radiator MITSUBISHI 3000GT 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 301 of 1146

COOLING - Service Adiustment Procedures.14-7

SERVICE ADJUSTMENT PROCEDURES

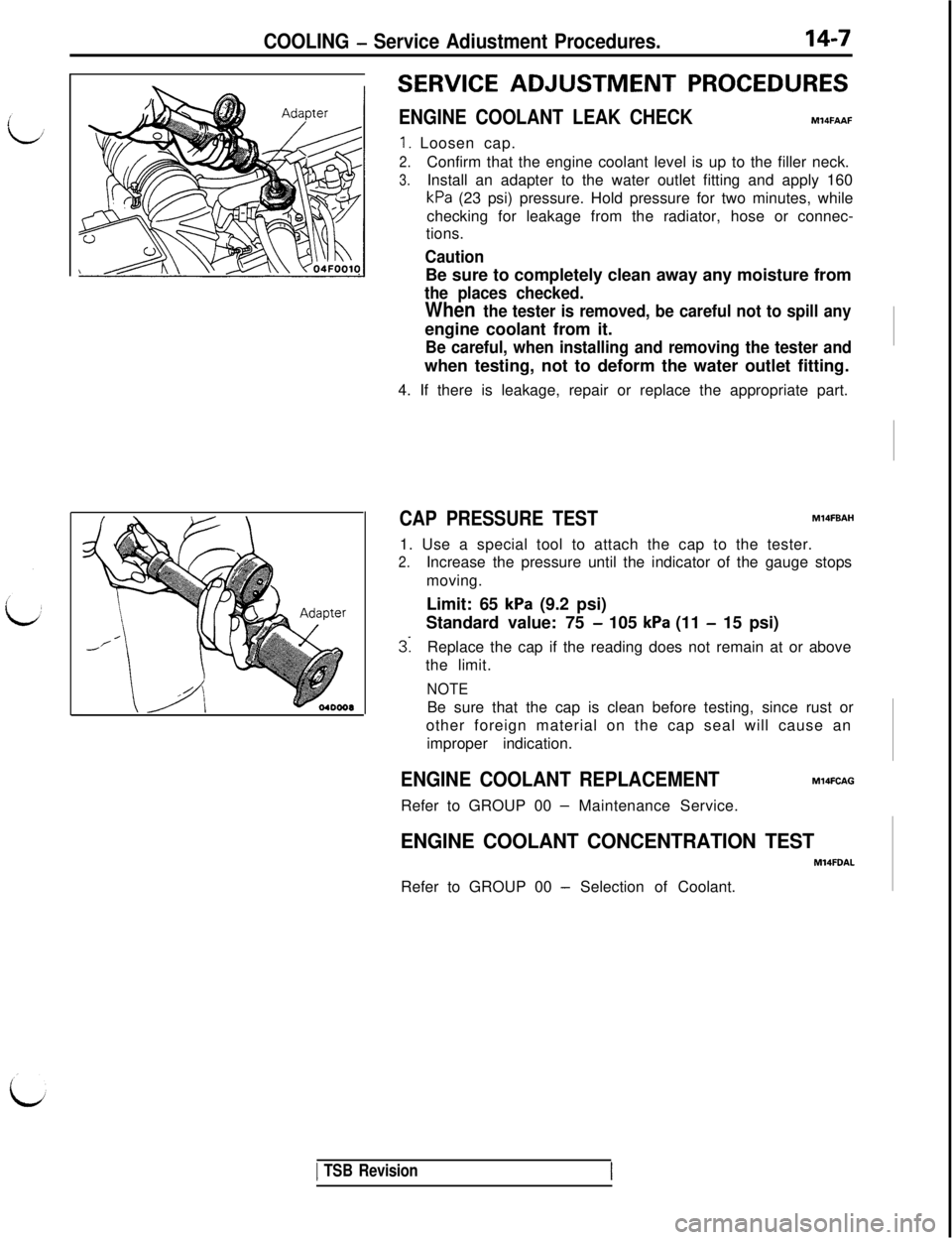

ENGINE COOLANT LEAK CHECKMl4FAAF

1. Loosen cap.

2.Confirm that the engine coolant level is up to the filler neck.

3.Install an adapter to the water outlet fitting and apply 160

kPa (23 psi) pressure. Hold pressure for two minutes, while

checking for leakage from the radiator, hose or connec-

tions.

CautionBe sure to completely clean away any moisture from

the places checked.

When the tester is removed, be careful not to spill anyengine coolant from it.

Be careful, when installing and removing the tester andwhen testing, not to deform the water outlet fitting.

4. If there is leakage, repair or replace the appropriate part.

CAP PRESSURE TESTM14FBAH1. Use a special tool to attach the cap to the tester.

2.Increase the pressure until the indicator of the gauge stops

moving.

Limit: 65

kPa (9.2 psi)

Standard value: 75

- 105 kPa (11 - 15 psi)

3:Replace the cap if the reading does not remain at or above

the limit.

NOTEBe sure that the cap is clean before testing, since rust or

other foreign material on the cap seal will cause an

improper indication.

ENGINE COOLANT REPLACEMENTM14FCAGRefer to GROUP 00

- Maintenance Service.

ENGINE COOLANT CONCENTRATION TEST

M14FDALRefer to GROUP 00

- Selection of Coolant.

