seat adjustment MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 65 of 1146

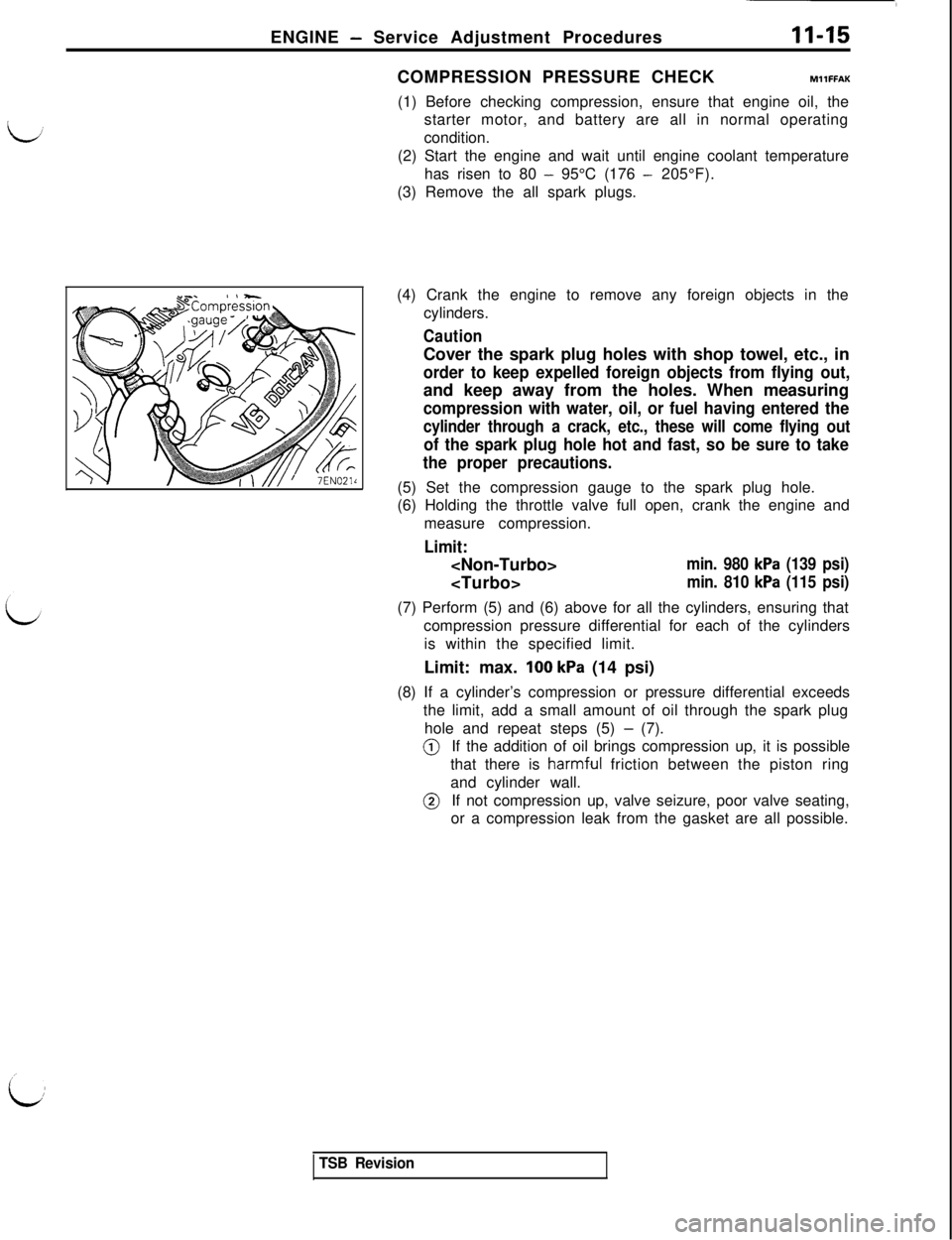

ENGINE - Service Adjustment Procedures11-15COMPRESSION PRESSURE CHECKMllFFAK

(1) Before checking compression, ensure that engine oil, the

starter motor, and battery are all in normal operating

condition.

(2) Start the engine and wait until engine coolant temperature

has risen to 80

- 95°C (176 - 205°F).

(3) Remove the all spark plugs.

(4) Crank the engine to remove any foreign objects in the

cylinders.

CautionCover the spark plug holes with shop towel, etc., in

order to keep expelled foreign objects from flying out,and keep away from the holes. When measuring

compression with water, oil, or fuel having entered the

cylinder through a crack, etc., these will come flying out

of the spark plug hole hot and fast, so be sure to take

the proper precautions.(5) Set the compression gauge to the spark plug hole.

(6) Holding the throttle valve full open, crank the engine and

measure compression.

Limit:

min. 980 kPa (139 psi)

min. 810 kPa (115 psi)(7) Perform (5) and (6) above for all the cylinders, ensuring that

compression pressure differential for each of the cylinders

is within the specified limit.

Limit: max.

100 kPa (14 psi)

(8) If a cylinder’s compression or pressure differential exceeds

the limit, add a small amount of oil through the spark plug

hole and repeat steps (5)

- (7).@If the addition of oil brings compression up, it is possible

that there is

harmf,uI friction between the piston ring

and cylinder wall.@If not compression up, valve seizure, poor valve seating,

or a compression leak from the gasket are all possible.

