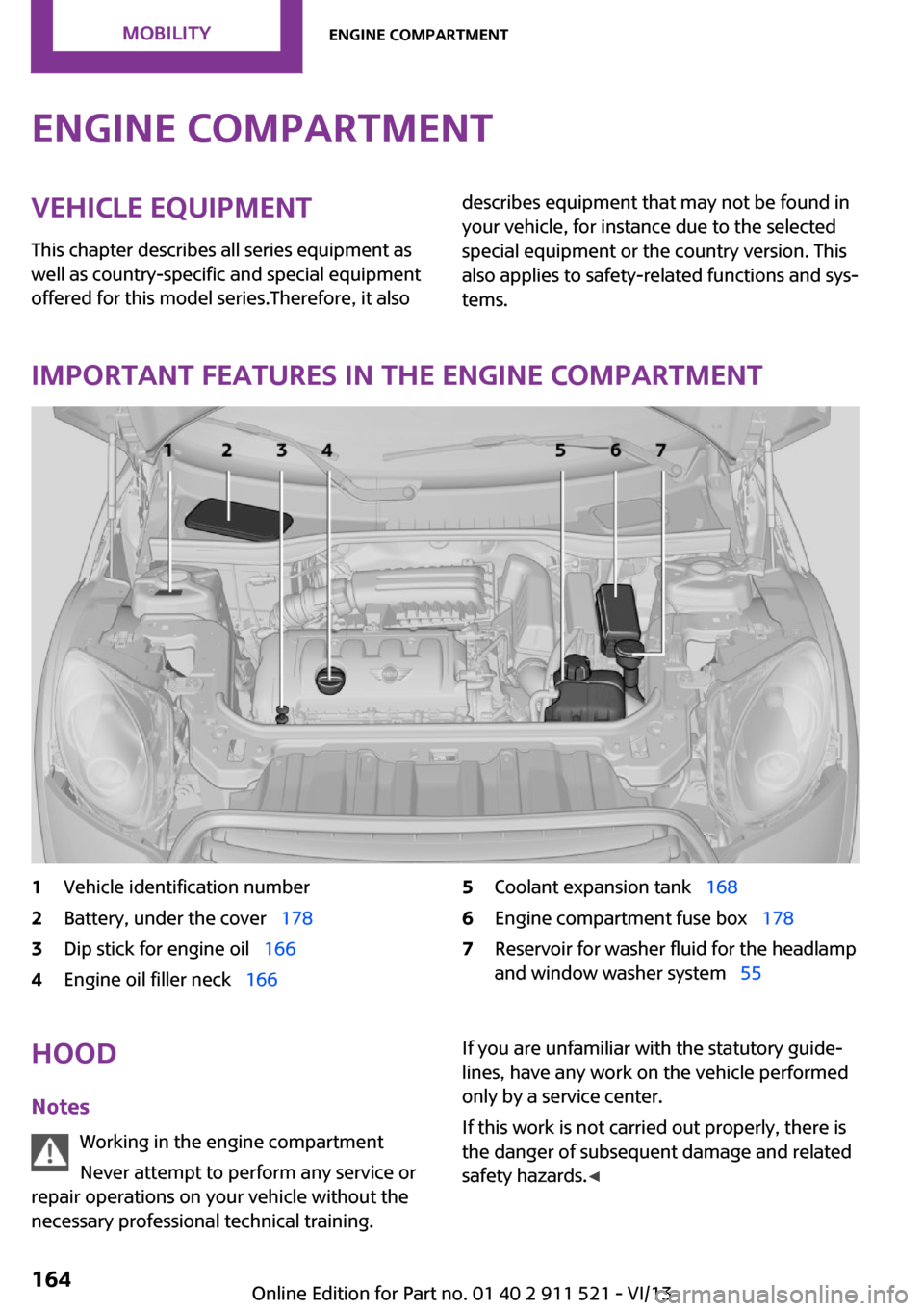

Important features in the engine compartment

1Vehicle identification number2Battery, under the cover 1783Dip stick for engine oil 1664Engine oil filler neck 1665Coolant expansion tank 1686Engine compartment fuse box 1787Reservoir for washer fluid for the headlamp

and window washer system 55Hood

Notes Working in the engine compartment

Never attempt to perform any service or

repair operations on your vehicle without the

necessary professional technical training.If you are unfamiliar with the statutory guide‐

lines, have any work on the vehicle performed

only by a service center.

