lights MITSUBISHI 3000GT 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 682 of 1146

33B-20 ELECTRONIC CONTROL SUSPENSION (ECS)-llwmtk Positkm .semor I stop tight switch I POriticm DetsctionSWitEh 1 DPmping Force changeover Acluatc., / EC3 Indii.ar l.igil*

THROTTLE POSITION SENSORM33ZKA6

INSPECTION AND ADJUSTMENTIRefer to GROUP 13

- Fuel System.‘lJ ’

STOP LIGHT SWITCHM33ZCAC

To remove or mount the stop light switch, refer to GROUP 35 -

Brake Pedal.

INSPECTIONRefer to GROUP 35

- Brake Pedal.

POSITION DETECTION SWITCH and

DAMPING FORCE CHANGEOVER

ACTUATORM33ZCAD

To remove or mount the position detection switch and dampingforce changeover actuator, refer to GROUP 33A

- Strut LJAssembly and GROUP 34

- Shock Absorber Assembly.

CautionThe position detection switch and damping force

changeover actuator are built into the shock absorber

assemblies of front and rear suspensions. Since they are ofthe non-disassembly type, remove or mount them in the

form of a strut assembly or shock absorber assembly.

ECS INDICATOR LIGHTM33ZLAB

To remove or mount the ECS indicator lights, refer to GROUP54

- Meters and Gauges.

