engine overheat MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 28 of 1146

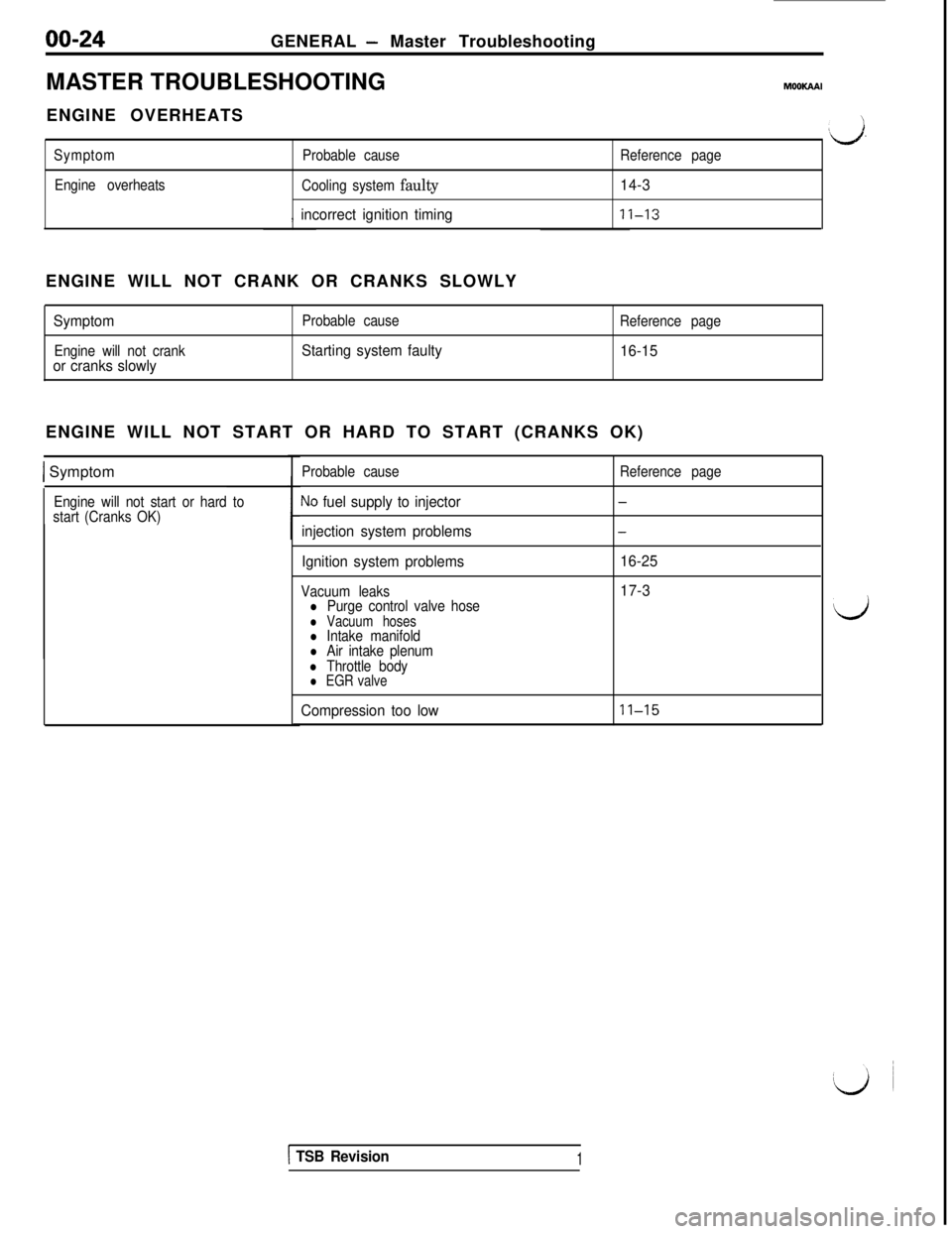

00-24GENERAL - Master Troubleshooting

MASTER TROUBLESHOOTING

MOOWWENGINE OVERHEATS

Symptom

Engine overheatsProbable cause

Cooling system

faulty

, incorrect ignition timing

Reference page

14-3

11-13

v’.ENGINE WILL NOT CRANK OR CRANKS SLOWLY

Symptom

Engine will not crankor cranks slowly

Probable cause

Starting system faulty

Reference page

16-15ENGINE WILL NOT START OR HARD TO START (CRANKS OK)