1 TSB Revision

Page 302 of 1146

14-8COOLING - Radiator

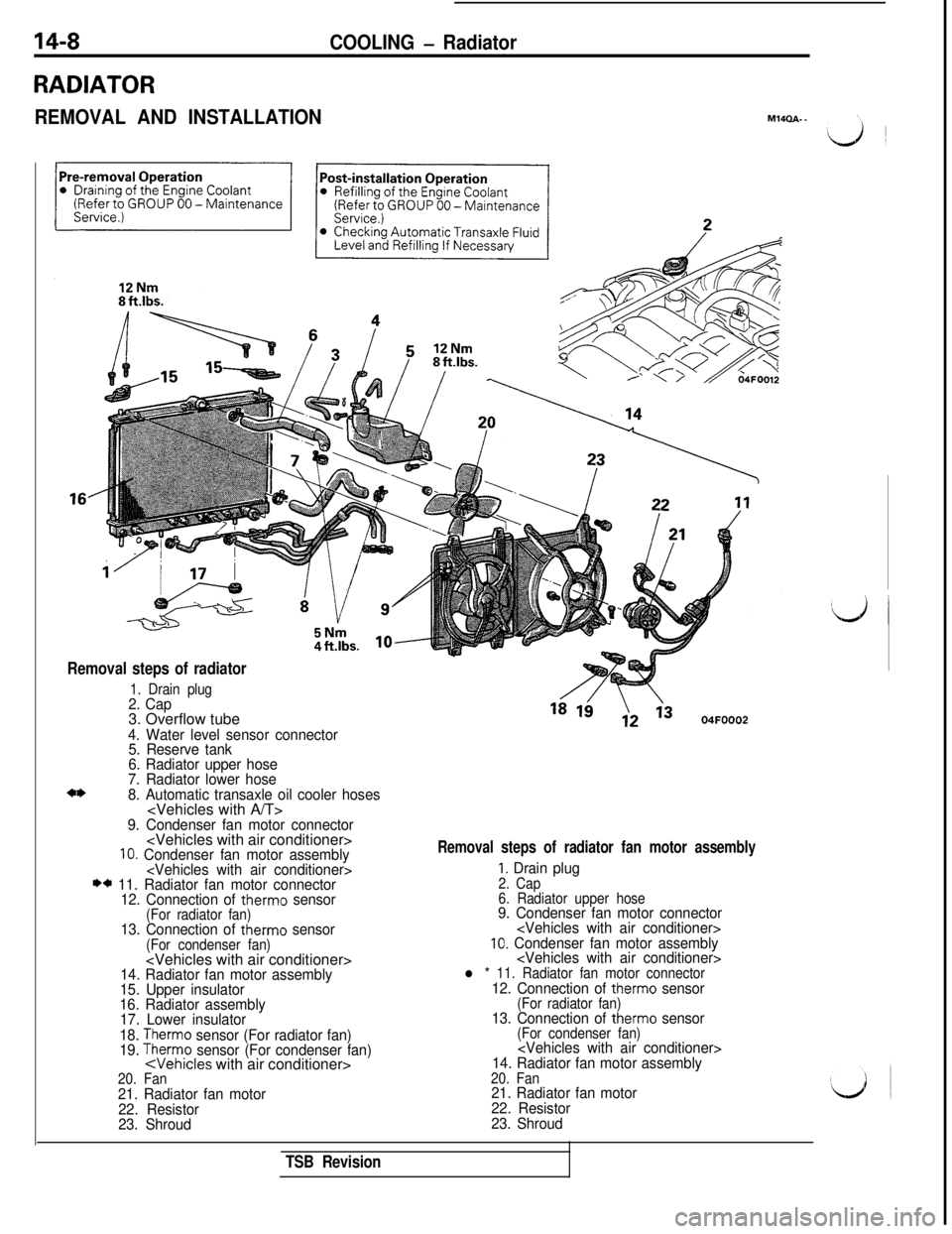

RADIATOR

REMOVAL AND INSTALLATIONM14QA..

Removal steps of radiator

1. Drain plug2. Cap3. Overflow tube

4. Water level sensor connector

5. Reserve tank

6. Radiator upper hose

7. Radiator lower hose

8. Automatic transaxle oil cooler hoses

9. Condenser fan motor connector

10. Condenser fan motor assembly

** 11. Radiator fan motor connector

12. Connection of therm0 sensor(For radiator fan)13. Connection of therm0 sensor(For condenser fan)

14. Radiator fan motor assembly

15. Upper insulator

16. Radiator assembly

17. Lower insulator

Removal steps of radiator fan motor assembly

1. Drain plug2. Cap

6. Radiator upper hose

9. Condenser fan motor connector

10. Condenser fan motor assembly

l * 11. Radiator fan motor connector12. Connection of therm0 sensor(For radiator fan)13. Connection of therm0 sensor

18.

Therm0 sensor (For radiator fan)

19. Therm0 sensor (For condenser fan)

(For condenser fan)

14. Radiator fan motor assembly20. Fan

21. Radiator fan motor21. Radiator fan motor

22. Resistor22. Resistor

23. Shroud23. Shroud

TSB Revision

Page 303 of 1146

COOLING - Radiator14-S

- 04N0002

SERVICE POINT OF REMOVALM14QBAK8. DISCONNECTION OF AUTOMATIC TRANSAXLE OIL

COOLER HOSESUse a plug or otherwise cover the hose and nipple part of

the radiator so that dust, dirt, foreign materials, etc. do not

enter after the hose has been disconnected from the

radiator.

INSPECTIONM14QCAN

l Check for foreign material between radiator fins.

l Check the radiator fins for bent, or damage.

l Check the radiator for corrosion, damage rust or scale.

lCheck the radiator hoses for cracks, damage or deteriora-

tion.

l Check the reserve tank for damage.

lCheck the automatic transaxle oil cooler hoses for cracking,

damage or deterioration.

