sensor MITSUBISHI 3000GT 1992 2.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1992, Model line: 3000GT, Model: MITSUBISHI 3000GT 1992 2.GPages: 738, PDF Size: 35.06 MB

Page 480 of 738

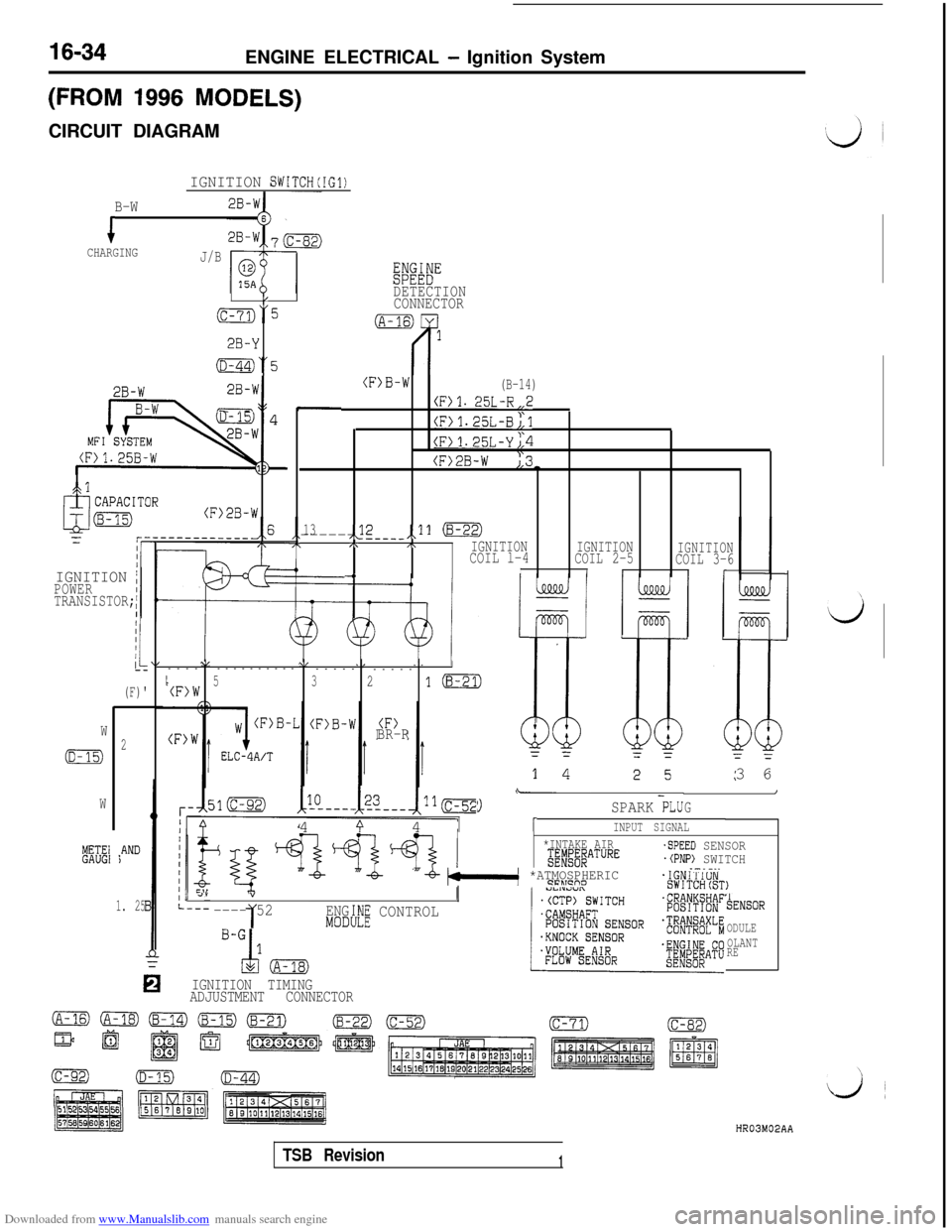

Downloaded from www.Manualslib.com manuals search engine 16-34ENGINE ELECTRICAL - Ignition System

(FROM 1996 MODELS)CIRCUIT DIAGRAM

IGNITION SWITCH(IG1)

B-W

iCHARGINGJ/B

Eiwi"

/DETECTION

(c-73)“5CONNECTOR

2B-Y

(D-44)“5

2B-W-I

2B-W

MFILS - --

(F>B-W(B-14)

(F)l. 25L-R,,2

(F)1.25L-B;,l

(F>1.25L-Yj,4

(F>2B-W ),3-

.

13,<2------ ---__,,11 (8-22),\,\IGNITIONCOIL l-4IGNITION

COIL 2-5IGNITIONCOIL 3-6-4III(r

,cl

(F>2B-W

IGNITION /POWER

TRANSISTOR;

I

(F)'

\I\/,I--------------

-----

-----

I5(F)W321m

BR-RW

(D-15)2

W

METE1GAUGI*AND)3 6

\-I

G9SPARK PLU4

9 41INPUT SIGNAL

*INTAKE AIRg;#j#ATURE

"-b- bkl *ATMOSPHERIC9FLTcno

-SPEED SENSOR.(PNP) SWITCH.-.-..

