light MINI Paceman 2015 Repair Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2015, Model line: Paceman, Model: MINI Paceman 2015Pages: 223, PDF Size: 5.51 MB

Page 139 of 223

▷Press: select the highlighted menu item

or store the setting.5Opens the main menu.6On/off, volume control.

Menu navigation

Selecting menu items

There are two ways to select a menu item on

the display.

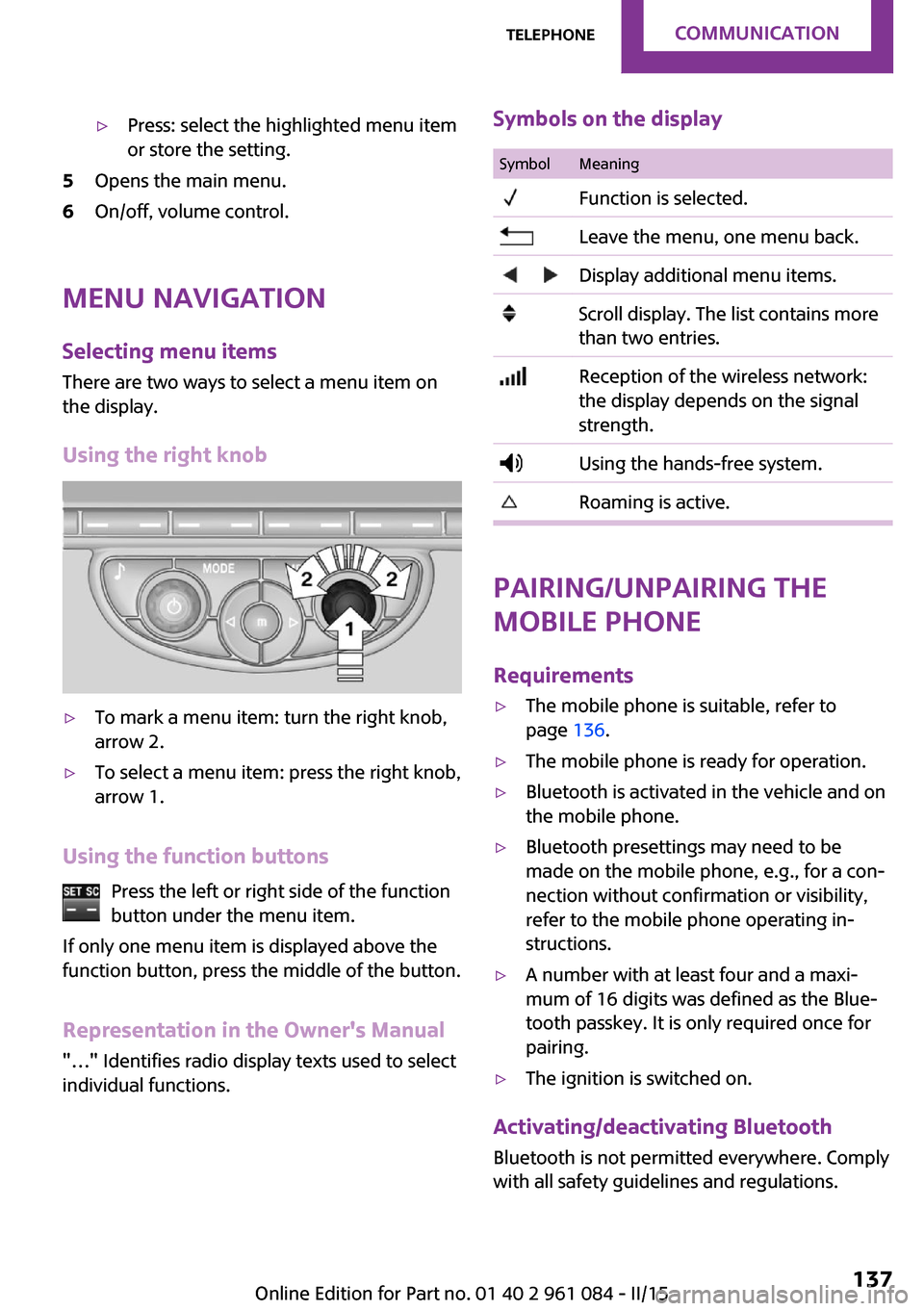

Using the right knob

▷To mark a menu item: turn the right knob,

arrow 2.▷To select a menu item: press the right knob,

arrow 1.

Using the function buttons

Press the left or right side of the functionbutton under the menu item.

If only one menu item is displayed above the

function button, press the middle of the button.

Representation in the Owner's Manual

"…" Identifies radio display texts used to select

individual functions.

Symbols on the displaySymbolMeaning Function is selected. Leave the menu, one menu back. Display additional menu items. Scroll display. The list contains more

than two entries. Reception of the wireless network:

the display depends on the signal

strength. Using the hands-free system. Roaming is active.

Pairing/unpairing the

mobile phone

Requirements

▷The mobile phone is suitable, refer to

page 136.▷The mobile phone is ready for operation.▷Bluetooth is activated in the vehicle and on

the mobile phone.▷Bluetooth presettings may need to be

made on the mobile phone, e.g., for a con‐

nection without confirmation or visibility,

refer to the mobile phone operating in‐

structions.▷A number with at least four and a maxi‐

mum of 16 digits was defined as the Blue‐

tooth passkey. It is only required once for

pairing.▷The ignition is switched on.

Activating/deactivating Bluetooth

Bluetooth is not permitted everywhere. Comply

with all safety guidelines and regulations.

Seite 137TelephoneCOMMUNICATION137

Online Edition for Part no. 01 40 2 961 084 - II/15

Page 162 of 223

Maximum speed of winter tires

If the maximum speed of the vehicle is higher

than the permissible speed for the winter tires,

then display a corresponding sign in the field of

vision. You can obtain this sign from the tire

specialist or from your service center.

Maximum speed for winter tires

Do not exceed the maximum speed for

the winter tires; otherwise, tire damage and ac‐

cidents can occur. ◀

Run-flat tires When mounting new tires or changing fromsummer to winter tires or vice versa, use run-

flat tires for your own safety. Also, a compact

wheel is not available in case of a flat tire. Your

service center will be glad to advise you.

Rotating wheels between axles

Different wear patterns occur on the front and

rear axles, depending on the individual condi‐

tions of use.

To ensure even wear on the tires, the wheels

can be rotated between the axles. Your service

center will be glad to advise you.

