dimensions MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 25 of 1146

GENERAL - General Data and Specifications

GENERAL DATA AND SPECIFICATIONS

00-21

MOOHA- -

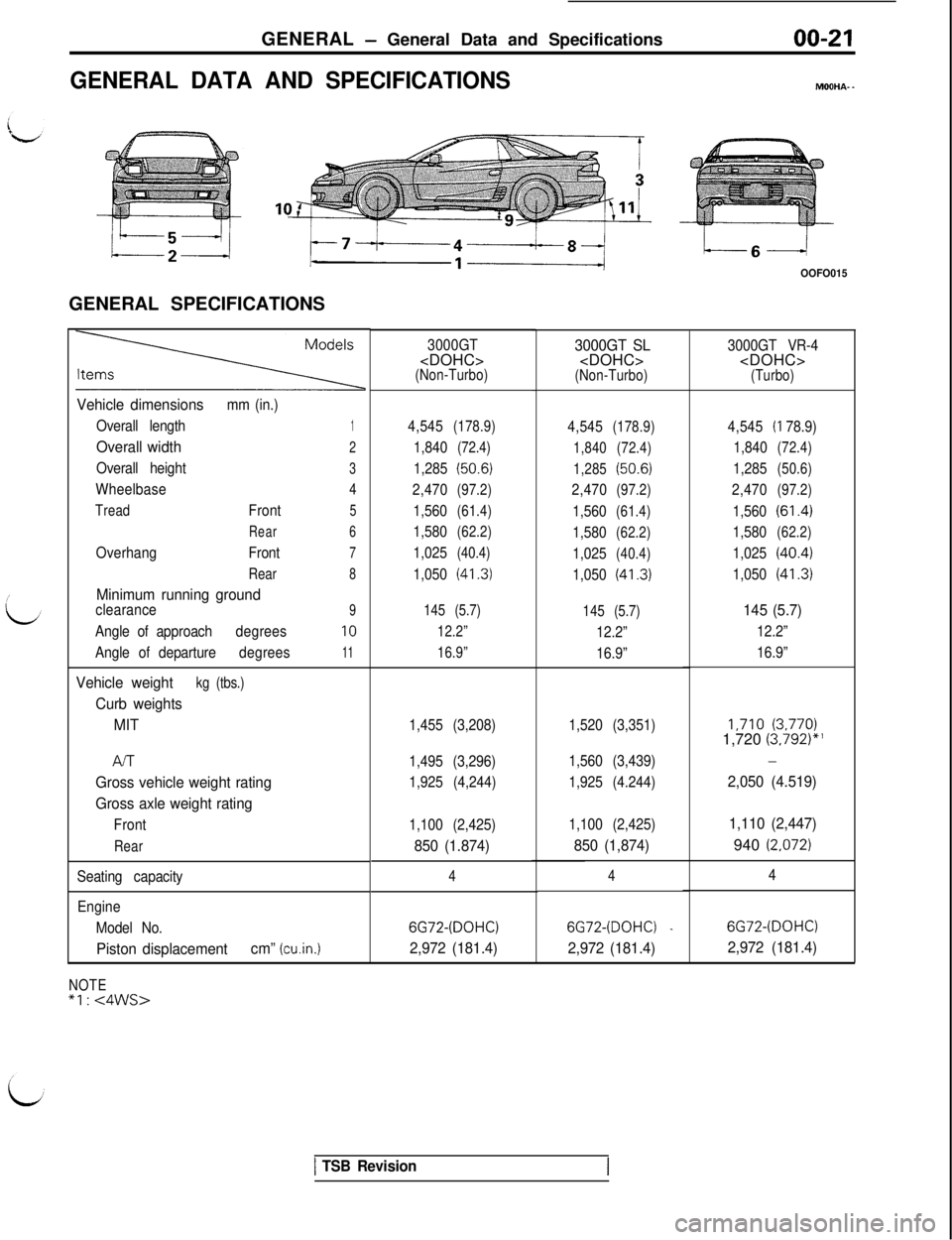

c-i----J---i!--8GENERALSPECIFICATIONS

Vehicle dimensionsmm (in.)

Overall length

1

Overall width2

Overall height3

Wheelbase4

Tread

Front5

Rear6

OverhangFront7

Rear8

Minimum running groundclearance9

Angle of approachdegrees10

Angle of departuredegrees11

Vehicle weightkg (tbs.)