, 4””

---- 521ENG:h!E CONTROLMODI

TENSOR

ODULE

OLANT

RE

IGNITION TIMING

ADJUSTMENT CONNECTOR

1. 25

HR03M02AA

TSB Revision1

Page 481 of 738

Downloaded from www.Manualslib.com manuals search engine i;ENGINE ELECTRICAL

- Ignition System16-35

OPERATIONl

Turn ignition switch to .“ON”position, and batteryvoltage will be applied to primary winding of

ignition coil.l

When crankshaft position sensor and camshaft

position sensor signal is input to engine control

module, engine control module makes ON-OFF

control of power transistors one by one.l When power transistor is turned on, current

flows from ignition coil (primary winding) to

ground through power transistor.l When power transistor A is turned from ON

to OFF, the spark plugs of No. 1 and No. 4

cylinders spark. Turning of power transistor B

from ON to OFF will produce sparking in spark

plugs of No. 2 and No. 5 cylinders. Furthermore,

when power transistor C is turned from ON toOFF, sparking is produced in spark plugs of

No. 3 and No. 6 cylinders.

TROUBLESHOOTING HINTS1. Engine cranks, but does not start.

(1) Spark is insufficient or does not occur at

all (on spark plug).l Check ignition coil.

l Check camshaft position sensor and

crankshaft position sensorl Check power transistor.

l Check spark plugs.

l Check spark plug cable.

(2) Spark is good.

l Check ignition timing.

2. Engine idles roughly or stalls.

l Check spark plugs.

l Check ignition timing.

l Check ignition coil.

l Check spark plug cable.

3. Poor acceleration

l Check ignition timing.

l Check spark plug cable.

l Check ignition coil.

TSB Revision

Page 491 of 738

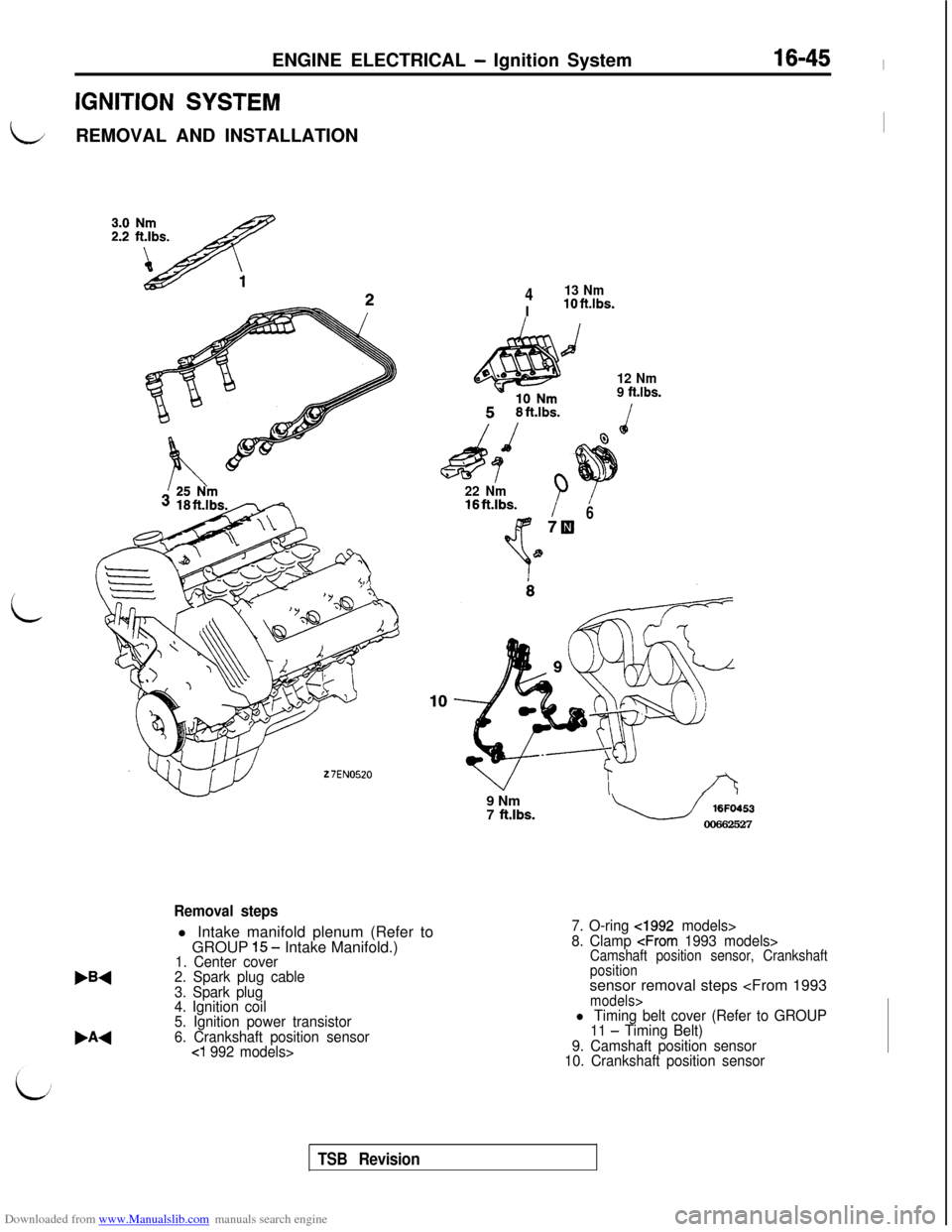

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition System16-45 l

IGNITION SYSTEM

LREMOVAL AND INSTALLATIONI

i

27EN0520

413 NmIlOft.lbs.

d

12 Nm

9 ft.lbs.