After changing the tires, check the tire inflation

pressure and correct it if necessary.

Storage Store wheels and tires in a cool, dry place with

as little exposure to light as possible.

Always protect tires against all contact with oil,

grease and fuels.

Do not exceed the maximum tire inflation pres‐

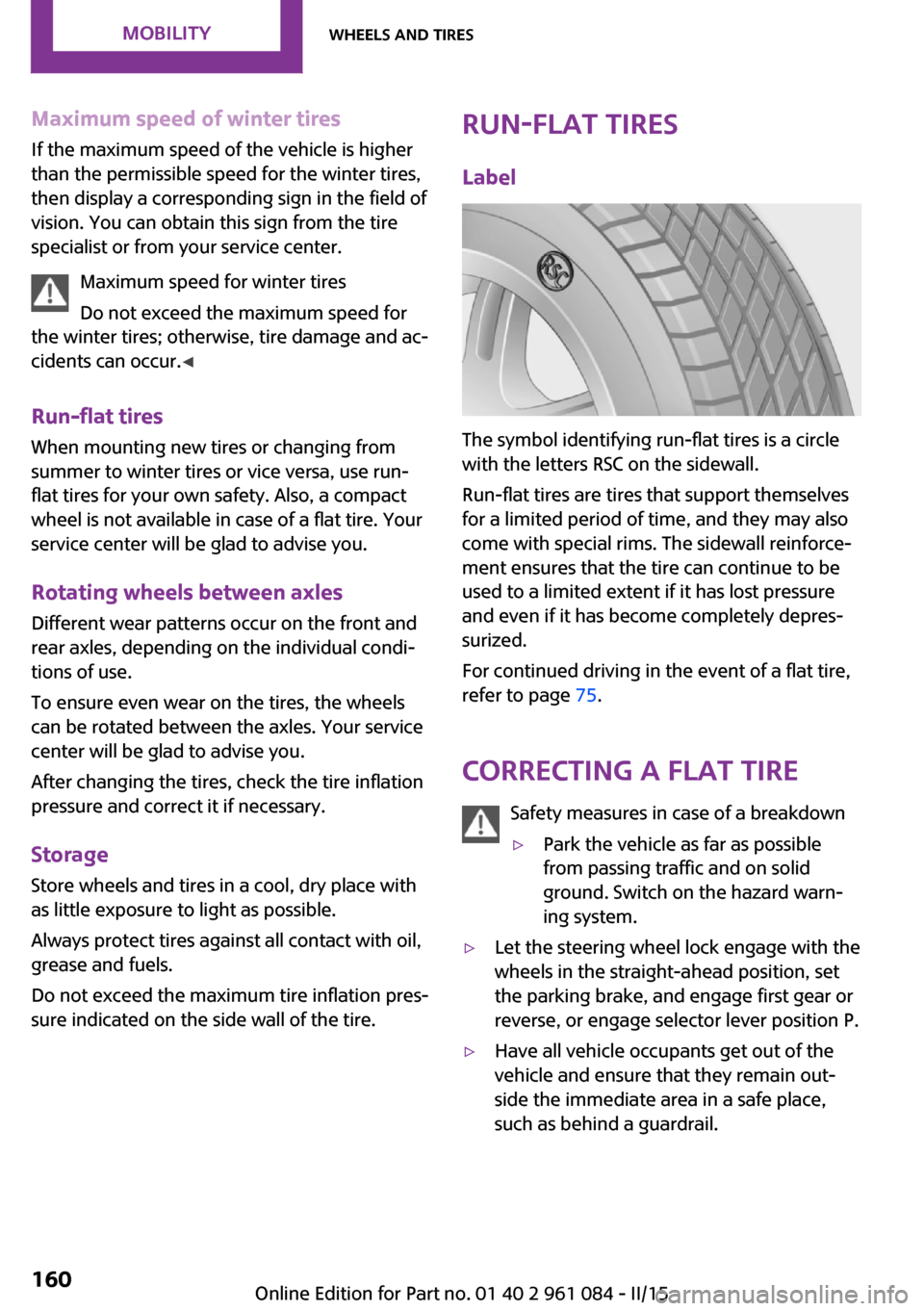

sure indicated on the side wall of the tire.Run-flat tires

Label

The symbol identifying run-flat tires is a circle

with the letters RSC on the sidewall.

Run-flat tires are tires that support themselves

for a limited period of time, and they may also

come with special rims. The sidewall reinforce‐

ment ensures that the tire can continue to be

used to a limited extent if it has lost pressure

and even if it has become completely depres‐

surized.

For continued driving in the event of a flat tire,

refer to page 75.

Correcting a flat tire Safety measures in case of a breakdown

▷Park the vehicle as far as possible

from passing traffic and on solid

ground. Switch on the hazard warn‐

ing system.▷Let the steering wheel lock engage with the

wheels in the straight-ahead position, set

the parking brake, and engage first gear or

reverse, or engage selector lever position P.▷Have all vehicle occupants get out of the

vehicle and ensure that they remain out‐

side the immediate area in a safe place,

such as behind a guardrail.Seite 160MOBILITYWheels and tires160

Online Edition for Part no. 01 40 2 961 084 - II/15

Page 163 of 223

▷If a warning triangle or portable hazard

warning lamp is required, set it up on the

roadside at an appropriate distance from

the rear of the vehicle. Comply with all

safety guidelines and regulations. ◀

The procedure to correct a flat tire depends on

the equipment in the vehicle:

▷Run-flat tires, refer to page 160.▷MINI Mobility System, refer to page 161.

MINI Mobility System

Notes

▷Follow the instructions on using the Mobi‐

lity System found on the compressor and

sealant bottle.▷Use of the Mobility System may be ineffec‐

tive if tire damage is greater than approx.

1/8 in/4 mm in size.▷Contact the nearest service center if the tire

cannot be made drivable.▷If possible, do not remove foreign bodies

that have penetrated the tire.▷Pull the speed limit sticker off the sealant

bottle and apply it to the steering wheel.