1 Symptom

Engine will not start or hard to

start (Cranks OK)Probable causeNo fuel supply to injector

injection system problems

Ignition system problems

Vacuum leaksl Purge control valve hosel Vacuum hosesl Intake manifoldl Air intake plenuml Throttle bodyl EGR valve

Reference page

-

-

16-25

17-3

Compression too low

11-15

d

1 TSB Revision1

Page 29 of 1146

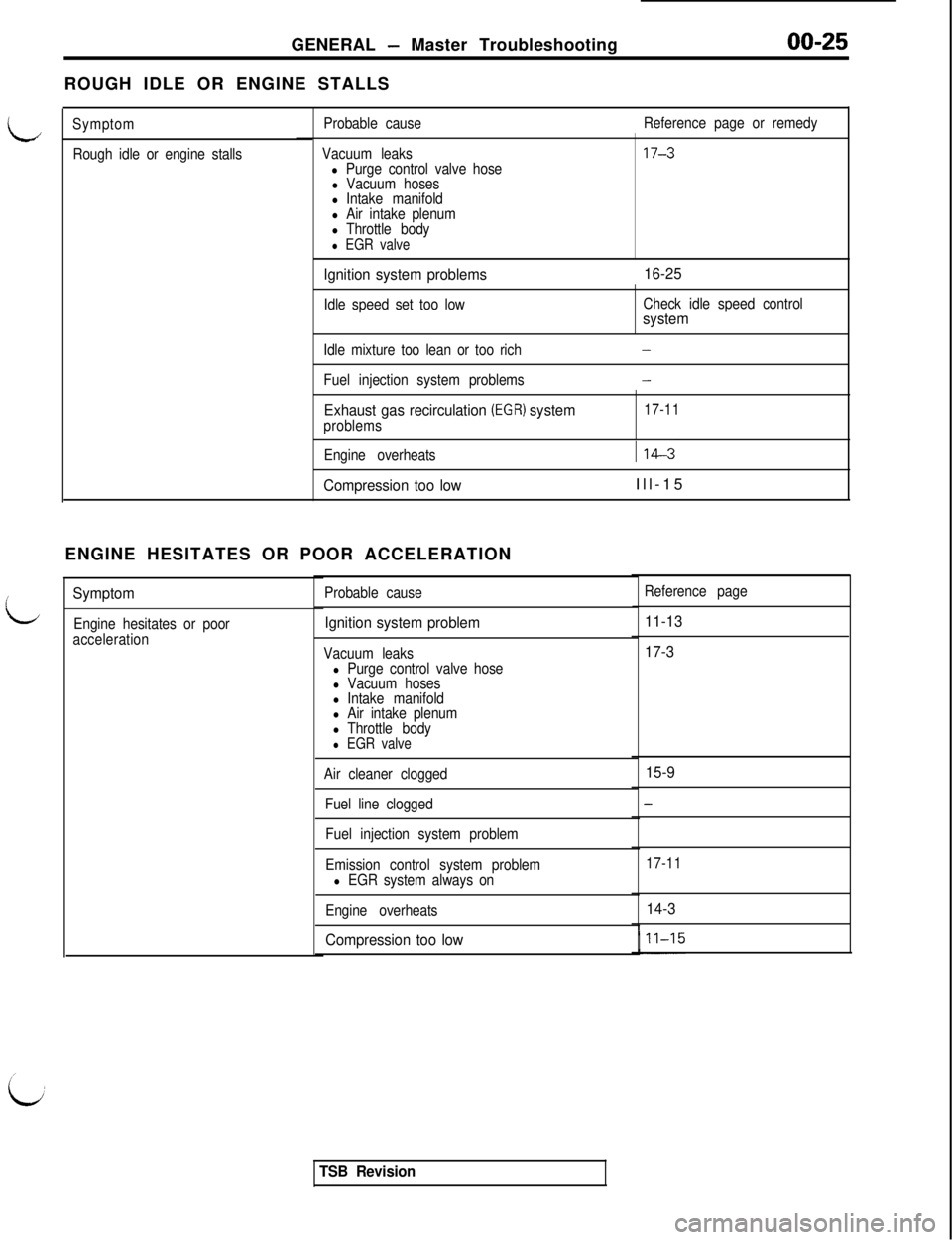

GENERAL - Master Troubleshooting

ROUGH IDLE OR ENGINE STALLS

LProbable causeReference page or remedy

Symptom

Rough idle or engine stallsVacuum leaks

l Purge control valve hosel Vacuum hosesl Intake manifoldl Air intake plenuml Throttle bodyl EGR valve