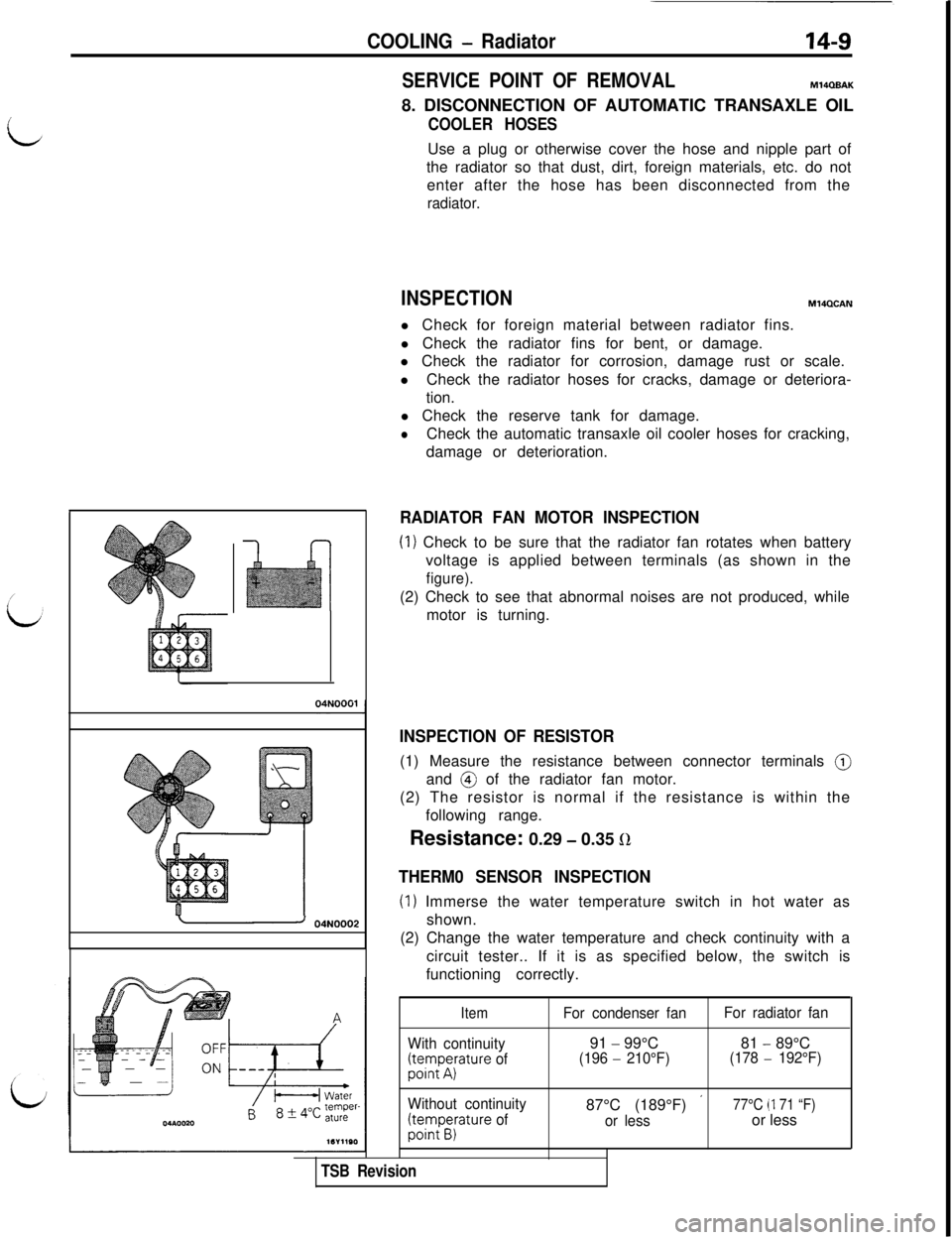

RADIATOR FAN MOTOR INSPECTION

(1) Check to be sure that the radiator fan rotates when battery

voltage is applied between terminals (as shown in the

figure).(2) Check to see that abnormal noises are not produced, while

motor is turning.

INSPECTION OF RESISTOR(1) Measure the resistance between connector terminals @

and @ of the radiator fan motor.

(2) The resistor is normal if the resistance is within the

following range.

Resistance: 0.29

- 0.35 IZ

THERM0 SENSOR INSPECTION

(1) Immerse the water temperature switch in hot water as

shown.

(2) Change the water temperature and check continuity with a

circuit tester.. If it is as specified below, the switch is

functioning correctly.

Item

With continuityb;F;;ature of

Without continuity

(t;,n-r3;rature ofFor condenser fanFor radiator fan91

- 99°C81 - 89°C(196 - 210°F)(178 - 192°F)87°C (189°F)

’77°C (I 71 “F)

or lessor less

TSB Revision

Page 304 of 1146

14-10COOLING - Radiator

r-----I

113

EY

4 :

2 :

i.-.-..i

0312161908

Ionnector04FOOO8

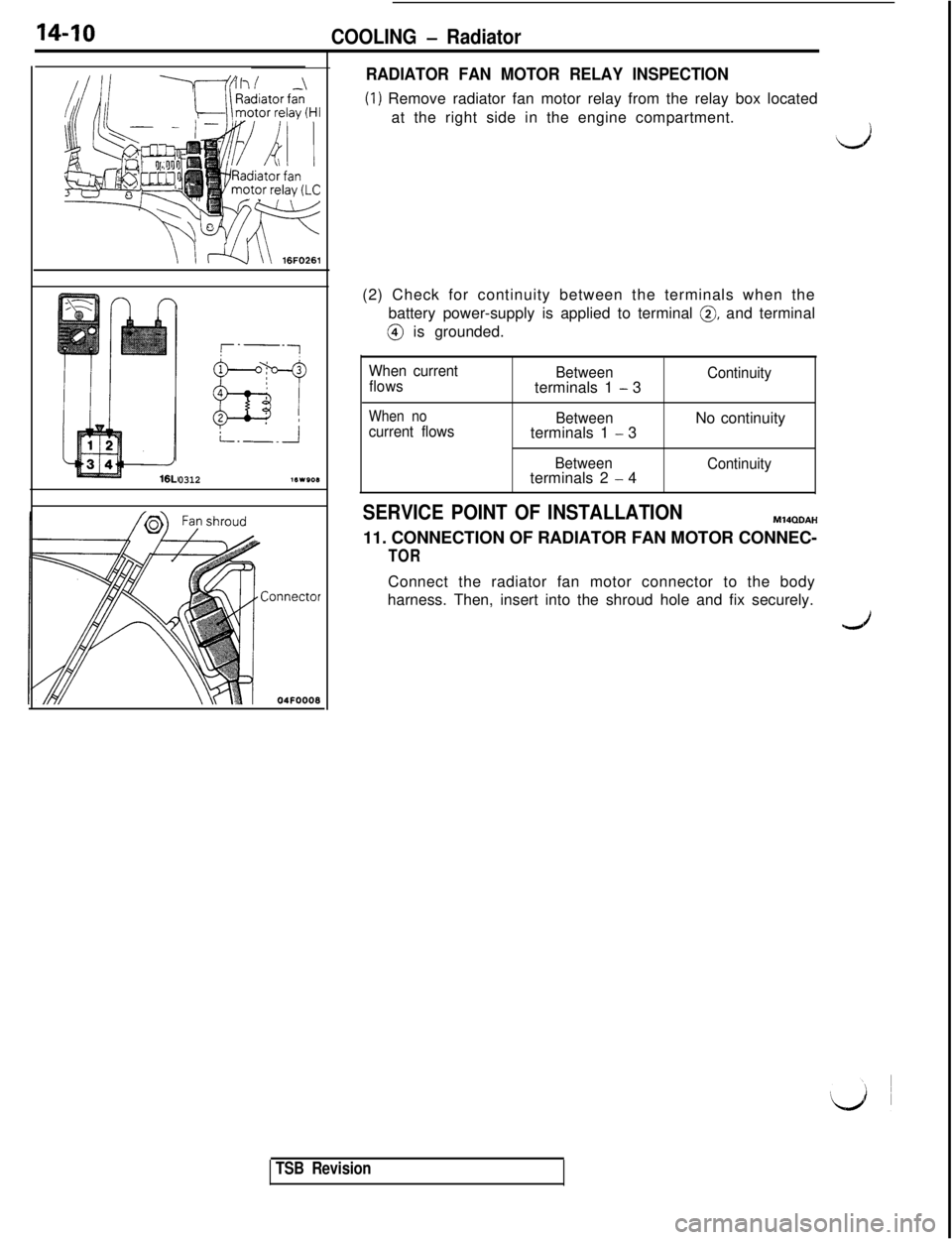

RADIATOR FAN MOTOR RELAY INSPECTION

(1) Remove radiator fan motor relay from the relay box located

at the right side in the engine compartment.