22 Nm16ftAbs.B678

W1

,A4

Removal stepsl Intake manifold plenum (Refer to

GROUP

1.5 - Intake Manifold.)1. Center cover

2. Spark plug cable

3. Spark plug

4. Ignition coil

5. Ignition power transistor

6. Crankshaft position sensor

cl 992 models>9 Nm

7

ft.lbs.u 16FO453

00662527

7. O-ring cl992 models>

8. Clamp

positionsensor removal steps

11 - Timing Belt)

9. Camshaft position sensor

10. Crankshaft position sensor

TSB Revision

Page 492 of 738

Downloaded from www.Manualslib.com manuals search engine 16-46ENGINE ELECTRICAL - Ignition Svstem

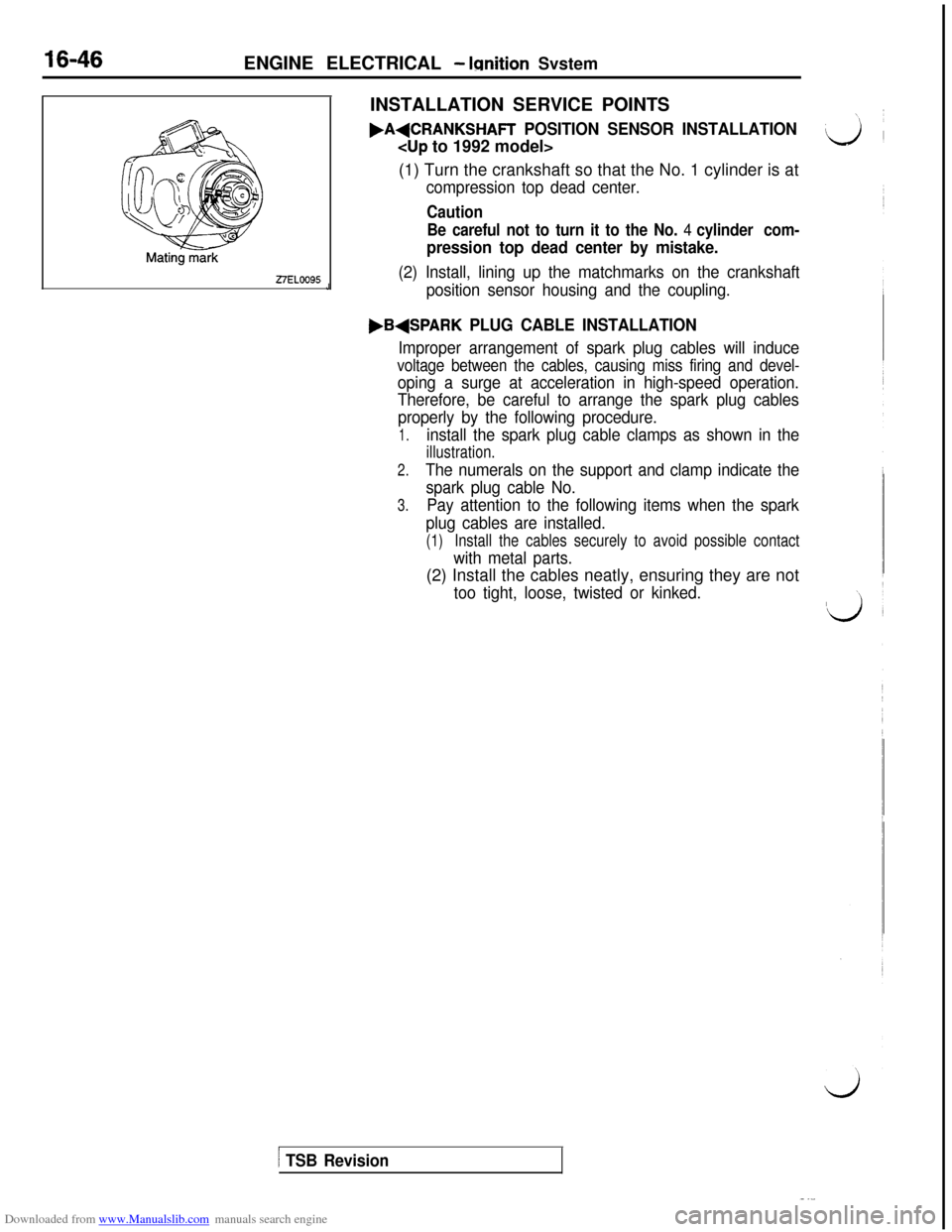

27ELOO95JINSTALLATION SERVICE POINTS.A+CRANKSHAFT

POSITION SENSOR INSTALLATION

(1) Turn the crankshaft so that the No. 1 cylinder is at

compression top dead center.

