MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 1 of 1146

Volume lm

I ‘k,‘6III

Engine, Chassis & Bodyf

Page 2 of 1146

Page 3 of 1146

d

L’ BackupServiceManual

3OOOG-r

1991: Volume 1

L

This Service Manual has been prepared with the

/

WE SUPPORT

I/National ,nwtute ‘or IIAUTOMOTIV E

/I

MITSUBISHI

li@ 1990 Mitsubishi Motors CorporationRqwinted in USA

I

General

..*............*......*.......................

Su;$emental Restraint System ....

*......*...........

I

NOTE:I

I I

Page 4 of 1146

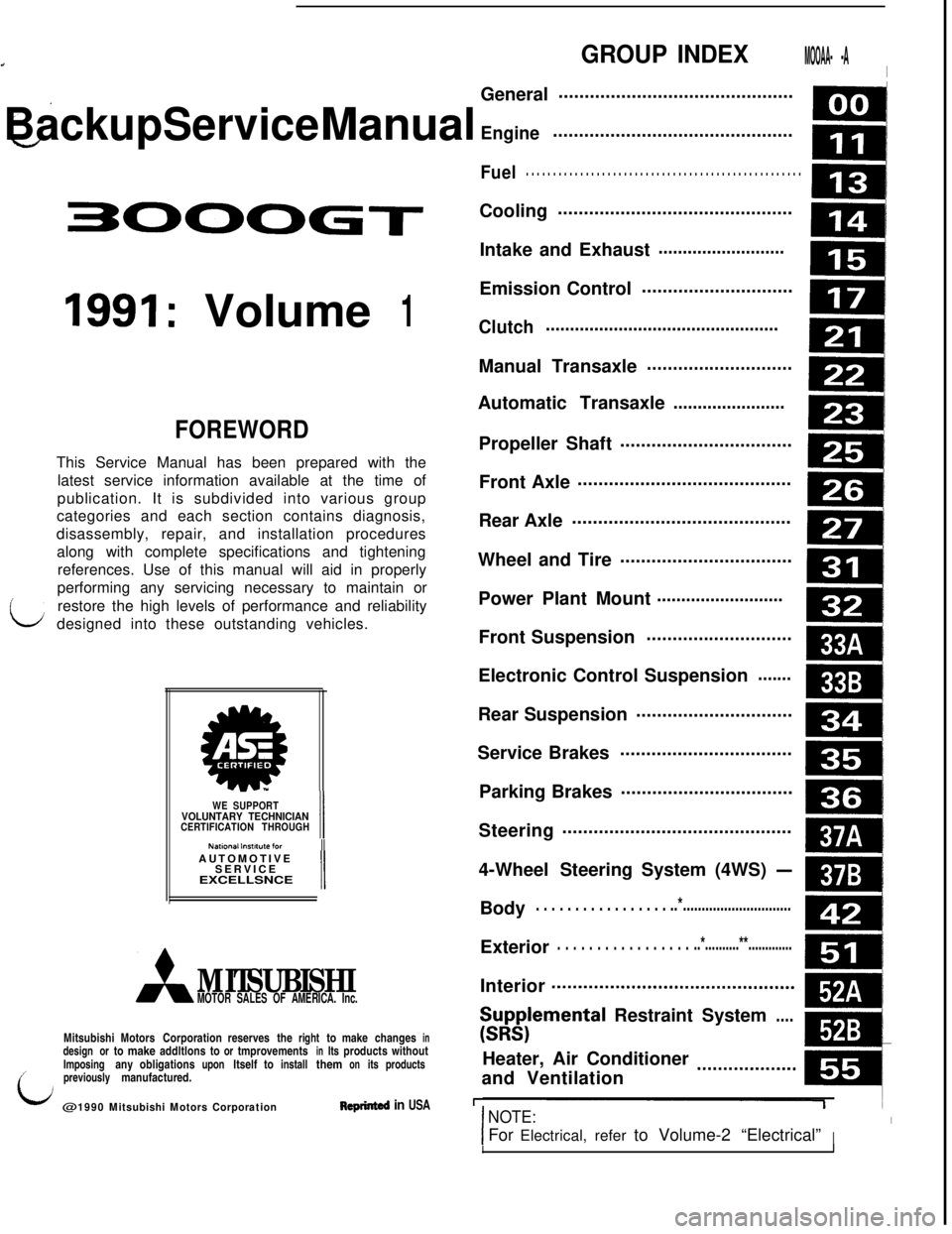

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

dir J

bag module, clock spring, interconnecting wiring. Other SRS-related comp\

onents (that may have to be

(*).