Ll(2) Check for continuity between the terminals when the

battery power-supply is applied to terminal

0, and terminal@ is grounded.

When current

flowsBetweenterminals 1

- 3Continuity

When nocurrent flowsBetweenterminals 1 - 3No continuity

Betweenterminals 2 - 4Continuity

SERVICE POINT OF INSTALLATIONM14QDAH

11. CONNECTION OF RADIATOR FAN MOTOR CONNEC-

TORConnect the radiator fan motor connector to the body

harness. Then, insert into the shroud hole and fix securely.

TSB Revision

Page 305 of 1146

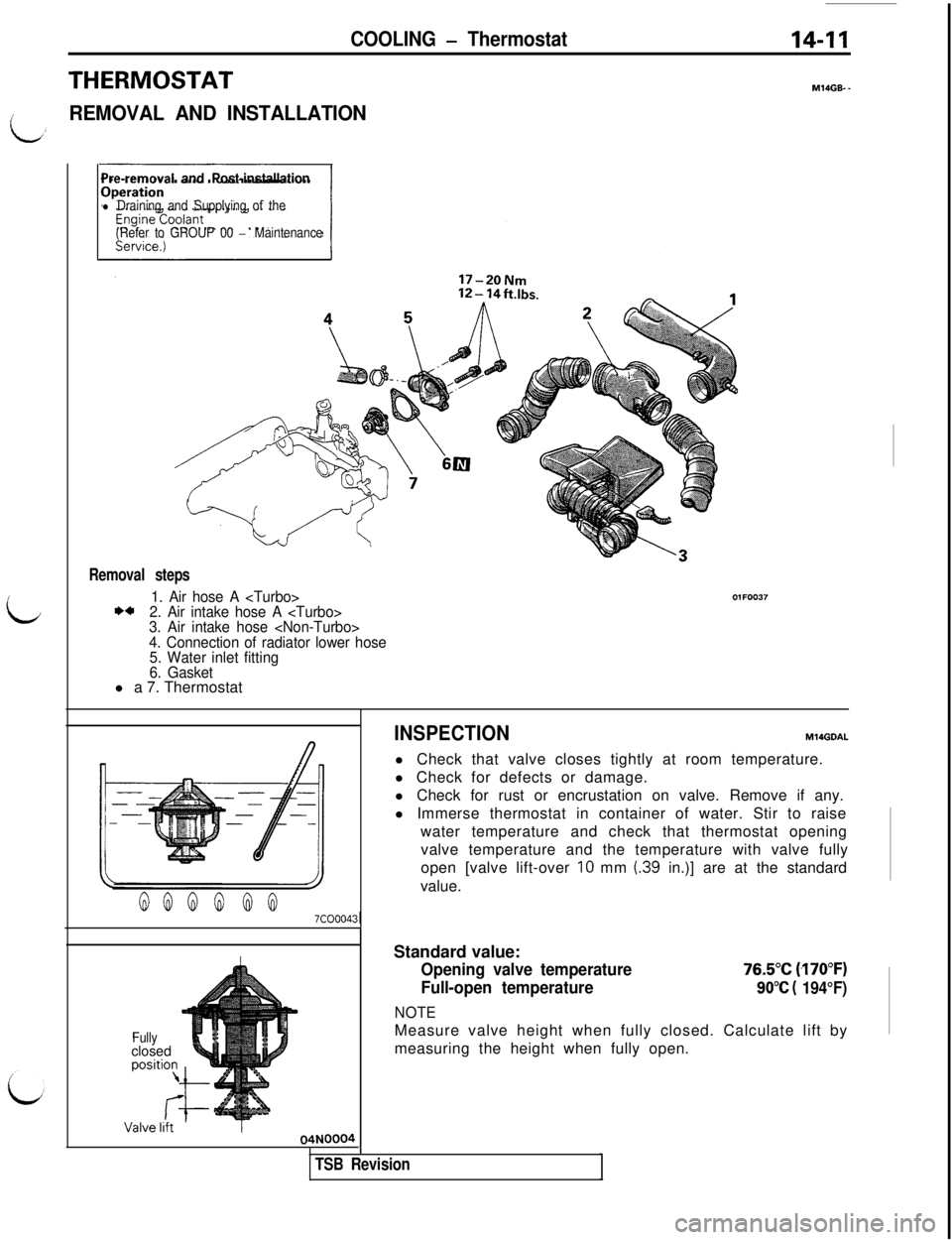

COOLING - Thermostat14-11

THERMOSTATMlbGB- -

iREMOVAL AND INSTALLATION

L

Pre-removal and Post-installation

l Draining and Supplying of the

(Refer to GROUP 00

- Maintenance

Removal steps

1. Air hose A

3. Air intake hose

4. Connection of radiator lower hose

5. Water inlet fitting

6. Gasketl a 7. Thermostat

OlFOO37

7cooo43l

Fullyclosed j

04N0004

INSPECTIONM14GDALl Check that valve closes tightly at room temperature.

l Check for defects or damage.

l Check for rust or encrustation on valve. Remove if any.

l Immerse thermostat in container of water. Stir to raise

water temperature and check that thermostat opening

valve temperature and the temperature with valve fully

open [valve lift-over

10 mm (39 in.)] are at the standard

value.

Standard value:

Opening valve temperature

Full-open temperature

NOTE76.5%

(‘170°F)

90°C ( 194°F)Measure valve height when fully closed. Calculate lift by

measuring the height when fully open.