Caution

Be careful not to turn it to the No.

4 cylinder com-

pression top dead center by mistake.

(2) Install, lining up the matchmarks on the crankshaft

position sensor housing and the coupling.

,B+SPARK PLUG CABLE INSTALLATION

Improper arrangement of spark plug cables will induce

voltage between the cables, causing miss firing and devel-

oping a surge at acceleration in high-speed operation.

Therefore, be careful to arrange the spark plug cables

properly by the following procedure.

1.install the spark plug cable clamps as shown in the

illustration.

2.The numerals on the support and clamp indicate the

spark plug cable No.

3.Pay attention to the following items when the spark

plug cables are installed.

(1)Install the cables securely to avoid possible contact

with metal parts.(2) Install the cables neatly, ensuring they are not

too tight, loose, twisted or kinked.

/ TSB Revision

Page 497 of 738

Downloaded from www.Manualslib.com manuals search engine 54-1

CHASSIS

ELECTRICAL

CONTENTS

AERO PARTS (ACTIVE AERO).....Refer to GROUP 51

ANTI-LOCK BRAKING SYSTEM....

Refer to GROUP 35

BATTERY...........................................-3

ON-VEHICLE SERVICE............................3

Battery Charging.................................4Battery Inspection................................3Battery Testing Procedure........................5

SPECIFICATIONS................................-3

General Specifications............................3

CIGARETTE LIGHTER.............................119

CIGARETTE LIGHTER..........................123

SPECIFICATIONS..............................

119

General Specifications............I...........119

TROUBLESHOOTING............................120

COLUMN SWITCH.................................

.lll

COLUMN SWITCH*............................112

SPECIAL TOOL.................................111

SPECIFICATIONS...............................111

General Specifications..........................111

CRUISE CONTROL SYSTEM . . . . . . . Refer to GROUP 17

DOOR GLASS AND REGULATOR

(POWER WINDOWS) . . . . . . . . . . . . . .Refer to GROUP 42

DOOR HANDLE AND LATCH

(CENTRAL DOOR LOCKING) . . . . . . Refer to GROUP 42

DOOR MIRROR (ELECTRONIC

CONTROLLED MIRROR). . . . . . . . . . .Refer to GROUP 51

ELECTRONIC CONTROL

SUSPENSION . . . . . . . . . . . . . . . . . . . . Refer to GROUP

338

FRONT SEAT (POWER SEAT) . . . . Refer to GROUP 52A

HEATER AND AIR CONDITIONING . Refer to GROUP 55

HORN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

115

HORN SWITCH* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

RELAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

118

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

115

General Specifications . . . . . . . . . . . . . . . . . . . . . . . .115

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . .115

KEYLESS ENTRY SYSTEM

(CENTRAL DOOR LOCKING) . . . . . . Refer to GROUP 42

CONTINUED ON NEXT PAGE

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the

SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from render-

ing the SRS inoperative).

(2) Service or maintenance of any SRS component or

SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3)MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

TSupplemental Re-

straint System (SRS) and GROUP 00 -Maintenance Service before beginning any service or maintenance of any com-

ponent of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: impact sensors, SRS diagnosis unit, SRS warning light, air bag module, clock spring

and interconnecting wiring. Other SRS-related components (that may

h,a”” to be removed/installed in connection with SRS serviceor maintenance) are indicated in the table of contents by an asterisk ( ).

Page 514 of 738

Downloaded from www.Manualslib.com manuals search engine 54-18CHASSIS ELECTRICAL - Meters and Gauges