TSB Revision

Page 733 of 1146

SERVICE BRAKES -Anti-lock Braking System Troubleshooting

35-11

Adapter

iarness%f&(MB9913771(Mi3991341)\12FOO57

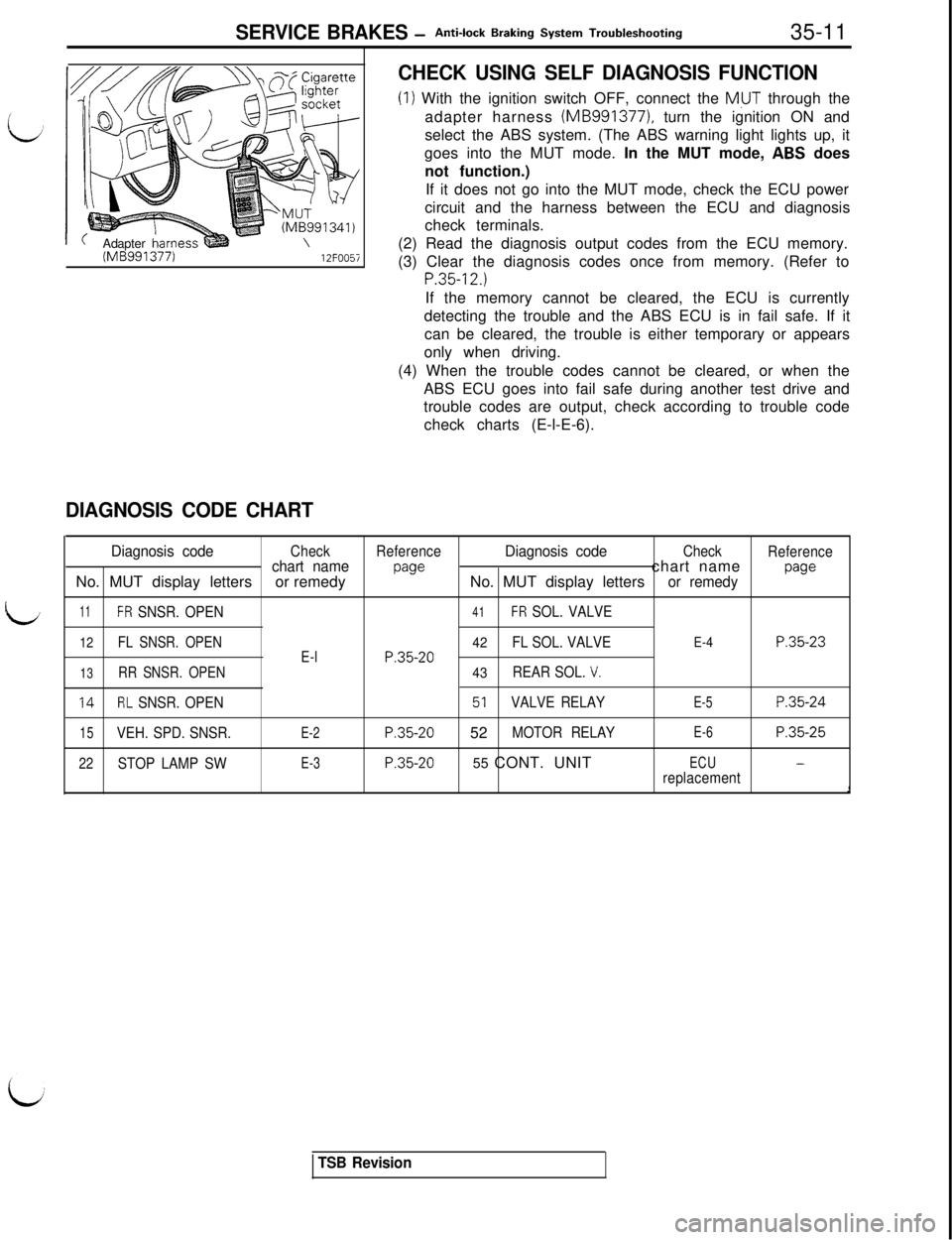

CHECK USING SELF DIAGNOSIS FUNCTION

(1) With the ignition switch OFF, connect the MUT through the

adapter harness

(MB9913771, turn the ignition ON and

select the ABS system. (The ABS warning light lights up, it

goes into the MUT mode. In the MUT mode, ABS does

not function.)

If it does not go into the MUT mode, check the ECU power

circuit and the harness between the ECU and diagnosis

check terminals.

(2) Read the diagnosis output codes from the ECU memory.

(3) Clear the diagnosis codes once from memory. (Refer to

P.35-12.)If the memory cannot be cleared, the ECU is currently

detecting the trouble and the ABS ECU is in fail safe. If it

can be cleared, the trouble is either temporary or appears

only when driving.

(4) When the trouble codes cannot be cleared, or when the

ABS ECU goes into fail safe during another test drive and

trouble codes are output, check according to trouble code

check charts (E-l-E-6).

DIAGNOSIS CODE CHART

Diagnosis codeCheckReferenceDiagnosis codeCheck

Referencechart namepagechart namepawNo. MUT display lettersor remedyNo. MUT display lettersor remedy

L11FR SNSR. OPEN41FR SOL. VALVE

12FL SNSR. OPEN42FL SOL. VALVEE-4P.35-23E-lP.35-2013RR SNSR. OPEN43REAR SOL. V.

14RL SNSR. OPEN51VALVE RELAYE-5P.35-24

15VEH. SPD. SNSR.E-2P.35-20 52MOTOR RELAYE-6P.35-25

22STOP LAMP SWE-3P.35-2055 CONT. UNITECU-

replacementI

TSB Revision

Page 735 of 1146

![MITSUBISHI 3000GT 1991 User Guide .SERVICE BRAKES -Anti-lock Braking System Troubleshooting35-13 A ABS warning light does not light at all.

iJ[Explanation][Hint]

When it does not light up at all, there is a strongIf other warning lig MITSUBISHI 3000GT 1991 User Guide .SERVICE BRAKES -Anti-lock Braking System Troubleshooting35-13 A ABS warning light does not light at all.

iJ[Explanation][Hint]

When it does not light up at all, there is a strongIf other warning lig](/img/19/57085/w960_57085-734.png)

.SERVICE BRAKES -Anti-lock Braking System Troubleshooting35-13 'A ABS warning light does not light at all.

iJ[Explanation][Hint]

When it does not light up at all, there is a strongIf other warning lights do not light up either, fuse is

possibility that there is trouble with ABS warningprobably blown.

light or with power to the light.

id

r

f%ER RELAY

110

* ::h=g

6

::5

d

.-2=

?Et0

~

2____--..-

?EI

5fir 4

I

4 -

IGNITIONSWITCH(IG2)m!--

mj:

JSIBLE LINK0tiB

2

L__---------___

0

Lp1%

%2

j:(L-R)dg

6-k

&h+&"..L"Ei SOLENOID1:

G-R

G-R

^ -tl- - D

HH H?bb

IN:IGl)-

59

1

ki@iNATION

iB

ABS-ECU

Kxss-AK-RSGOIA

1 TSB RevisionI

Page 751 of 1146

SERVICE BRAKES -Anti-lock Braking System Troubleshooting

MUT

I/(MB991 341)

\03A0211

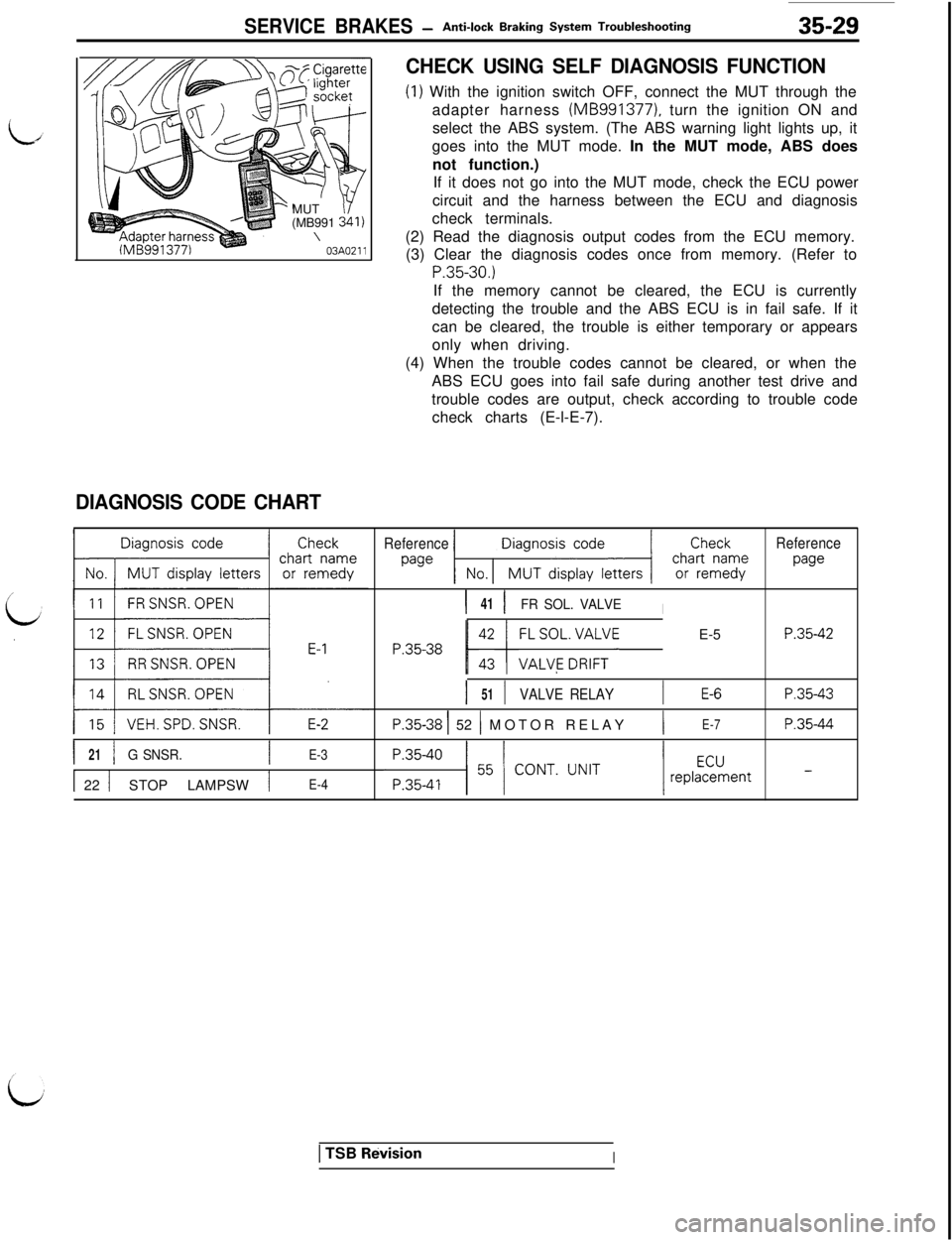

DIAGNOSIS CODE CHART

I I21G SNSR.IE-3

[ 22 1 STOP LAMPSW 1E-4

CHECK USING SELF DIAGNOSIS FUNCTION

(1) With the ignition switch OFF, connect the MUT through the

adapter harness (MB991377). turn the ignition ON and

select the ABS system. (The ABS warning light lights up, it

goes into the MUT mode. In the MUT mode, ABS does

not function.)

If it does not go into the MUT mode, check the ECU power

circuit and the harness between the ECU and diagnosis

check terminals.

(2) Read the diagnosis output codes from the ECU memory.

(3) Clear the diagnosis codes once from memory. (Refer to

P.35-30.)If the memory cannot be cleared, the ECU is currently

detecting the trouble and the ABS ECU is in fail safe. If it

can be cleared, the trouble is either temporary or appears

only when driving.

(4) When the trouble codes cannot be cleared, or when the

ABS ECU goes into fail safe during another test drive and

trouble codes are output, check according to trouble code

check charts (E-l-E-7).

Reference

we -1 ;+EiT;

I I41FR SOL. VALVEI

P.35-381 ;; / ;;tS;L;;;E/ E-5

I I51VALVE RELAY

P.35-38 1 52 1 MOTOR RELAY)E-7

si 55 / ‘ONT. UNlT/ replaEcCeUment

Reference

iwe

P.35-42

P.35-43

P.35-44

-

1 TSB RtivisionI

Page 753 of 1146

![MITSUBISHI 3000GT 1991 User Guide SERVICE BRAKES -Anti-lock Braking System Troubleshooting35-31

L’A ABS warning light does not light at all.

[Explanation][Hint]