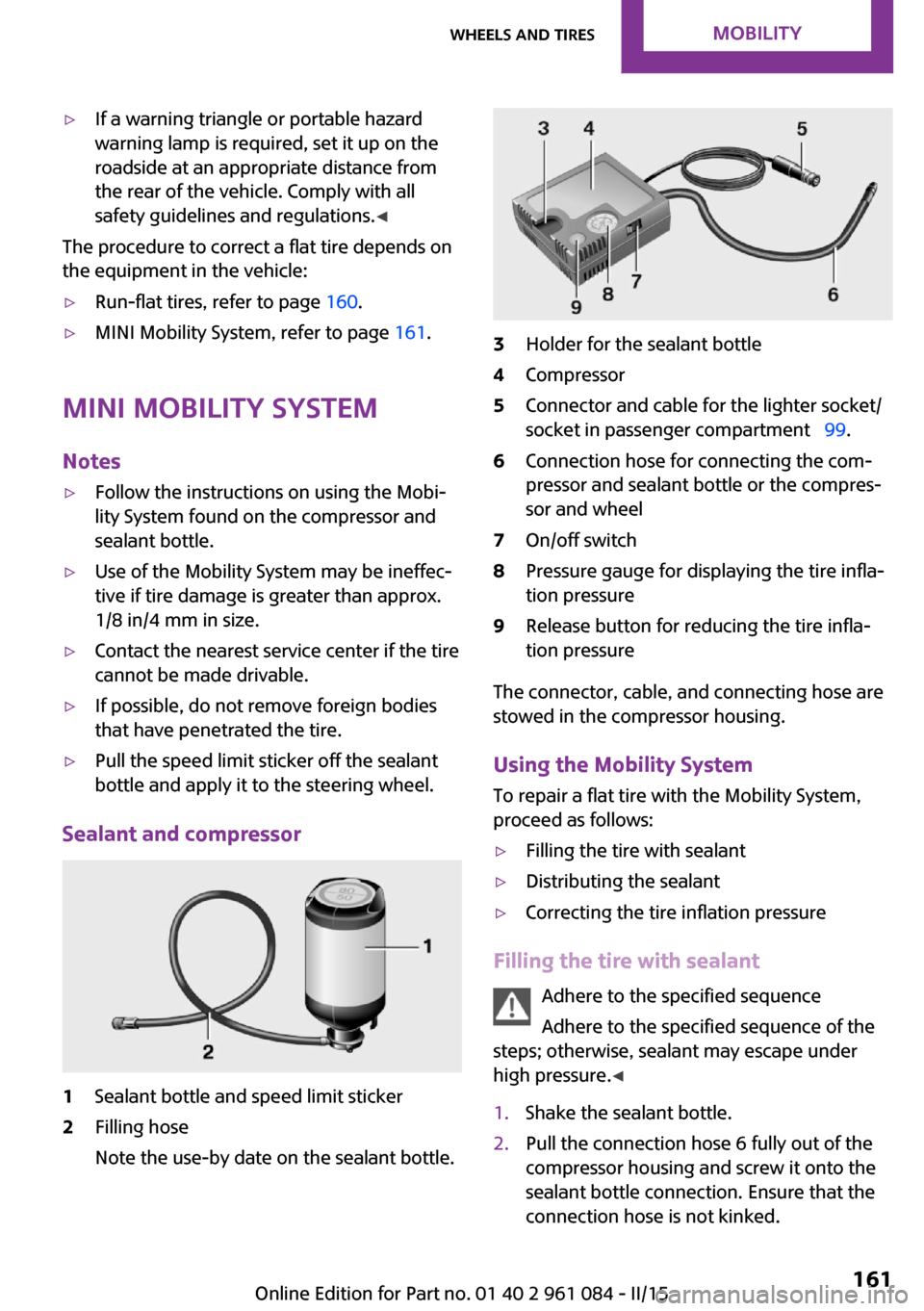

Sealant and compressor

1Sealant bottle and speed limit sticker2Filling hose

Note the use-by date on the sealant bottle.3Holder for the sealant bottle4Compressor5Connector and cable for the lighter socket/

socket in passenger compartment 99.6Connection hose for connecting the com‐

pressor and sealant bottle or the compres‐

sor and wheel7On/off switch8Pressure gauge for displaying the tire infla‐

tion pressure9Release button for reducing the tire infla‐

tion pressure

The connector, cable, and connecting hose are

stowed in the compressor housing.

Using the Mobility System

To repair a flat tire with the Mobility System,

proceed as follows:

▷Filling the tire with sealant▷Distributing the sealant▷Correcting the tire inflation pressure