Ignition system problems16-25

Idle speed set too lowCheck idle speed controlsystem

Idle mixture too lean or too rich-

Fuel injection system problems-

Exhaust gas recirculation (EGR) systemproblems17-11

Engine overheats

114-3

Compression too lowIll-15

ENGINE HESITATES OR POOR ACCELERATION

L

Reference pageSymptomProbable cause

Ignition system problem

Vacuum leaksl Purge control valve hosel Vacuum hosesl Intake manifoldl Air intake plenuml Throttle bodyl EGR valve

Air cleaner clogged

Fuel line clogged

Fuel injection system problem

Emission control system problem

l EGR system always on

Engine overheats

Compression too low11-13

Engine hesitates or poor

acceleration

17-3

15-9

-

17-11

14-3

TSB Revision

Page 295 of 1146

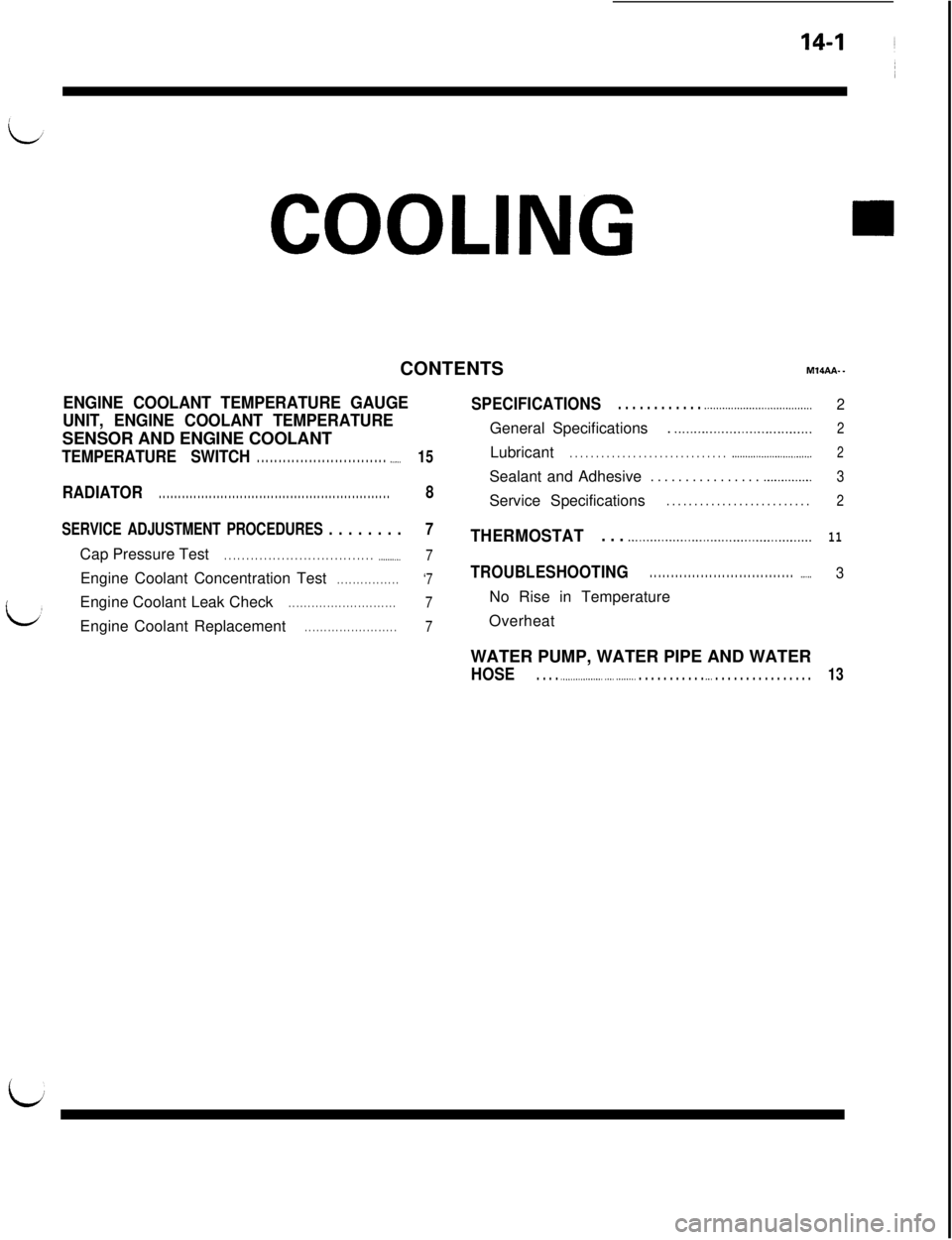

COOLINGCONTENTS

M14AA..

ENGINE COOLANT TEMPERATURE GAUGE

UNIT, ENGINE COOLANT TEMPERATURESENSOR AND ENGINE COOLANT

TEMPERATURE SWITCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.__15

RADIATOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

SERVICE ADJUSTMENT PROCEDURES . . . . . . . .7Cap Pressure Test

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.......7Engine Coolant Concentration Test

. . . . . . . . . . . . . . . .‘7

L,Engine Coolant Leak Check

. . . . . . . . . . . . . . . . . . . . . . . . . . . .7Engine Coolant Replacement

. . . . . . . . . . . . . . . . . . . . . . . .7

SPECIFICATIONS. . . . . . . . . . . . .._.................................General Specifications

. ..___....___._...___.__............Lubricant

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.................._........Sealant and Adhesive

. . . . . . . . . . . . . . . . .._...........Service Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . .

THERMOSTAT. . . ..__......................_.._...................

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._...No Rise in Temperature

Overheat

WATER PUMP, WATER PIPE AND WATER

HOSE. . . . _......_........_ _.._ .._..... . . . . . . . . . . . ._. . . . . . . . . . . . . . . . .

