four wheel drive MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 208 of 1146

13-102FUEL SYSTEM - On-vehicle Inspection of MPI Components

TROUBLESHOOTING HINTSHint 1: If the engine is hard to start when hot, check fuel pressure and check the injector for leaks.

Hint 2:If the injector does not when the engine that is hard to start is cranked, the following as well as the

Iinjector itself may be responsible.

(1) Faulty power supply circuit to the engine control unit, faulty ground circuit

\-J

-(2) Faulty control relay

Hint 3:(3) Faulty crank angle sensor, top dead center sensor

If there is any cylinder whose idle state remains unchanged when the fuel injection of injectors is cut

one after another during idling, make following checks about such cylinder.

(1) Injector and harness check

(2) Ignition plug and high tension cable check

(3) Compression pressure check

Hint 4: If the injector harness and individual part checks have resulted normal but the injector drive time is

out of specification, the following troubles are suspected.

(1)Poor combustion in the cylinder (faulty ignition plug, ignition coil, compression pressure, etc.)

(2) Loose EGR valve seating

(3) High engine resistance

INSPECTIONUsing Multi-use Tester

FunctionItem No. Data displayCheck conditionCoolant temperatureStandard valueData reading 41

Drive time”’Engine: Cranking0°C (32”F)*zApprox. 17 ms

20°C (68°F)Approx. 46 ms

8O"C(176"F)Approx. 11 ms

Function

Data readingItem No.Data display

41Drive time*3l Engine coolant tem-perature: 80 to 95°C700 rpm (Idle)2.4-3.0 ms

(176 to 205°F)2,000 rpm2.0-2.6

msl Lamps, electric coolingfan, accessory units:When sharp racing isTo increaseAll OFF

madel Transaxle: Neutral

(P range for vehicle

with A/T)l Steering wheel: Neutral

Check conditionEngine stateStandard value ,

.---NOTE“I : The injector drive time refers to when the supply voltage is 11 V and the cranking speed is less than 250 rpm.*2: When coolant temperature is lower than 0°C (32°F). injection ismade by four-cylinders.---simultaneously.

“3: When the vehicle is new [within initial operation of about 500 km (300 miles)], the injector drive time may be about

10% longer.

Function

Actuator testItem No.

Drive content

Check conditionNormal state

01No. 1 injector shut offEngine: Idling afterIdle state to change

02No. 2 injector shut offwarm-up

(Shut off the injectorsfurther (becoming less

in sequence during afterstable or stalling)

03

No. 3 injector shut offengine warm-up, check

04No. 4 injector shut offthe idling condition)

05No. 5 injector shut off

06No. 6 injector shut off

TSB Revision

Page 212 of 1146

13-106FUEL SYSTEM - On-vehicle Inspection of MPI Components

INSPECTION

Using Multi-use Tester

FunctionItem No.Data displayCheck conditionCoolant temperatureStandard value‘L,,,J

DataDrive time*’0°C (32’F)*’readingiRea:bankiEngine: CrankingApprox. 53 ms

(FronT7bank)20°C (68°F)

Approx. 29 ms

80°C (176°F)Approx. 7 ms

FunctionItem No.

Data displayCheck conditionEngine stateStandard value

Datareading(Reaebank)Drive time*3l Engine coolant tem-700 rpm (Idle)1.9 - 2.5 ms

perature: 80 to 95°C

(Front7banki(176 to 205°F)2,000 rpm1.6 - 2.2 ms

l Lamps, electric coolingfan, accessory units:To increase

All OFFWhen sharp racing is

made

l Transaxle: Neutral(P range for vehicle

with A/T)

l Steering wheel: Neutral

NOTE“I : The injector drive time refers to when the supply voltage is 11 V and the cranking speed is less than 250 rpm.

“2: When coolant temperature is lower than 0°C (32°F). injection is made by four cylinders simultaneously.

“3: When the vehicle is new [within initial operation of about 500 km (300 miles)], the injector drive time may be about

10% longer.

Function

Actuator testItem No.

Drive contentCheck conditionNormal state

01No. 1 injector shut offEngine: Idling afterIdle state to changewarm-upfurther (becoming less

02No. 2 injector shut off(Shut off the injectorsstable or stalling)

03in sequence during afterNo. 3 injector shut offengine warm-up, checkthe idling condition)