If this work is not carried out properly, there is

the danger of subsequent damage and related

safety hazards. ◀Seite 164MobilityEngine compartment164

Online Edition for Part no. 01 40 2 911 521 - VI/13

Page 165 of 218

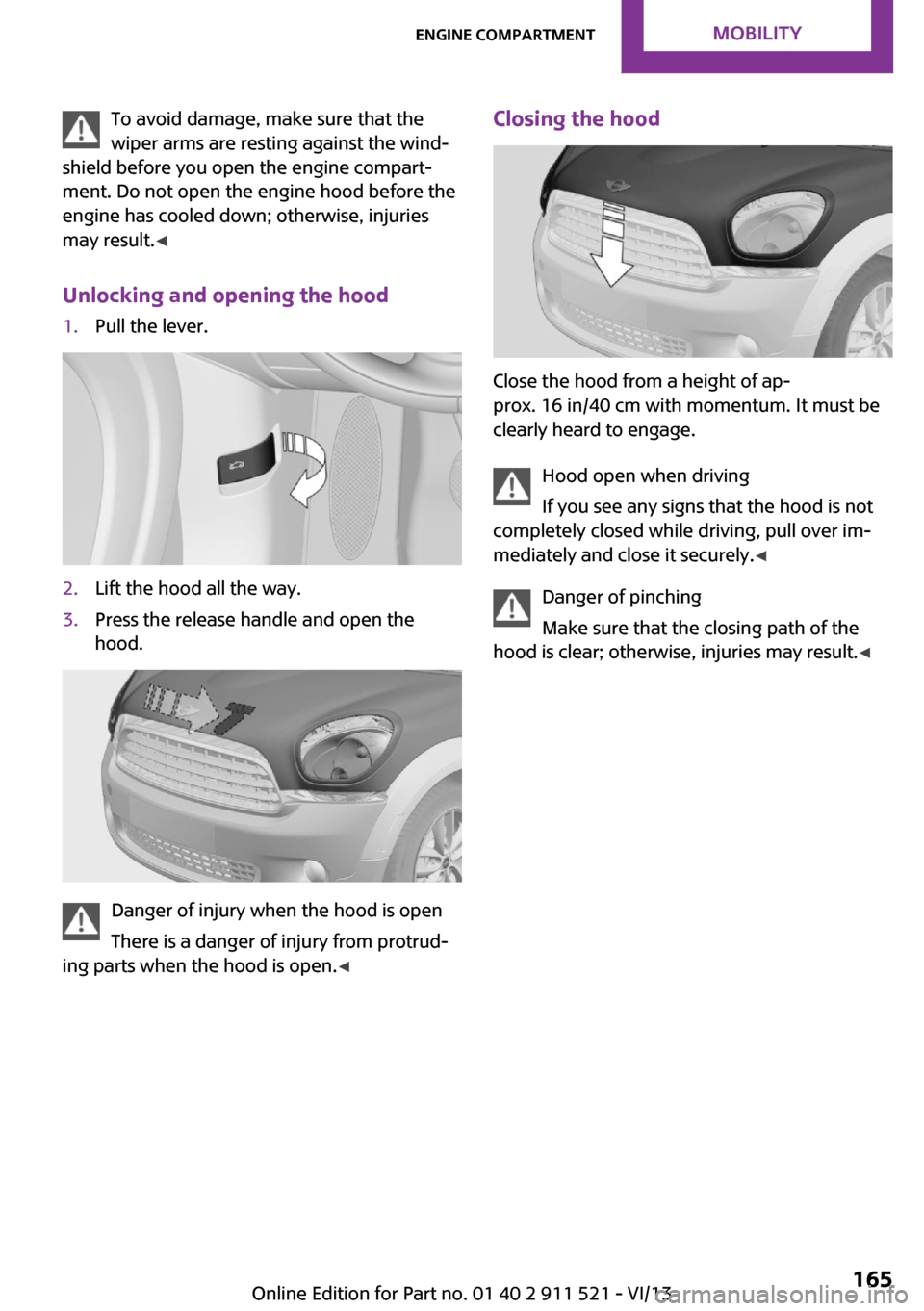

To avoid damage, make sure that the

wiper arms are resting against the wind‐

shield before you open the engine compart‐

ment. Do not open the engine hood before the

engine has cooled down; otherwise, injuries

may result. ◀

Unlocking and opening the hood1.Pull the lever.2.Lift the hood all the way.3.Press the release handle and open the

hood.

Danger of injury when the hood is open

There is a danger of injury from protrud‐

ing parts when the hood is open. ◀

Closing the hood

Close the hood from a height of ap‐

prox. 16 in/40 cm with momentum. It must be

clearly heard to engage.

Hood open when driving

If you see any signs that the hood is not

completely closed while driving, pull over im‐

mediately and close it securely. ◀

Danger of pinching

Make sure that the closing path of the

hood is clear; otherwise, injuries may result. ◀

Seite 165Engine compartmentMobility165

Online Edition for Part no. 01 40 2 911 521 - VI/13

Page 166 of 218

Engine oilVehicle equipment

This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series.Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

Engine oil General information

Engine oil consumption depends on the driving

style and the conditions of use. A highly sporty

driving style, for example, results in considera‐

bly higher engine oil consumption.