Filling the tire with sealant

Adhere to the specified sequence

Adhere to the specified sequence of the

steps; otherwise, sealant may escape under

high pressure. ◀

1.Shake the sealant bottle.2.Pull the connection hose 6 fully out of the

compressor housing and screw it onto the

sealant bottle connection. Ensure that the

connection hose is not kinked.Seite 161Wheels and tiresMOBILITY161

Online Edition for Part no. 01 40 2 961 084 - II/15

Page 164 of 223

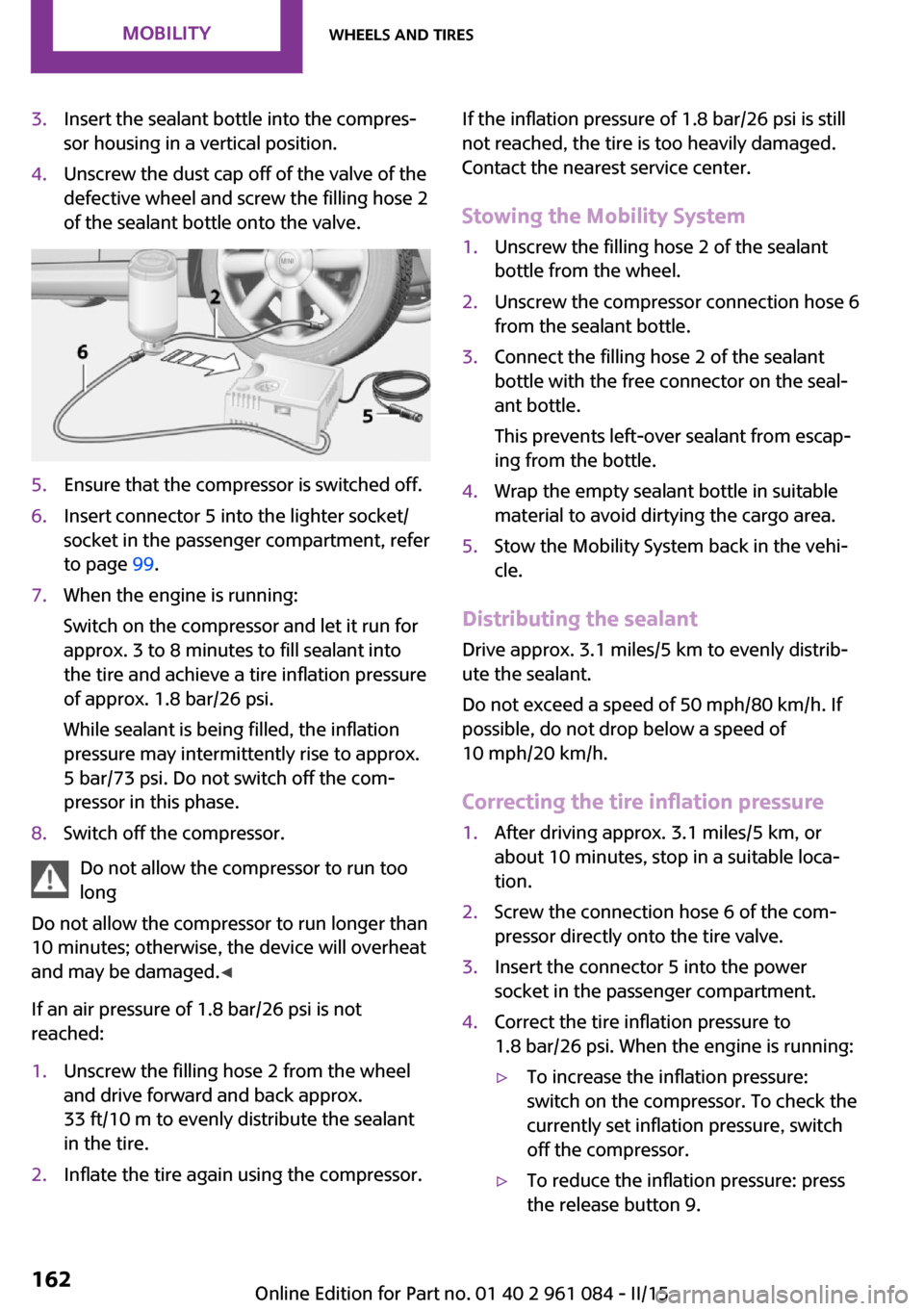

3.Insert the sealant bottle into the compres‐

sor housing in a vertical position.4.Unscrew the dust cap off of the valve of the

defective wheel and screw the filling hose 2

of the sealant bottle onto the valve.5.Ensure that the compressor is switched off.6.Insert connector 5 into the lighter socket/

socket in the passenger compartment, refer

to page 99.7.When the engine is running:

Switch on the compressor and let it run for

approx. 3 to 8 minutes to fill sealant into

the tire and achieve a tire inflation pressure

of approx. 1.8 bar/26 psi.

While sealant is being filled, the inflation

pressure may intermittently rise to approx.

5 bar/73 psi. Do not switch off the com‐

pressor in this phase.8.Switch off the compressor.

Do not allow the compressor to run too

long

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged. ◀

If an air pressure of 1.8 bar/26 psi is not

reached:

1.Unscrew the filling hose 2 from the wheel

and drive forward and back approx.

33 ft/10 m to evenly distribute the sealant

in the tire.2.Inflate the tire again using the compressor.If the inflation pressure of 1.8 bar/26 psi is still

not reached, the tire is too heavily damaged.

Contact the nearest service center.

Stowing the Mobility System1.Unscrew the filling hose 2 of the sealant

bottle from the wheel.2.Unscrew the compressor connection hose 6

from the sealant bottle.3.Connect the filling hose 2 of the sealant

bottle with the free connector on the seal‐

ant bottle.

This prevents left-over sealant from escap‐

ing from the bottle.4.Wrap the empty sealant bottle in suitable

material to avoid dirtying the cargo area.5.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Drive approx. 3.1 miles/5 km to evenly distrib‐

ute the sealant.

Do not exceed a speed of 50 mph/80 km/h. If

possible, do not drop below a speed of

10 mph/20 km/h.

Correcting the tire inflation pressure

1.After driving approx. 3.1 miles/5 km, or

about 10 minutes, stop in a suitable loca‐

tion.2.Screw the connection hose 6 of the com‐

pressor directly onto the tire valve.3.Insert the connector 5 into the power

socket in the passenger compartment.4.Correct the tire inflation pressure to

1.8 bar/26 psi. When the engine is running:▷To increase the inflation pressure:

switch on the compressor. To check the

currently set inflation pressure, switch

off the compressor.▷To reduce the inflation pressure: press

the release button 9.Seite 162MOBILITYWheels and tires162

Online Edition for Part no. 01 40 2 961 084 - II/15

Page 166 of 223

Engine compartmentVehicle equipment

This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series. Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selectedspecial equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

When using the features and systems described

here, adhere to local regulations.