TSB Revision

Page 316 of 1146

15-6INTAKE AND EXHAUST - Service Adjustment Procedures

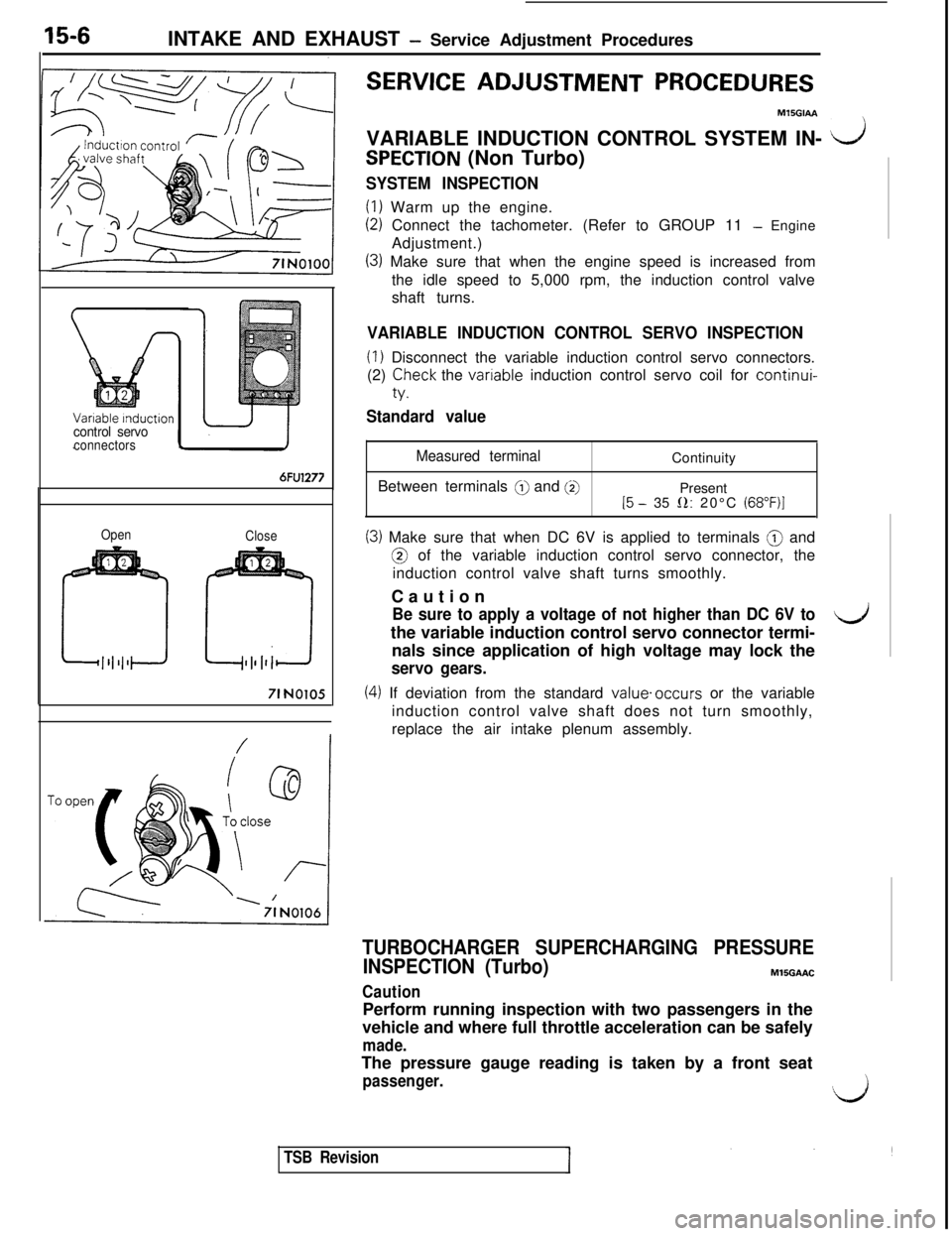

Variable rnductiorcontrol servoconnectors

6FU1277

Open

Close

71 NO105

SERVICE ADJUSTMENT PROCEDURESMlSGlAA

VARIABLE INDUCTION CONTROL SYSTEM IN-

d

SPECTION (Non Turbo)

SYSTEM INSPECTION

(1) Warm up the engine.

(2) Connect the tachometer. (Refer to GROUP 11 - Engine

Adjustment.)

(3) Make sure that when the engine speed is increased from

the idle speed to 5,000 rpm, the induction control valve

shaft turns.

VARIABLE INDUCTION CONTROL SERVO INSPECTION

(1) Disconnect the variable induction control servo connectors.

(2)

Teck the vanable induction control servo coil for continui-

Standard value

Measured terminalBetween terminals

@ and @]Continuity

Present

15 - 35 0: 20°C (68”F)I

(3) Make sure that when DC 6V is applied to terminals @ and@ of the variable induction control servo connector, the

induction control valve shaft turns smoothly.

Caution

Be sure to apply a voltage of not higher than DC 6V tothe variable induction control servo connector termi-4nals since application of high voltage may lock the

servo gears.

(4) If deviation from the standard value.occurs or the variable

induction control valve shaft does not turn smoothly,

replace the air intake plenum assembly.