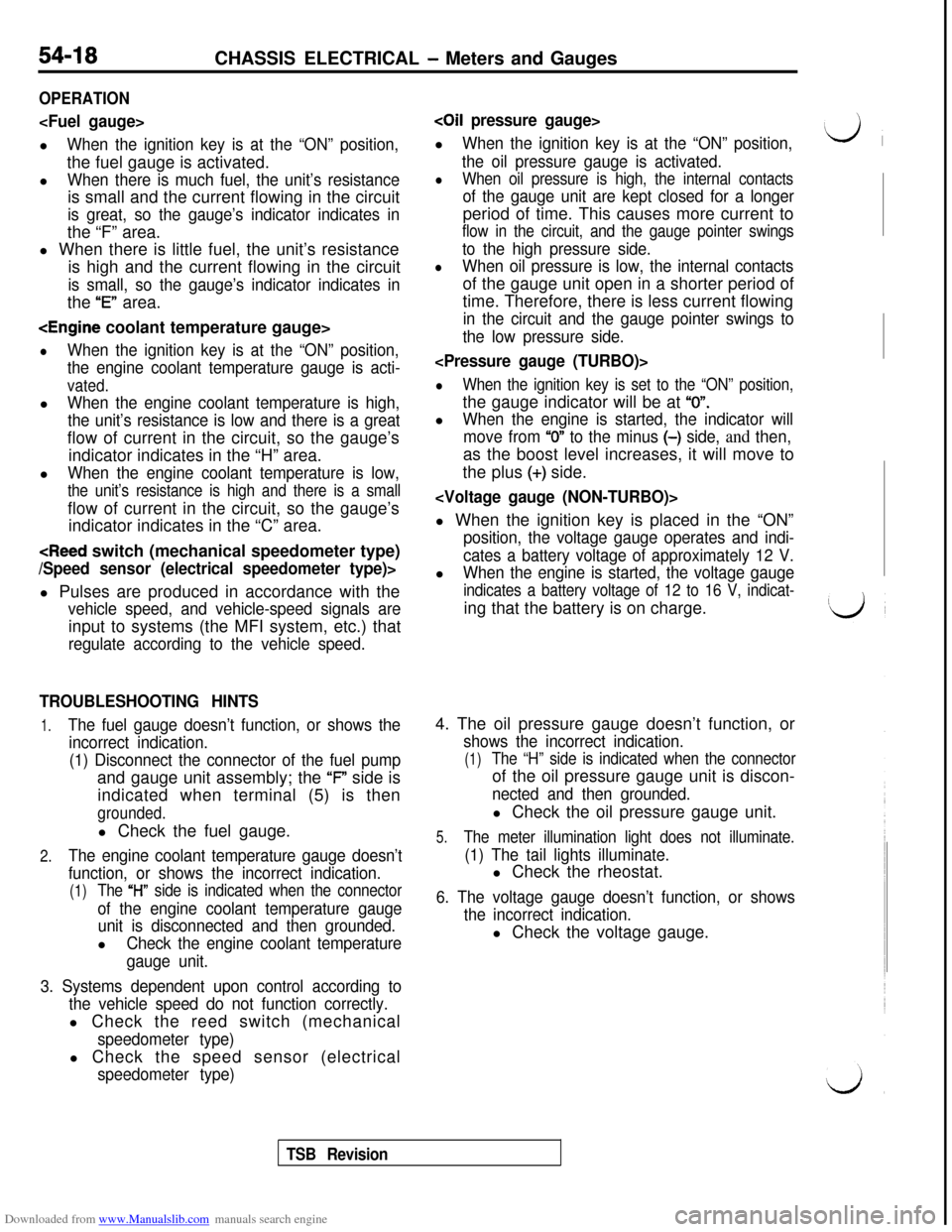

OPERATION

When the ignition key is at the “ON” position,the fuel gauge is activated.

l

When there is much fuel, the unit’s resistanceis small and the current flowing in the circuit

is great, so the gauge’s indicator indicates inthe “F” area.

l When there is little fuel, the unit’s resistance

is high and the current flowing in the circuit

is small, so the gauge’s indicator indicates inthe

“E” area.

lWhen the ignition key is at the “ON” position,

the engine coolant temperature gauge is acti-

vated.l

When the engine coolant temperature is high,

the unit’s resistance is low and there is a greatflow of current in the circuit, so the gauge’s

indicator indicates in the “H” area.

l

When the engine coolant temperature is low,

the unit’s resistance is high and there is a smallflow of current in the circuit, so the gauge’s

indicator indicates in the “C” area.

vehicle speed, and vehicle-speed signals areinput to systems (the MFI system, etc.) that

regulate according to the vehicle speed.

TROUBLESHOOTING HINTS

1.The fuel gauge doesn’t function, or shows the

incorrect indication.

(1) Disconnect the connector of the fuel pumpand gauge unit assembly; the ‘F” side is

indicated when terminal (5) is then

grounded.l Check the fuel gauge.

2.The engine coolant temperature gauge doesn’t

function, or shows the incorrect indication.

(1)The “l-l” side is indicated when the connector

of the engine coolant temperature gauge

unit is disconnected and then grounded.l

Check the engine coolant temperature

gauge unit.

3. Systems dependent upon control according to

the vehicle speed do not function correctly.l Check the reed switch (mechanical

speedometer type)l Check the speed sensor (electrical

speedometer type)

coil pressure gauge>l

When the ignition key is at the “ON” position,

the oil pressure gauge is activated.

lWhen oil pressure is high, the internal contacts

of the gauge unit are kept closed for a longerperiod of time. This causes more current to

flow in the circuit, and the gauge pointer swings

to the high pressure side.

lWhen oil pressure is low, the internal contactsof the gauge unit open in a shorter period of

time. Therefore, there is less current flowing

in the circuit and the gauge pointer swings to

the low pressure side.

lWhen the ignition key is set to the “ON” position,the gauge indicator will be at

“0”.l

When the engine is started, the indicator will

move from

“0” to the minus (-) side, and then,as the boost level increases, it will move to

the plus

(+) side.

position, the voltage gauge operates and indi-

cates a battery voltage of approximately 12 V.l

When the engine is started, the voltage gauge

indicates a battery voltage of 12 to 16 V, indicat-ing that the battery is on charge.

4. The oil pressure gauge doesn’t function, or

shows the incorrect indication.