-

TSB Revision

Page 307 of 1146

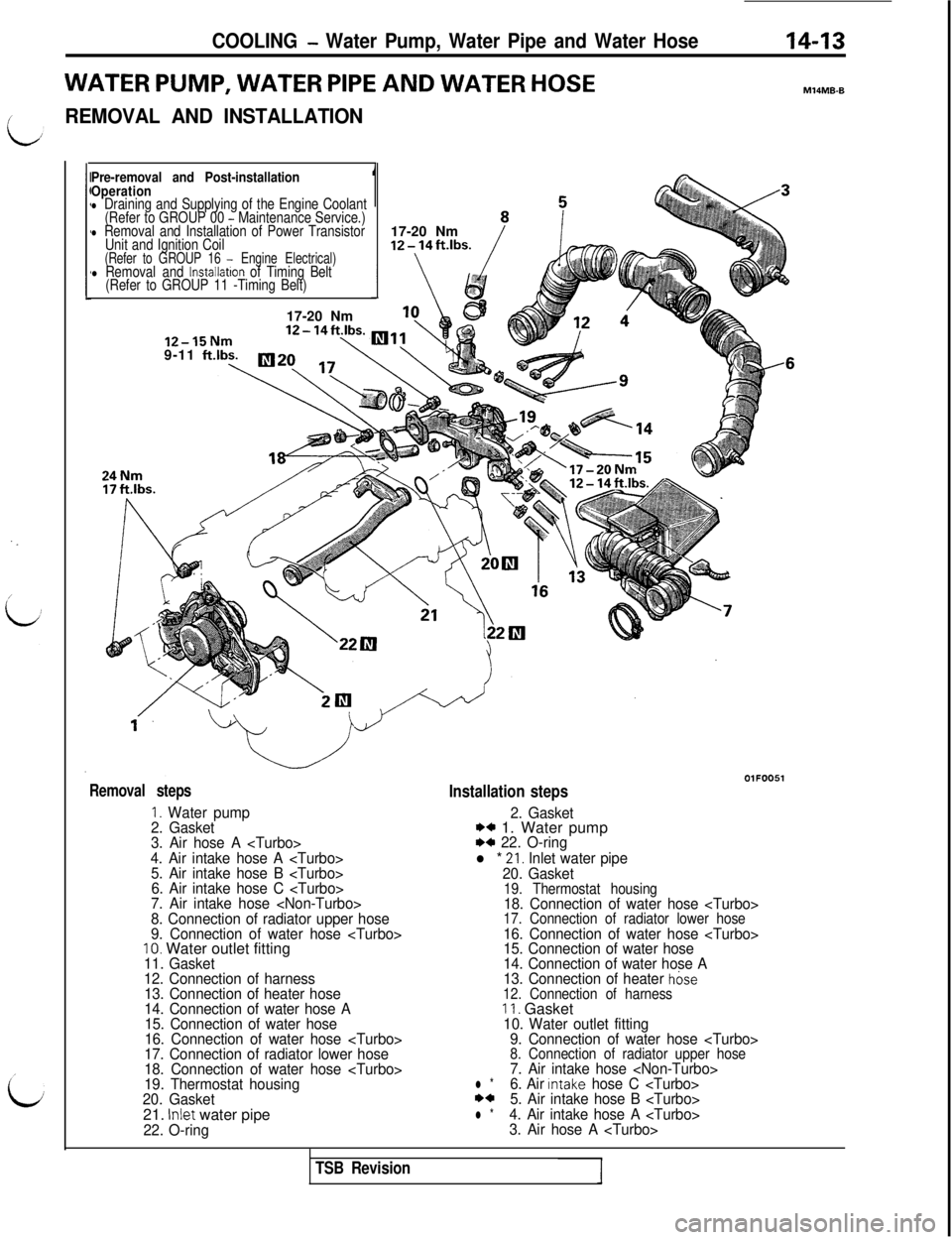

COOLING - Water Pump, Water Pipe and Water Hose

WATER PUMP, WATER PIPE AND WATER HOSE

14-13

M14MB-B

/REMOVAL AND INSTALLATION

Pre-removal and Post-installation

Operation

l Draining and Supplying of the Engine Coolant

(Refer to GROUP 00 - Maintenance Service.)l Removal and Installation of Power Transistor

Unit and Ignition Coil

(Refer to GROUP 16 - Engine Electrical)l Removal and lnstallatlon of Timing Belt

(Refer to GROUP 11 -Timing Belt)17-20 Nm17-20 Nm

12-14ft.lbs.