TURBOCHARGER SUPERCHARGING PRESSURE

INSPECTION (Turbo)MlSGAAC

CautionPerform running inspection with two passengers in the

vehicle and where full throttle acceleration can be safely

made.The pressure gauge reading is taken by a front seat

passenger.‘,k,i

TSB Revision

Page 368 of 1146

a-10CLUTCH - Clutch Control

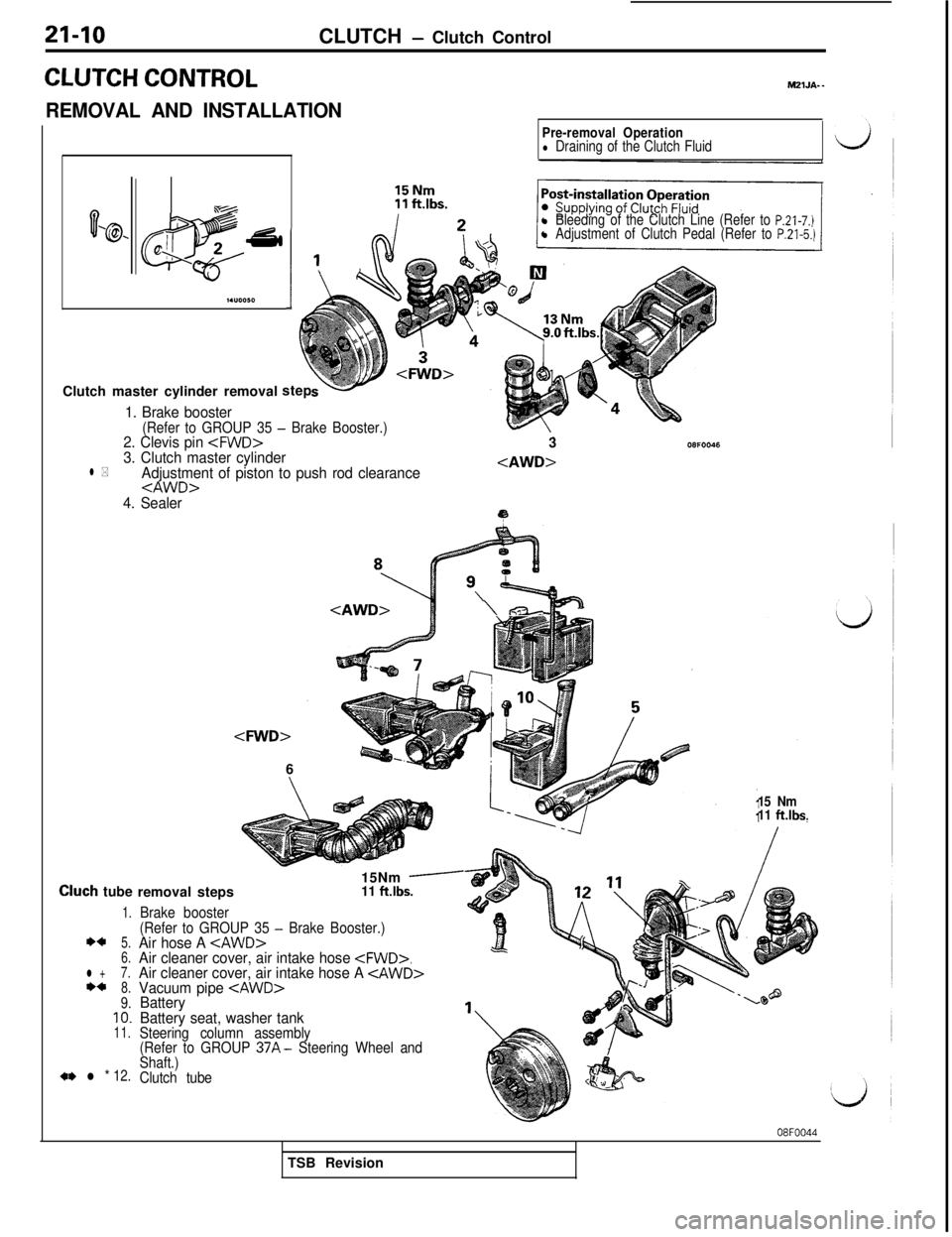

CLUTCH CONTROL

REMOVAL AND INSTALLATIONMZlJA-

-

03% J 2’ti

m

I.“0050I

Pre-removal Operationl Draining of the Clutch Fluid

l Bleeding of the Clutch Line (Refer to P.21-7.)l Adjustment of Clutch Pedal (Refer to P.21-5.)Clutch master cylinder removalstep

1. Brake booster(Refer to GROUP 35 - Brake Booster.)2. Clevis pin

4. Sealer3

9

Cluch tube

1.

**5.

6.

l +7.**8.9.IO.11.

a* l * 12.

removal steps

Brake booster15Nm

-11 ft.lbs.

(Refer to GROUP 35

- Brake Booster.)Air hose A

Battery seat, washer tank

Steering column assembly

(Refer to GROUP 37A- Steering Wheel and

Shaft.)

Clutch tube15 Nm

11

ft.lbs.

