parking brake MITSUBISHI 3000GT 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 609 of 1146

REAR AXLE

,,rmr

SERVICE ADJUSTMENT PROCEDURES

REAR AXLE TOTAL BACKLASH CHECKM27FAAG

If the vehicle vibrates and produces a booming sound due to an

imbalance of the driving system, measure the rear axle total

backlash by the following procedures to see if the differential

carrier assembly required removal.

(1) Place the gearshift lever in the neutral position, apply the

parking brake and jack up the vehicle.

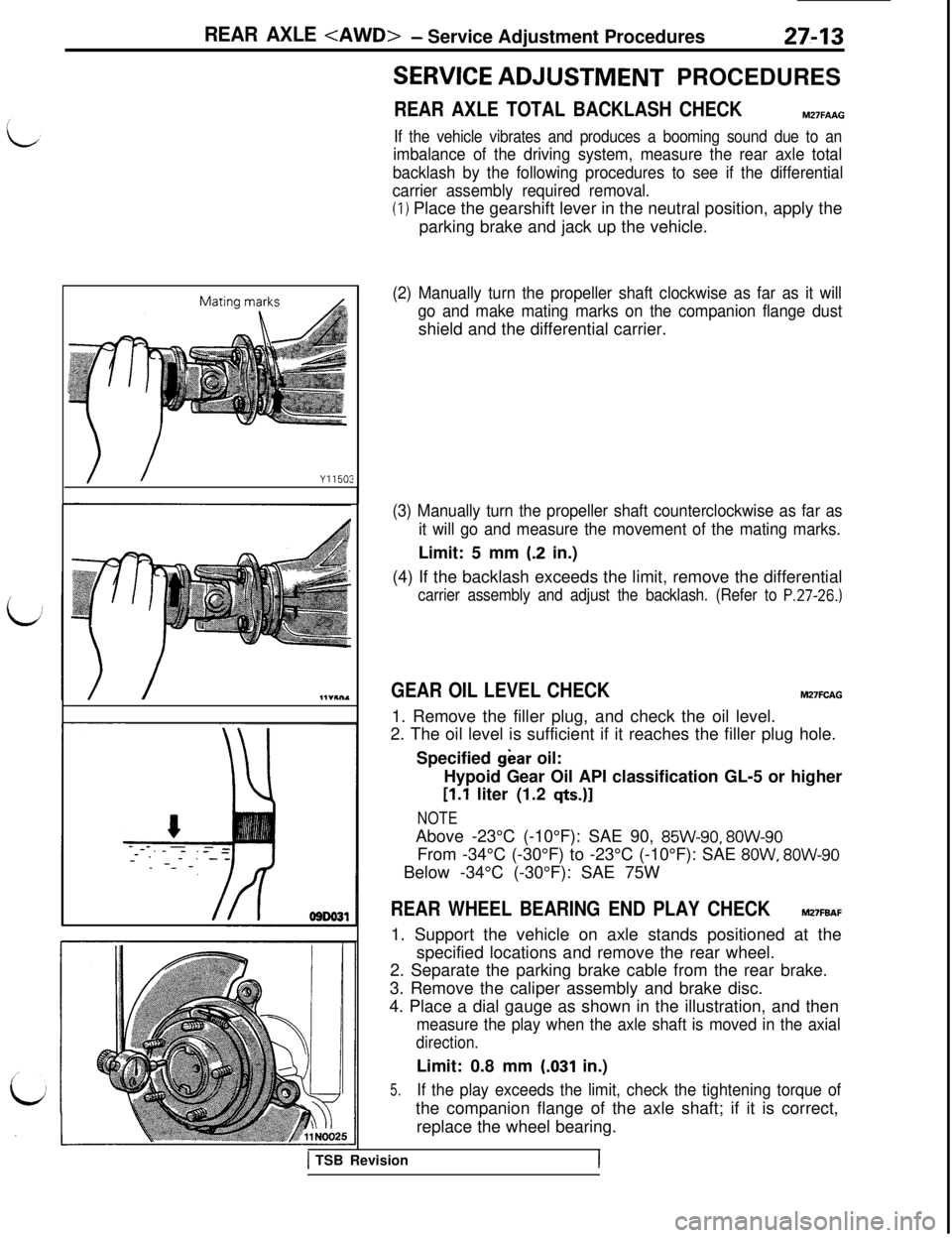

(2) Manually turn the propeller shaft clockwise as far as it will

go and make mating marks on the companion flange dustshield and the differential carrier.

(3) Manually turn the propeller shaft counterclockwise as far as

it will go and measure the movement of the mating marks.Limit: 5 mm

(.2 in.)

(4) If the backlash exceeds the limit, remove the differential

carrier assembly and adjust the backlash. (Refer to P.27-26.)

GEAR OIL LEVEL CHECKM27FCAG1. Remove the filler plug, and check the oil level.

2. The oil level is sufficient if it reaches the filler plug hole.

Specified

gear oil:

Hypoid Gear Oil API classification GL-5 or higher

[l.l liter (1.2 q&J]

NOTEAbove -23°C (-10°F): SAE 90,

85W-90, 8OW-90From -34°C (-30°F) to -23°C (-10°F): SAE

8OW, 8OW-90Below -34°C (-30°F): SAE 75W

REAR WHEEL BEARING END PLAY CHECKM27FBAF1. Support the vehicle on axle stands positioned at the

specified locations and remove the rear wheel.

2. Separate the parking brake cable from the rear brake.

3. Remove the caliper assembly and brake disc.

4. Place a dial gauge as shown in the illustration, and then

measure the play when the axle shaft is moved in the axial

direction.Limit: 0.8 mm

(.031 in.)

5.If the play exceeds the limit, check the tightening torque ofthe companion flange of the axle shaft; if it is correct,

replace the wheel bearing.