The Supplemental Restraint System (SRSI-related components are shown in the following MASTER TABLE

OF CONTENTS. Be sure to carefully read and understand the WARNING below \

before proceeding.

Group number

22.23

32

36

42

52A

Group nameSRS-related components

FUELCRUISE CONTROL SYSTEM/ P.13-185

MANUALTRANSAXLE.TRANSAXLE CONTROLAUTOMATIC TRANSAXLE

POWER PLANT MOUNTRIGHT MEMBER, LEFT MEMBER AND CROSSMEMBERP.32-6

ELECTRONIC CONTROLSUSPENSION’STEERING ANGULAR VELOCITY SENSORP.33B-19

PARKING BRAKESPARKING BRAKE LEVER AND PARKiNG BRAKE CABLE/ P.36~5I

STEERING/POWER STEERING GEAR BOX/ P.37A-17

/STEERING WHEEL AND SHAFTj P.37A-13

BODY

INTERIOR

FENDER

FLOOR CONSOLE/ P.52A-11

FRONT SEAT

INSTRUMENT PANEL

P52A-18

P.52A-8

CHASSIS ELECTRICAL

SEAT BELT

COLUMN SWITCH

HORN SWITCH

IGNITION SWITCH

P.52A-25

P.54-73

P.54-78

1 P.54-6

RADIO REMOTE-CONTROL/ P.54.110

HEATER, AIR CONDITIONERAIR-CONDITIONER CONTROL PANELAND VENTILATIONAIR-CONDITIONER CONTROL UNITP.55-56

/DAMPER CONTROL MOTOR ASSEMBLYI

/HEATER CONTROL ASSEMBLY1 P.55-18I

HEATER UNIT.1 P.55-22

WARNING!

VENTILATORS (INSTRUMENT PANEL)P.55-36

(1) Improper service or maintenance of any component of the SRS, or an\

y SRSrelated component,

can lead to personal injury or death to service personnel (from inadver\

tent firing of the air bag) or

to the driver (from rendering the SRS inoperative).

(260°F) in baking or in

drying after painting, remove the SRS components (air bag module, SRS d\

iagnosis unit, front

perfarmed

only at an authorized MITSUBISHI dealer.

52B

- Supplemental Restraint System (SRS), before beginning any service or m\

aintenance of any

component of the SRS or any SRS-related component.

1 TSB RevisionI

Page 5 of 1146

,

b

00-I

GENERALCONTENTS

MOOOA- .

GENERAL DATA AND SPECIFICATIONS . . . . . .21

HOW TO USE THIS MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . .3Definition of Terms

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Explanation of Circuit Diagrams

. . . . . .._...........7Explanation of Manual Contents

. . . . . . . . . . . . . . . . . . . .4

Explanation of the Troubleshooting Guide . .

6ModelIndications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Scope of Maintenance, Repair and

ServicingExplanations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Troubleshooting

. . . . . . .._.......................................3

LUBRICATION AND MAINTENANCE. . . . . .._....31SCHEDULED MAINTENANCE TABLE. . . . . . .._.

MAIN SEALANT AND ADHESIVE TABLE. . .44

MAINTENANCE SERVICE

. . . . . . . . . . . . . . . .._......_.....__Air Cleaner Element

. . . . . . .._......._......_................Automatic Transaxle

. . . . . . . . . . . . . . . . . . . . . . . . .._......._.....Ball Joint and Steering Linkage Seals

. . . . . . . . . . . .

BrakeHoses. . . . . . . . . . . . . . . . . . . . . . . . . . . .._......._.._...._......._..

Disc Brake Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Drive Belt (For Alternator)

. . . . . . . . .._.........._..........Drive Shaft Boots

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Engine Coolant

. . . . . . . . . . . . ..__.._.............................Engine Oil

.._....__._.................................................Engine Oil Filter

. . . . .._._.......__.................. . . . . . . . . . . .Exhaust System

_....._......._.....__._............,...........Fuel Hoses

..__......__............................................36

3740

42

42

42

38

43

41

38

39

43

36

FuelSystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Manual Transaxle

. . . . . . . . . .._........................_.......Rear Axle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._..._.._..____.._.......

SparkPlugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._...............TimingBelt

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MASTER TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . .

PRECAUTIONS BEFORE SERVICE. . . . . . . . . . . . . . . .

RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIES TABLE. . . . . . .._........

SPECIAL HANDLING INSTRUCTIONS

FOR AWD MODELS. . . . . . . . . . . . .._...._........................

TIGHTENING TORQUE. . . . . . . . . . . . . . . ..__.....................

TOWING AND HOISTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VEHICLE IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . .._.....Chassis Number .

.._............................................Engine Model Stamping

.._..........................._...._Theft Protection

. . . . .._.........................................Vehicle Identification Code Chart Plate

.._.....Vehicle Identification Number List

.._._....._..._.Vehicle Identification Number Location

. . . .._

Vehicle Information Code Plate . . . . .._._......_.......Vehicle Safety Certification Label

. . . ..I . . . . .._..._...

36

3943

37

3724

1532

35

20

23

16

8

10

11

11

8

9

8

10

10

Page 6 of 1146

c.

Page 7 of 1146

GENERAL - How to Use This Manual00-3HOW TO USE THIS MANUAL

MOOBAAF

c;SCOPE OF MAINTENANCE, REPAIR AND

DEFINITION OF TERMS

SERVICING EXPLANATIONSSTANDARD VALUE

bThis manual provides explanations, etc. concerning

procedures for the inspection, maintenance, repair

and servicing of the subject model. Unless other-

wise specified, each service procedure covers all

models. Procedures covering specific models are

identified by the model codes, or similar designation

(engine type, transaxle type, etc.). A description of

these designations is covered in this unit under

“VEHICLE IDENTIFICATION”.

SERVICE ADJUSTMENT PROCEDURES“Service Adjustment Procedures” are procedures

for performing inspections and adjustments of

particularly important locations with regard to the

construction and for maintenance and servicing, but

other inspections (for looseness, play, cracking,

damage, etc.) must also be performed.

SERVICE PROCEDURESThe service steps are arranged in numerical order

and attentions to be paid in performing vehicle

service are described in detail in SERVICE POINTS.

TROUBLESHOOTING

Troubleshootings are classified into master trouble-

shooting and group troubleshooting and located as

follows:

The master troubleshooting is prepared when the

trouble symptom relates to two or more groups and

given in MASTER TROUBLESHOOTING.

The group troubleshooting guide is prepared for

causes of problems related to that individual groupIndicates the value used as the standard for judging

the quality of a part or assembly on inspection or the

value to which the part or assembly is corrected and

adjusted. It is given by tolerance.

LIMITShows the standard for judging the quality of a part

or assembly on inspection and means the maximum

or minimum value within which the part or assembly

must be kept functionally or in strength. It is a value

established outside the range of standard value.

REFERENCE VALUEIndicates the adjustment value prior to starting the

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be com-

pleted in a shorter time).

CAUTIONIndicates the presentation of information particularly

vital to the worker during the performance of

maintenance’ and servicing procedures in order to

avoid the possibility of injury to the worker; or

damage to component

.parts, or a reduction of

component or vehicle function or performance, etc.

INDICATION OF TIGHTENING TORQUEThe tightening torque shown in this manual is a

basic value with a tolerance of

+lO% except the

following cases when the upper and lower limits of

tightening torque are given.

(1) The tolerance for the basic value is within

+ I no/-

only; a troubleshooting guide is prepared for eachI iv,“.appropriate group.(2) Special bolts or the like are in use.

(3) Special tighteningmethods are used.

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.M/T:Indicates the manual transaxle, or models equipped with the manual transaxle.

A/T:Indicates the automatic transaxle, or models equipped with the automatic transaxle.

MPI: Indicates the multi-point injection, or engines equipped with the multi-point injection.

Turbo: Indicates an engine with turbocharger, or a model equipped with such an engine.

Non-Turbo: Indicates an engine without turbocharger, or a model equipped with such an engine.

FWD: Indicates the front wheel drive vehicles.

AWD; Indicates the all wheel drive vehicles.

ABS:Indicates the anti-lock braking system or models equipped with the anti-lock braking system.

ECS: Indicates the electronic control suspension or models equipped with the electronic control

suspension.

4WS:Indicates the 4-wheel steering system or models .equipped with the 4-wheel steering system.