When it does not light up at all, there is a strongIf other warning lig MITSUBISHI 3000GT 1991 User Guide SERVICE BRAKES -Anti-lock Braking System Troubleshooting35-31

L’A ABS warning light does not light at all.

[Explanation][Hint]

When it does not light up at all, there is a strongIf other warning lig](/img/19/57085/w960_57085-752.png)

SERVICE BRAKES -Anti-lock Braking System Troubleshooting35-31

L’A ABS warning light does not light at all.

[Explanation][Hint]

When it does not light up at all, there is a strongIf other warning lights do not light up either, fuse is

possibility that there is trouble with ABS warningprobably blown.

light or with power to the light.

FUSIBLE LINEI

L--L5--

i

IGNITIONSWITCH(IG2)IGNITIONSWITCH(IG1)

(L-R)-' .3

G-RI

7

!

m59COMBINATION

iMETER

1:I1o‘r_- ----- ‘2 -- ‘Ti----‘%--‘79 -_----- -7 -- “j-+3 -----1

=p!Rq3;

g:W

25

b

ABS-ECU

n=

1 TSB Revision

Page 780 of 1146

35-58SERVICE BRAKES - Service Adjustment Procedures

POINTS IN WAVEFORM MEASUREMENT

Symptom

Too small or zero waveform

amplitudeProbable causes

Faulty wheel speed sensorRemedy

Replace sensor

Incorrect pole piece-to-rotor clearance

Adjust clearance

Waveform amplitude fluctuates

excessively (this is no problem ifAxle hub eccentric or with large runout

Replace hub

the minimum amplitude is

100 mV

or more)

Noisy or disturbed waveformOpen circuit in sensor

Open circuit in harness

Incorrectly mounted wheel speed sensor

Rotor with missing or damaged teethReplace sensor

Correct harness

Mount correctly

Replace rotor

NOTEThe wheel speed sensor cable moves following motion of the front or rear suspension. Therefore, it is likely that it has an

open circuit only when driving on rough roads and it functions normally on ordinary roads. It is, therefore, recommended

to observe sensor output voltage waveform also under special conditions, such as rough road driving,