(1)The “H” side is indicated when the connectorof the oil pressure gauge unit is discon-

nected and then grounded.l Check the oil pressure gauge unit.

5.The meter illumination light does not illuminate.

(1) The tail lights illuminate.l Check the rheostat.

6. The voltage gauge doesn’t function, or shows

the incorrect indication.l Check the voltage gauge.

TSB Revision

Page 517 of 738

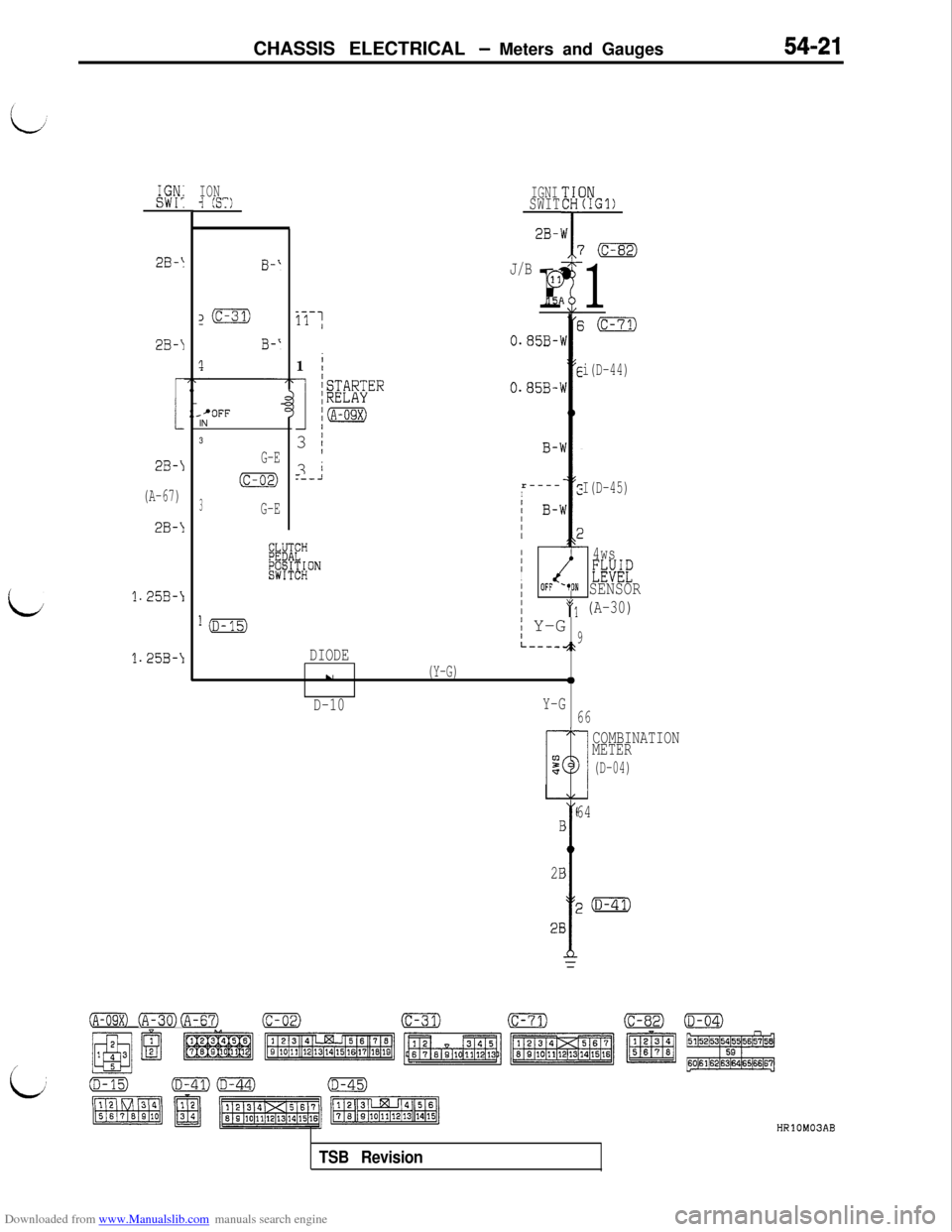

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Meters and Gauges54-21

L

IGN:IONsw1:-I (ST)IGNISWIT

2B-'

2B-IB-‘

z(c-31)

B-‘

1

_--11 1

J/B

r

G

151

2B-I

i

2B-I

(A-67)

2B-1

1.25B-\

1.25B-\11

/

1

kTARTERIRELAY.'OFFINim

3

G-E3 /

(c-02)3 i.--J

3G-E

EK”&#ON

l(D-15)

DIODE

E0.85B-'w

E0.85B-'

B-1r----

Ic

1 B-1IIIE

II4wsIIEW1OFF '*ON SENSORII

j Y-G

*q (A-30)

9L----~\

IN(IGl)

'(c-82)

1

i(c-71)

i(D-44)

I(D-45)

L

u(Y-G)0

D-10Y-G

66

COMBINATION

METER

(D-04)

64B

2B

1p(D-41)