Curb weights

MIT

AI-T

Gross vehicle weight rating

Gross axle weight rating

Front

Rear

Seating capacity

Engine

Model No.

Piston displacementcm” (cu.in.)

3000GT

(Non-Turbo)

4,545(178.9)

1,840(72.4)

1,285(50.6)

2,470(97.2)

1,560(61.4)

1,580(62.2)

1,025(40.4)

1,050(41.3)

145(5.7)

12.2”

16.9”

1,455 (3,208)

1,495 (3,296)

1,925 (4,244)

1,100 (2,425)

850 (1.874)

4

6G72-(DOHC)

2,972 (181.4)3000GT SL

(Non-Turbo)

4,545(178.9)

1,840(72.4)

1,285

(50.6)

2,470(97.2)

1,560(61.4)

1,580(62.2)

1,025(40.4)

1,050(41.3)

145(5.7)

12.2”

16.9”

1,520 (3,351)

1,560 (3,439)

1,925 (4.244)

1,100 (2,425)

850 (1,874)

4

6G72-(DOHC) -

2,972 (181.4)

+64

OOFO015

3000GT VR-4

(Turbo)

4,545(I 78.9)

1,840

(72.4)

1,285(50.6)

2,470(97.2)

1,560(61.4)

1,580(62.2)

1,025(40.4)

1,050(41.3)

145 (5.7)

12.2”

16.9”

1,710 (3.770)1,720 (3,792)“’

-

2,050 (4.519)

1,110 (2,447)940

(2,072)

4

6G72-(DOHC)

2,972 (181.4)