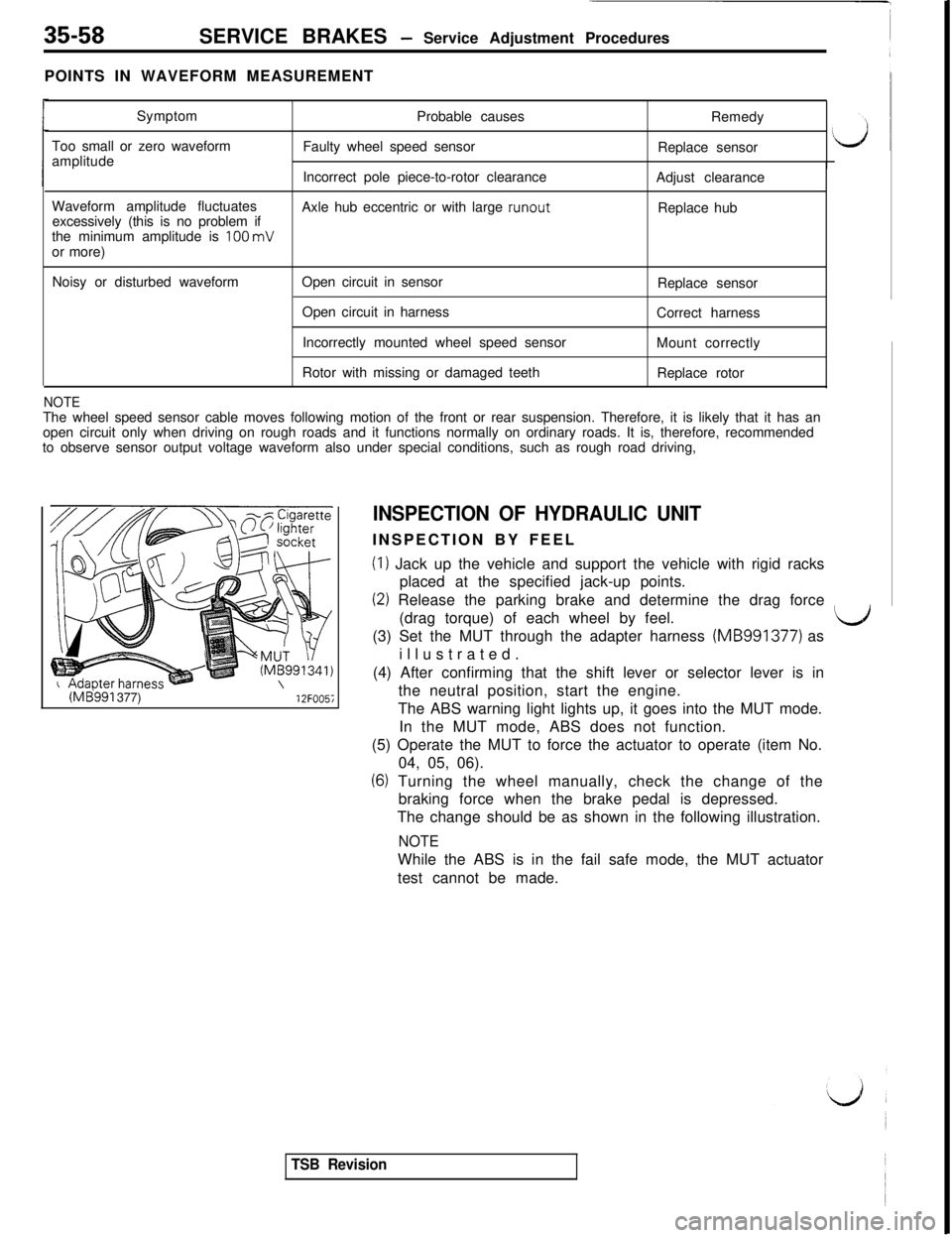

(ME!991 377)12FOO5i

INSPECTION OF HYDRAULIC UNITINSPECTION BY FEEL

(I) Jack up the vehicle and support the vehicle with rigid racks

placed at the specified jack-up points.