04No. 4 injector shut off

05

No. 5 injector shut off

06

No. 6 injector shut off

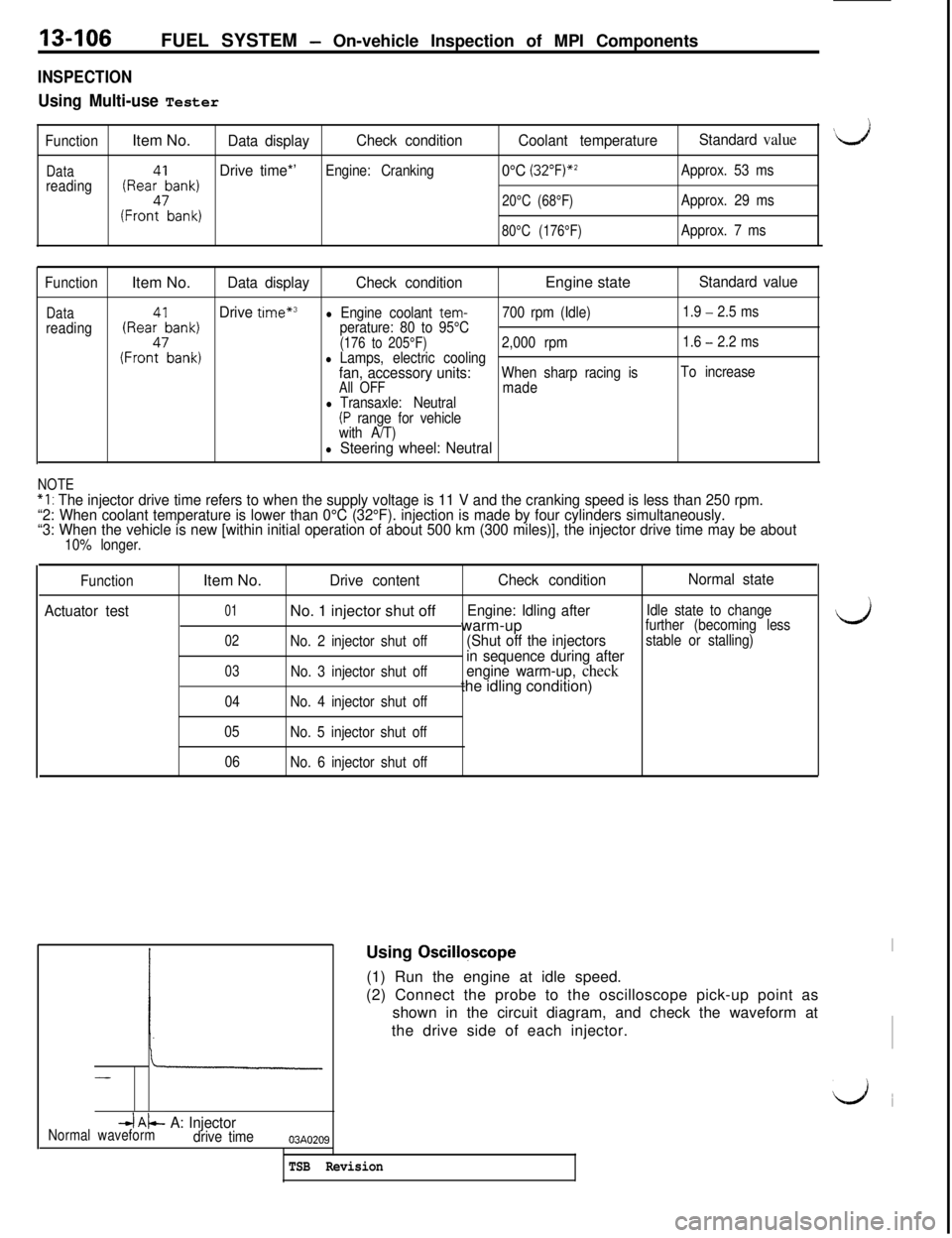

\,iUsing

OscillqscopeI(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform at

the drive side of each injector.~

-

LJ

4 AL A: InjectorNormal waveformdrive time03A0209

TSB Revision

Page 622 of 1146

27-26

REAR AXLE

SERVICE POINTS OF INSTALLATION

7. INSTALLATION OF DIFFERENTIAL CARRIERm27lDAL

Install the rear wheel oil pump by inserting it through the

mounting hole and install the differential carrier securely.\yiIlYl61

Caution

Use care not to damage the rear wheel oil pump gears.

3. CONNECTION OF PROPELLER SHAFTAlign the mating marks on the flange yoke and the

companion flange to install the propeller shaft.