1 TSB RevisionI

Page 610 of 1146

27-14REAR AXLE

Incorrect

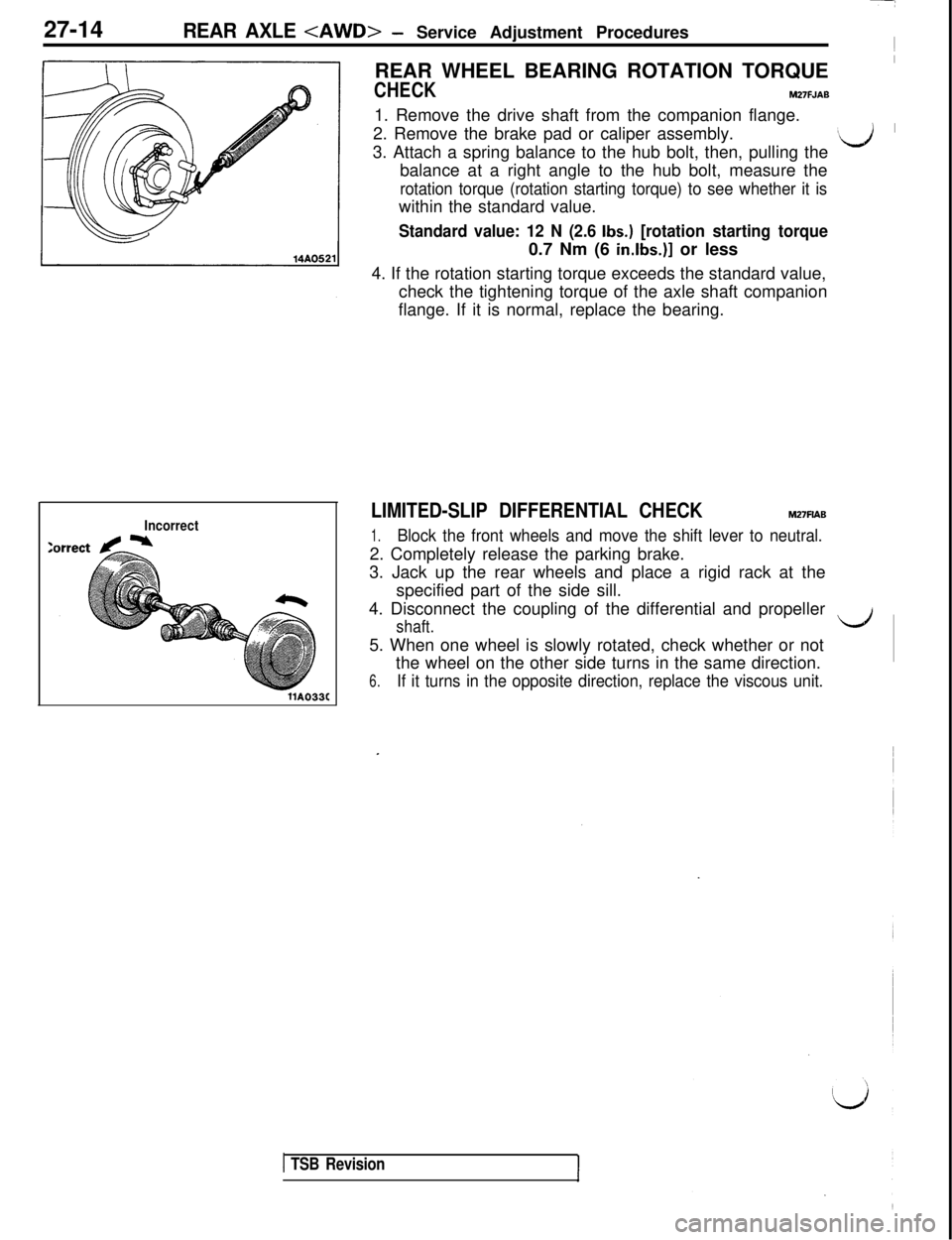

llA033CREAR WHEEL BEARING ROTATION TORQUE

I

CHECKM27FJAB1. Remove the drive shaft from the companion flange.

2. Remove the brake pad or caliper assembly.

3. Attach a spring balance to the hub bolt, then, pulling the

‘d ’balance at a right angle to the hub bolt, measure the

rotation torque (rotation starting torque) to see whether it iswithin the standard value.

Standard value: 12 N (2.6 Ibs.) [rotation starting torque0.7 Nm (6

in.lbs.)] or less

4. If the rotation starting torque exceeds the standard value,

check the tightening torque of the axle shaft companion

flange. If it is normal, replace the bearing.

LIMITED-SLIP DIFFERENTIAL CHECKM27FlAB

1.Block the front wheels and move the shift lever to neutral.2. Completely release the parking brake.

3. Jack up the rear wheels and place a rigid rack at the

specified part of the side sill.

4. Disconnect the coupling of the differential and propeller

shaft.LJ5. When one wheel is slowly rotated, check whether or not

the wheel on the other side turns in the same direction.

6.If it turns in the opposite direction, replace the viscous unit.