TSB Revision

Page 8 of 1146

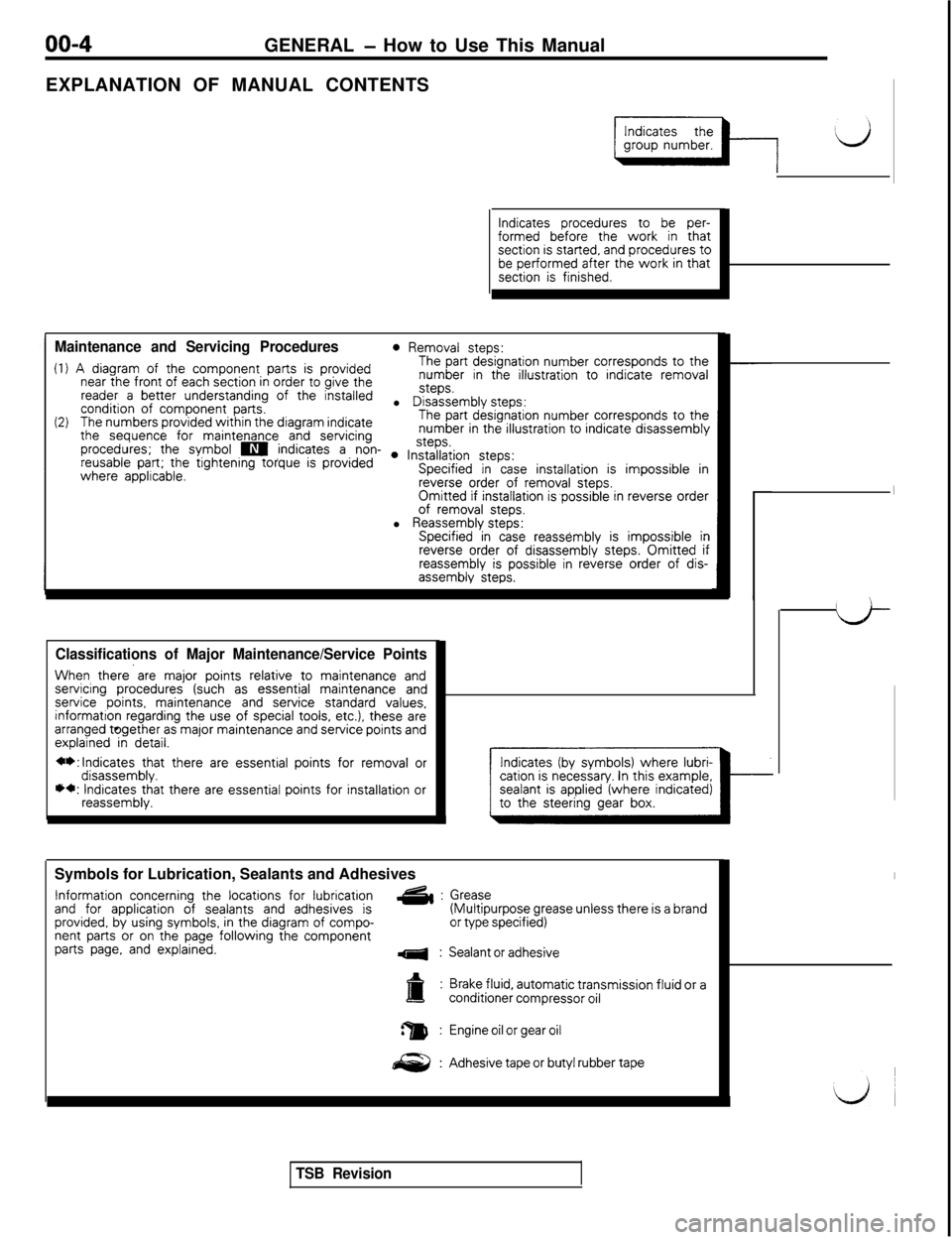

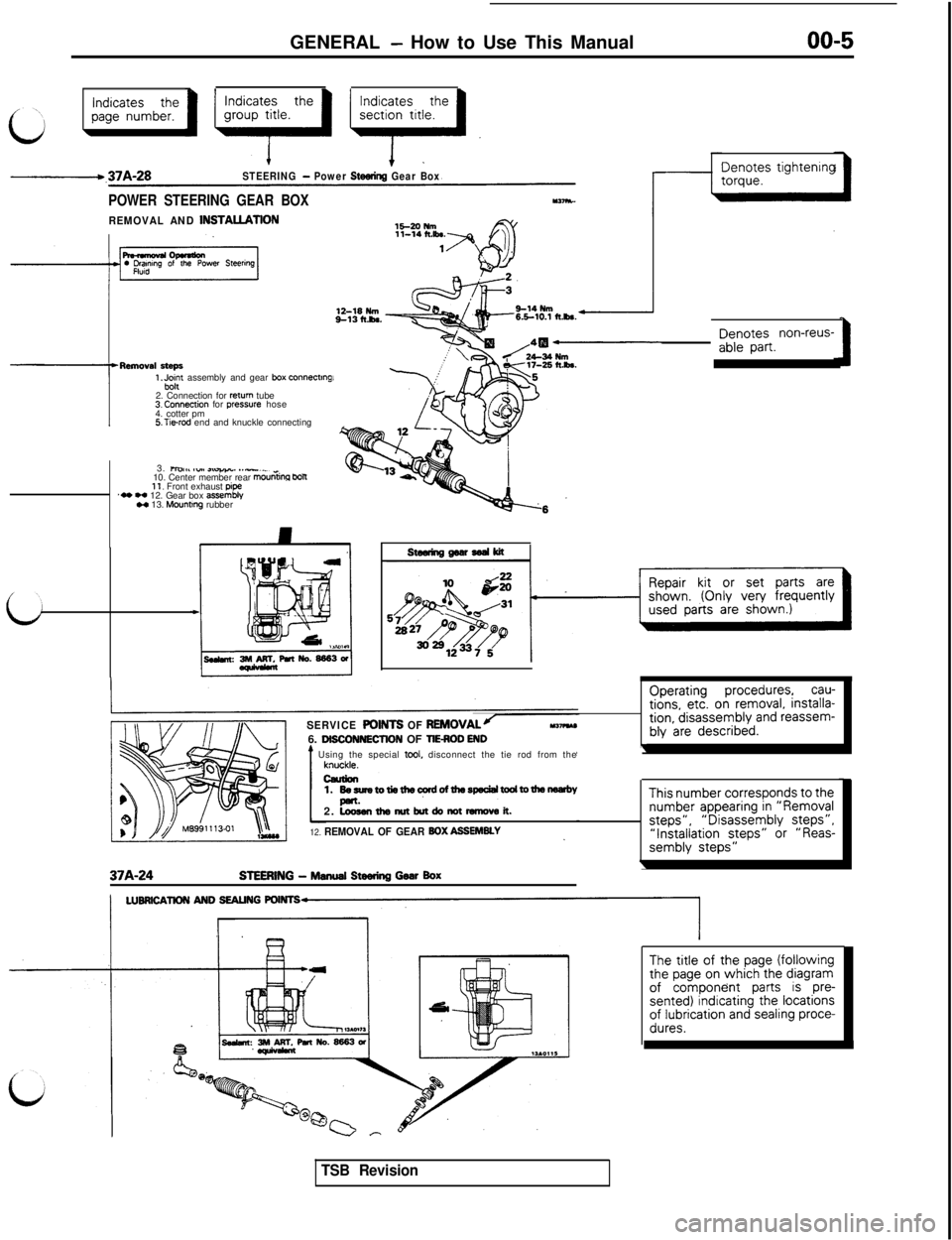

GENERAL - How to Use This Manual

EXPLANATION OF MANUAL CONTENTS

Indicates procedures to be per-formed before the work in thatsection is started, and procedures tobe performed after the work in thatsection is finished.

Maintenance and Servicing Procedures0 Removal steps:

(1) A diagram of the component parts is providedThe part designation number corresponds to the

near the front of each section in order to give thenumber in the illustration to indicate removal

reader a better understanding of the installedsteps.

condition of component parts.l Disassembly steps:

(2)The numbers provided within the diagram indicateThe part designation number corresponds to the

the sequence for maintenance and servicingnumber in the illustration to indicate disassembly

procedures; the symbol m indicates a non- . ln~~~~iion steps:reusable part; the tightening torque is providedwhere applicable.Specified in case installation is impossible inreverse order of removal steps.Omitted if installation is,possible in reverse orderof removal steps.l Reassembly steps:Specified in case reassembly is impossible inreverse order of disassembly steps. Omitted ifreassembly is possible in reverse order of dis-assembly steps.

Classifications of Major Maintenance/Service Points

When there’are major points relative to maintenance andservicing procedures (such as essential maintenance andservice points, maintenance and service standard values,informatton regarding the use of special toois, etc.), these arearranged together as major maintenance and service points andexplained in detail.