1

12-15Nm9-11 ft.1bs.q

Removal steps

1. Water pump

2. Gasket

3. Air hose A

4. Air intake hose A

5. Air intake hose B

6. Air intake hose C

7. Air intake hose

8. Connection of radiator upper hose

9. Connection of water hose

IO. Water outlet fitting11. Gasket

12. Connection of harness

13. Connection of heater hose

14. Connection of water hose A

15. Connection of water hose

16. Connection of water hose

17. Connection of radiator lower hose

18. Connection of water hose

19. Thermostat housing

20. Gasket21.

Her water pipe22. O-ringOlFOO51

Installation steps

2. Gasket** 1. Water pumpI)+ 22. O-ring

l * 21. Inlet water pipe

20. Gasket

19. Thermostat housing18. Connection of water hose

15. Connection of water hose

14. Connection of water hose A

13. Connection of heater h&e

12. Connection of harness11. Gasket10. Water outlet fitting

9. Connection of water hose

8. Connection of radiator upper hose7. Air intake hose

3. Air hose A

TSB Revision

Page 309 of 1146

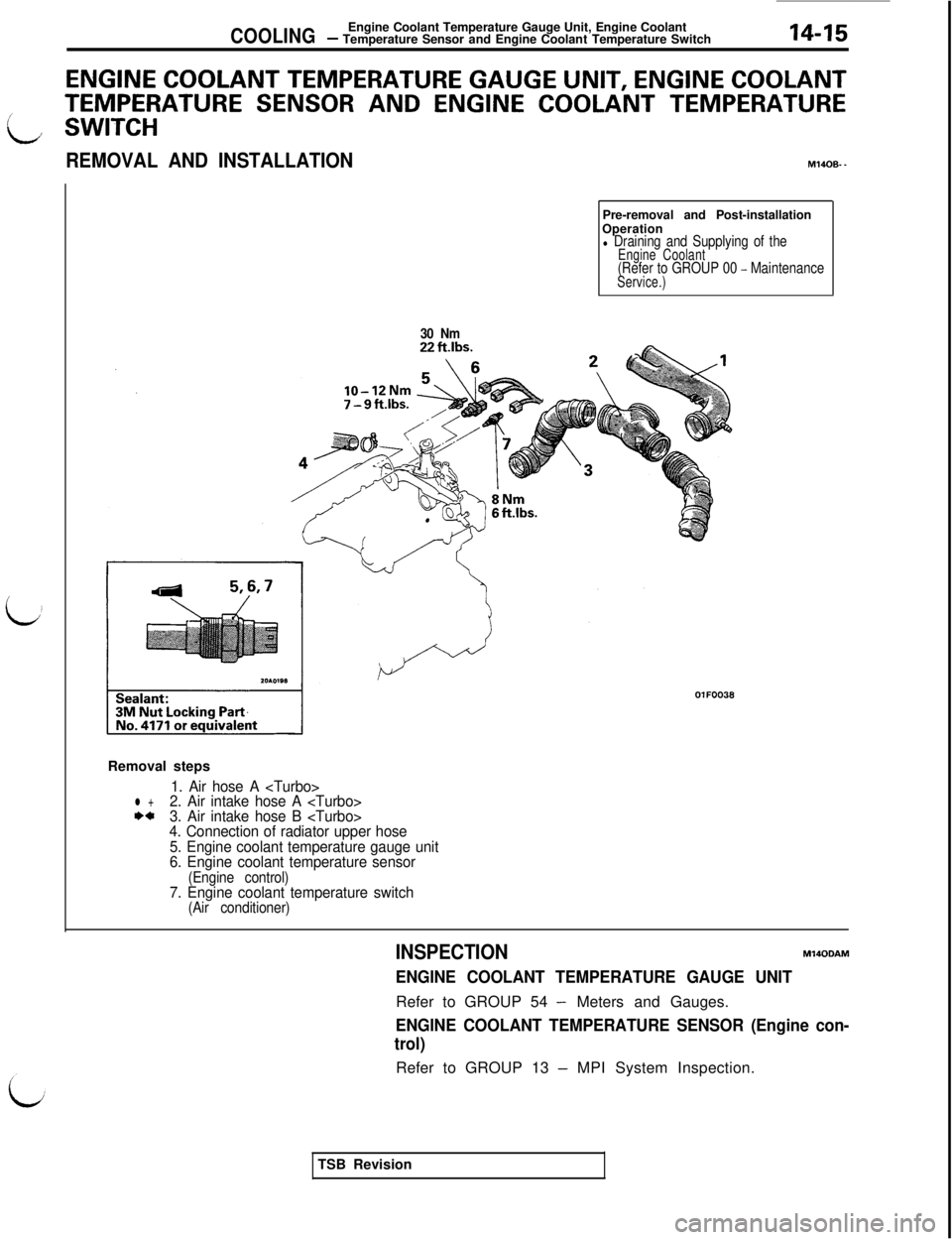

COOLINGEngine Coolant Temperature Gauge Unit, Engine Coolant- Temperature Sensor and Engine Coolant Temperature Switch14-15

ENGINE COOLANT TEMPERATURE GAUGE UNIT, ENGINE COOLANT

TEMPERATURE SENSOR AND ENGINE COOLANT TEMPERATURE

L,SWITCH

REMOVAL AND INSTALLATIONM140B. -Pre-removal and Post-installation

Operation

l Draining and Supplying of theEngine Coolant(Refer to GROUP 00 - MaintenanceService.)

30 NmOlFOO38

Removal steps

1. Air hose A

4. Connection of radiator upper hose

5. Engine coolant temperature gauge unit

6. Engine coolant temperature sensor

(Engine control)7. Engine coolant temperature switch(Air conditioner)

INSPECTIONM140DAM

ENGINE COOLANT TEMPERATURE GAUGE UNITRefer to GROUP 54

- Meters and Gauges.

ENGINE COOLANT TEMPERATURE SENSOR (Engine con-

trol)Refer to GROUP 13

- MPI System Inspection.