1 TSB Revision

Page 692 of 1146

34-6REAR SUSPENSION

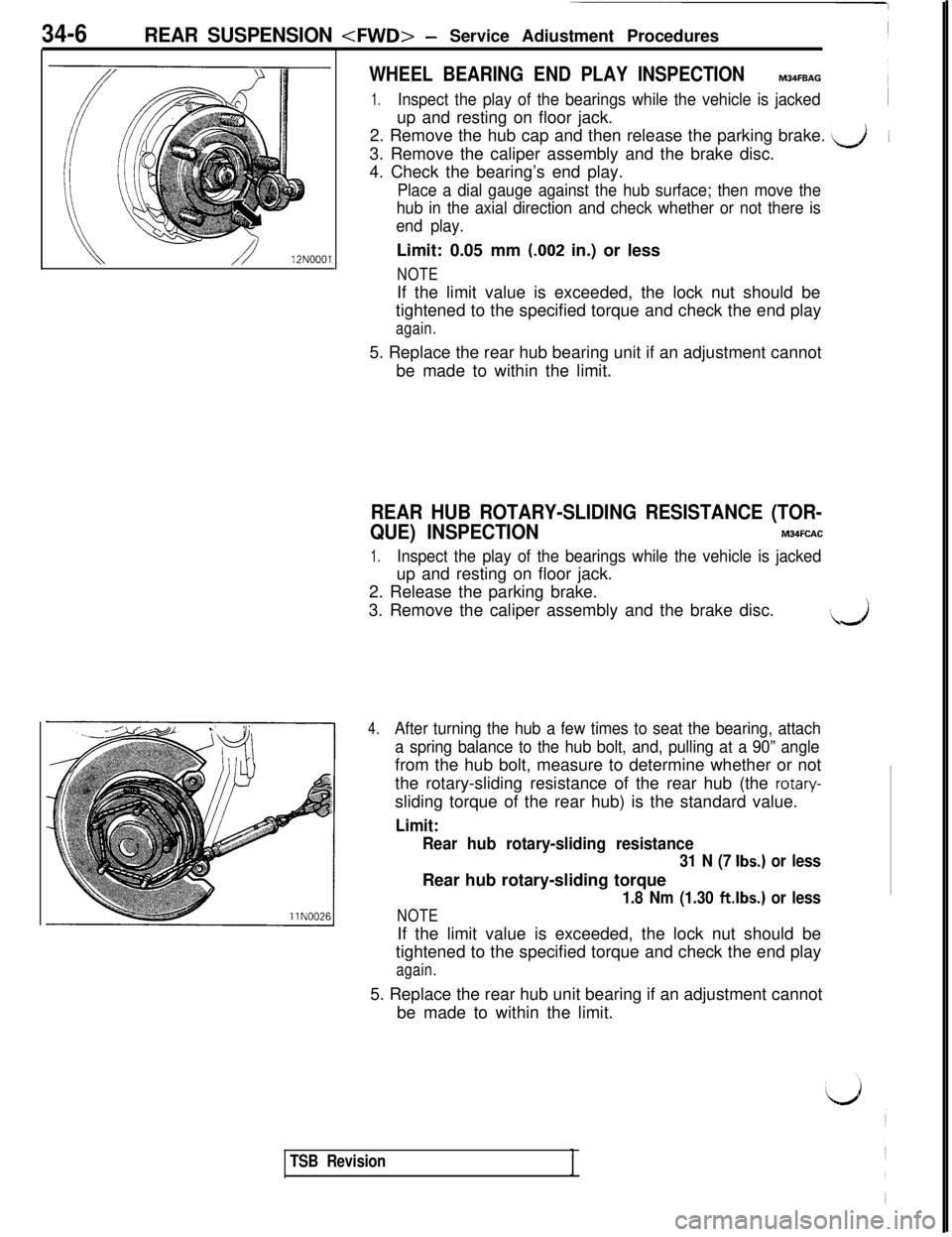

WHEEL BEARING END PLAY INSPECTIONM34FBAG

1.Inspect the play of the bearings while the vehicle is jackedup and resting on floor jack.

2. Remove the hub cap and then release the parking brake.

s&i3. Remove the caliper assembly and the brake disc.

4. Check the bearing’s end play.

Place a dial gauge against the hub surface; then move the

hub in the axial direction and check whether or not there is

end play.Limit: 0.05 mm

(.002 in.) or less

NOTEIf the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.5. Replace the rear hub bearing unit if an adjustment cannot

be made to within the limit.

REAR HUB ROTARY-SLIDING RESISTANCE (TOR-

QUE) INSPECTION

M34FCAC

1.Inspect the play of the bearings while the vehicle is jackedup and resting on floor jack.

2. Release the parking brake.

3. Remove the caliper assembly and the brake disc.

..J

4.After turning the hub a few times to seat the bearing, attach

a spring balance to the hub bolt, and, pulling at a 90” anglefrom the hub bolt, measure to determine whether or not

the rotary-sliding resistance of the rear hub (the

rotary-sliding torque of the rear hub) is the standard value.

Limit:

Rear hub rotary-sliding resistance

31 N (7 Ibs.) or lessRear hub rotary-sliding torque

1.8 Nm (1.30 ftlbs.) or less

NOTEIf the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.5. Replace the rear hub unit bearing if an adjustment cannot

be made to within the limit.

TSB Revision

Page 693 of 1146

REAR SUSPENSION

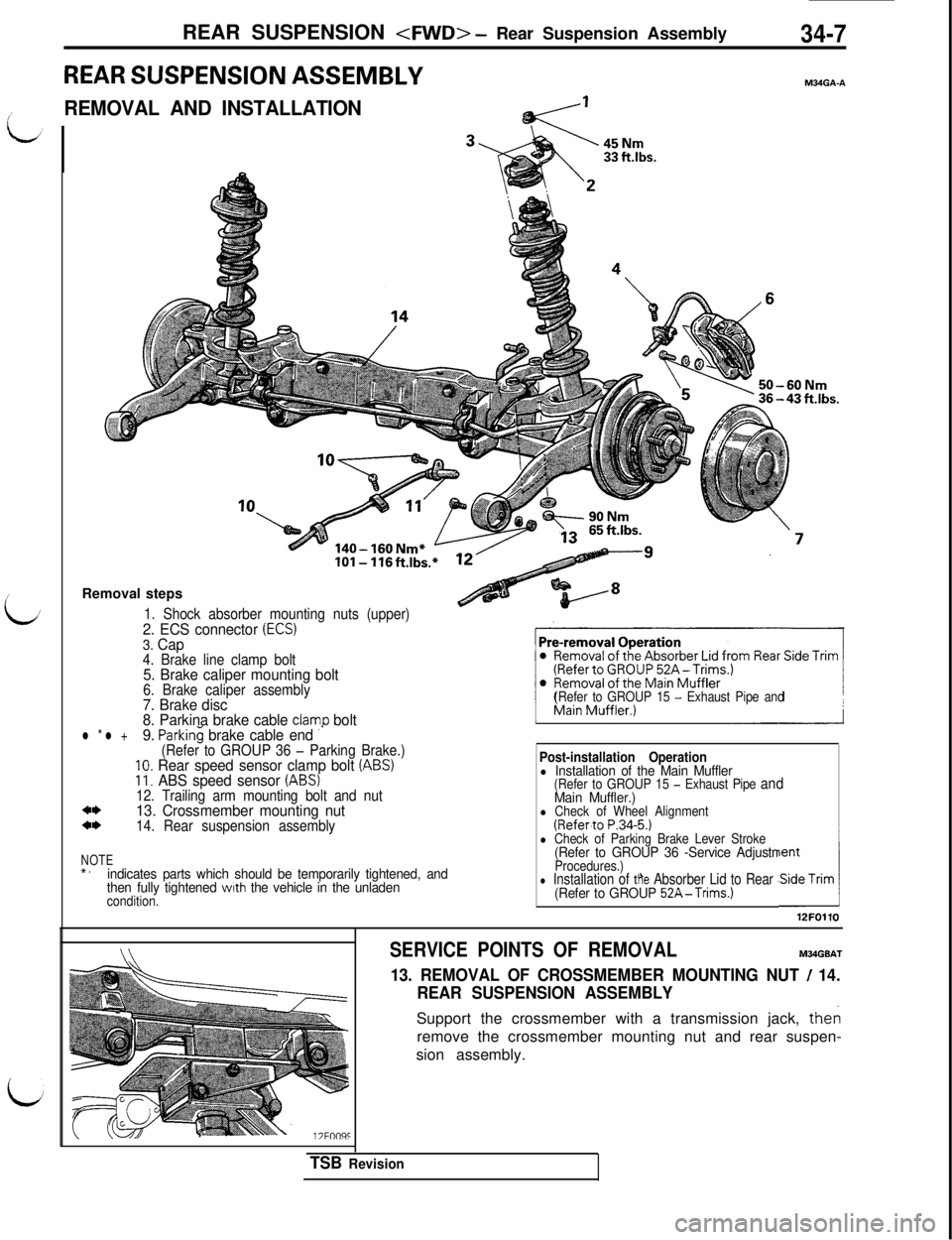

REAR SUSPENSION ASSEMBLYM34GA-A

L/

REMOVAL AND INSTALLATION

140- 160 Nm*IOI- 116ftlbs.