Therefore, regularly check the engine oil level

after refueling.

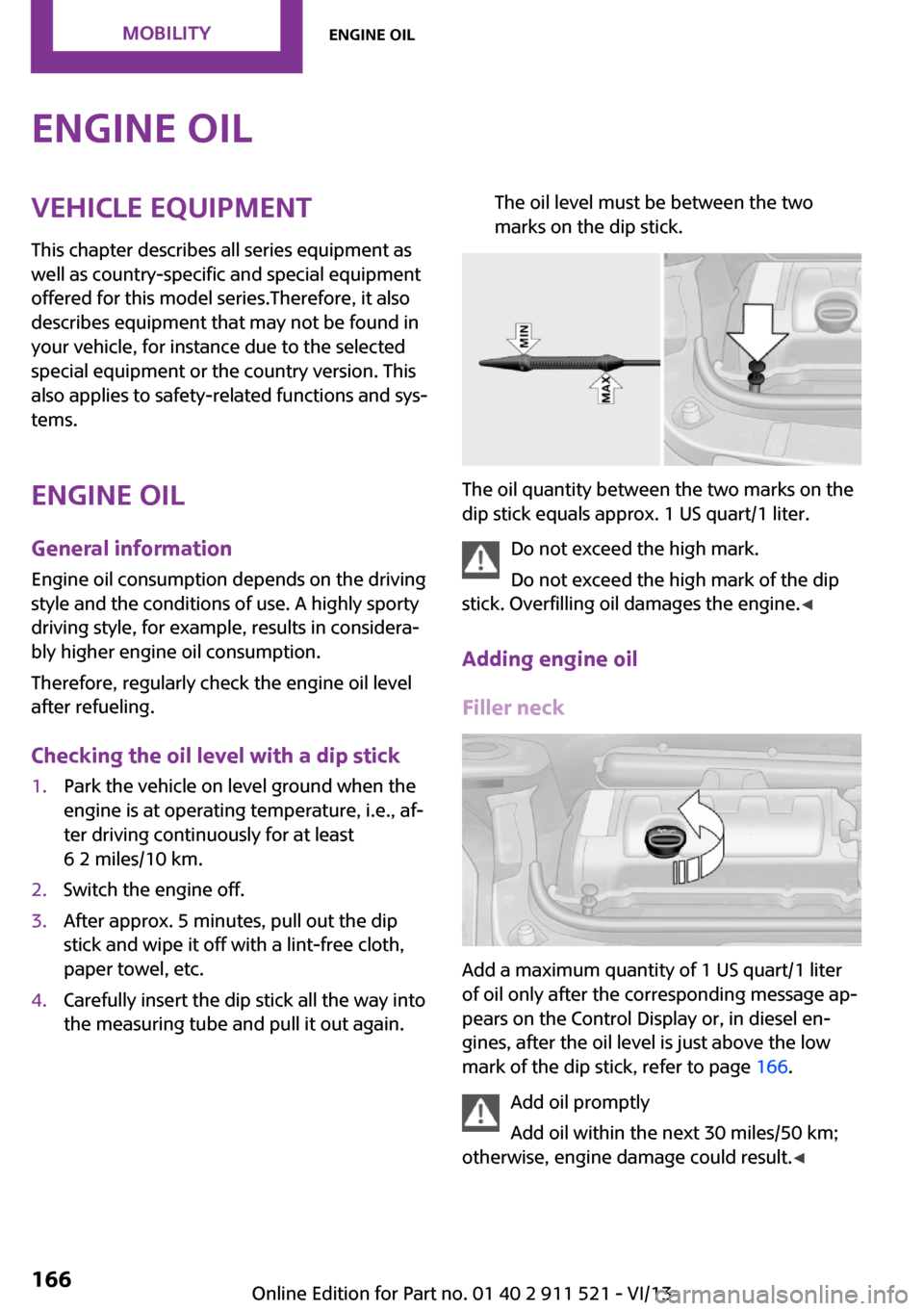

Checking the oil level with a dip stick1.Park the vehicle on level ground when the

engine is at operating temperature, i.e., af‐

ter driving continuously for at least

6 2 miles/10 km.2.Switch the engine off.3.After approx. 5 minutes, pull out the dip

stick and wipe it off with a lint-free cloth,

paper towel, etc.4.Carefully insert the dip stick all the way into

the measuring tube and pull it out again.The oil level must be between the two

marks on the dip stick.

The oil quantity between the two marks on the

dip stick equals approx. 1 US quart/1 liter.

Do not exceed the high mark.