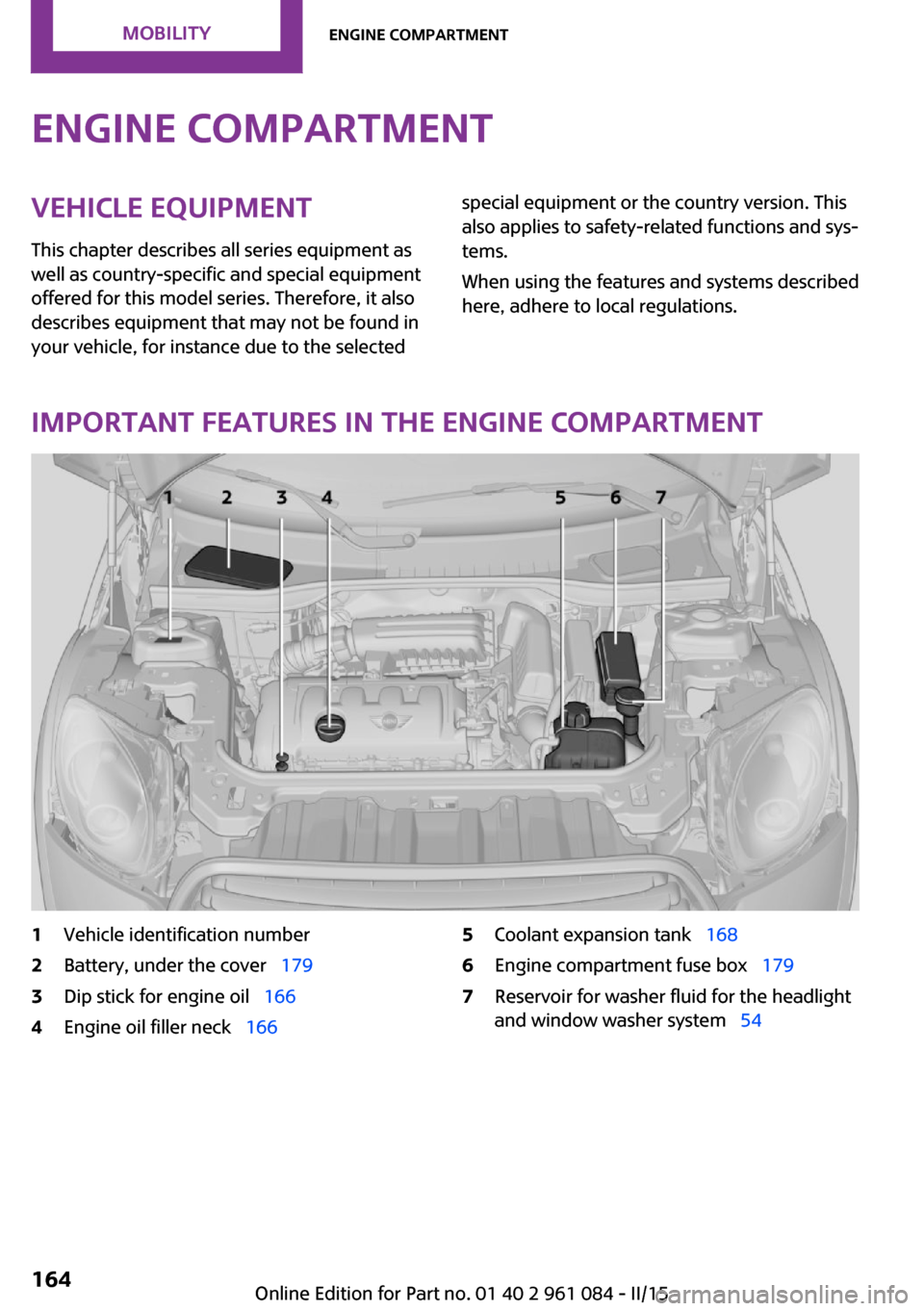

Important features in the engine compartment

1Vehicle identification number2Battery, under the cover 1793Dip stick for engine oil 1664Engine oil filler neck 1665Coolant expansion tank 1686Engine compartment fuse box 1797Reservoir for washer fluid for the headlight

and window washer system 54Seite 164MOBILITYEngine compartment164

Online Edition for Part no. 01 40 2 961 084 - II/15

Page 170 of 223

CoolantVehicle equipment

This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series. Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

When using the features and systems described

here, adhere to local regulations.

General information Danger of burns from hot engine

Do not open the cooling system while the

engine is hot; otherwise, escaping coolant may

cause burns. ◀

Suitable additives

Only use suitable additives; otherwise,

engine damage may occur. The additives are

harmful to your health. ◀

Coolant consists of water and additives.

Not all commercially available additives are

suitable for your MINI vehicle. Ask your service

center for suitable additives.

Coolant temperature

If the coolant and therefore the engine over‐

heat, a warning lamp lights up, refer to

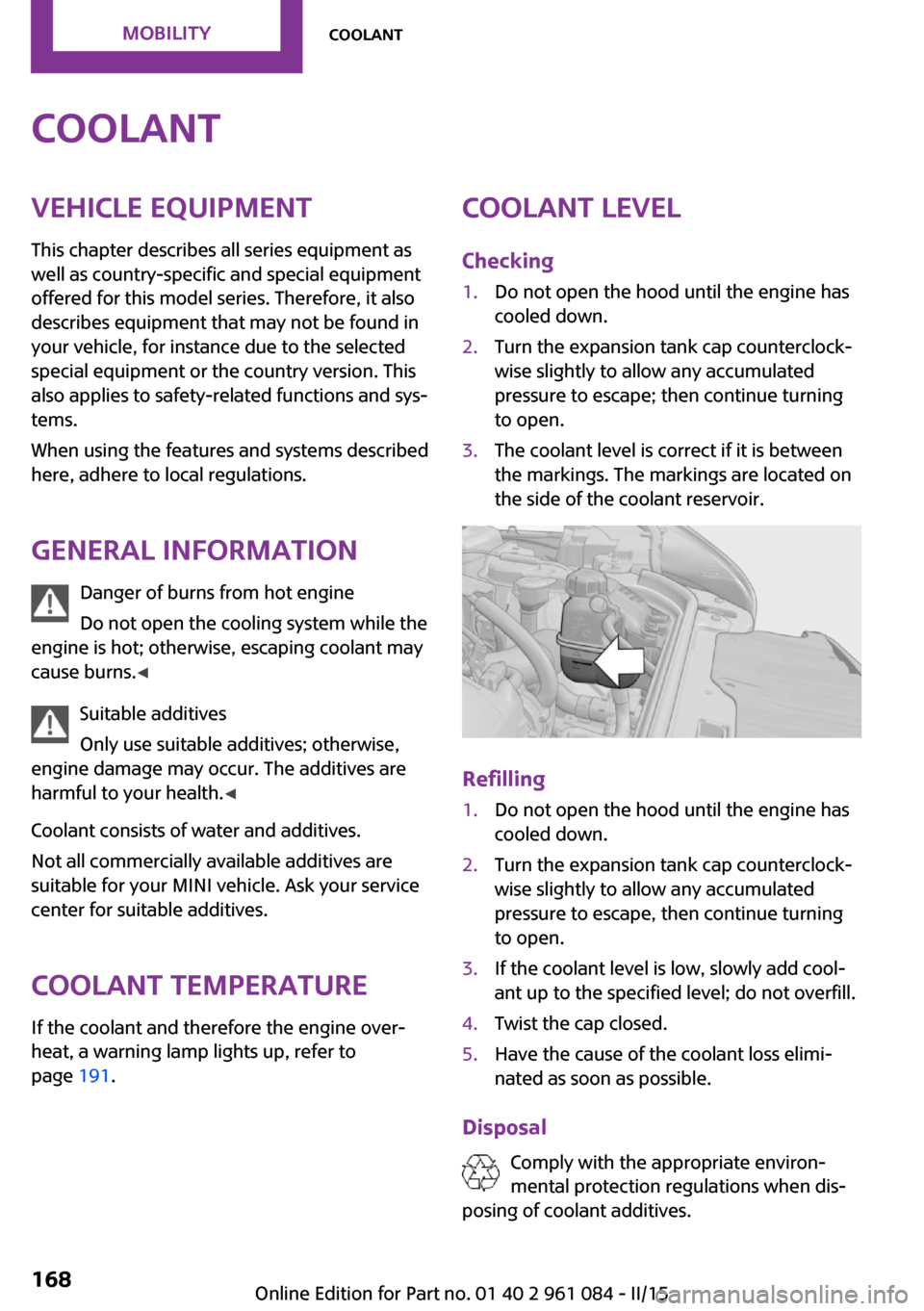

page 191.Coolant level

Checking1.Do not open the hood until the engine has

cooled down.2.Turn the expansion tank cap counterclock‐

wise slightly to allow any accumulated

pressure to escape; then continue turning

to open.3.The coolant level is correct if it is between

the markings. The markings are located on

the side of the coolant reservoir.