NOTE“I : <4ws>

1 TSB Revision

Page 440 of 1146

22-60MANUAL TRANSAXLE

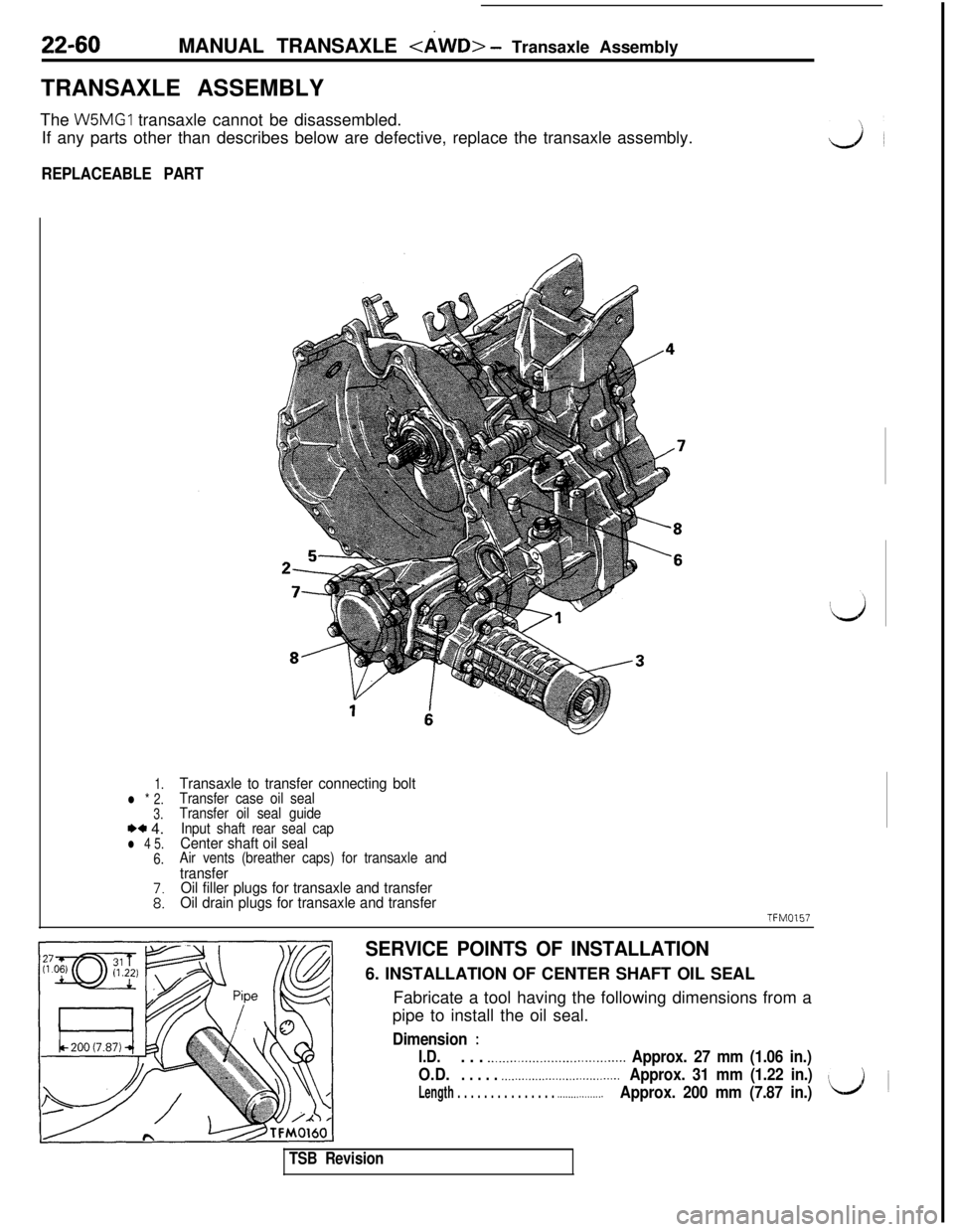

TRANSAXLE ASSEMBLY

The W5MGl transaxle cannot be disassembled.

If any parts other than describes below are defective, replace the transaxle assembly.

REPLACEABLE PART

1.l * 2.

3.

*a 4.l 4 5.6.

Transaxle to transfer connecting boltTransfer case oil seal

Transfer oil seal guide

Input shaft rear seal cap

Center shaft oil sealAir vents (breather caps) for transaxle and

transfer

Oil filler plugs for transaxle and transfer

Oil drain plugs for transaxle and transfer

TFM0157

SERVICE POINTS OF INSTALLATION6. INSTALLATION OF CENTER SHAFT OIL SEAL

Fabricate a tool having the following dimensions from a

pipe to install the oil seal.

Dimension :

I.D.. . . ..___........._...................... Approx. 27 mm (1.06 in.)

O.D.

. . . . . .._...........___............_.....Approx. 31 mm (1.22 in.)

Length . . . . . . . . . . . . . . . ..__......._____.Approx. 200 mm (7.87 in.)