Do not exceed the high mark of the dip

stick. Overfilling oil damages the engine. ◀

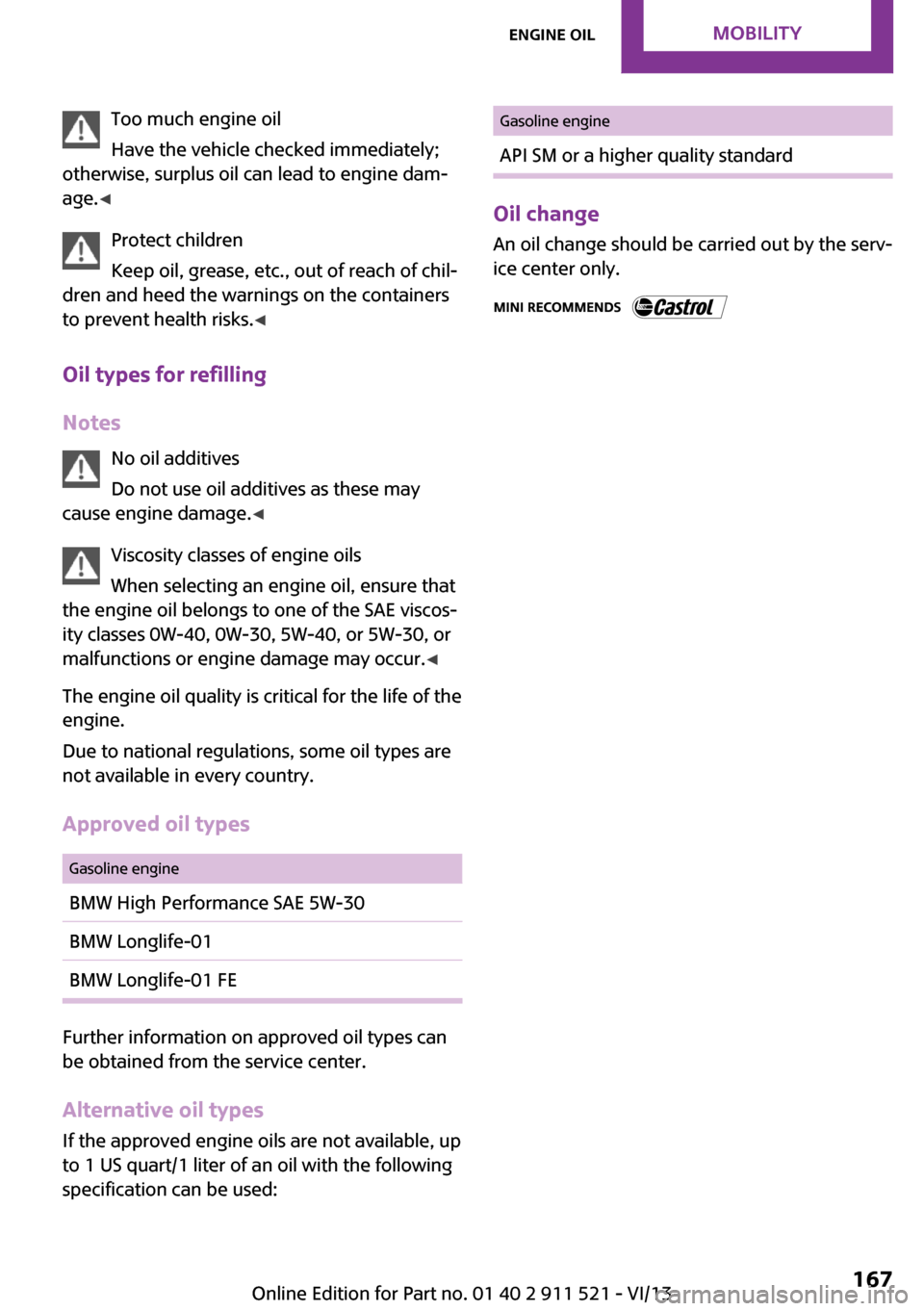

Adding engine oil

Filler neck

Add a maximum quantity of 1 US quart/1 liter

of oil only after the corresponding message ap‐

pears on the Control Display or, in diesel en‐

gines, after the oil level is just above the low

mark of the dip stick, refer to page 166.

Add oil promptly

Add oil within the next 30 miles/50 km;

otherwise, engine damage could result. ◀

Seite 166MobilityEngine oil166

Online Edition for Part no. 01 40 2 911 521 - VI/13

Page 167 of 218

Too much engine oil

Have the vehicle checked immediately;

otherwise, surplus oil can lead to engine dam‐

age. ◀

Protect children

Keep oil, grease, etc., out of reach of chil‐

dren and heed the warnings on the containers

to prevent health risks. ◀

Oil types for refilling

Notes No oil additives

Do not use oil additives as these may

cause engine damage. ◀

Viscosity classes of engine oils

When selecting an engine oil, ensure that

the engine oil belongs to one of the SAE viscos‐

ity classes 0W-40, 0W-30, 5W-40, or 5W-30, or

malfunctions or engine damage may occur. ◀

The engine oil quality is critical for the life of the

engine.