08FOO44TSB Revision

Page 586 of 1146

26-10

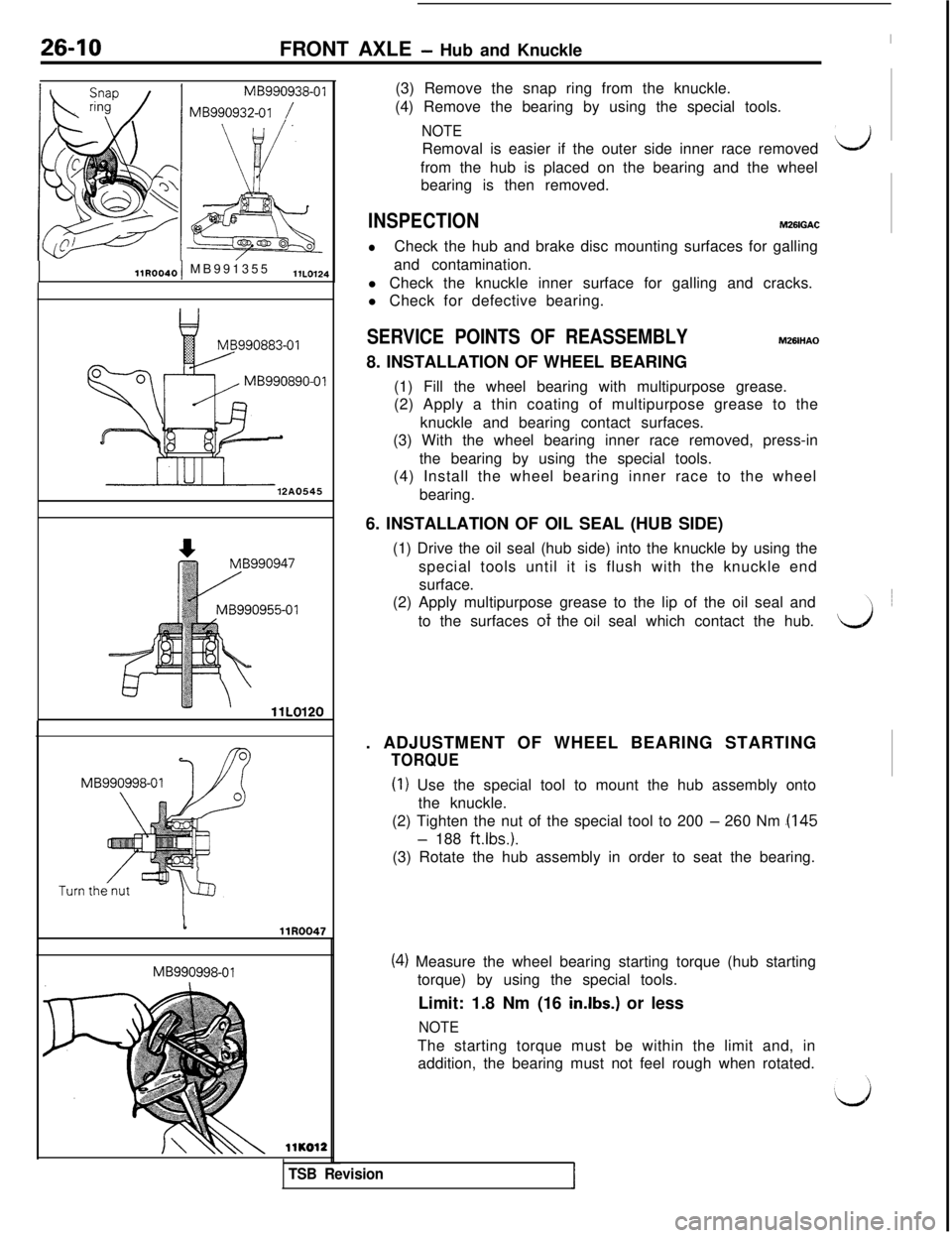

FRONT AXLE - Hub and KnuckleMB990938-01MB990932-01

/

llR00401 MB991355llL0124

12A0545MB990998-01MB990998-01(3) Remove the snap ring from the knuckle.

(4) Remove the bearing by using the special tools.

NOTERemoval is easier if the outer side inner race removedLJfrom the hub is placed on the bearing and the wheel

bearing is then removed.

INSPECTIONM261GAC

lCheck the hub and brake disc mounting surfaces for galling

and contamination.

l Check the knuckle inner surface for galling and cracks.

l Check for defective bearing.

SERVICE POINTS OF REASSEMBLYMZBIHAO8. INSTALLATION OF WHEEL BEARING

(1) Fill the wheel bearing with multipurpose grease.

(2) Apply a thin coating of multipurpose grease to the

knuckle and bearing contact surfaces.

(3) With the wheel bearing inner race removed, press-in

the bearing by using the special tools.

(4) Install the wheel bearing inner race to the wheel

bearing.

6. INSTALLATION OF OIL SEAL (HUB SIDE)

(1) Drive the oil seal (hub side) into the knuckle by using the

special tools until it is flush with the knuckle end

surface.

(2) Apply multipurpose grease to the lip of the oil seal and

_to the surfaces ot the 011 seal which contact the hub.d. ADJUSTMENT OF WHEEL BEARING STARTING

TORQUE

(I) Use the special tool to mount the hub assembly onto

the knuckle.

(2) Tighten the nut of the special tool to 200

- 260 Nm .(I45

- 188 ft.lbs.).

(3) Rotate the hub assembly in order to seat the bearing.llKO12

TSB Revision

(4) Measure the wheel bearing starting torque (hub starting

torque) by using the special tools.