28

(A-09X) (A-30)@%?')(c-02)(c-31)(c-71)(C-82)0

/

HRlOM03AB

TSB Revision

Page 520 of 738

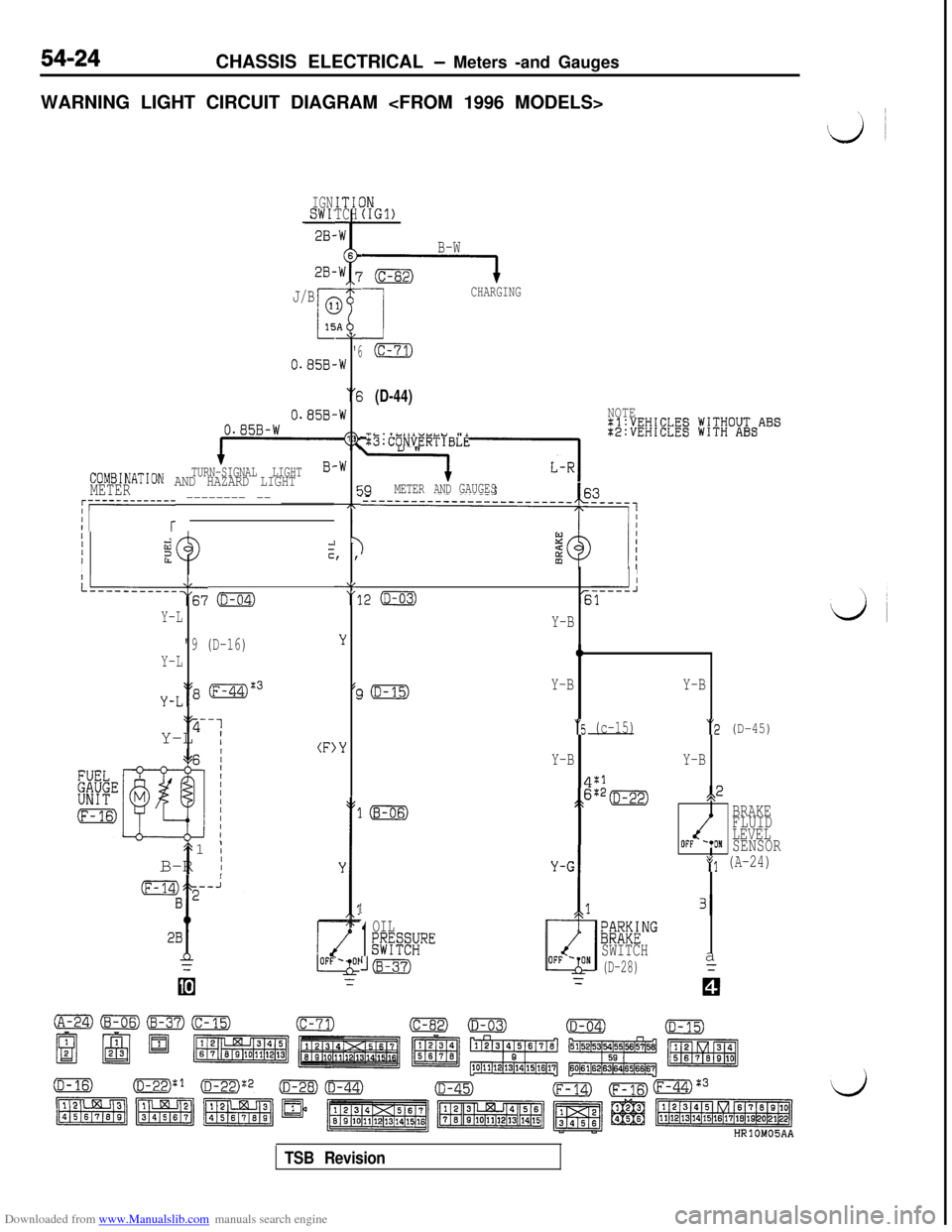

Downloaded from www.Manualslib.com manuals search engine 54-24CHASSIS ELECTRICAL - Meters -and Gauges

WARNING LIGHT CIRCUIT DIAGRAM

IGNSWI'28-ITICTCH

2B-

J/B

0.85B-

0.858,0.85B-W

TURN-SIGNAL LIGHTCOMBINATION AND HAZARD LIGHTMETER

AL

'6.W

“6

-W

13

-W

cc7T,

I y, ,

‘8"11

;;i;EW;EElg jV;V;O&ABS

:B:CONVERTIBLE

j9METER ANDGAUGES~r-----------r -------- -- _______

IIIiizzIcI

L--------‘:67 o

Y-L

"9 (D-16)

Y-L

y-L‘18 (F-44)%3‘y-1

Y-L

I(F)

t1

;B-R

I

IN(IGl)

B-W

G----l

1

CHARGING

(c-71)

(D-44)NOTE

II

.2 (D-03)-----J61

LL

'3

Y

(c

,Y

Y-B

0

Y-BY-B

“5 (c-15)“2 (D-45)

Y-BY-B

4:1

;>6:*=s,2

BRAKE

FLUID

LEVEL

OFF '*ONSENSOR

*(I (A-24)

1

1

OIL;@SRE

((B-37)