Refilling

1.Do not open the hood until the engine has

cooled down.2.Turn the expansion tank cap counterclock‐

wise slightly to allow any accumulated

pressure to escape, then continue turning

to open.3.If the coolant level is low, slowly add cool‐

ant up to the specified level; do not overfill.4.Twist the cap closed.5.Have the cause of the coolant loss elimi‐

nated as soon as possible.

Disposal

Comply with the appropriate environ‐mental protection regulations when dis‐

posing of coolant additives.

Seite 168MOBILITYCoolant168

Online Edition for Part no. 01 40 2 961 084 - II/15

Page 172 of 223

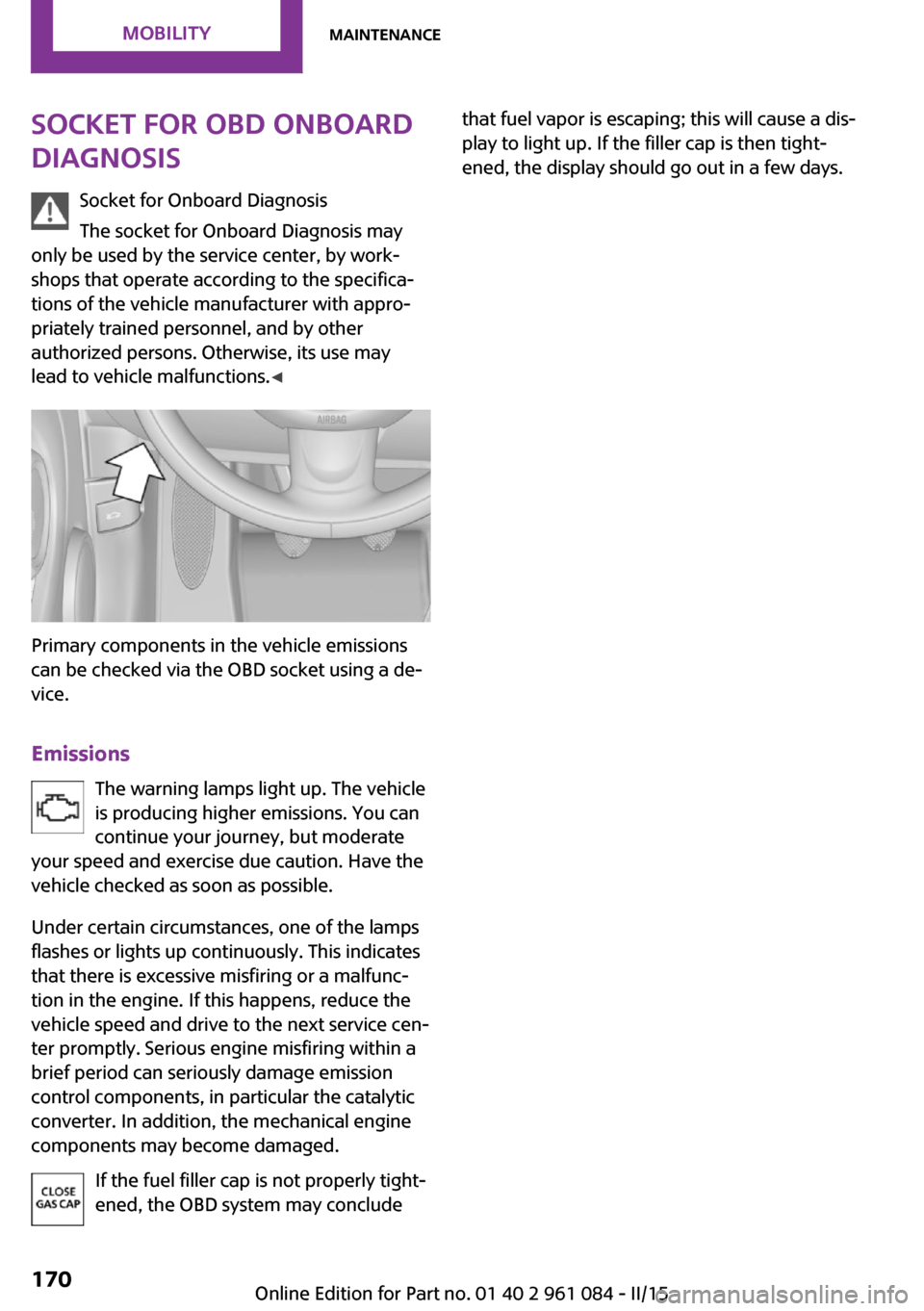

Socket for OBD Onboard

Diagnosis

Socket for Onboard Diagnosis

The socket for Onboard Diagnosis may

only be used by the service center, by work‐

shops that operate according to the specifica‐

tions of the vehicle manufacturer with appro‐

priately trained personnel, and by other

authorized persons. Otherwise, its use may

lead to vehicle malfunctions. ◀

Primary components in the vehicle emissions

can be checked via the OBD socket using a de‐

vice.

Emissions The warning lamps light up. The vehicle

is producing higher emissions. You can

continue your journey, but moderate

your speed and exercise due caution. Have the

vehicle checked as soon as possible.

Under certain circumstances, one of the lamps

flashes or lights up continuously. This indicates

that there is excessive misfiring or a malfunc‐

tion in the engine. If this happens, reduce the

vehicle speed and drive to the next service cen‐

ter promptly. Serious engine misfiring within a

brief period can seriously damage emission

control components, in particular the catalytic

converter. In addition, the mechanical engine

components may become damaged.