2

2

2

3

2

11

3

13

Page 297 of 1146

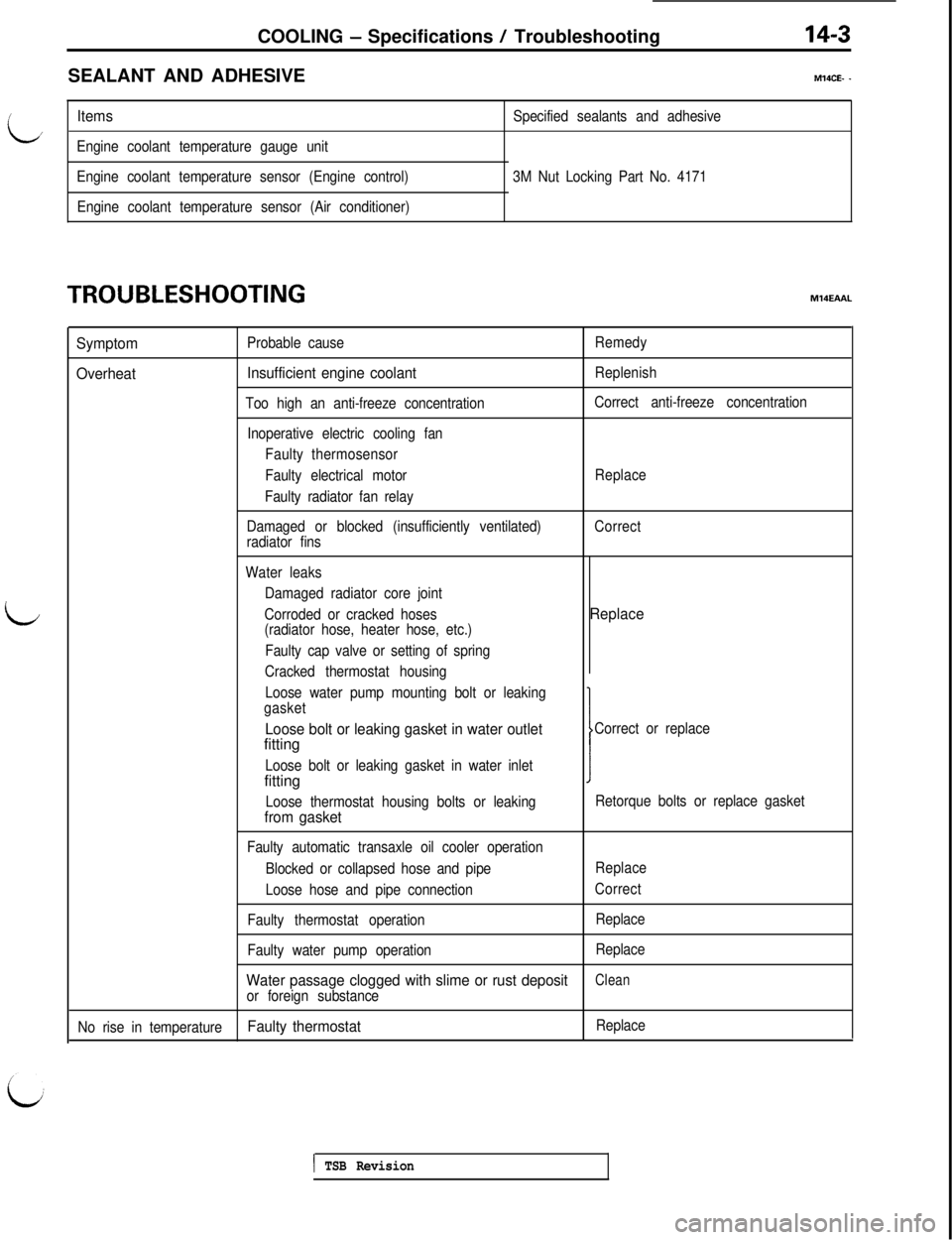

COOLING - Specifications / Troubleshooting

SEALANT AND ADHESIVE14-3

MMCE- -

/

id

ItemsSpecified sealants and adhesive/

Engine coolant temperature gauge unit

Engine coolant temperature sensor (Engine control)

Engine coolant temperature sensor (Air conditioner)3M Nut Locking Part No. 4171

TROUBLESHOOTING

L

MllEAAL

Symptom

OverheatProbable cause

Insufficient engine coolant

Too high an anti-freeze concentration

Inoperative electric cooling fan

Faulty thermosensor

Faulty electrical motor

Faulty radiator fan relayRemedy

Replenish

Correct anti-freeze concentration

Replace

Damaged or blocked (insufficiently ventilated)

radiator finsCorrect

Water leaks

Damaged radiator core joint

Corroded or cracked hoses

(radiator hose, heater hose, etc.)

Faulty cap valve or setting of spring

Cracked thermostat housing

Loose water pump mounting bolt or leaking

gasket

Replace

Loose bolt or leaking gasket in water outlet

I

Correct or replacefitting

Loose bolt or leaking gasket in water inletfitting

Loose thermostat housing bolts or leakingfrom gasket

Retorque bolts or replace gasket

Faulty automatic transaxle oil cooler operation

Blocked or collapsed hose and pipeReplace

Loose hose and pipe connectionCorrect

Faulty thermostat operationReplace

Faulty water pump operationReplace

Water passage clogged with slime or rust depositClean

or foreign substance

No rise in temperature

Faulty thermostatReplace

( TSB Revision

Page 358 of 1146

17-14 EMISSION CONTROL -Exhaust Gas Recirculation (EGR) System / Catalytic Converter