Removal steps

1. Shock absorber mounting nuts (upper)2. ECS connector (ECS)3. Cap4. Brake line clamp bolt5. Brake caliper mounting bolt6. Brake caliper assembly7. Brake disc

8. Parkina brake cable clamo bolt

(Refer to GROUP 15 - Exhaust Pipe and

l * l +9. ParkinG brake cable end ”(Refer to GROUP 36 - Parking Brake.)10. Rear speed sensor clamp bolt (ABS)11. ABS speed sensor (ABS)12. Trailing arm mounting bolt and nut*I)13. Crossmember mounting nut*I)14. Rear suspension assembly

NOTE*.indicates parts which should be temporarily tightened, and

then fully tightened with the vehicle in the unladencondition.

Post-installation Operationl Installation of the Main Muffler(Refer to GROUP 15 - Exhaust Pipe andMain Muffler.)l Check of Wheel Alignment(Refer.to P.34-5.)l Check of Parking Brake Lever Stroke(Refer to GROUP 36 -Service AdjustmentProcedures.)l Installation of the Absorber Lid to Rear Side Trim(Refer to GROUP 52A-Trims.)A12FOllO

SERVICE POINTS OF REMOVALM34GBAT

13. REMOVAL OF CROSSMEMBER MOUNTING NUT / 14.

REAR SUSPENSION ASSEMBLYSupport the crossmember with a transmission jack, then

remove the crossmember mounting nut and rear suspen-

sion assembly.

TSB Revision

Page 697 of 1146

REAR SUSPENSION

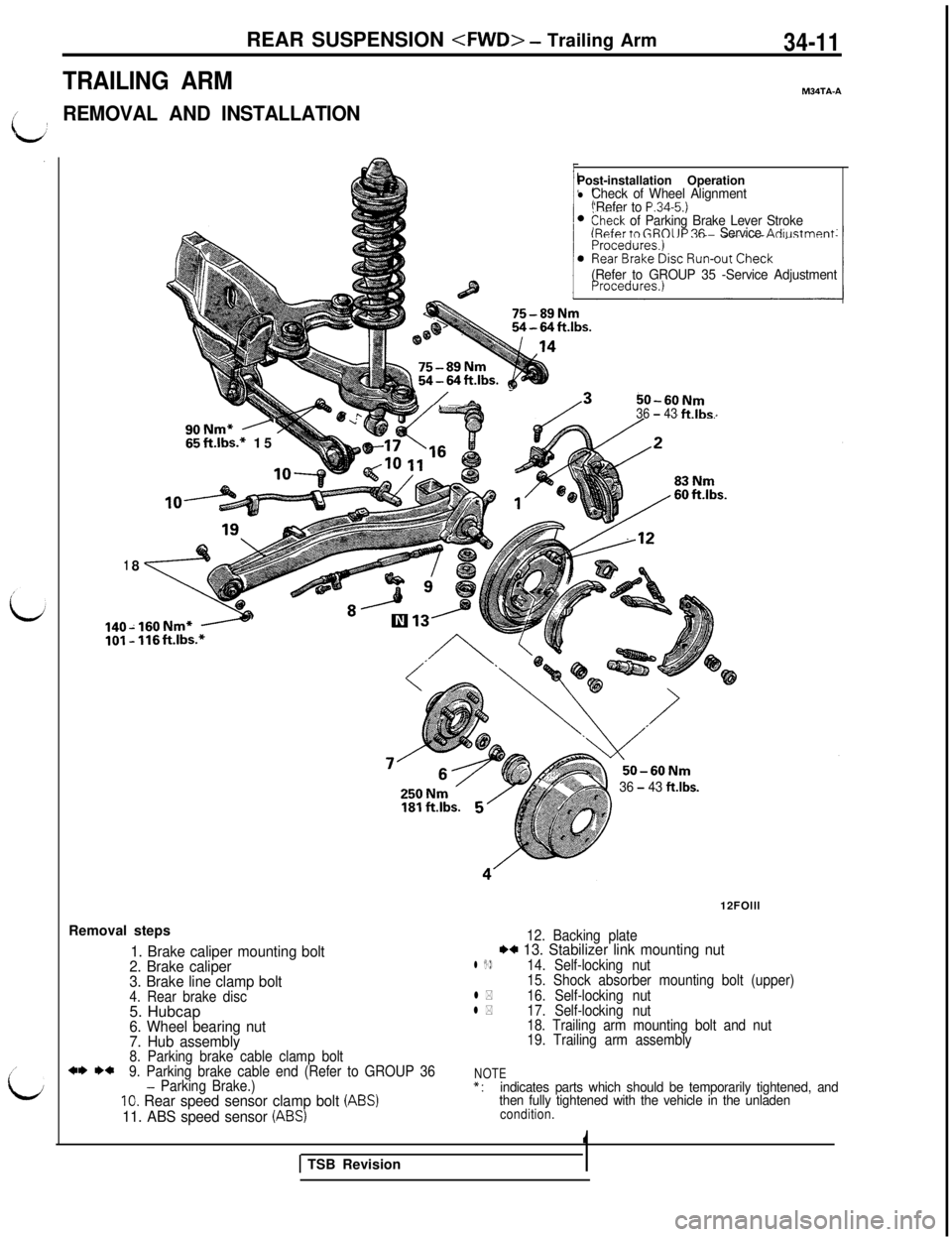

TRAILING ARMM34TA-A

t’REMOVAL AND INSTALLATION

,’

i;

18

90Nm* A65ft.lbs.* 15Post-installation Operation

lCheck of Wheel Alignment

‘Refer to P.34-5.)>heck of Parking Brake Lever Stroke(Refer tn GROIJP 36 - Service Adiustment

r/A -50-60Nm36 - 43ftlbs.

(Refer to GROUP 35 -Service Adjustment

-160Nm* -- 116ft.lbs.*Removal steps

1. Brake caliper mounting bolt

2. Brake caliper

3. Brake line clamp bolt

4. Rear brake disc5. Hubcap

6. Wheel bearing nut

7. Hub assembly

8. Parking brake cable clamp bolt*I) I)*9. Parking brake cable end (Refer to GROUP 36- Parking Brake.)IO. Rear speed sensor clamp bolt (ABS)

11. ABS speed sensor (ABS)

36 - 43 ftlbs.12FOlll

12. Backing plateI)+ 13. Stabilizer link mounting nutl I)14. Self-locking nut

15. Shock absorber mounting bolt (upper)

l *16. Self-locking nutl *17. Self-locking nut

18. Trailing arm mounting bolt and nut

19. Trailing arm assembly

NOTE*:indicates parts which should be temporarily tightened, and

then fully tightened with the vehicle in the unladen

condition.