Limit: 1.8 Nm (16

in.lbs.) or less

NOTEThe starting torque must be within the limit and, in

addition, the bearing must not feel rough when rotated.

Page 599 of 1146

REAR AXLE

llN00261 SERVICE ADJUSTMENT

PRbCEDURES

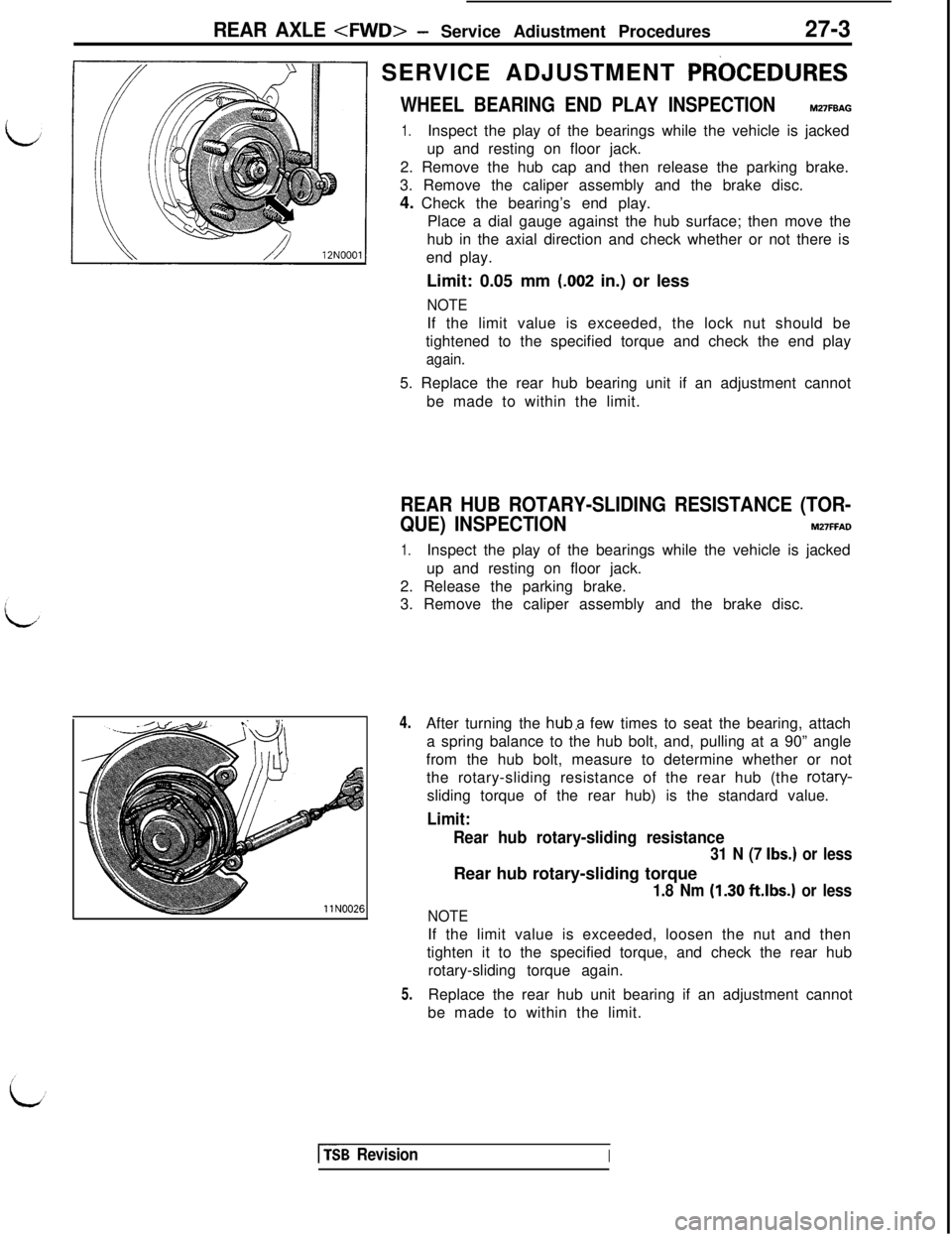

WHEEL BEARING END PLAY INSPECTIONM27FBAG

1.Inspect the play of the bearings while the vehicle is jacked

up and resting on floor jack.

2. Remove the hub cap and then release the parking brake.

3. Remove the caliper assembly and the brake disc.

4. Check the bearing’s end play.

Place a dial gauge against the hub surface; then move the

hub in the axial direction and check whether or not there is

end play.

Limit: 0.05 mm

(.002 in.) or less

NOTEIf the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.5. Replace the rear hub bearing unit if an adjustment cannot

be made to within the limit.

REAR HUB ROTARY-SLIDING RESISTANCE (TOR-

QUE) INSPECTION

M27FFAD

1.Inspect the play of the bearings while the vehicle is jacked

up and resting on floor jack.

2. Release the parking brake.

3. Remove the caliper assembly and the brake disc.

4.

5.After turning the

huba few times to seat the bearing, attach

a spring balance to the hub bolt, and, pulling at a 90” angle

from the hub bolt, measure to determine whether or not

the rotary-sliding resistance of the rear hub (the rotary-

sliding torque of the rear hub) is the standard value.