(2) Release the parking brake and determine the drag force

(drag torque) of each wheel by feel.

LJ(3) Set the MUT through the adapter harness (MB991377) as

illustrated.

(4) After confirming that the shift lever or selector lever is in

the neutral position, start the engine.

The ABS warning light lights up, it goes into the MUT mode.

In the MUT mode, ABS does not function.

(5) Operate the MUT to force the actuator to operate (item No.

04, 05, 06).

(6) Turning the wheel manually, check the change of the

braking force when the brake pedal is depressed.

The change should be as shown in the following illustration.

NOTEWhile the ABS is in the fail safe mode, the MUT actuator

test cannot be made.

TSB Revision

Page 782 of 1146

35-60SERVICE BRAKES - Service Adjustment Procedures

INSPECTION BY USING BRAKE FORCE TESTER

NOTE

(1) The brake force tester roller and tire must be dry during the

test.

(2) When testing the front brakes, apply the parking brake and

when testing the rear brakes, apply chocks to the front

wheels to lock them.

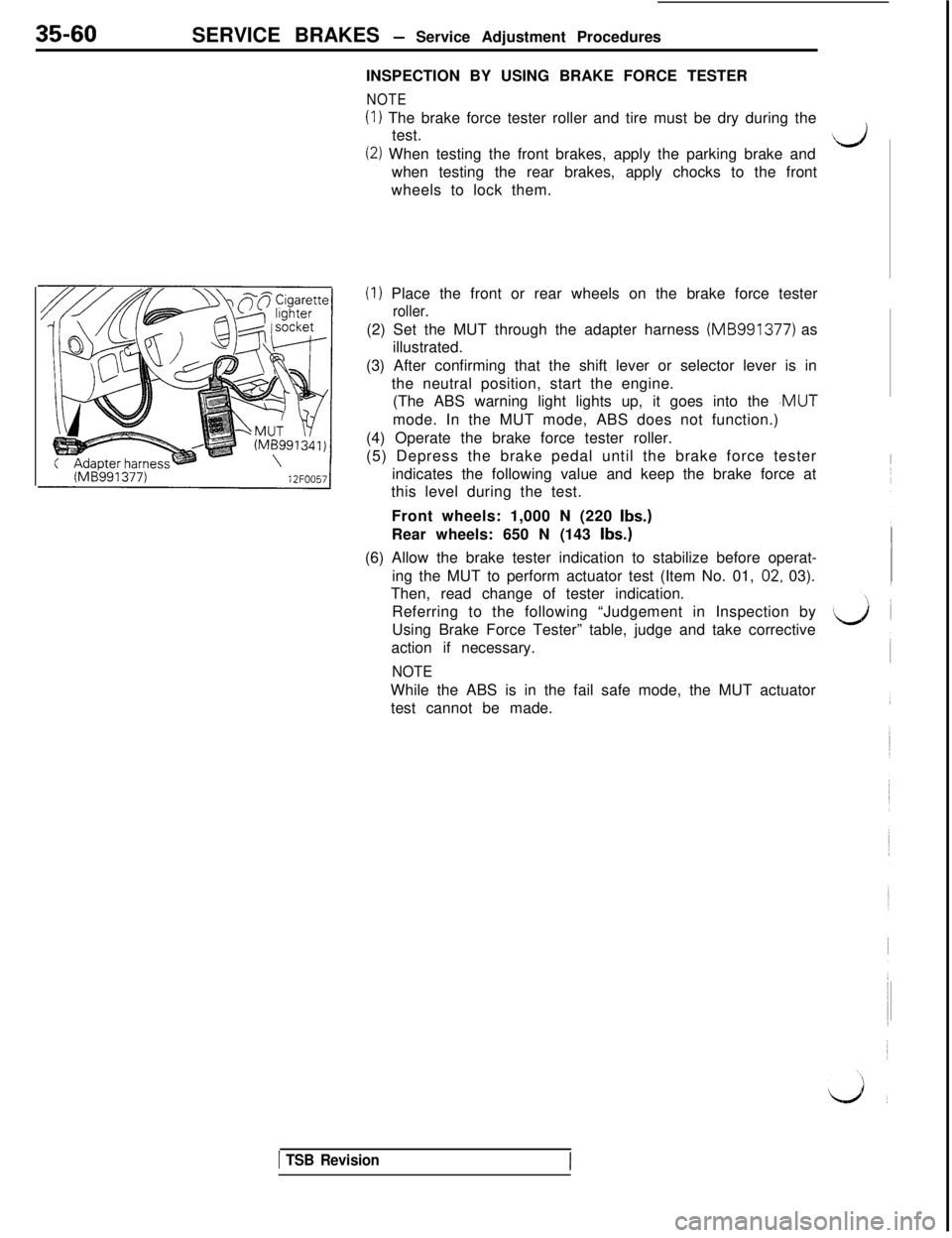

(I) Place the front or rear wheels on the brake force tester

roller.(2) Set the MUT through the adapter harness

(MB9913771 as

illustrated.

(3) After confirming that the shift lever or selector lever is in

the neutral position, start the engine.

(The ABS warning light lights up, it goes into the

-MUTmode. In the MUT mode, ABS does not function.)

(4) Operate the brake force tester roller.

(5) Depress the brake pedal until the brake force tester