1 TSB Revision1

Page 710 of 1146

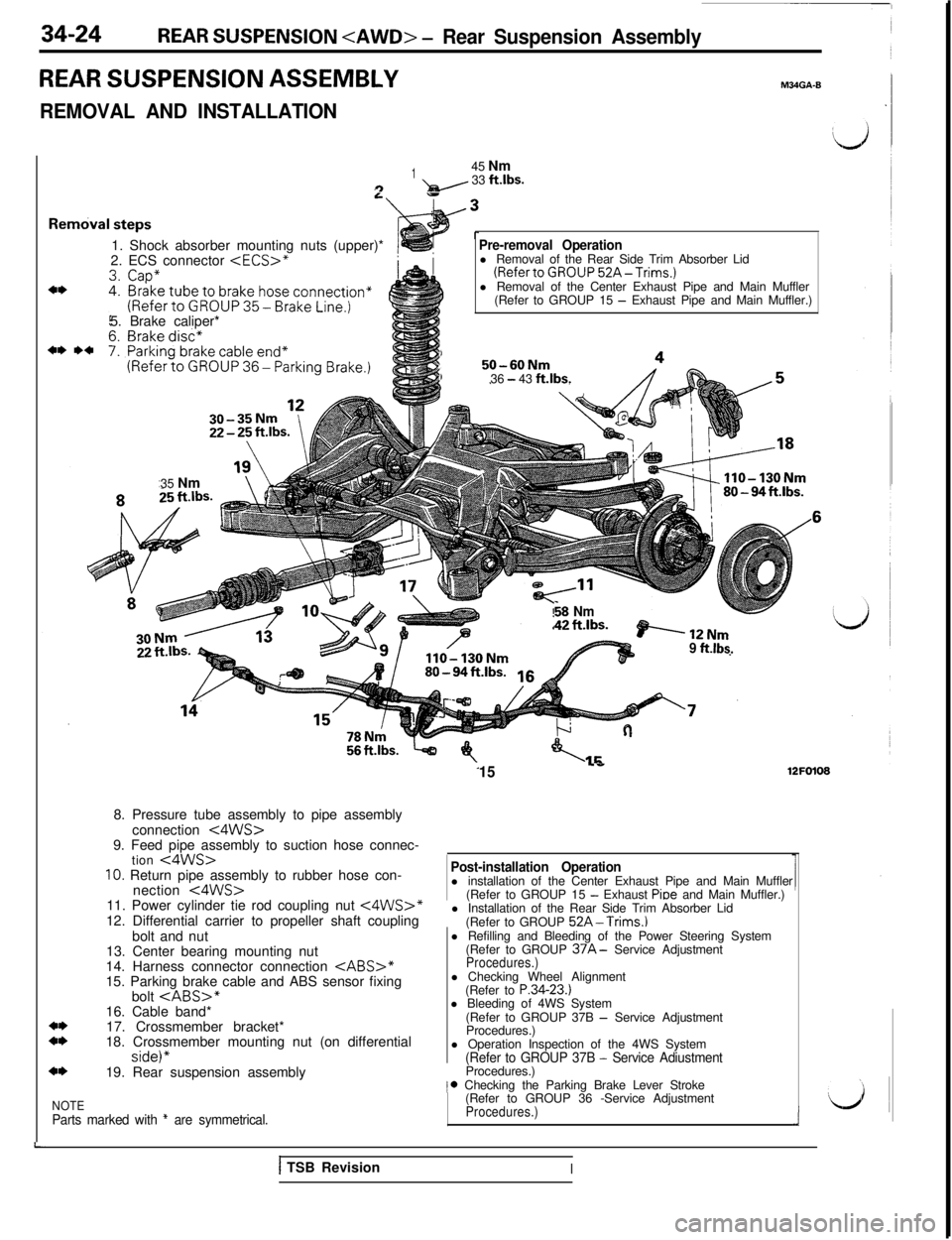

34-24REAR SUSPENSION

REAR SUSPENSION ASSEMBLY

REMOVAL AND INSTALLATION

M34GA-B

L

Rel

145 Nm9- 33 ftlbs.

1. Shock absorber mounting nuts (upper)*

2. ECS connector

(RefertoGROUP52A-Trims.)l Removal of the Center Exhaust Pipe and Main Muffler

(Refer to GROUP 15

- Exhaust Pipe and Main Muffler.)

5. Brake caliper*

1,50-60NmI36 - 43 ft.lbs.35 Nm

$8 Nm“?C,ILc. ashwez I,..“=.BP’----12Nm9 ftlbs.

15..e12FO1088. Pressure tube assembly to pipe assembly

connection

<4WS>9. Feed pipe assembly to suction hose connec-

tion

<4WS>10. Return pipe assembly to rubber hose con-

nection t4WS>11. Power cylinder tie rod coupling nut <4WS>*12. Differential carrier to propeller shaft coupling

bolt and nut

Post-installation Operationl installation of the Center Exhaust Pipe and Main Muffler

(Refer to GROUP 15

- Exhaust Pioe and Main Muffler.)

l Installation of the Rear Side Trim Absorber Lid

(Refer to GROUP

52A-Trims.)13. Center bearing mounting nut

14. Harness connector connection

CABS>*15. Parking brake cable and ABS sensor fixingl Refilling and Bleeding of the Power Steering System

(Refer to GROUP

37A- Service AdjustmentProcedures.)bolt

17. Crossmember bracket*

18. Crossmember mounting nut (on differential

side)”19. Rear suspension assemblyl Checking Wheel Alignment

(Refer to P.34-23.)

l Bleeding of 4WS System

(Refer to GROUP 37B

- Service Adjustment

Procedures.)

l Operation Inspection of the 4WS System

(Refer to GROUP 37B - Service AdiustmentProcedures.)

NOTEParts marked with * are symmetrical.

