battery location MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 985 of 1146

INTERIOR - Troubleshooting52A-7OPERATION

Key-reminder warning

L0 Battery voltage is always supplied, through

fusible link No. 6 to the key-reminder switch.

l When the driver’s seat is opened while the

ignition key is still in the key cylinder, the door

switch is switched ON, electricity flows to

fusible link No. 6, the key-reminder switch, the

buzzer, the door switch, and ground, and the

buzzer sounds.

Seat belt warning

lBattery voltage is applied, through fuse No. 11

to the ETACS unit when the ignition key is at the

“ON” position.

l Electricity flows to fusible link No. 6, the seat

belt warning light, the ETACS unit, and ground,

and the seat belt warning light flashes for

approx. 6 seconds.

lIf the driver does not buckle the seat belt, the

seat belt switch is switched ON, electricity

flows to fusible link No. 6, the key-reminder

switch, the buzzer, the seat belt switch, the

ETACS unit, and ground, and the buzzer sounds

for approx. 6 seconds.

lWhen the driver buckles the seat belt, the seat

belt switch is switched OFF and the buzzer

stops.

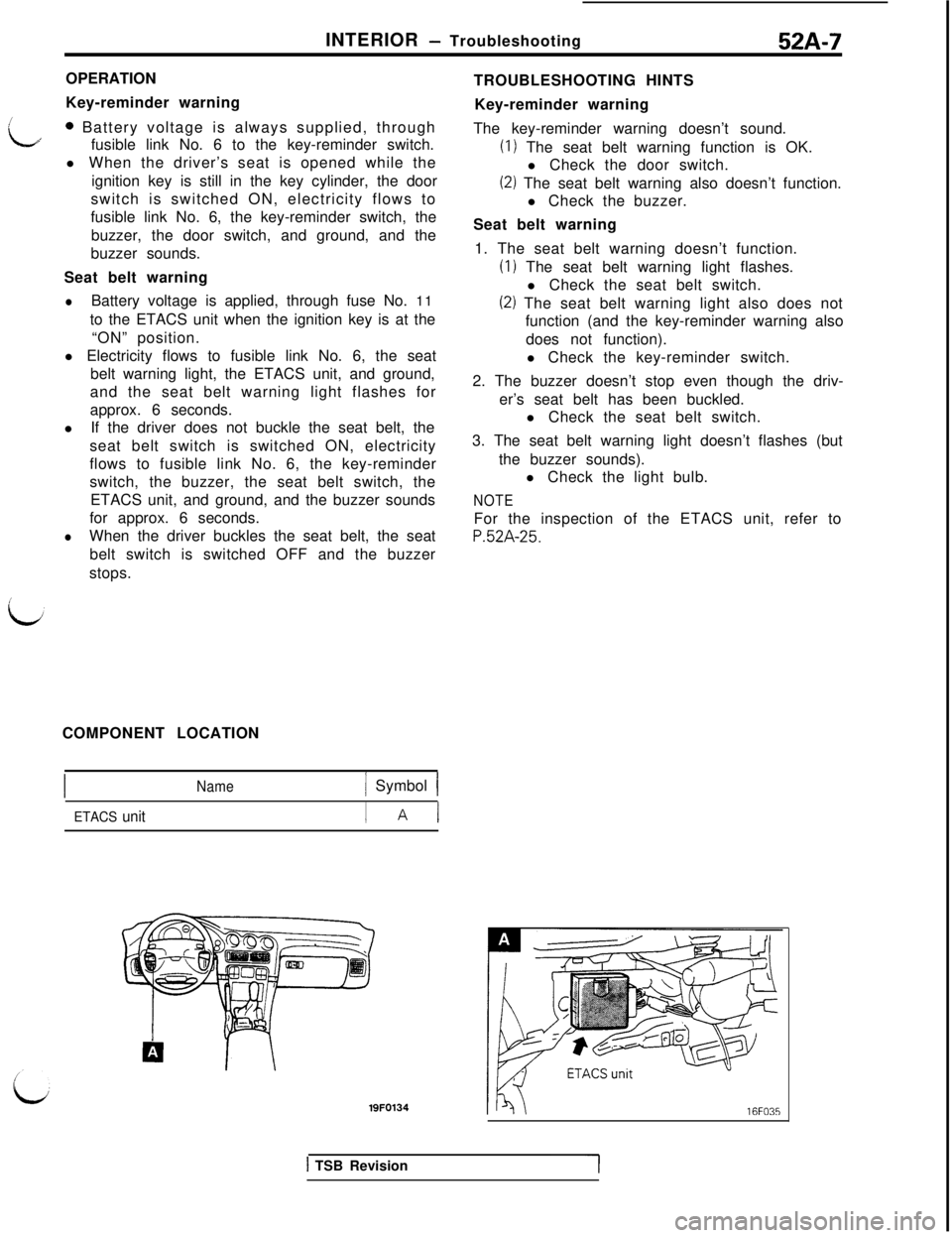

COMPONENT LOCATION

Name1 Symbol (

ETACS unitIA t19FO134TROUBLESHOOTING HINTS

Key-reminder warning

The key-reminder warning doesn’t sound.