indicates the following value and keep the brake force at

this level during the test.

Front wheels: 1,000 N (220

Ibs.)Rear wheels: 650 N (143

Ibs.)(6) Allow the brake tester indication to stabilize before operat-

ing the MUT to perform actuator test (Item No. 01,

02, 03).

Then, read change of tester indication.

Referring to the following “Judgement in Inspection by

Using Brake Force Tester” table, judge and take corrective

action if necessary.

NOTEWhile the ABS is in the fail safe mode, the MUT actuator

test cannot be made.

1 TSB Revision

Page 1099 of 1146

HEATERS AND MANUAL AIR CbNDlTlONER -Service Adjustment Procedures 55 17

ADJUSTMENT PROCEDURES(1) Select a quiet area for testing. Duplicate conditions as much

as possible. Switch compressor on and off several times to

clearly identify compressor noise.

To duplicate high ambient conditions (high head pressure),

restrict air flow through condenser. Install manifold gauge

set to make sure discharge pressure doesn’t exceed 2,070

kPa (300 psi).

(2) Tighten all compressor mounting bolts, clutch mounting

bolt, and compressor drive belt. Check to assure clutch coil

is tight (no rotation or wobble).

(3) Check refrigerant hoses for rubbing or interference that can

cause unusual noises.

(4) Check refrigerant charge. (See “Charging System”.)

(5) Recheck compressor noise as in Step 1.

(6) If noise still exists, loosen compressor mounting bolts and

retorque. Repeat Step 1.

(7) If noise continues, replace compressor and repeat Step 1.