,* Checking the Parking Brake Lever Stroke

(Refer to GROUP 36 -Service Adjustment

Procedures.)i

1 TSB RevisionI

Page 716 of 1146

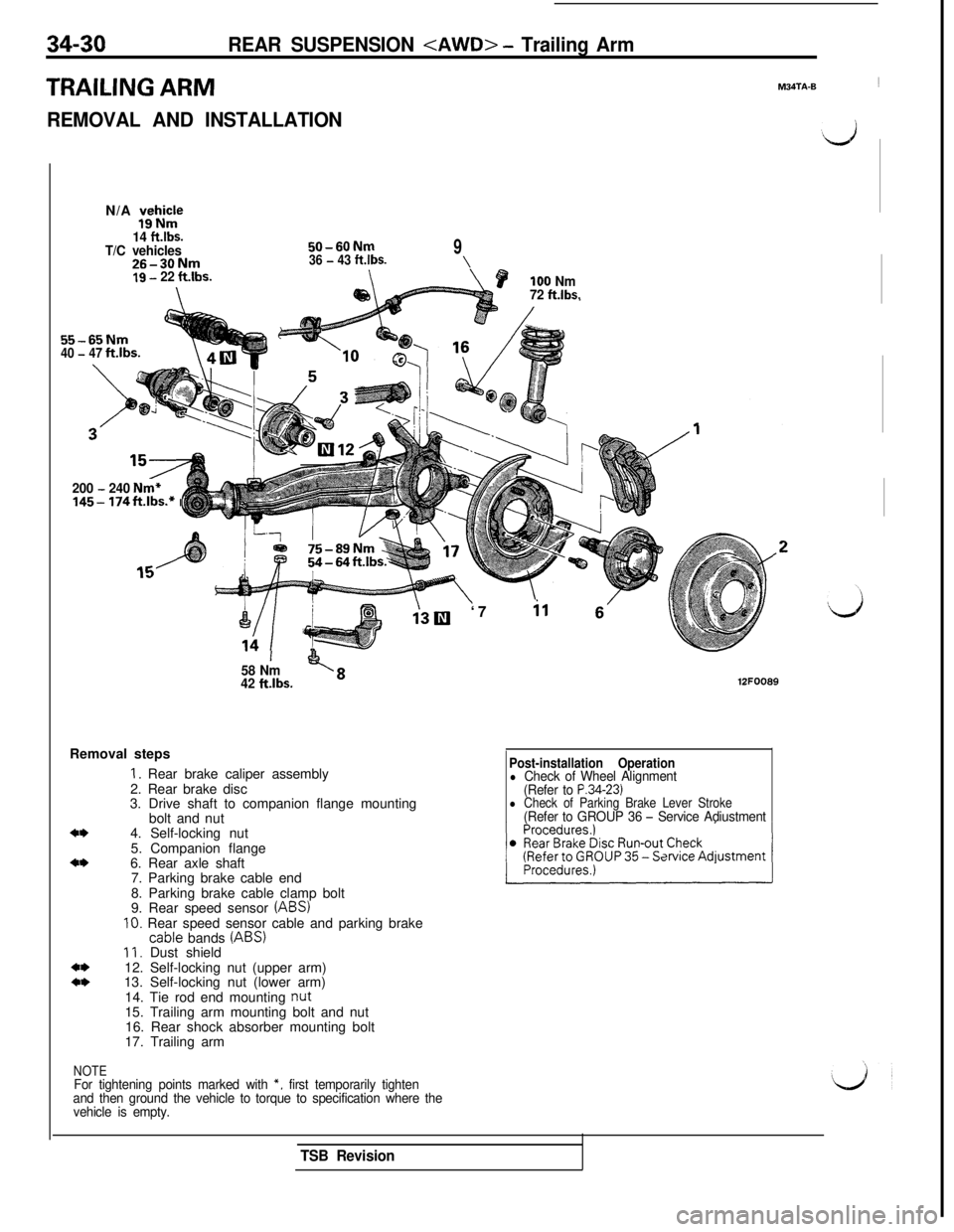

34-30REAR SUSPENSION

TRAILING ARMM34TA-B1

REMOVAL AND INSTALLATIONN/A

$icJ

14 ft.lbs.T/C vehicles26-30Nm

50-60Nm936 - 43 ftlbs.\19 - 22 ft.lbs.

55-65Nm40 - 47ft.lbs.

200

- 240 Nm*145- 174ft.lbs.* I

P100 Nm

72 ft.lbs.

58 Nm’ <842 ft.lbs.Removal steps

*I)

*I)

+*+*

1. Rear brake caliper assembly

2. Rear brake disc

3. Drive shaft to companion flange mounting

bolt and nut

4. Self-locking nut

5. Companion flange

6. Rear axle shaft

7. Parking brake cable end

8. Parking brake cable clamp bolt

9. Rear speed sensor

(ABS)IO. Rear speed sensor cable and parking brake

cable bands (ABS)II. Dust shield

12. Self-locking nut (upper arm)

13. Self-locking nut (lower arm)

14. Tie rod end mounting

nut15. Trailing arm mounting bolt and nut

16. Rear shock absorber mounting bolt

17. Trailing arm

NOTEFor tightening points marked with *, first temporarily tighten

and then ground the vehicle to torque to specification where the

vehicle is empty.‘7

il 6’

12FOO89

Post-installation Operationl Check of Wheel Alignment

(Refer to P.34-23)l Check of Parking Brake Lever Stroke(Refer to GROUP 36 - Service Adiustment