(I) The seat belt warning function is OK.

l Check the door switch.

(2) The seat belt warning also doesn’t function.

l Check the buzzer.

Seat belt warning

1. The seat belt warning doesn’t function.

(I) The seat belt warning light flashes.

l Check the seat belt switch.

(2) The seat belt warning light also does not

function (and the key-reminder warning also

does not function).

l Check the key-reminder switch.

2. The buzzer doesn’t stop even though the driv-

er’s seat belt has been buckled.

l Check the seat belt switch.

3. The seat belt warning light doesn’t flashes (but

the buzzer sounds).

l Check the light bulb.

NOTEFor the inspection of the ETACS unit, refer to

P.52A-25.16FO35

1 TSB Revision

Page 1033 of 1146

r

/

lliSUPPLEMENTAL RESTRAINT SYSTEM (SRS)

- Troubleshootina 52B-23

L

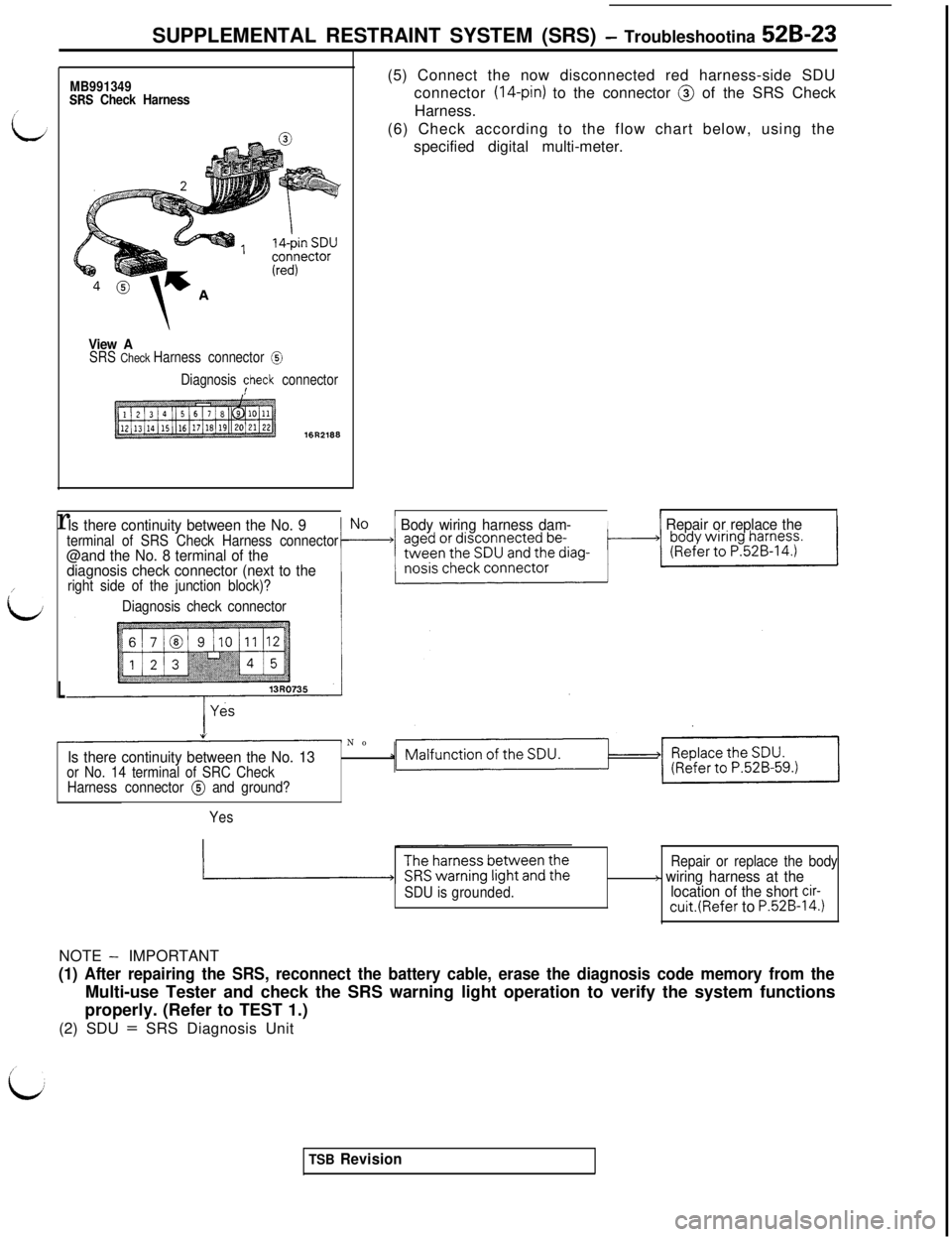

MB991349SRS Check Harness

View ASRS Check Harness connector @

Diagnosis Fheck connector16R2166(5) Connect the now disconnected red harness-side SDU

connector

(l&pin) to the connector @ of the SRS Check

Harness.

(6) Check according to the flow chart below, using the

specified digital multi-meter.

III1 Body wiring harness dam-/1 Repair or replace the1Is there continuity between the No. 9terminal of SRS Check Harness connector@and the No. 8 terminal of the

diagnosis check connector (next to the

right side of the junction block)?

Diagnosis check connectorv

~ No

Is there continuity between the No. 13or No. 14 terminal of SRC Check

Harness connector @ and ground?

Yes

SDU is grounded.Repair or replace the body

+ wiring harness at the

location of the short cir-cuit.(Refer to P.52B-14.)NOTE

- IMPORTANT

(1) After repairing the SRS, reconnect the battery cable, erase the diagnosis code memory from theMulti-use Tester and check the SRS warning light operation to verify the system functions

properly. (Refer to TEST 1.)

(2) SDU

= SRS Diagnosis Unit

TSB Revision

Page 1081 of 1146

idAir Bag Module

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

- Disposal Procedures 52B-71

2.