TSB Revision

Page 602 of 1146

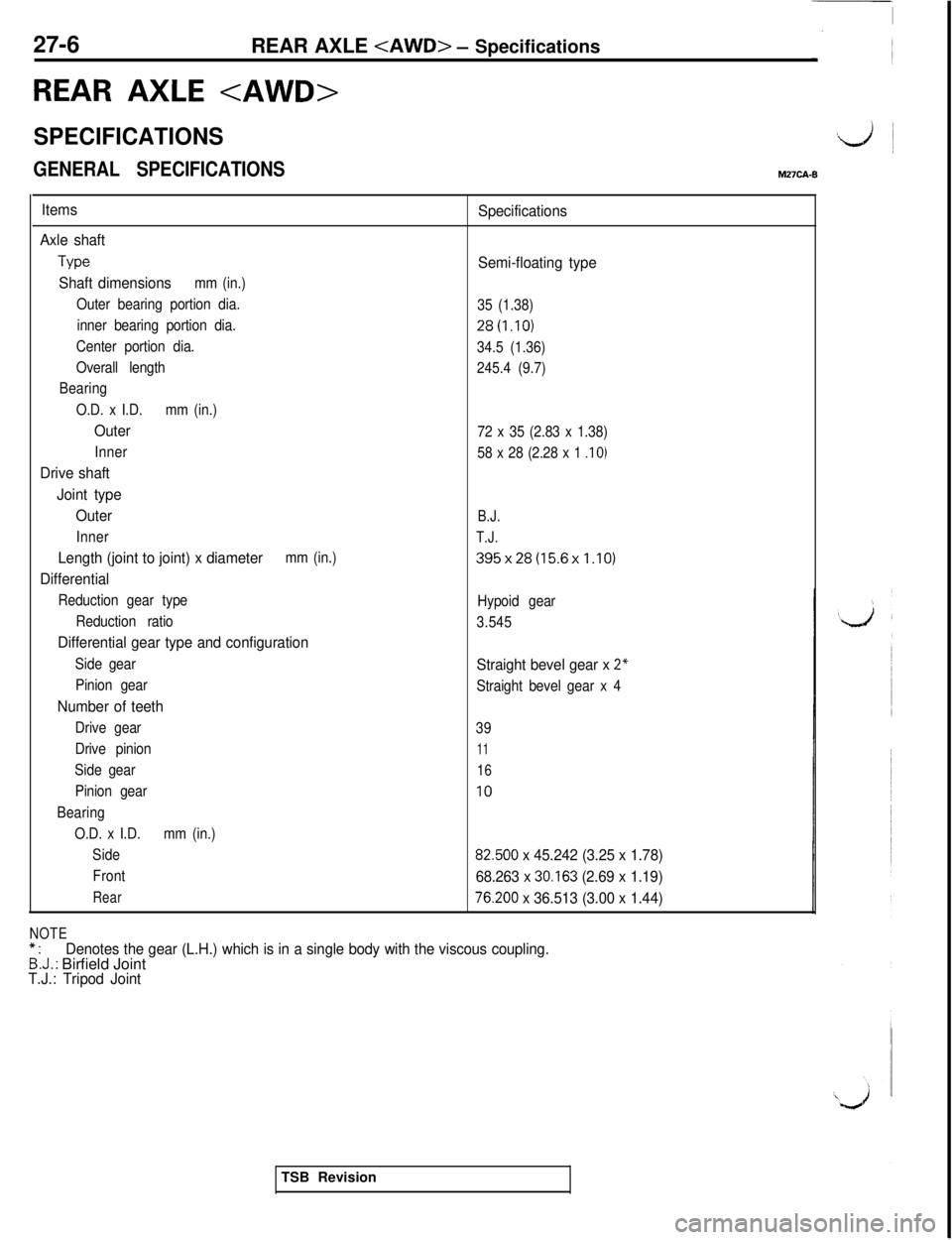

27-6

REAR AXLE tAWD> - Specifications

REAR AXLE

SPECIFICATIONS&L/j ~

GENERAL SPECIFICATIONSM27CA-8

Items

Axle shaft

We

Shaft dimensionsmm (in.)

Outer bearing portion dia.

inner bearing portion dia.

Center portion dia.

Overall length

Bearing

O.D. x I.D.mm (in.)

Outer

Inner

Drive shaft

Joint type

Outer

Inner

Length (joint to joint) x diametermm (in.)

Differential

Reduction gear type

Reduction ratio

Differential gear type and configuration

Side gear

Pinion gear

Number of teeth

Drive gear

Drive pinion

Side gear

Pinion gear

Bearing

O.D. x I.D.mm (in.)

Side

Front

Rear

Specifications

Semi-floating type

35 (1.38)

28(1.10)

34.5 (1.36)

245.4 (9.7)

72 x 35 (2.83 x 1.38)

58 x 28 (2.28 x 1

.I 0)

B.J.

T.J.

395x28(15.6x1.10)

Hypoid gear

3.545

Straight bevel gear x 2”

Straight bevel gear x 4

39

11

16

IO

82.500 x 45.242 (3.25 x 1.78)

68.263 x

30.163 (2.69 x 1.19)

76.200 x 36.513 (3.00 x 1.44)

NOTE*.Denotes the gear (L.H.) which is in a single body with the viscous coupling.B:J.: Birfield JointT.J.: Tripod JointTSB Revision