If the fuel filler cap is not properly tight‐

ened, the OBD system may conclude

that fuel vapor is escaping; this will cause a dis‐

play to light up. If the filler cap is then tight‐

ened, the display should go out in a few days.Seite 170MOBILITYMaintenance170

Online Edition for Part no. 01 40 2 961 084 - II/15

Page 174 of 223

Lamp and bulb replace‐

ment

Notes

Lamps and bulbs Lamps and bulbs make an essential contribu‐

tion to vehicle safety. Therefore, exercise cau‐

tion when handling lights and bulbs.

The manufacturer of the vehicle recommends

that you entrust corresponding procedures to

the service center if you are unfamiliar with

them or they are not described here.

You can obtain a selection of replacement

bulbs at the service center.

Danger of burns

Only change bulbs when they are cool;

otherwise, there is the danger of getting

burned. ◀

Working on the lighting system

When working on the lighting system,

you should always switch off the lights affected

to prevent short circuits.

To avoid possible injury or equipment damage

when replacing bulbs, observe any instructions

provided by the bulb manufacturer. ◀

Do not touch the bulbs

Do not touch the glass of new bulbs with

your bare hands, as even minute amounts of

contamination will burn into the bulb's surface

and reduce its service life.

Use a clean tissue, cloth or something similar,

or hold the bulb by its base. ◀

Caring for the headlights, refer to page 187.

For bulb replacement that is not described

here, please contact the service center or a

workshop that works according to the repair

procedures of the manufacturer with corre‐

spondingly trained personnel.For checking and adjusting headlight aim,

please contact your MINI dealer.

Light-emitting diodes LEDs In some equipment, the light source is provided

by light-emitting diodes behind a cover.

These light-emitting diodes, which operate us‐

ing a concept similar to that applied in conven‐

tional lasers, are designated as Class 1 light-

emitting diodes.

Do not remove the covers

Do not remove the covers, and never

stare into the unfiltered light for several hours;

otherwise, irritation of the retina could result. ◀

Headlight glass Condensation can form on the inside of the

headlights in cool or humid weather. When the

light is switched on, the condensation evapo‐

rates after a short time. The headlights do not

need to be changed.

If the condensation in the headlights does not

evaporate after trips with the lights switched

on, and the amount of moisture in the head‐

lights increases, for example if water droplets

form, have them checked by your service cen‐

ter.

Bi-xenon headlights

These bulbs have a very long life and the likeli‐

hood of failure is very low, provided that they

are not switched on and off excessively. If a

bulb should nevertheless fail, you can continue

driving cautiously with the front fog lights, pro‐

vided this is permitted by local laws.

Do not perform work/bulb replacement

on xenon headlamps

Have any work on the xenon lighting system,

including bulb replacement, performed only by

a service center.

Due to the high voltage present in the system,

there is the danger of fatal injuries if work is

carried out improperly. ◀Seite 172MOBILITYReplacing components172

Online Edition for Part no. 01 40 2 961 084 - II/15

Page 175 of 223

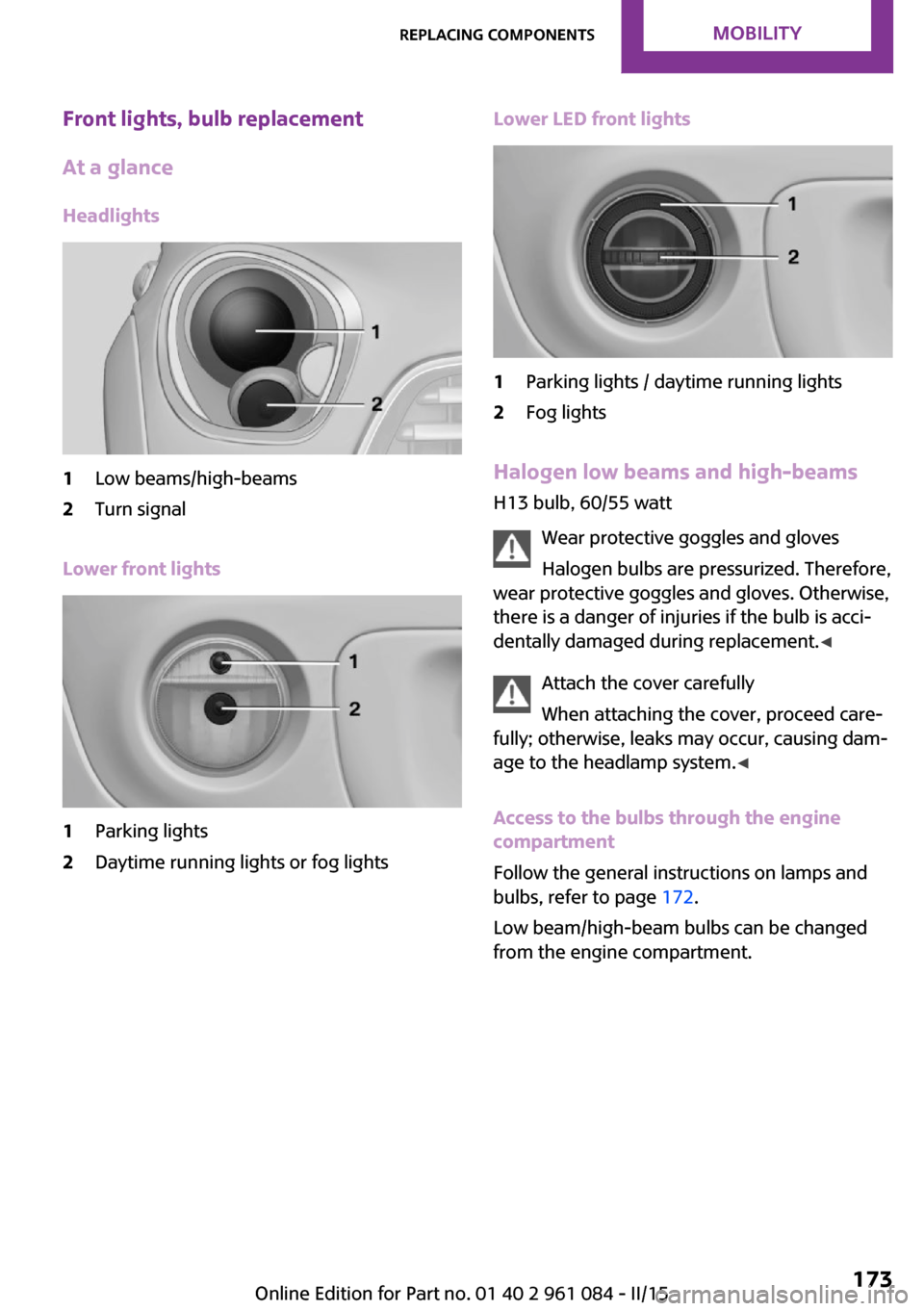

Front lights, bulb replacement

At a glance

Headlights1Low beams/high-beams2Turn signal

Lower front lights

1Parking lights2Daytime running lights or fog lightsLower LED front lights1Parking lights / daytime running lights2Fog lights