Due to national regulations, some oil types are

not available in every country.

Approved oil typesGasoline engineBMW High Performance SAE 5W-30BMW Longlife-01BMW Longlife-01 FE

Further information on approved oil types can

be obtained from the service center.

Alternative oil types

If the approved engine oils are not available, up

to 1 US quart/1 liter of an oil with the following

specification can be used:

Gasoline engineAPI SM or a higher quality standard

Oil change

An oil change should be carried out by the serv‐

ice center only.

Seite 167Engine oilMobility167

Online Edition for Part no. 01 40 2 911 521 - VI/13

Page 168 of 218

CoolantVehicle equipment

This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series.Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

General information Danger of burns from hot engine

Do not open the cooling system while the

engine is hot; otherwise, escaping coolant may

cause burns. ◀

Suitable additives

Only use suitable additives; otherwise,

engine damage may occur. The additives are

harmful to your health. ◀

Coolant consists of water and additives.

Not all commercially available additives are

suitable for your MINI vehicle. Ask your service

center for suitable additives.

Coolant temperature

If the coolant and therefore the engine over‐

heat, a warning lamp lights up, refer to

page 190.

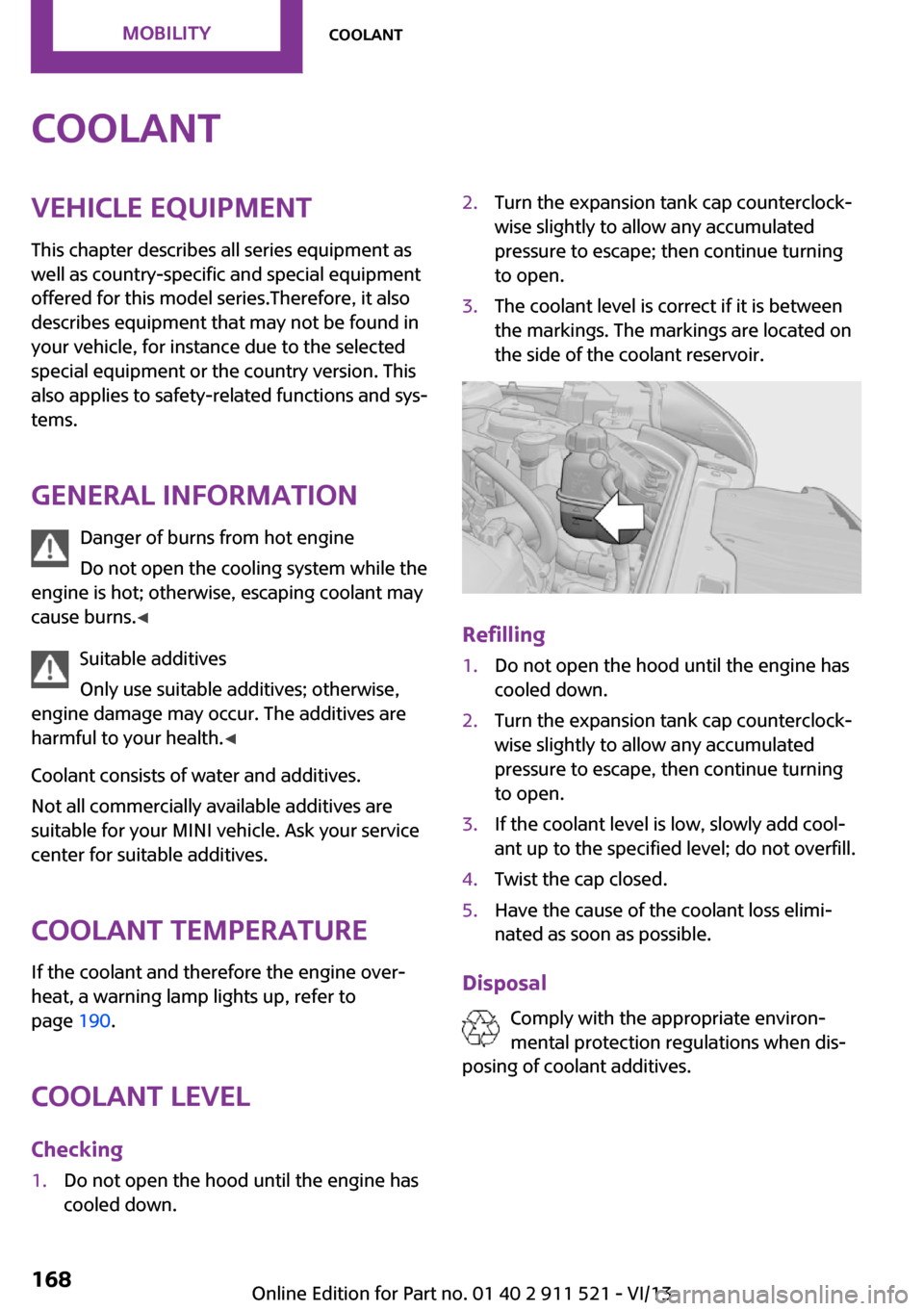

Coolant level

Checking1.Do not open the hood until the engine has

cooled down.2.Turn the expansion tank cap counterclock‐

wise slightly to allow any accumulated

pressure to escape; then continue turning

to open.3.The coolant level is correct if it is between

the markings. The markings are located on

the side of the coolant reservoir.

Refilling

1.Do not open the hood until the engine has

cooled down.2.Turn the expansion tank cap counterclock‐

wise slightly to allow any accumulated

pressure to escape, then continue turning

to open.3.If the coolant level is low, slowly add cool‐

ant up to the specified level; do not overfill.4.Twist the cap closed.5.Have the cause of the coolant loss elimi‐

nated as soon as possible.

Disposal

Comply with the appropriate environ‐mental protection regulations when dis‐

posing of coolant additives.