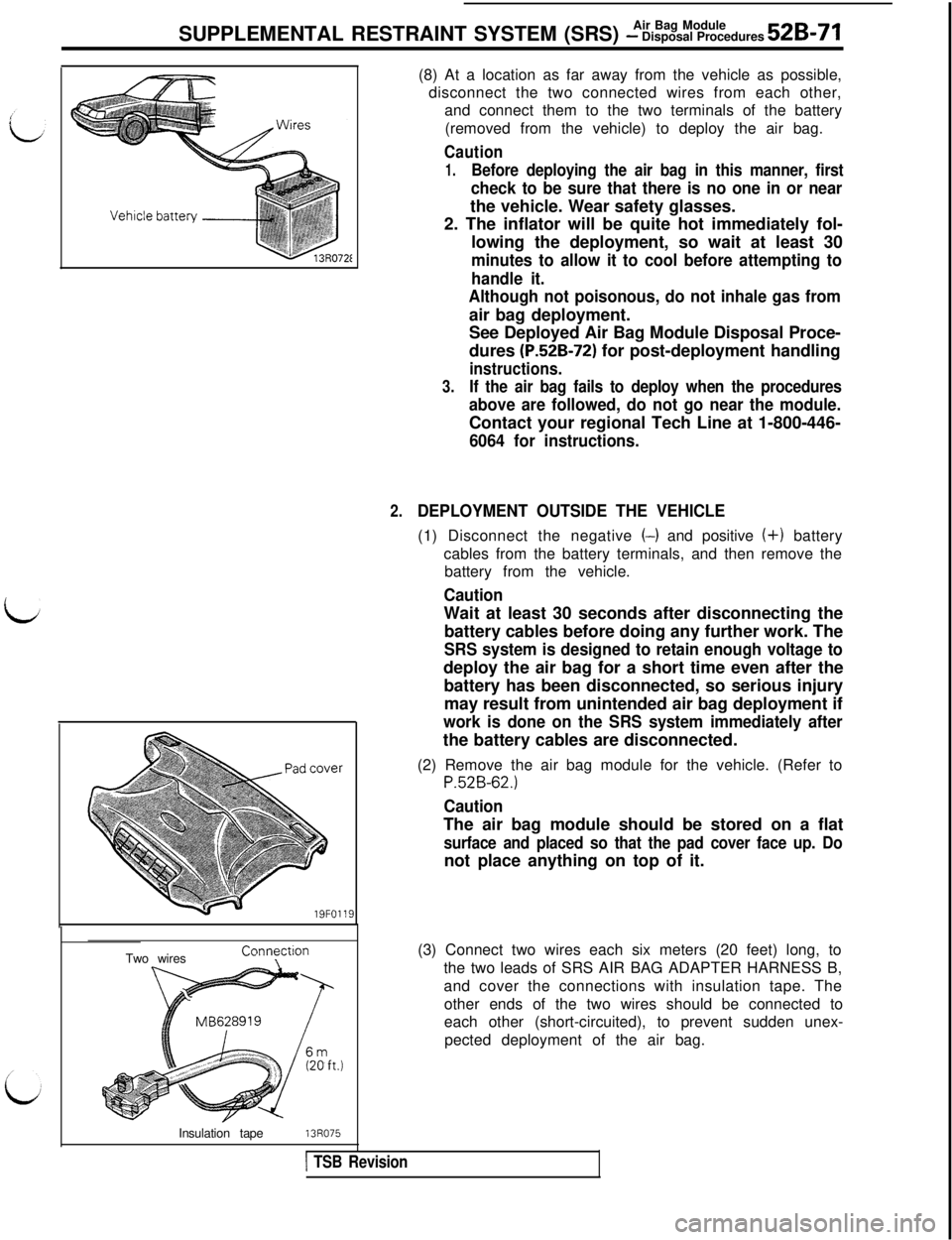

19FO119Two wires

ConytionInsulation tape

13~075(8) At a location as far away from the vehicle as possible,

disconnect the two connected wires from each other,

and connect them to the two terminals of the battery

(removed from the vehicle) to deploy the air bag.

Caution

1.Before deploying the air bag in this manner, first

check to be sure that there is no one in or nearthe vehicle. Wear safety glasses.

2. The inflator will be quite hot immediately fol-

lowing the deployment, so wait at least 30

minutes to allow it to cool before attempting to

handle it.

Although not poisonous, do not inhale gas fromair bag deployment.

See Deployed Air Bag Module Disposal Proce-

dures

(P.52B-72) for post-deployment handling

instructions.

3.If the air bag fails to deploy when the procedures

above are followed, do not go near the module.Contact your regional Tech Line at 1-800-446-

6064 for instructions.

DEPLOYMENT OUTSIDE THE VEHICLE(1) Disconnect the negative

(4 and positive (+) battery

cables from the battery terminals, and then remove the

battery from the vehicle.

CautionWait at least 30 seconds after disconnecting the

battery cables before doing any further work. The

SRS system is designed to retain enough voltage todeploy the air bag for a short time even after the

battery has been disconnected, so serious injury

may result from unintended air bag deployment if

work is done on the SRS system immediately afterthe battery cables are disconnected.

(2) Remove the air bag module for the vehicle. (Refer toP.528-62.)

CautionThe air bag module should be stored on a flat

surface and placed so that the pad cover face up. Donot place anything on top of it.

(3) Connect two wires each six meters (20 feet) long, to

the two leads of SRS AIR BAG ADAPTER HARNESS B,

and cover the connections with insulation tape. The

other ends of the two wires should be connected to

each other (short-circuited), to prevent sudden unex-

pected deployment of the air bag.