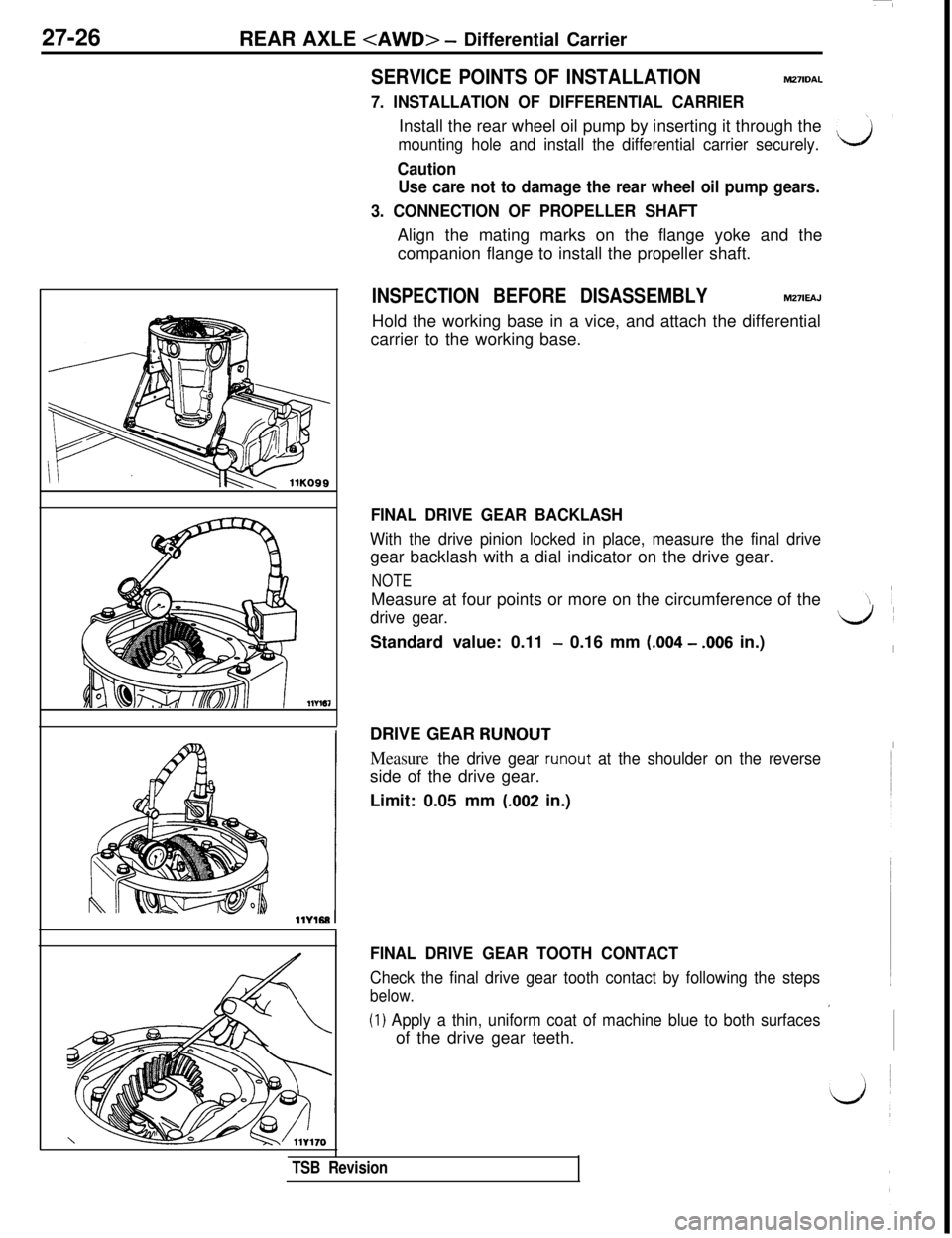

INSPECTION BEFORE DISASSEMBLYM27lEAJHold the working base in a vice, and attach the differential

carrier to the working base.

FINAL DRIVE GEAR BACKLASH

With the drive pinion locked in place, measure the final drivegear backlash with a dial indicator on the drive gear.

NOTEMeasure at four points or more on the circumference of the

drive gear.d’Standard value: 0.11

- 0.16 mm (.004 - .006 in.)IDRIVE GEAR

RUNOUTI

Measure the drive gear runout at the shoulder on the reverseside of the drive gear.

Limit: 0.05 mm

(.002 in.)

FINAL DRIVE GEAR TOOTH CONTACT

Check the final drive gear tooth contact by following the steps

below.

(1) Apply a thin, uniform coat of machine blue to both surfaces ’of the drive gear teeth.