Limit:

Rear hub rotary-sliding resistance

31 N (7 Ibs.) or lessRear hub rotary-sliding torque

1.8 Nm (1.30 ft.lbs.) or less

NOTEIf the limit value is exceeded, loosen the nut and then

tighten it to the specified torque, and check the rear hub

rotary-sliding torque again.

Replace the rear hub unit bearing if an adjustment cannot

be made to within the limit.

[fsB RevisionI

Page 631 of 1146

REAR AXLE

MB990802-01

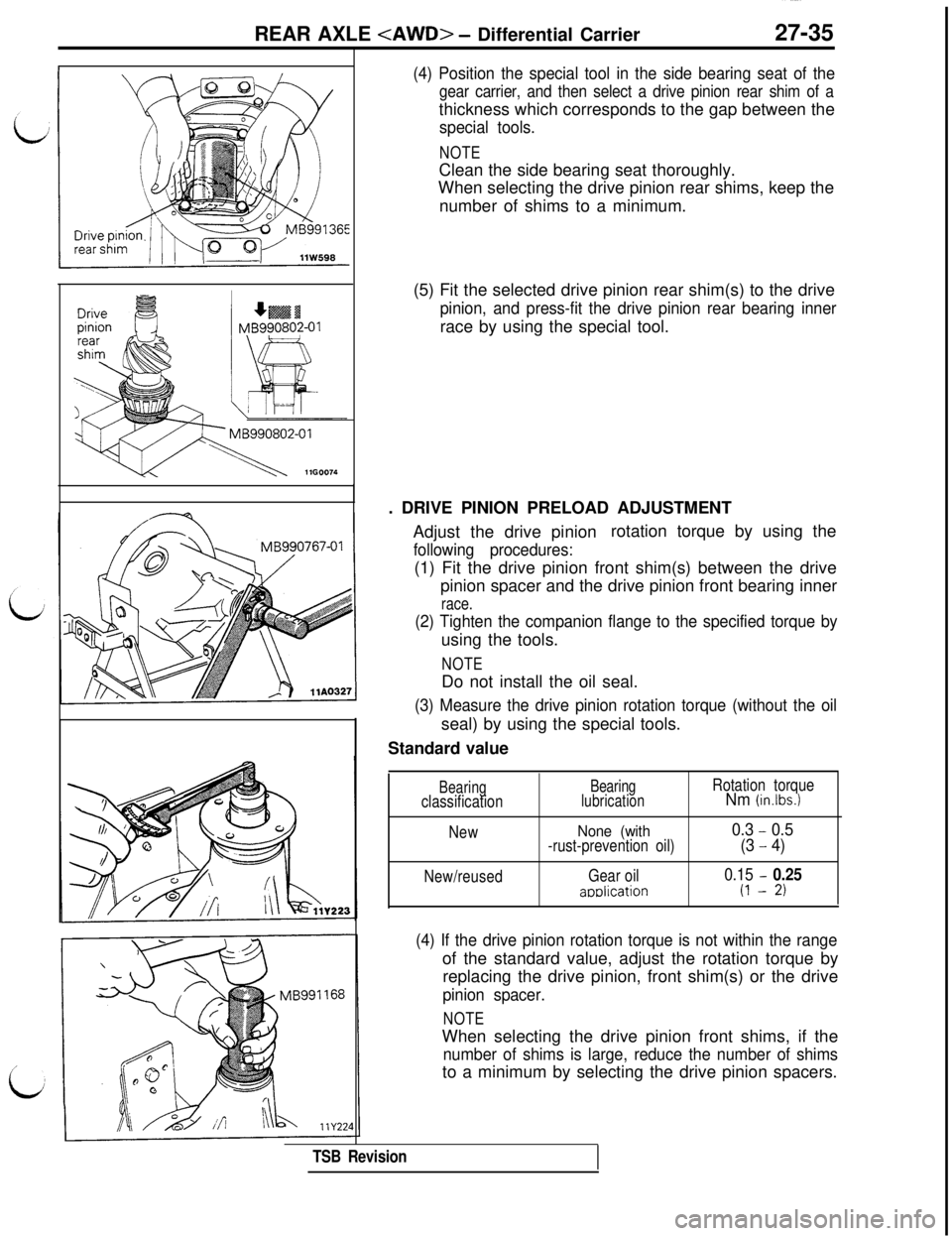

(4) Position the special tool in the side bearing seat of the

gear carrier, and then select a drive pinion rear shim of athickness which corresponds to the gap between the

special tools.

NOTEClean the side bearing seat thoroughly.

When selecting the drive pinion rear shims, keep the

number of shims to a minimum.

(5) Fit the selected drive pinion rear shim(s) to the drive

pinion, and press-fit the drive pinion rear bearing innerrace by using the special tool.

. DRIVE PINION PRELOAD ADJUSTMENT

Adjust the drive pinionrotation torque by using the

following procedures:(1) Fit the drive pinion front shim(s) between the drive

pinion spacer and the drive pinion front bearing inner

race.

(2) Tighten the companion flange to the specified torque byusing the tools.

NOTEDo not install the oil seal.

(3) Measure the drive pinion rotation torque (without the oilseal) by using the special tools.

Standard value

Bearingclassification

New

New/reusedBearing

lubrication

None (with-rust-prevention oil)

Gear oil

amlication

Rotation torqueNm (in.lbs.)