Seite 168MobilityCoolant168

Online Edition for Part no. 01 40 2 911 521 - VI/13

Page 170 of 218

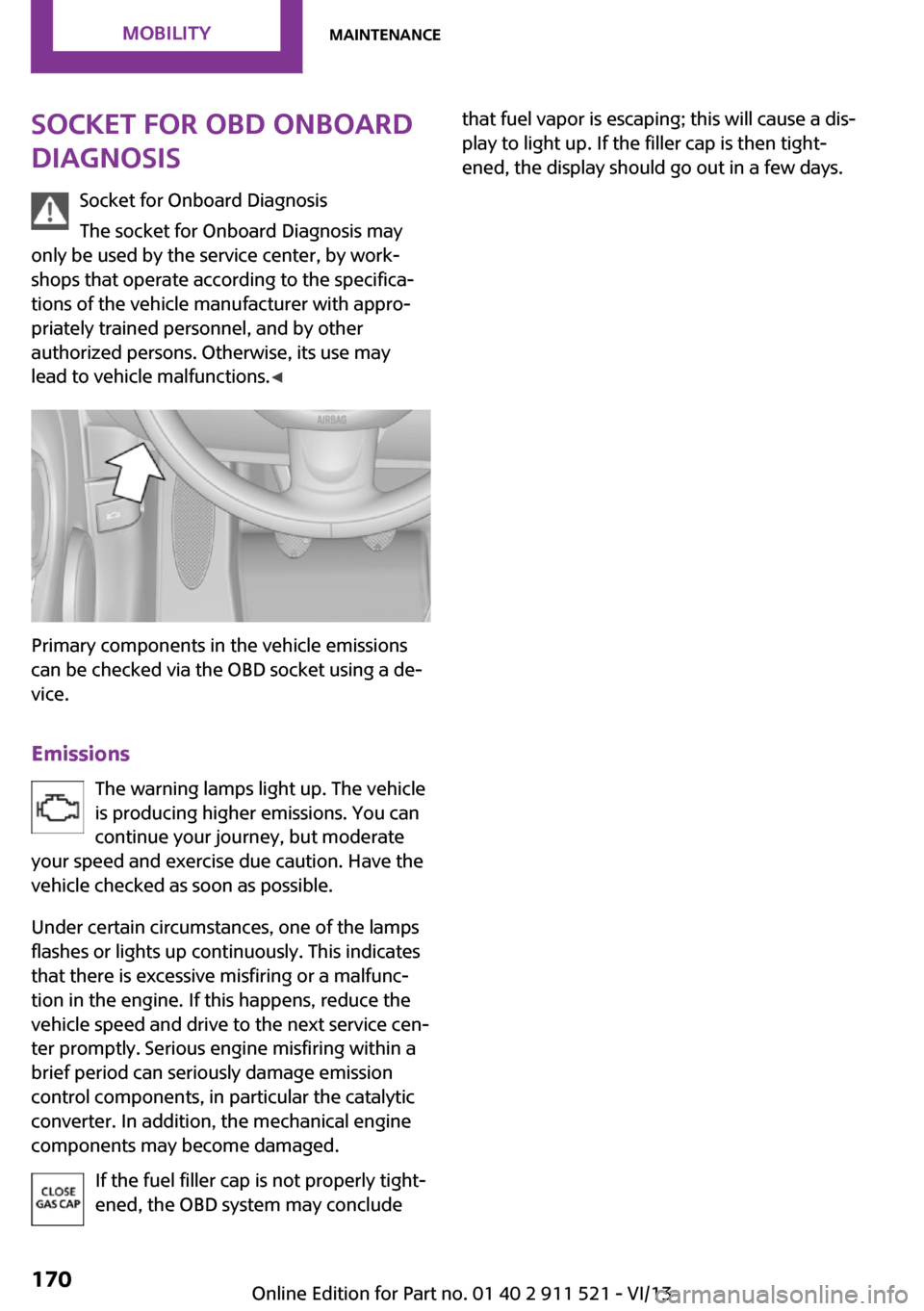

Socket for OBD Onboard

Diagnosis

Socket for Onboard Diagnosis

The socket for Onboard Diagnosis may

only be used by the service center, by work‐

shops that operate according to the specifica‐

tions of the vehicle manufacturer with appro‐

priately trained personnel, and by other

authorized persons. Otherwise, its use may

lead to vehicle malfunctions. ◀

Primary components in the vehicle emissions

can be checked via the OBD socket using a de‐

vice.

Emissions The warning lamps light up. The vehicle

is producing higher emissions. You can

continue your journey, but moderate

your speed and exercise due caution. Have the

vehicle checked as soon as possible.

Under certain circumstances, one of the lamps

flashes or lights up continuously. This indicates

that there is excessive misfiring or a malfunc‐

tion in the engine. If this happens, reduce the

vehicle speed and drive to the next service cen‐

ter promptly. Serious engine misfiring within a

brief period can seriously damage emission

control components, in particular the catalytic

converter. In addition, the mechanical engine

components may become damaged.