TSB Revision

Page 802 of 1146

35-80SERVICE BRAKES - Front Disc Brake14FOOl14FOO4

14FOO2:

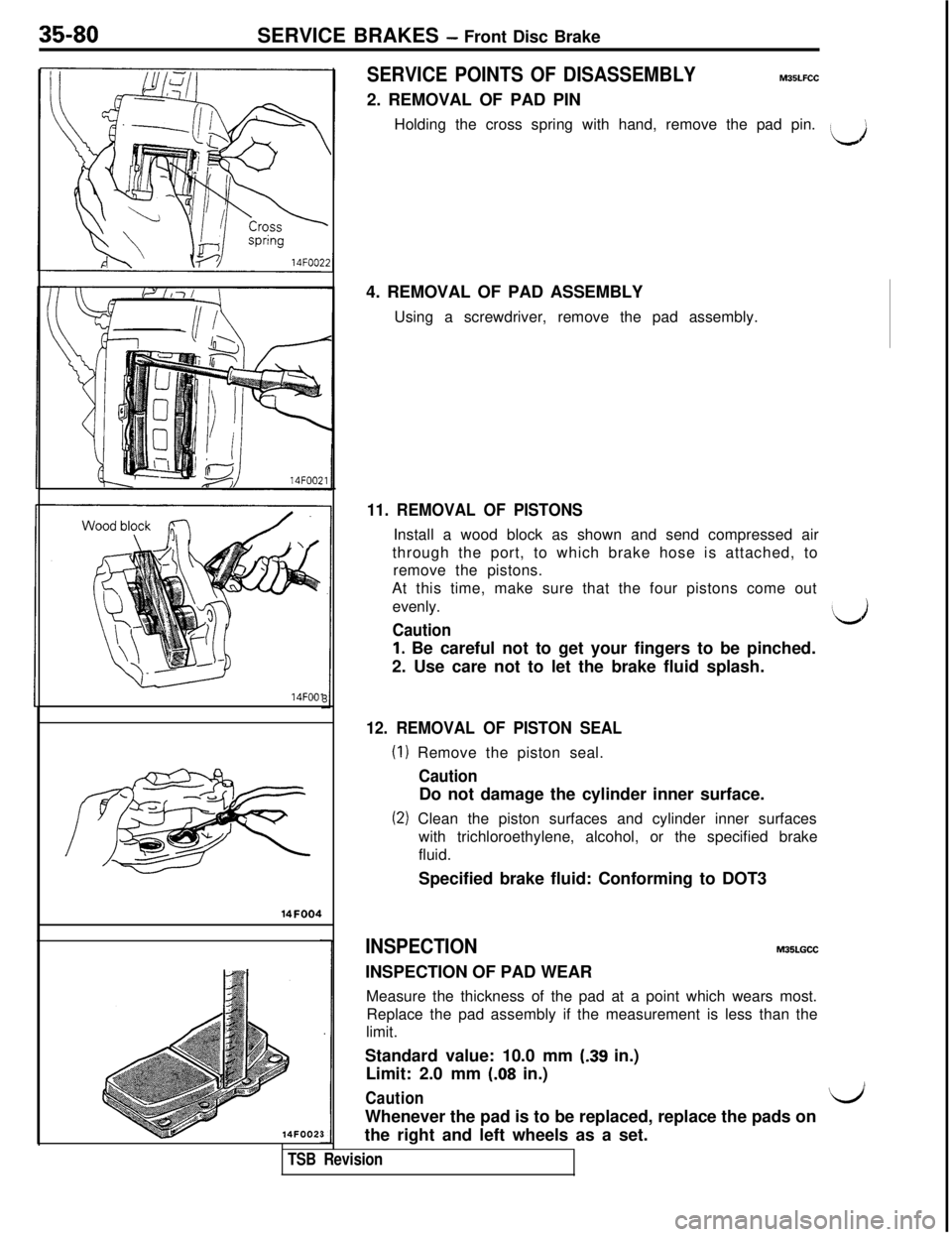

SERVICE POINTS OF DISASSEMBLYM35LFCC2. REMOVAL OF PAD PIN

Holding the cross spring with hand, remove the pad pin.

4. REMOVAL OF PAD ASSEMBLY

Using a screwdriver, remove the pad assembly.

11. REMOVAL OF PISTONSInstall a wood block as shown and send compressed air

through the port, to which brake hose is attached, to

remove the pistons.

At this time, make sure that the four pistons come out

evenly.

Caution

1. Be careful not to get your fingers to be pinched.

2. Use care not to let the brake fluid splash.

‘d

12. REMOVAL OF PISTON SEAL

(1) Remove the piston seal.

CautionDo not damage the cylinder inner surface.

(2) Clean the piston surfaces and cylinder inner surfaces

with trichloroethylene, alcohol, or the specified brake

fluid.

Specified brake fluid: Conforming to DOT3

INSPECTIONMJSLGCCINSPECTION OF PAD WEAR

Measure the thickness of the pad at a point which wears most.

Replace the pad assembly if the measurement is less than the

limit.

Standard value: 10.0 mm

(.39 in.)

Limit: 2.0 mm

(.08 in.)

CautionI/’Whenever the pad is to be replaced, replace the pads on

the right and left wheels as a set.

TSB Revision