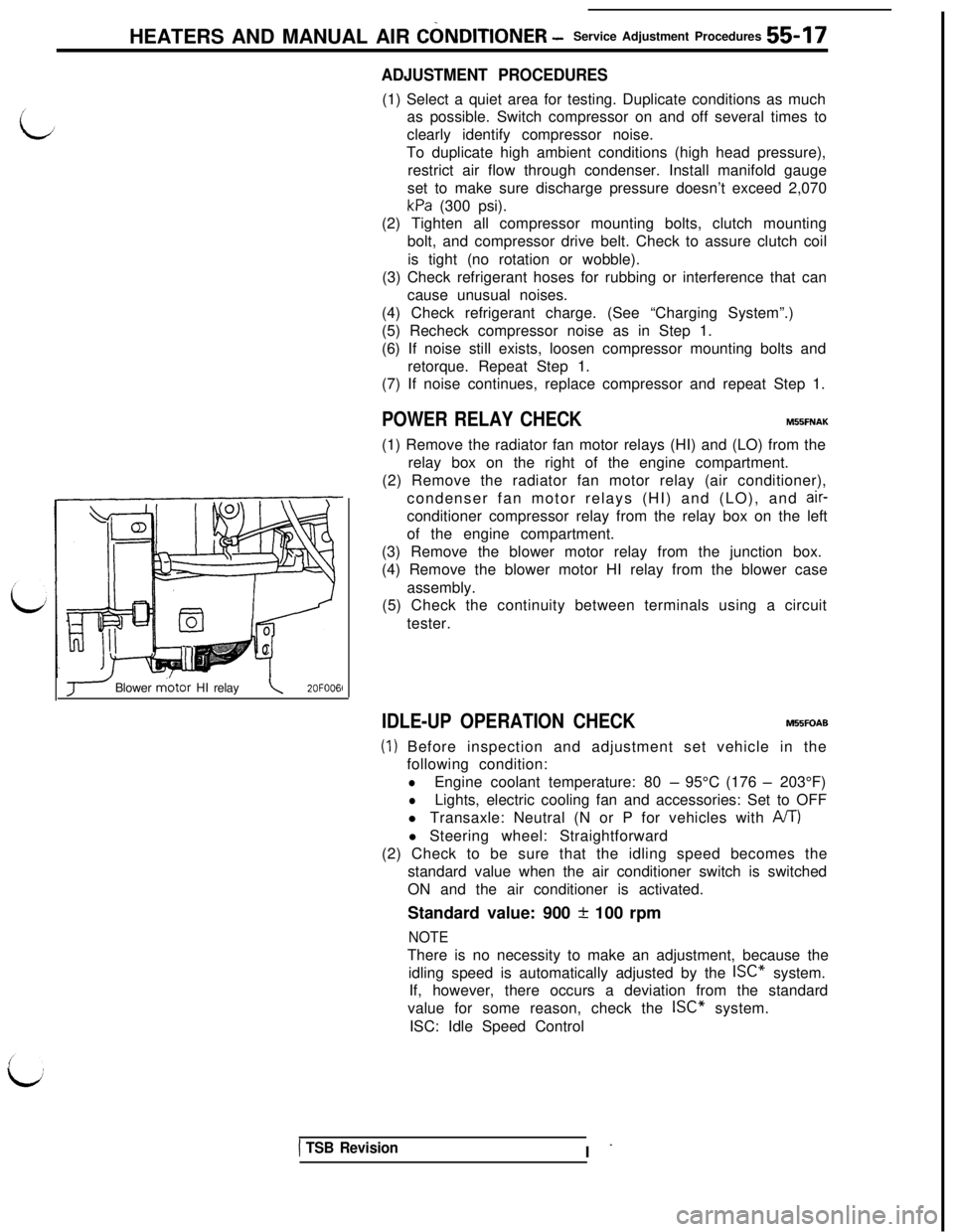

POWER RELAY CHECKMBBFNAK(1) Remove the radiator fan motor relays (HI) and (LO) from the

relay box on the right of the engine compartment.

(2) Remove the radiator fan motor relay (air conditioner),

condenser fan motor relays (HI) and (LO), and

air-conditioner compressor relay from the relay box on the left

of the engine compartment.

(3) Remove the blower motor relay from the junction box.

(4) Remove the blower motor HI relay from the blower case

assembly.

(5) Check the continuity between terminals using a circuit

tester.

J Blower m.otor HI relay\2OFOO6l

IDLE-UP OPERATION CHECKM55FOAB

(1) Before inspection and adjustment set vehicle in the

following condition:

lEngine coolant temperature: 80 - 95°C (176 - 203°F)

lLights, electric cooling fan and accessories: Set to OFF

l Transaxle: Neutral (N or P for vehicles with

A/T)l Steering wheel: Straightforward

(2) Check to be sure that the idling speed becomes the

standard value when the air conditioner switch is switched

ON and the air conditioner is activated.

Standard value: 900

+ 100 rpm

NOTEThere is no necessity to make an adjustment, because the

idling speed is automatically adjusted by the ISC” system.

If, however, there occurs a deviation from the standard

value for some reason, check the ISC” system.

ISC: Idle Speed Control

1 TSB RevisionI -