TSB Revision

Page 720 of 1146

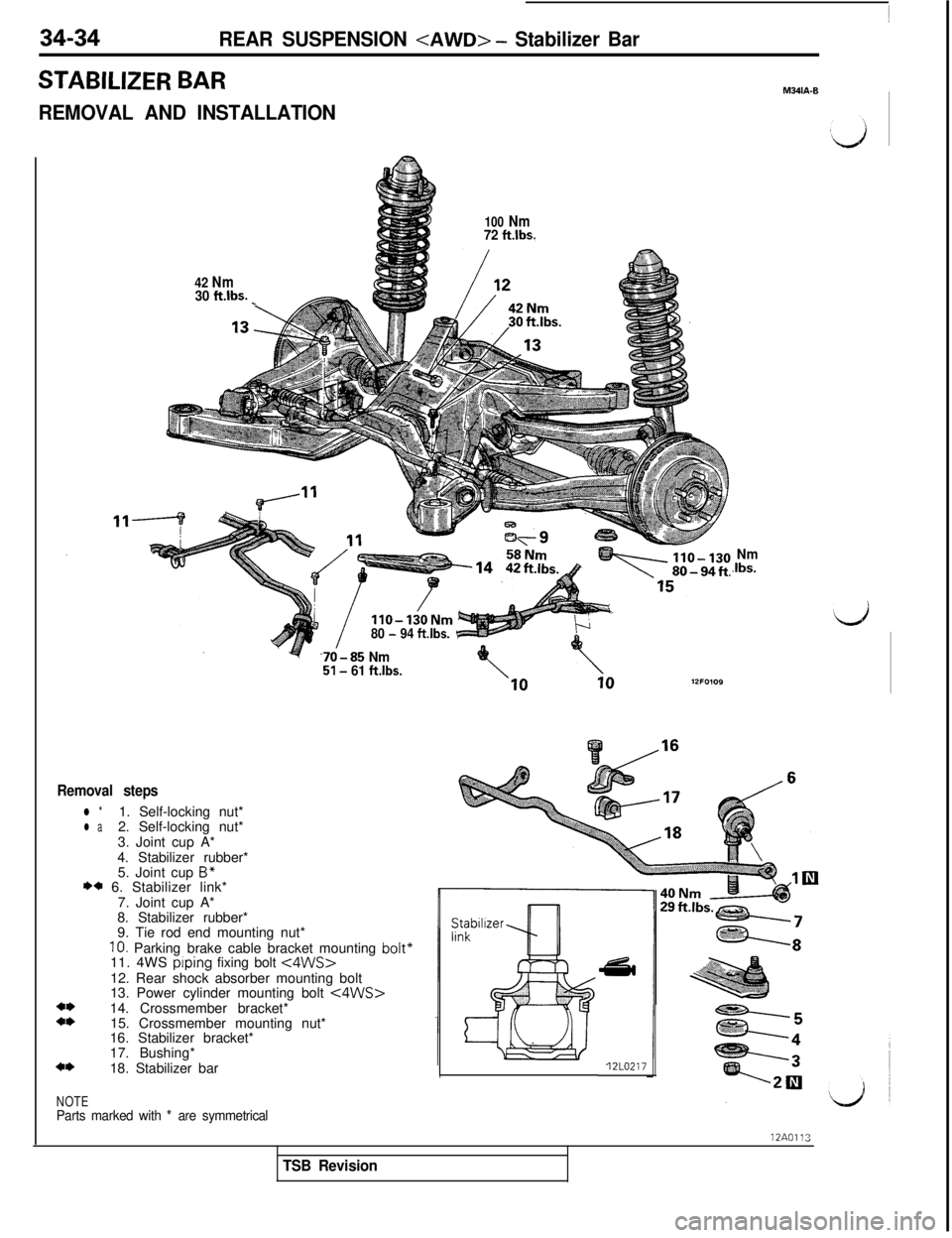

34-34REAR SUSPENSION

STABILIZER BAR

REMOVAL AND INSTALLATION

100 Nm72 ft.lbs.

42 Nm4

30 ft.lbs._

/IIO-130Nm80 - 94 ftlbs.

70-85 Nm51- 61 ftlbs.

Removal steps

l *1. Self-locking nut*l a2. Self-locking nut*

3. Joint cup A*

4. Stabilizer rubber*

5. Joint cup

B”I)* 6. Stabilizer link*

7. Joint cup A*

8. Stabilizer rubber*

9. Tie rod end mounting nut*

IO. Parking brake cable bracket mounting bolt”11. 4WS prping fixing bolt <4WS>12. Rear shock absorber mounting bolt

13. Power cylinder mounting bolt

<4WS>14. Crossmember bracket*

15. Crossmember mounting nut*

16. Stabilizer bracket*

17. Bushing*

18. Stabilizer bar

NOTEParts marked with * are symmetrical12L0217

Nm.Ibs.

M341A.B12A0113

TSB Revision

Page 728 of 1146

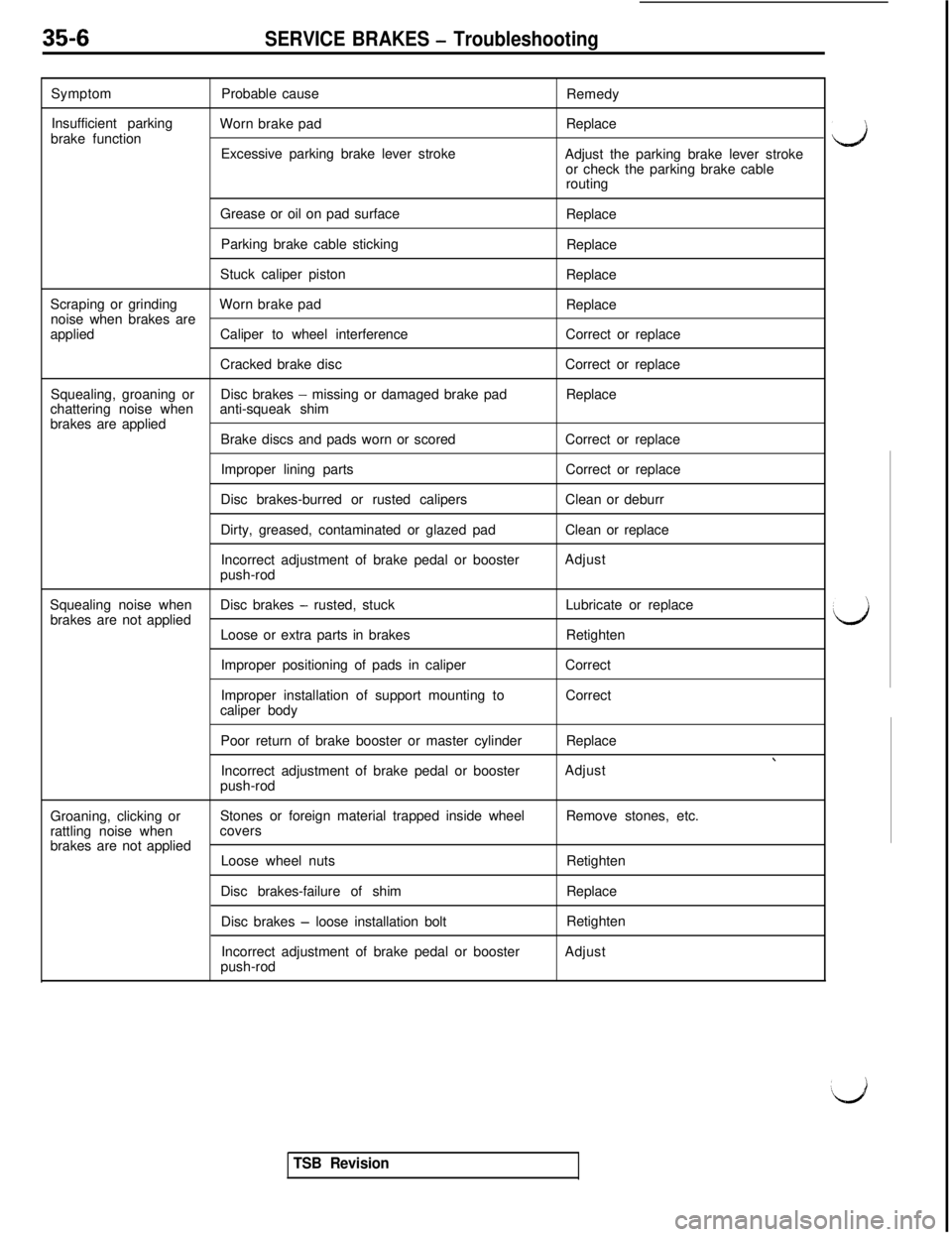

35-6SERVICE BRAKES - TroubleshootingSymptomProbable cause

Remedy

Insufficient parking

Worn brake pad

brake functionReplace

Excessive parking brake lever stroke

Adjust the parking brake lever stroke

or check the parking brake cable

routing

Grease or oil on pad surface

Replace

Parking brake cable sticking

Replace

Stuck caliper piston

Replace

Scraping or grindingWorn brake pad

noise when brakes areReplace

appliedCaliper to wheel interferenceCorrect or replace

Cracked brake discCorrect or replace

Squealing, groaning or

chattering noise whenDisc brakes

- missing or damaged brake pad

anti-squeak shimReplace

brakes are applied

Brake discs and pads worn or scoredCorrect or replace

Improper lining partsCorrect or replace

Disc brakes-burred or rusted calipersClean or deburr

Dirty, greased, contaminated or glazed padClean or replace

Incorrect adjustment of brake pedal or booster

push-rodAdjust

Squealing noise whenDisc brakes

- rusted, stuck

brakes are not appliedLubricate or replace

Loose or extra parts in brakesRetighten

Improper positioning of pads in caliperCorrect

Improper installation of support mounting toCorrect

caliper body

Poor return of brake booster or master cylinderReplace

Incorrect adjustment of brake pedal or booster

push-rodAdjust

Groaning, clicking orStones or foreign material trapped inside wheelRemove stones, etc.