1 TSB Revision

Page 1082 of 1146

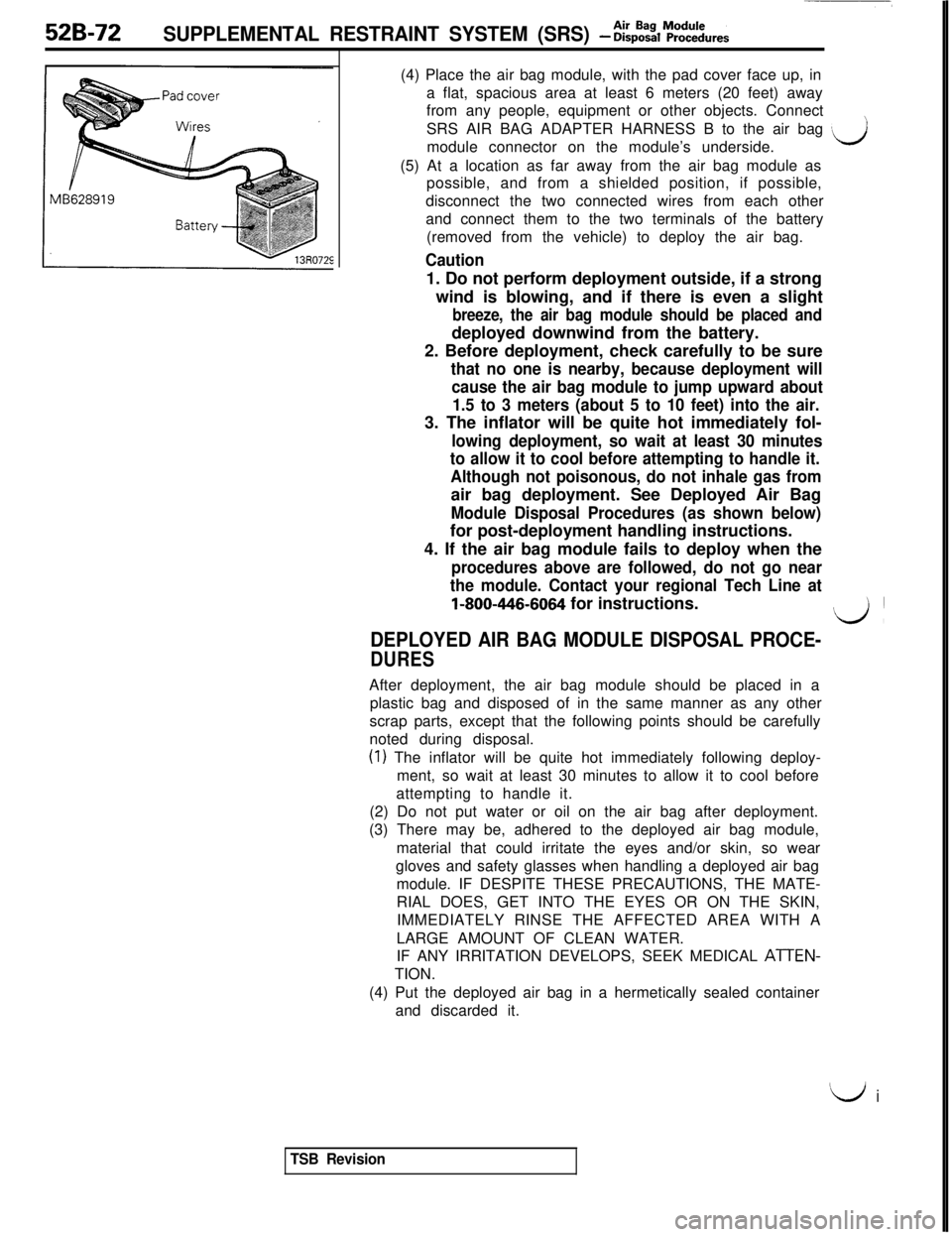

52B-72SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - &%~~~~~ures(4) Place the air bag module, with the pad cover face up, in

a flat, spacious area at least 6 meters (20 feet) away

from any people, equipment or other objects. Connect

SRS AIR BAG ADAPTER HARNESS B to the air bag

mdmodule connector on the module’s underside.

(5) At a location as far away from the air bag module as

possible, and from a shielded position, if possible,

disconnect the two connected wires from each other

and connect them to the two terminals of the battery

(removed from the vehicle) to deploy the air bag.

Caution1. Do not perform deployment outside, if a strong

wind is blowing, and if there is even a slight

breeze, the air bag module should be placed anddeployed downwind from the battery.

2. Before deployment, check carefully to be sure

that no one is nearby, because deployment will

cause the air bag module to jump upward about

1.5 to 3 meters (about 5 to 10 feet) into the air.3. The inflator will be quite hot immediately fol-

lowing deployment, so wait at least 30 minutes

to allow it to cool before attempting to handle it.

Although not poisonous, do not inhale gas fromair bag deployment. See Deployed Air Bag