Page 868 of 1146

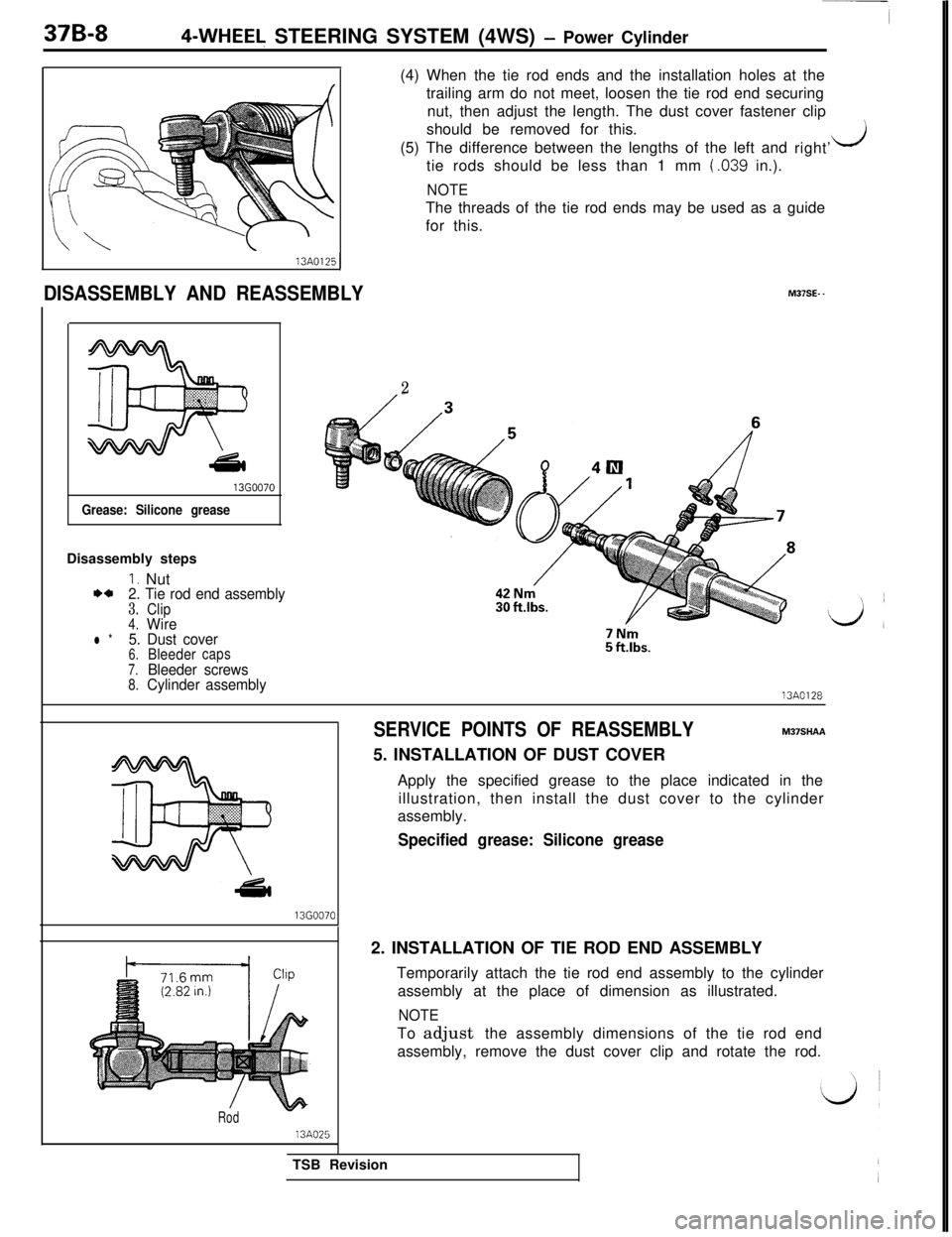

37B-84-WHEEL STEERING SYSTEM (4WS) - Power Cylinder

(4) When the tie rod ends and the installation holes at the

trailing arm do not meet, loosen the tie rod end securing

nut, then adjust the length. The dust cover fastener clip

should be removed for this.

(5) The difference between the lengths of the left and

right’

Ljtie rods should be less than 1 mm

( ,039 in.).

NOTEThe threads of the tie rod ends may be used as a guide

for this.

DISASSEMBLY AND REASSEMBLYM37SE. -

::::::::::::;::: ::.

&

:::::y .:::5;:;. . . . . . . . .. .

11.

13G0070

Grease: Silicone greaseDisassembly steps

1. Nut**2. Tie rod end assembly3.Clip4.Wirel *5. Dust cover6.Bleedercaps

7.Bleeder screws8.Cylinder assembly

2

13A0128

13G0070

Rod13A025

SERVICE POINTS OF REASSEMBLYM37SHAA5. INSTALLATION OF DUST COVER

Apply the specified grease to the place indicated in the

illustration, then install the dust cover to the cylinder

assembly.

Specified grease: Silicone grease2. INSTALLATION OF TIE ROD END ASSEMBLY

Temporarily attach the tie rod end assembly to the cylinder

assembly at the place of dimension as illustrated.

NOTETo adjust the assembly dimensions of the tie rod end

assembly, remove the dust cover clip and rotate the rod.

TSB Revision