rattling noise whencovers

brakes are not applied

Loose wheel nutsRetighten

Disc brakes-failure of shimReplace

Disc brakes

- loose installation boltRetighten

Incorrect adjustment of brake pedal or booster

push-rodAdjust

TSB Revision

d

d

Page 775 of 1146

L.

SERVICE BRAKES -Service Adjustment Procedures35-53

I14A0398

14F003r

i14A04014NOO27

7

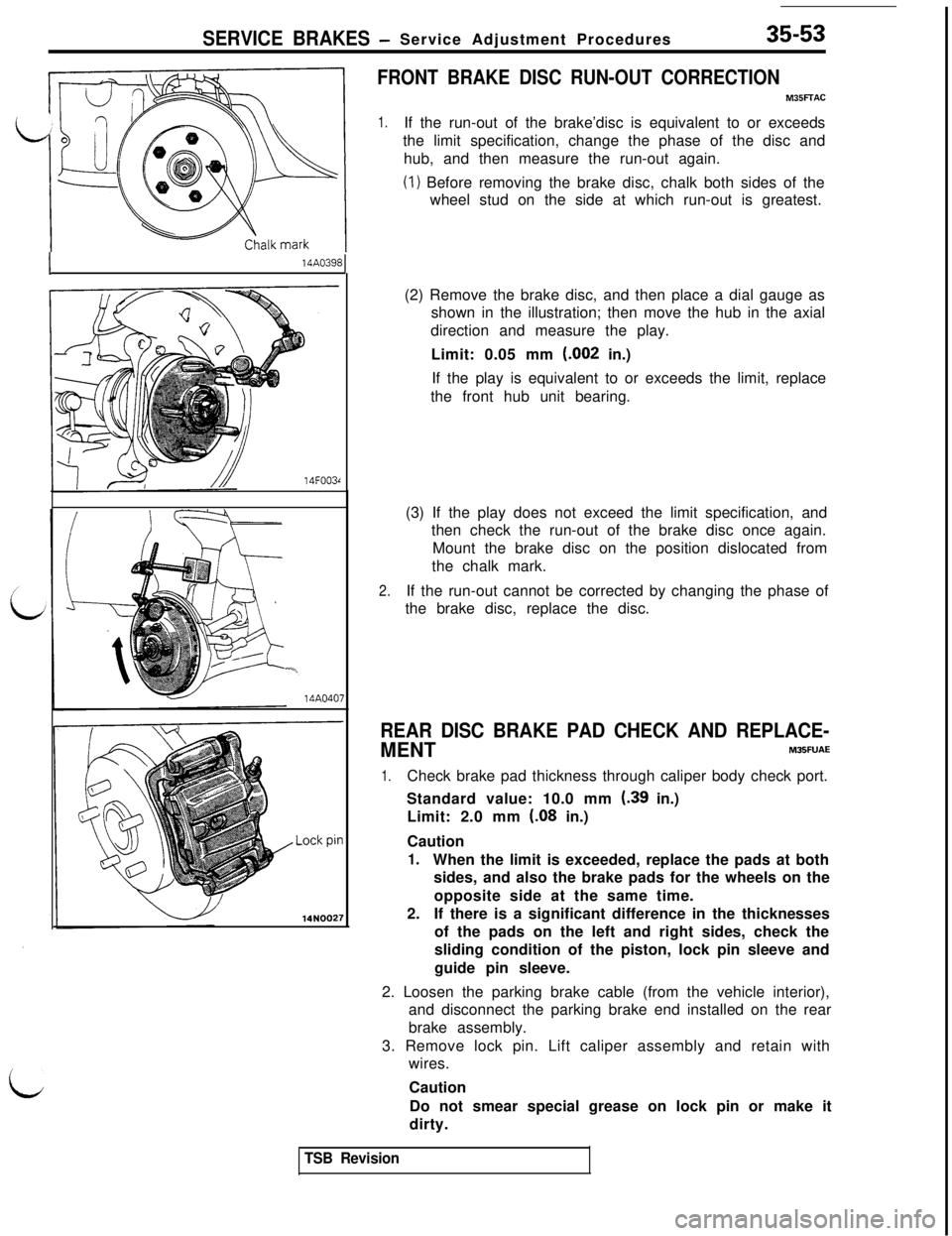

FRONT BRAKE DISC RUN-OUT CORRECTION

M35FFAC

1.If the run-out of the brake’disc is equivalent to or exceeds

the limit specification, change the phase of the disc and

hub, and then measure the run-out again.

(1) Before removing the brake disc, chalk both sides of the

wheel stud on the side at which run-out is greatest.

(2) Remove the brake disc, and then place a dial gauge as

shown in the illustration; then move the hub in the axial

direction and measure the play.

Limit: 0.05 mm (.002 in.)

If the play is equivalent to or exceeds the limit, replace

the front hub unit bearing.

(3) If the play does not exceed the limit specification, and

then check the run-out of the brake disc once again.

Mount the brake disc on the position dislocated from

the chalk mark.

2.If the run-out cannot be corrected by changing the phase of

the brake disc, replace the disc.

REAR DISC BRAKE PAD CHECK AND REPLACE-

MENTM35FUAE

1.Check brake pad thickness through caliper body check port.

Standard value: 10.0 mm

(39 in.)

Limit: 2.0 mm

(08 in.)

Caution

1.When the limit is exceeded, replace the pads at both

sides, and also the brake pads for the wheels on the

opposite side at the same time.

2.If there is a significant difference in the thicknesses

of the pads on the left and right sides, check the

sliding condition of the piston, lock pin sleeve and

guide pin sleeve.

2. Loosen the parking brake cable (from the vehicle interior),

and disconnect the parking brake end installed on the rear

brake assembly.

3. Remove lock pin. Lift caliper assembly and retain with

wires.

Caution

Do not smear special grease on lock pin or make it

dirty.

TSB Revision