0.3 - 0.5

(3

- 4)

0.15 - 0.25

(I - 2)

(4) If the drive pinion rotation torque is not within the rangeof the standard value, adjust the rotation torque by

replacing the drive pinion, front shim(s) or the drive

pinion spacer.

NOTEWhen selecting the drive pinion front shims, if the

number of shims is large, reduce the number of shimsto a minimum by selecting the drive pinion spacers.

TSB Revision

Page 692 of 1146

34-6REAR SUSPENSION

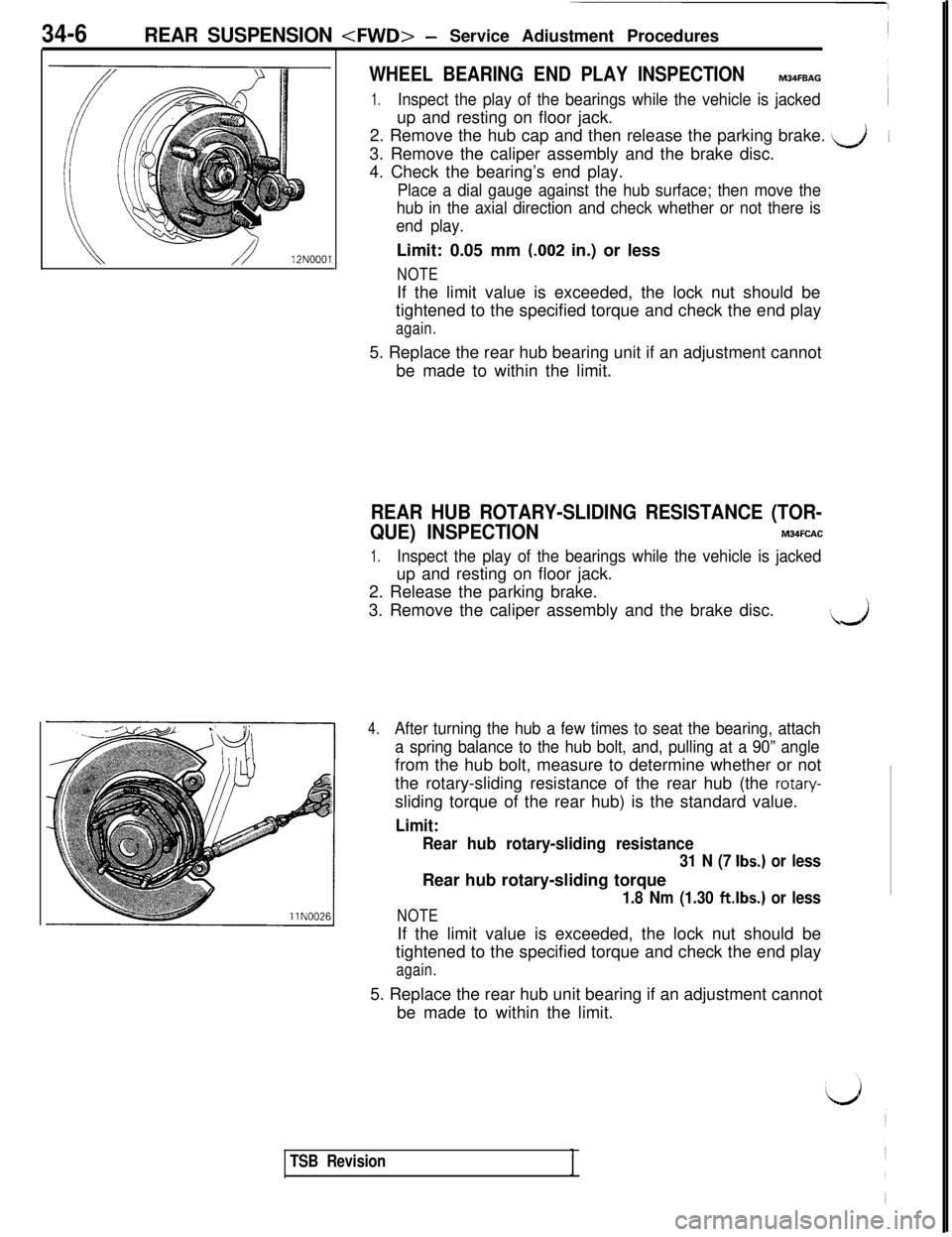

WHEEL BEARING END PLAY INSPECTIONM34FBAG

1.Inspect the play of the bearings while the vehicle is jackedup and resting on floor jack.

2. Remove the hub cap and then release the parking brake.

s&i3. Remove the caliper assembly and the brake disc.

4. Check the bearing’s end play.

Place a dial gauge against the hub surface; then move the

hub in the axial direction and check whether or not there is

end play.Limit: 0.05 mm

(.002 in.) or less

NOTEIf the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.5. Replace the rear hub bearing unit if an adjustment cannot

be made to within the limit.

REAR HUB ROTARY-SLIDING RESISTANCE (TOR-

QUE) INSPECTION

M34FCAC

1.Inspect the play of the bearings while the vehicle is jackedup and resting on floor jack.

2. Release the parking brake.

3. Remove the caliper assembly and the brake disc.

..J

4.After turning the hub a few times to seat the bearing, attach

a spring balance to the hub bolt, and, pulling at a 90” anglefrom the hub bolt, measure to determine whether or not

the rotary-sliding resistance of the rear hub (the

rotary-sliding torque of the rear hub) is the standard value.