Module Disposal Procedures (as shown below)for post-deployment handling instructions.

4. If the air bag module fails to deploy when the

procedures above are followed, do not go near

the module. Contact your regional Tech Line at

l-800-446-6064 for instructions.\J’

DEPLOYED AIR BAG MODULE DISPOSAL PROCE-

DURESAfter deployment, the air bag module should be placed in a

plastic bag and disposed of in the same manner as any other

scrap parts, except that the following points should be carefully

noted during disposal.

(1) The inflator will be quite hot immediately following deploy-

ment, so wait at least 30 minutes to allow it to cool before

attempting to handle it.

(2) Do not put water or oil on the air bag after deployment.

(3) There may be, adhered to the deployed air bag module,

material that could irritate the eyes and/or skin, so wear

gloves and safety glasses when handling a deployed air bag

module. IF DESPITE THESE PRECAUTIONS, THE MATE-

RIAL DOES, GET INTO THE EYES OR ON THE SKIN,

IMMEDIATELY RINSE THE AFFECTED AREA WITH A

LARGE AMOUNT OF CLEAN WATER.

IF ANY IRRITATION DEVELOPS, SEEK MEDICAL

A-I-TEN-TION.

(4) Put the deployed air bag in a hermetically sealed container

and discarded it.

‘LJ i

TSB Revision