If the fuel filler cap is not properly tight‐

ened, the OBD system may conclude

that fuel vapor is escaping; this will cause a dis‐

play to light up. If the filler cap is then tight‐

ened, the display should go out in a few days.Seite 170MobilityMaintenance170

Online Edition for Part no. 01 40 2 911 521 - VI/13

Page 173 of 218

Due to the high voltage present in the system,

there is the danger of fatal injuries if work is

carried out improperly. ◀

Front lamps, bulb replacement

Halogen low beams and high beams

Bulb H13, 60/55 watt

Wear protective goggles and gloves

Halogen bulbs are pressurized. Therefore,

wear protective goggles and gloves. Otherwise,

there is a danger of injuries if the bulb is acci‐

dentally damaged during replacement. ◀

Attach the cover carefully

When attaching the cover, proceed care‐

fully; otherwise, leaks may occur, causing dam‐

age to the headlamp system. ◀

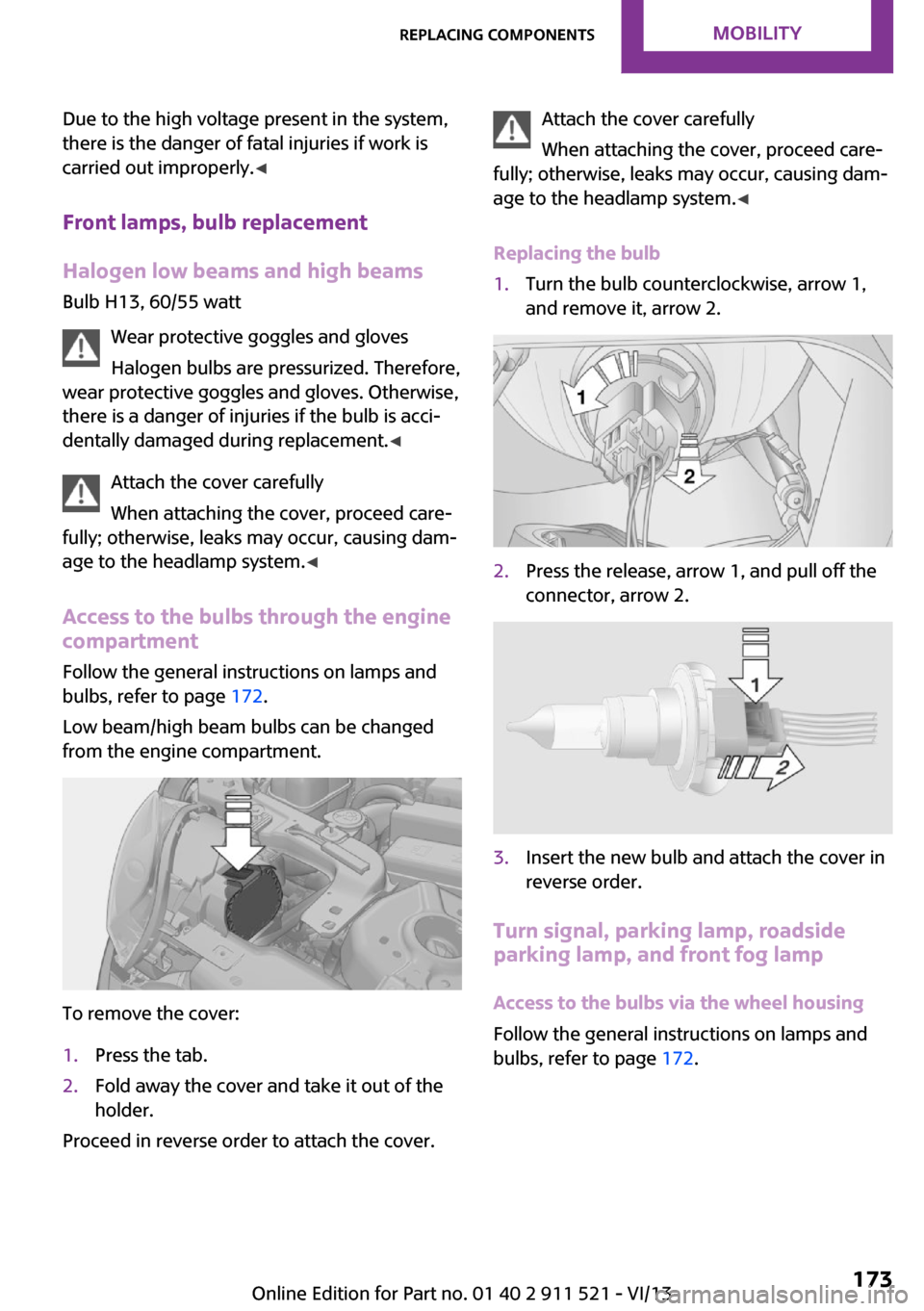

Access to the bulbs through the engine compartment

Follow the general instructions on lamps and

bulbs, refer to page 172.

Low beam/high beam bulbs can be changed

from the engine compartment.

To remove the cover:

1.Press the tab.2.Fold away the cover and take it out of the

holder.

Proceed in reverse order to attach the cover.

Attach the cover carefully

When attaching the cover, proceed care‐

fully; otherwise, leaks may occur, causing dam‐

age to the headlamp system. ◀

Replacing the bulb1.Turn the bulb counterclockwise, arrow 1,

and remove it, arrow 2.2.Press the release, arrow 1, and pull off the

connector, arrow 2.3.Insert the new bulb and attach the cover in

reverse order.

Turn signal, parking lamp, roadside

parking lamp, and front fog lamp

Access to the bulbs via the wheel housing

Follow the general instructions on lamps and

bulbs, refer to page 172.

Seite 173Replacing componentsMobility173

Online Edition for Part no. 01 40 2 911 521 - VI/13

Page 178 of 218

Vehicle batteryMaintenance

The battery is maintenance-free, i.e., the elec‐

trolyte will last for the life of the battery in tem‐

perate climate conditions.

The service center will be happy to answer any

questions on the battery.

Battery replacement Use approved vehicle batteries