TSB Revision

Page 328 of 1146

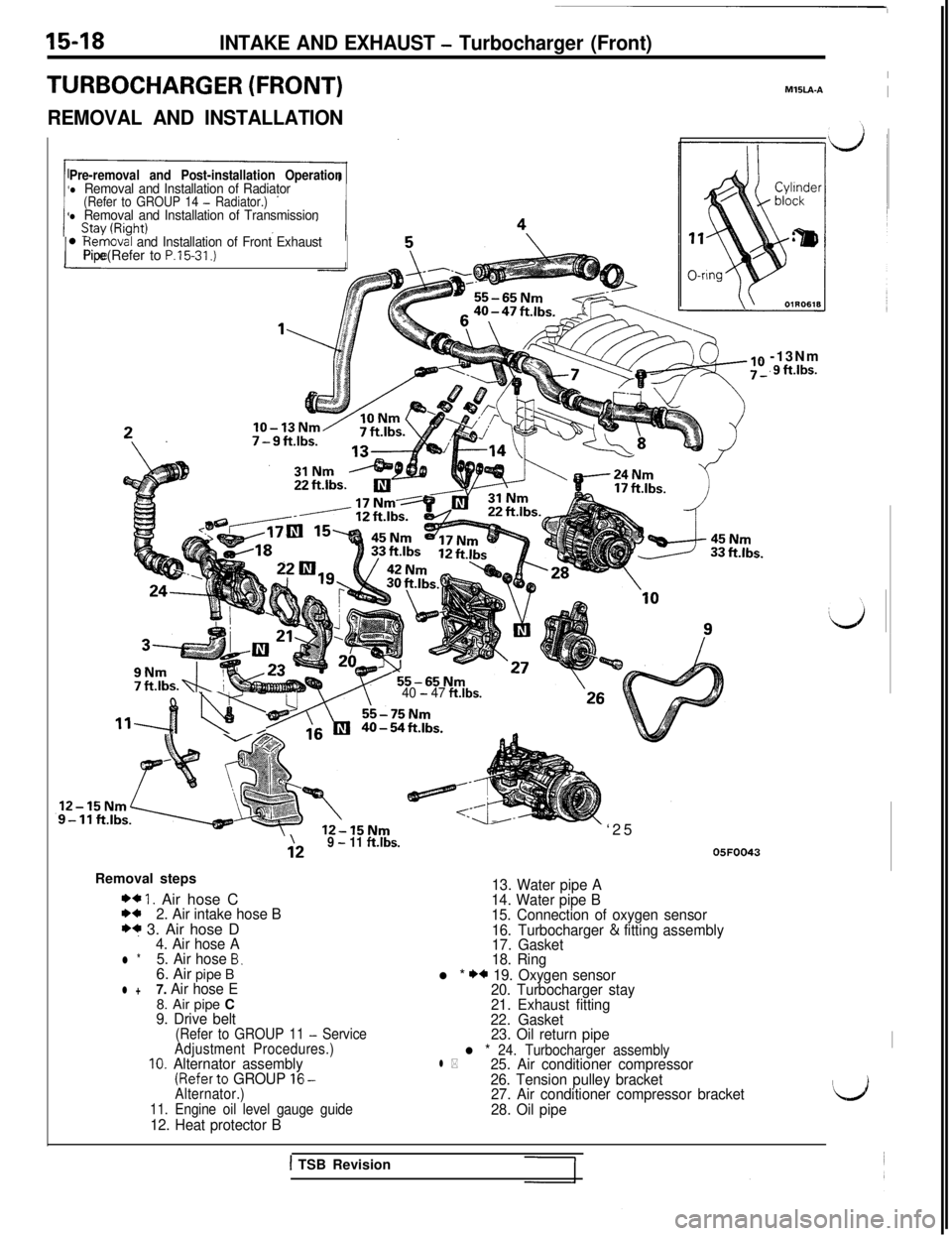

15-18INTAKE AND EXHAUST - Turbocharger (Front)

TURBOCHARGER (FRONT)

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operationl Removal and Installation of Radiator(Refer to GROUP 14 - Radiator.)l Removal and Installation of Transmission

l Rerr

IPipeioval and Installation of Front Exhaust(Refer to P.15-31.)

lJl QG!?

IMlSLA-AI

40 - 47 ft.lbs.

1\29 - 11 ft.lbs.Removal steps

** 1. Air hose C*+2. Air intake hose B*+ 3. Air hose D4. Air hose Al *5. Air hose B.6. Air pipe B

l +7. Air hose E8. Air pipe C

9. Drive belt(Refer to GROUP 11 - Service

Adjustment Procedures.)

10. Alternator assembly(Referto GROUP 16-Alternator.)

11. Engine oil level gauge guide

12. Heat protector B-13Nm

‘9 ft.lbs.

-‘25

05FOO43

13. Water pipe A

14. Water pipe B

15. Connection of oxygen sensor

16. Turbocharger

& fitting assembly

17. Gasket

18. Ring

l * ** 19. Oxygen sensor

20. Turbocharger stay

21. Exhaust fitting

22. Gasket

23. Oil return pipe

l * 24. Turbocharger assemblyl *25. Air conditioner compressor

26. Tension pulley bracket

27. Air conditioner compressor bracket

28. Oil pipe

I

LJ

1 TSB Revision

Page 337 of 1146

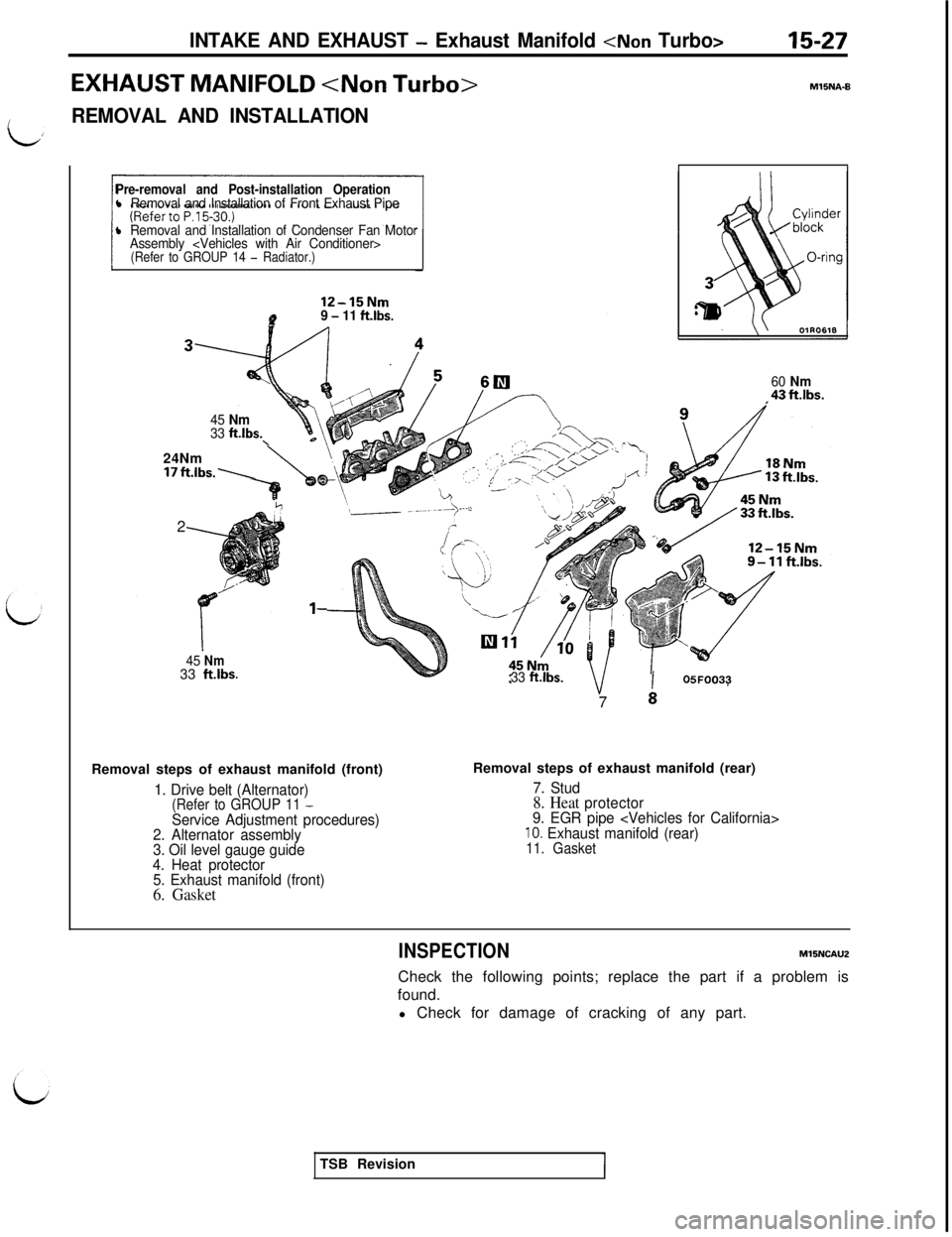

INTAKE AND EXHAUST - Exhaust Manifold

EXHAUST MANIFOLD

iREMOVAL AND INSTALLATION

Pre-removal and Post-installation Operationl Removal and Installation of Front Exhaust Pipe

l Removal and Installation of Condenser Fan Motor

Assembly

(Refer to GROUP 14 - Radiator.)