**:lndicates that there are essential points for removal ordisassembly.*+: Indicates that there are essential points for installation orreassembly.Symbols for Lubrication, Sealants and Adhesives

Information concerning the locations for lubricationand for application of sealants and adhesives isG&:

provided, by using symbols, in the diagram of compo-nent parts or on the page following the componentparts page, and explained.4:

Indicates (by symbols) where lubri-cation is necessary. In this example,

Grease(Multipurpose grease unless there is a brandor type specified)

Sealant or adhesive

Brake fluid, automatic transmission fluid or aconditioner compressor oil

Engine oil or gear oil

Adhesive tape or butyl rubber tape

TSB Revision

Page 9 of 1146

GENERAL - How to Use This Manual00-5

Indicates thepage number.

\

-.37A-28STEERING - Power Steering Gear Box

POWER STEERING GEAR BOX

REMOVAL AND INSTAUATION1!3-20 Plm

-7-Renloval steps

1 .Jrnyt assembly and gear box connecting2. Connection for

return tube3.Connection for press.ure hose

4. cotter pm

5.T1erod end and knuckle connecting

3.

maI,% ,v*, ,tu&w.,. *.-._10. Center member rear mourha WR11, Front exhaust pipe‘0 w 12. Gear box assembly” 13. Mountmg rubber

Denotes tightenrng

Denotes non-reus-able part.

SERVICE POINTS OF REMOVALJ-Y-6. Ol6CONN6CTtON OF TIE-ROD END* Using the special tool, disconnect the tie rod from the

Operating procedures, cau-tions, etc. on removal, installa-tion, disassembly and reassem-bly are described.

\

37A-24

1.60sumtotie6lec?rdofthaspecialwJdtotheneflrbY2.

~thsmItbutdonDt-vsit.

12. REMOVAL OF GEAR 60X ASSEMBLY

STEERING - Manual Steering Gwr Box

This number corresponds to thenumber appearing in “Removalsteps”,“Disassembly steps”,“installation steps” or “Reas-sembly steps”

\

The title of the page (followingthe page on which the diagramof component parts is pre-sented) indicating the locationsof lubrication and sealing proce-dures.