Only use vehicle batteries that have been

approved for your vehicle by the manufacturer;

otherwise, the vehicle could be damaged and

systems or functions may not be fully availa‐

ble. ◀

Have the vehicle battery registered by the serv‐

ice center after it is replaced to ensure that all

comfort functions are available without restric‐

tions and that any associated Check Control

messages are no longer displayed.

Charging the battery

Note Do not connect the charger to the socket

Do not connect the battery charger to the

socket installed in the vehicle at the factory as

this could damage the battery. ◀

Only charge the battery in the vehicle when the engine is switched off. Connections, refer to

page 180.

General information Ensure that the battery is sufficiently charged to

achieve the full battery life.

It may be necessary to charge the battery in

the following cases:▷When the vehicle is frequently used to

travel short distances.▷When the vehicle has not been driven for

more than one month.Power failure

After a temporary power failure, some equip‐

ment will be restricted in its use and will need

to be reinitialized. In addition, certain individual

settings will be lost and must be updated:▷Time and date: the values must be up‐

dated, refer to page 63.▷Radio: the stations need to be stored again,

refer to page 126.▷Glass sunroof, electrical: it may only be pos‐

sible to tilt the roof. The system needs to be

initialized. Contact the service center.

Disposing of old batteries

Have used batteries disposed of by the

service center after they are replaced or

take them to a recycling center.

Maintain the battery in an upright position for

transport and storage. Secure the battery so

that it does not tip over during transport.

Fuses Replacing fuses

Never attempt to repair a blown fuse and

do not replace a defective fuse with a substi‐

tute of another color or amperage rating; this

could lead to a circuit overload, ultimately re‐

sulting in a fire in the vehicle. ◀

Fuses should be replaced by the service center.

Information on the fuses can be found on the

inside of the covers.

Seite 178MobilityReplacing components178

Online Edition for Part no. 01 40 2 911 521 - VI/13