Limit:

Rear hub rotary-sliding resistance

31 N (7 Ibs.) or lessRear hub rotary-sliding torque

1.8 Nm (1.30 ftlbs.) or less

NOTEIf the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.5. Replace the rear hub unit bearing if an adjustment cannot

be made to within the limit.

TSB Revision

Page 889 of 1146

BODY - Service Adjustment Procedures

42-17

I18FOO33

Front floor pan+ Drain plug

lFlFOO91

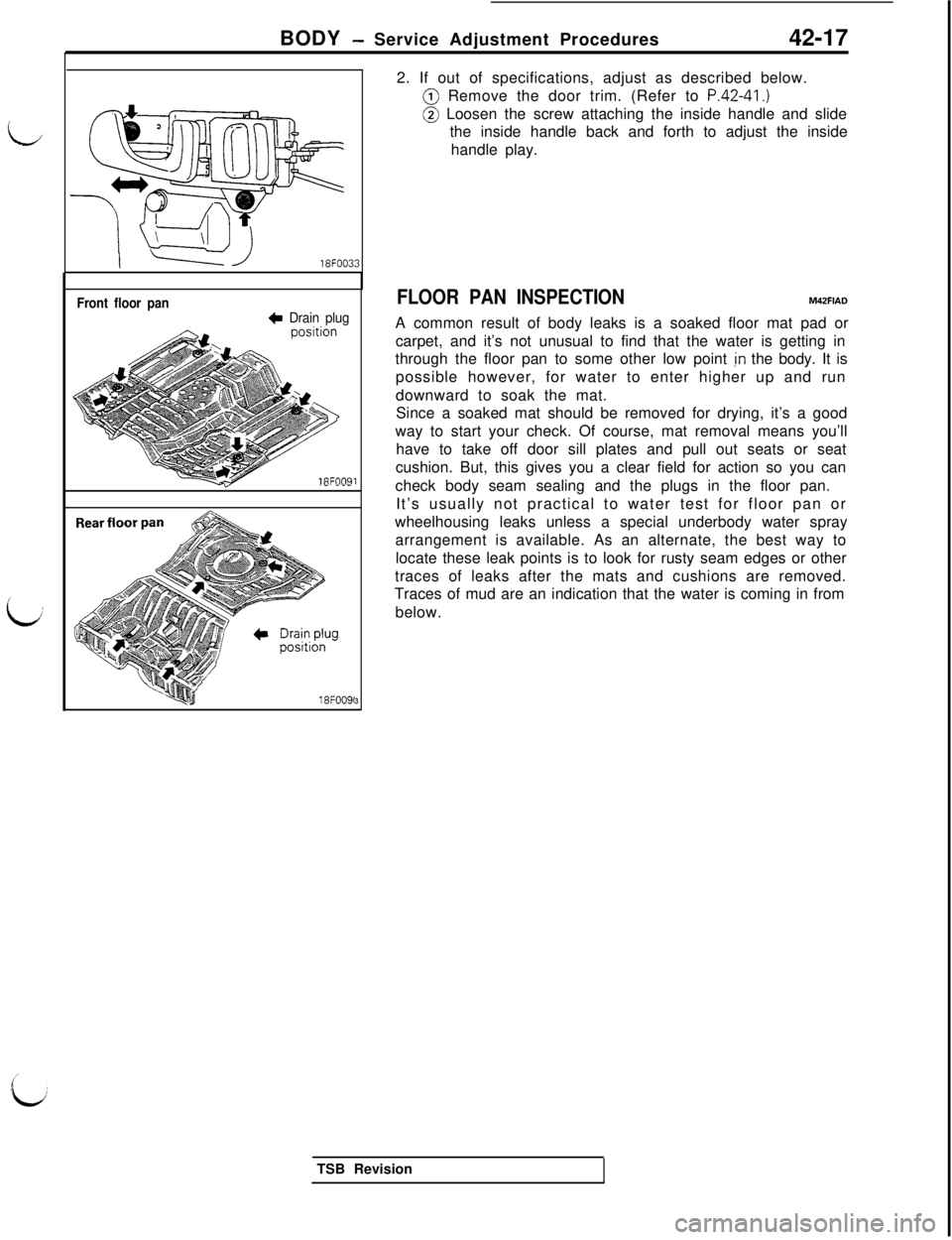

18FOO9132. If out of specifications, adjust as described below.@ Remove the door trim. (Refer to

P.42-41.)@ Loosen the screw attaching the inside handle and slide

the inside handle back and forth to adjust the inside

handle play.

FLOOR PAN INSPECTIONM42FIADA common result of body leaks is a soaked floor mat pad or

carpet, and it’s not unusual to find that the water is getting in

through the floor pan to some other low point

jn the body. It is

possible however, for water to enter higher up and run

downward to soak the mat.

Since a soaked mat should be removed for drying, it’s a good

way to start your check. Of course, mat removal means you’ll

have to take off door sill plates and pull out seats or seat

cushion. But, this gives you a clear field for action so you can

check body seam sealing and the plugs in the floor pan.

It’s usually not practical to water test for floor pan or

wheelhousing leaks unless a special underbody water spray

arrangement is available. As an alternate, the best way to

locate these leak points is to look for rusty seam edges or other

traces of leaks after the mats and cushions are removed.

Traces of mud are an indication that the water is coming in from

below.

TSB Revision