TSB Revision

Page 10 of 1146

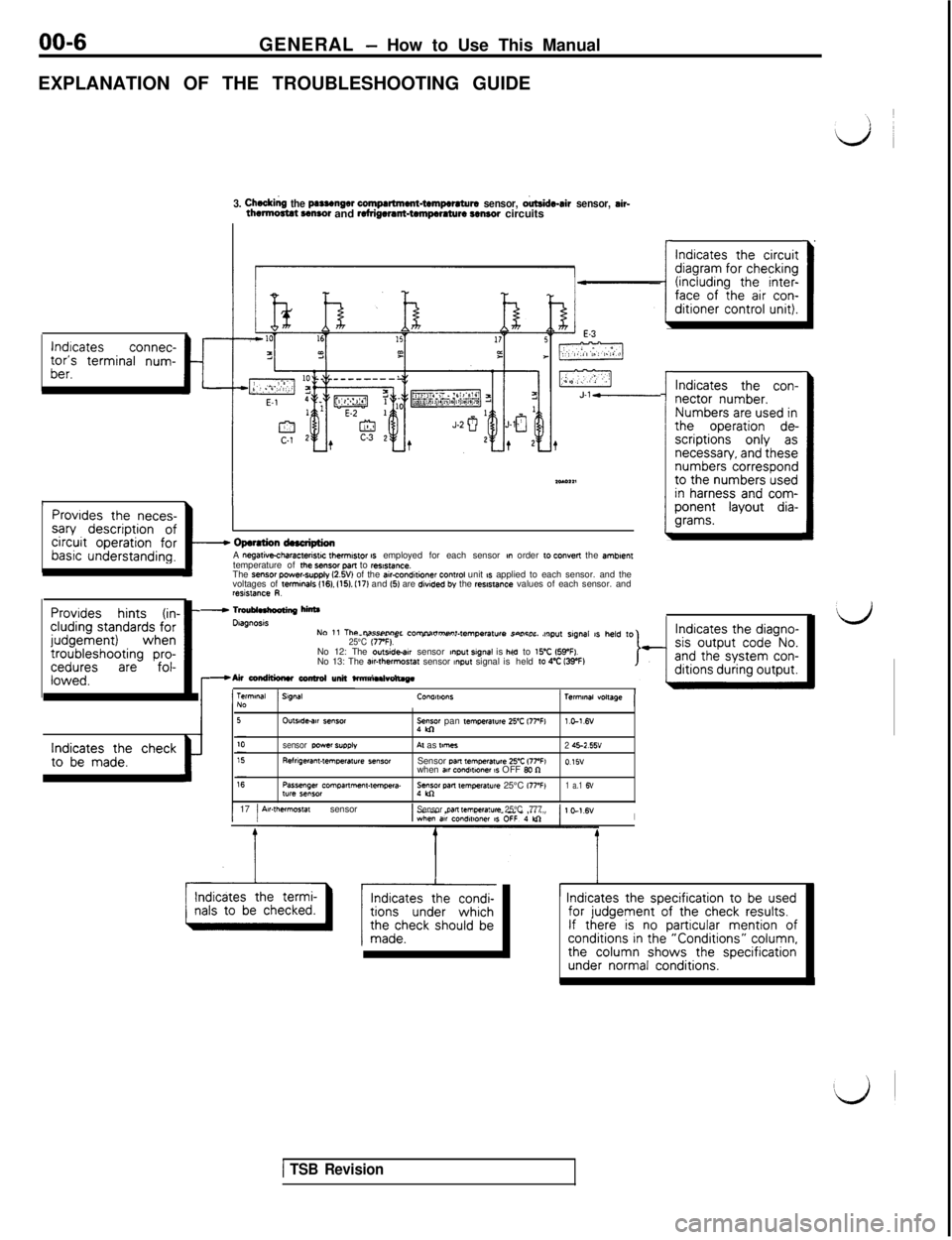

00-6

GENERAL - How to Use This Manual

EXPLANATION OF THE TROUBLESHOOTING GUIDE

lndrcatesconnec-tor’s terminal num-ber.t

3. Cheddng the psssenger compartment-tempwsturs sensor, o&de-sir sensor, sir-thwtmctat CMSO~ and refrigerant-tempcmture sensor circuits

1.IProvides the neces-sary description ofcircuit operation forbasic understanding.I

Provides hints (in- -eluding standards forjudgement)whentroubleshooting pro-ceduresarefol-lowed.

- Opsrstion dnctiptionA negatkcharactensw fhemwor IS employed for each sensor nn order 10 convert the smbnen,temperature of rhe SB”SOf pan to ,es,s,ance.The sensor power-supply l2.W) of the air-condaioner control unit 1s applied to each sensor. and the

voltages of terminals 1161. 1151. I171 and 15) are divtded by the rwstance values of each sensor. andresislance R.

Indicates the checkto be made.t

-

I

Indicates the circuitdiagram for checking(including the inter-face of the air con-ditioner control unit).

Indicates the con-nector number.Numbers are used inthe operation de-scriptions only asnecessary, and thesenumbers correspondto the numbers usedin harness and com-ponent layout dia-grams.

- Tmublnkooting hff

NO 1, The DilFW+““P, P”m”il”m~“l.l~m~~=,,,,~ concnr ,w,p”t s,g”a, ,s ,,e,d ,o_ -____ .=_ __ .~_. .._... ._...r_._._._ ” -..--. ..,25°C 17rF).No 12: The outside-w sensor mput srgnal is he.----la to ,,“C IWFI.

-Air conditiuw ccnlml unit ta-.--* -.. No 13: The

awthwmos,a, sensor ~npu, signal isheld 10 4% IWF)l?mlMI “obuge

^I_I1Terminal) SWAW”IIWO”SNO

Dtagnosls

OUlYdedlr semorye pan ,emperatwe 25’C l77Wl.c-1.6v

sensor wwsr

SUPPI”Al as ,mlles2 45-2.55vRelngeran,.,emwrature *ensorSensor WR temperawe 25-Z 17PFI015”

when aar condwmer 1s OFF Bo nPassenger Compa*me”,-tempera.:“gol pm mnperat”re 25°C i77’FI1 a.1 6”lyre sensor

1 17 j Air-thermostat sensor1Sensor pan ,empelat”re 25°C ,777,I

’ Indicates the specification to be usedfor judgement of the check results.If there is no particular mention ofconditions in the “Conditions” column,the column shows the specificationunder normal conditions.

I

I

1 TSB Revision