12-15Nm

P9 - 11 ft.lbs.

45 Nm33 ft.lbs.\24Nm

17ft.lbs.1

Li2

l-

45 Nm33 ft.lbs.

MSNA-8Removal steps of exhaust manifold (front)

1. Drive belt (Alternator)(Refer to GROUP 11 -Service Adjustment procedures)

2. Alternator assembly

3. Oil level gauge guide

4. Heat protector

5. Exhaust manifold (front)

6. Gasket

60 Nm,43 ft.lbs.

33 ftlbs.1 05F00337

8Removal steps of exhaust manifold (rear)

7. Stud

8. Heat protector

9. EGR pipe

IO. Exhaust manifold (rear)11. Gasket

INSPECTIONhllSNCAU2

Check the following points; replace the part if a problem is

found.

l Check for damage of cracking of any part.

TSB Revision

I

Page 513 of 1146

AUTOMATIC TRANSAXLE - T

ransaxle Oil Cooler, Hoses, Tubes23-61OQFOO95

OQFOOQt

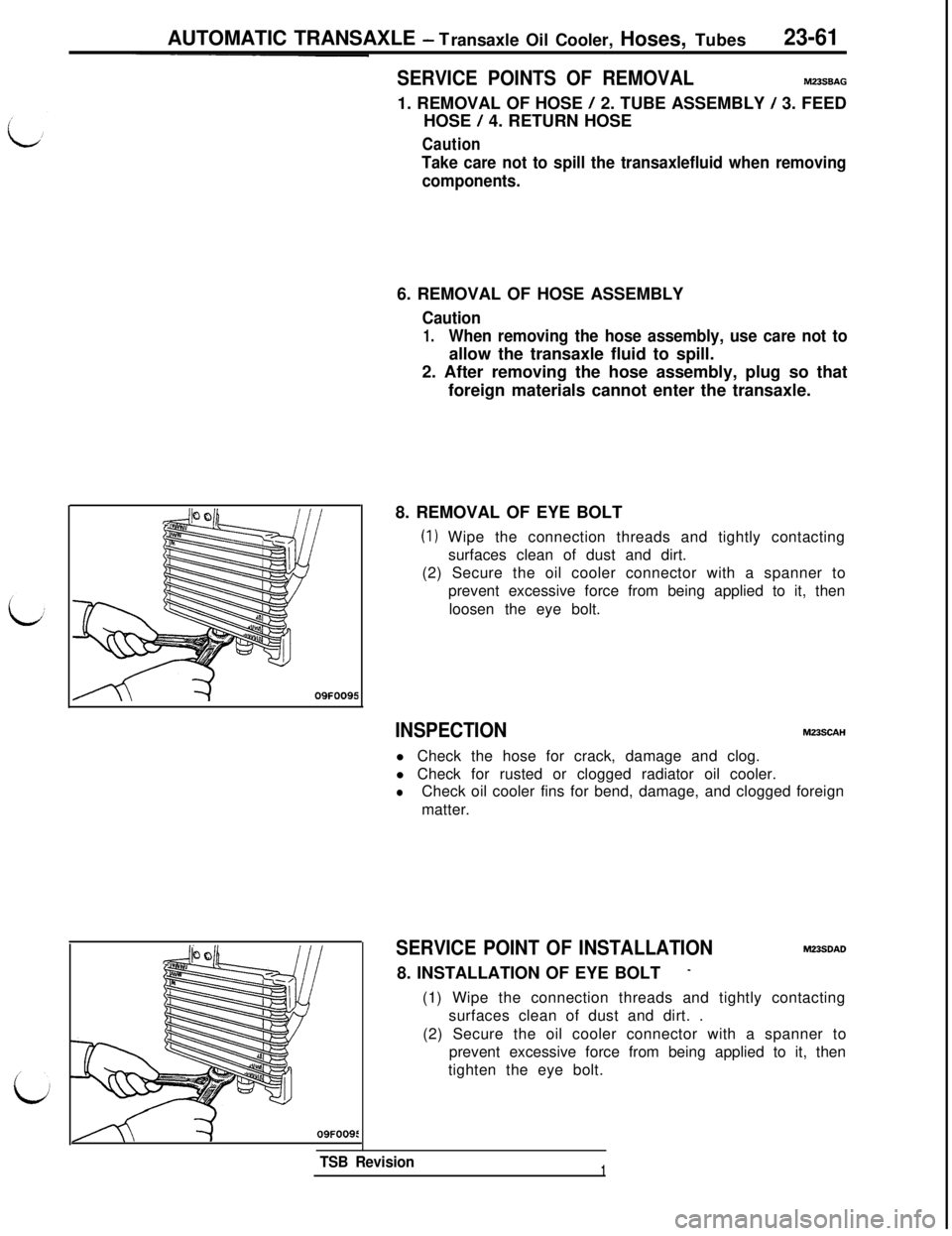

SERVICE POINTS OF REMOVALM23SBAG1. REMOVAL OF HOSE

/ 2. TUBE ASSEMBLY J 3. FEED

HOSE

/ 4. RETURN HOSE

Caution

Take care not to spill the transaxlefluid when removing

components.6. REMOVAL OF HOSE ASSEMBLY

Caution

1.When removing the hose assembly, use care not toallow the transaxle fluid to spill.

2. After removing the hose assembly, plug so that

foreign materials cannot enter the transaxle.

8. REMOVAL OF EYE BOLT

(1) Wipe the connection threads and tightly contacting

surfaces clean of dust and dirt.

(2) Secure the oil cooler connector with a spanner to

prevent excessive force from being applied to it, then

loosen the eye bolt.

INSPECTIONMZ3SCAHl Check the hose for crack, damage and clog.

l Check for rusted or clogged radiator oil cooler.

lCheck oil cooler fins for bend, damage, and clogged foreign

matter.

SERVICE POINT OF INSTALLATIONM23SDAD8. INSTALLATION OF EYE BOLT

-(1) Wipe the connection threads and tightly contacting

surfaces clean of dust and dirt. .

(2) Secure the oil cooler connector with a spanner to

prevent excessive force from being applied to it, then

tighten the eye bolt.

TSB Revision1