Halogen low beams and high-beams

H13 bulb, 60/55 watt

Wear protective goggles and glovesHalogen bulbs are pressurized. Therefore,

wear protective goggles and gloves. Otherwise,

there is a danger of injuries if the bulb is acci‐

dentally damaged during replacement. ◀

Attach the cover carefully

When attaching the cover, proceed care‐

fully; otherwise, leaks may occur, causing dam‐

age to the headlamp system. ◀

Access to the bulbs through the engine

compartment

Follow the general instructions on lamps and

bulbs, refer to page 172.

Low beam/high-beam bulbs can be changed

from the engine compartment.

Seite 173Replacing componentsMOBILITY173

Online Edition for Part no. 01 40 2 961 084 - II/15

Page 176 of 223

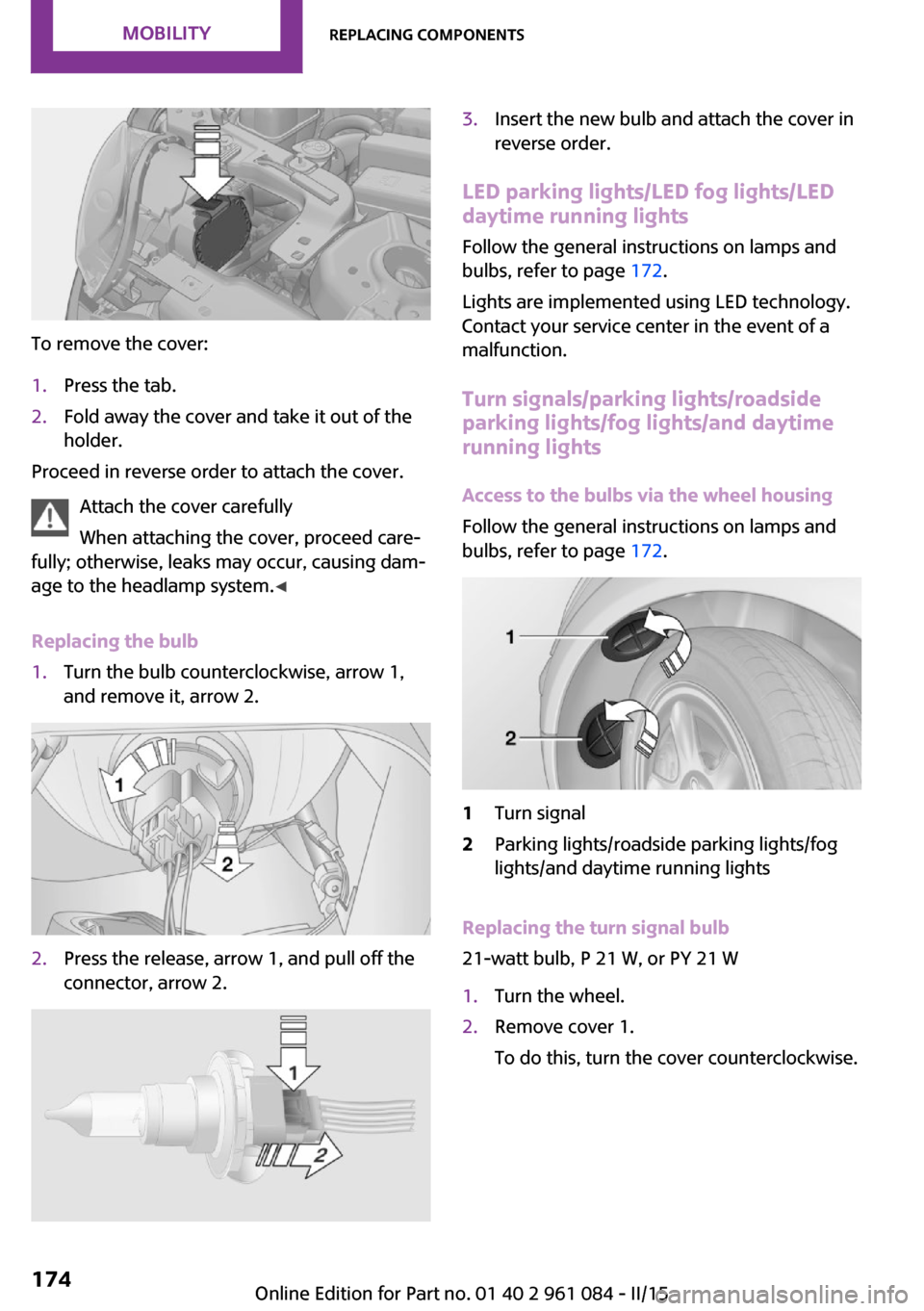

To remove the cover:

1.Press the tab.2.Fold away the cover and take it out of the

holder.

Proceed in reverse order to attach the cover.

Attach the cover carefully

When attaching the cover, proceed care‐

fully; otherwise, leaks may occur, causing dam‐

age to the headlamp system. ◀

Replacing the bulb

1.Turn the bulb counterclockwise, arrow 1,

and remove it, arrow 2.2.Press the release, arrow 1, and pull off the

connector, arrow 2.3.Insert the new bulb and attach the cover in

reverse order.

LED parking lights/LED fog lights/LED

daytime running lights

Follow the general instructions on lamps and

bulbs, refer to page 172.

Lights are implemented using LED technology.

Contact your service center in the event of a

malfunction.

Turn signals/parking lights/roadside

parking lights/fog lights/and daytime

running lights

Access to the bulbs via the wheel housing

Follow the general instructions on lamps and

bulbs, refer to page 172.

1Turn signal2Parking lights/roadside parking lights/fog

lights/and daytime running lights

Replacing the turn signal bulb

21-watt bulb, P 21 W, or PY 21 W

1.Turn the wheel.2.Remove cover 1.

To do this, turn the cover counterclockwise.Seite 174MOBILITYReplacing components174

Online Edition for Part no. 01 40 2 961 084 - II/15