6EM01871

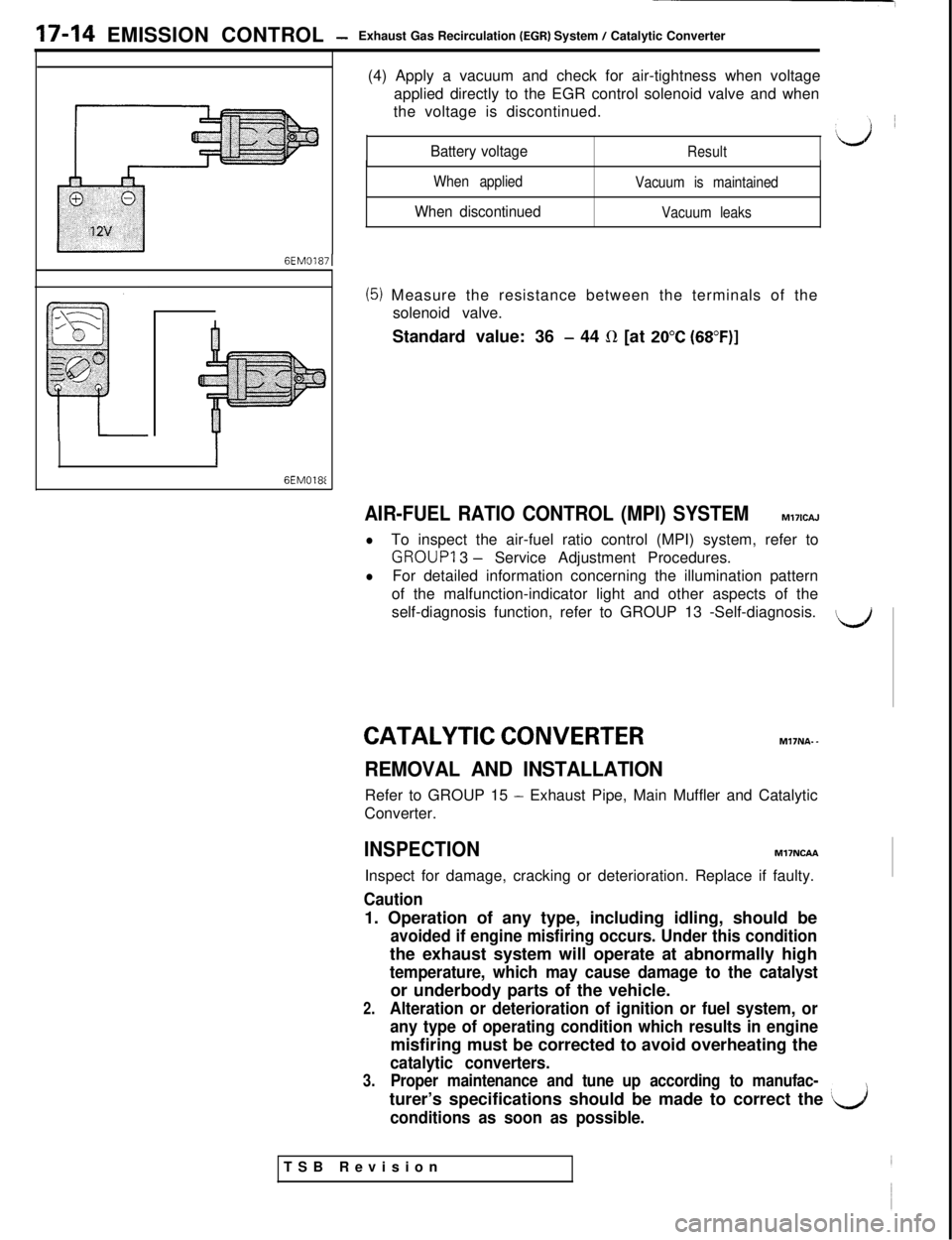

6EM0181(4) Apply a vacuum and check for air-tightness when voltage

applied directly to the EGR control solenoid valve and when

the voltage is discontinued.

Battery voltageResult

When applied

When discontinued

Vacuum is maintained

Vacuum leaks

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36

- 44 R [at 20°C (68”F)]

AIR-FUEL RATIO CONTROL (MPI) SYSTEMM17ICAJ

lTo inspect the air-fuel ratio control (MPI) system, refer to

GROUP1 3 - Service Adjustment Procedures.

lFor detailed information concerning the illumination pattern

of the malfunction-indicator light and other aspects of the

self-diagnosis function, refer to GROUP 13 -Self-diagnosis.

\.J

CATALYTIC CONVERTERMl7N& -

REMOVAL AND INSTALLATIONRefer to GROUP 15

- Exhaust Pipe, Main Muffler and Catalytic

Converter.

INSPECTIONMl7NCAA

Inspect for damage, cracking or deterioration. Replace if faulty.

Caution1. Operation of any type, including idling, should be

avoided if engine misfiring occurs. Under this conditionthe exhaust system will operate at abnormally high

temperature, which may cause damage to the catalystor underbody parts of the vehicle.

2.Alteration or deterioration of ignition or fuel system, or

any type of operating condition which results in enginemisfiring must be corrected to avoid overheating the

catalytic converters.

3.Proper maintenance and tune up according to manufac-turer’s specifications should be made to correct the

‘bi

conditions as soon as possible.TSB Revision