/

131

;~M&NG

SWITCH

(D-28)a

TSB Revision

Page 524 of 738

Downloaded from www.Manualslib.com manuals search engine 54-28CHASSIS ELECTRICAL - Meters and Gauges

16FO11500002300

16Fo255 00002383

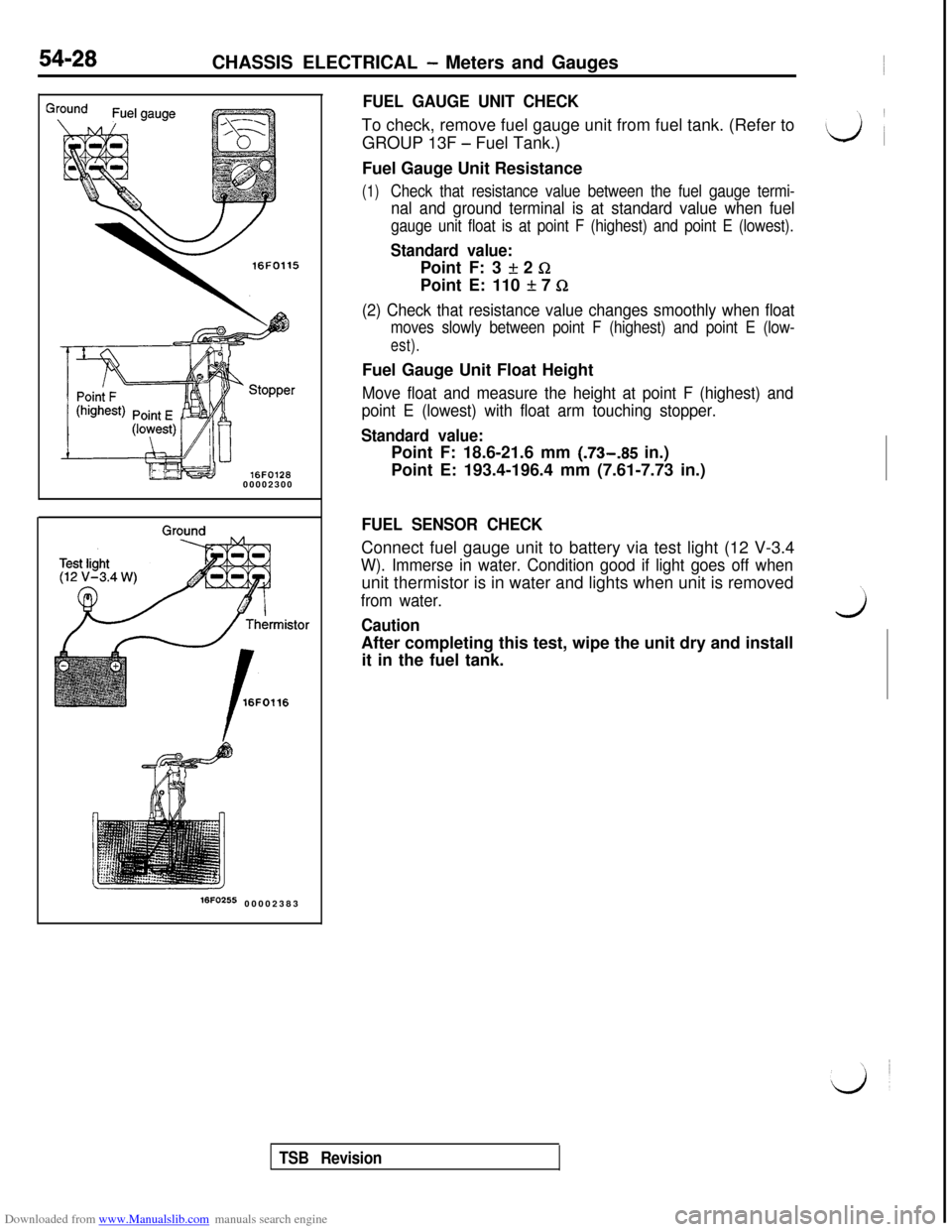

FUEL GAUGE UNIT CHECKTo check, remove fuel gauge unit from fuel tank. (Refer to

GROUP 13F

- Fuel Tank.)

Fuel Gauge Unit Resistance

(1)Check that resistance value between the fuel gauge termi-

nal and ground terminal is at standard value when fuel

gauge unit float is at point F (highest) and point E (lowest).

Standard value:Point F: 3

If: 2 GPoint E: 110

It 7 Q

(2) Check that resistance value changes smoothly when float

moves slowly between point F (highest) and point E (low-

est).Fuel Gauge Unit Float Height

Move float and measure the height at point F (highest) and

point E (lowest) with float arm touching stopper.

Standard value:Point F: 18.6-21.6 mm (.73-.85 in.)

Point E: 193.4-196.4 mm (7.61-7.73 in.)

FUEL SENSOR CHECKConnect fuel gauge unit to battery via test light (12 V-3.4

W). Immerse in water. Condition good if light goes off whenunit thermistor is in water and lights when unit is removed

from water.

CautionwAfter completing this test, wipe the unit dry and install

it in the fuel tank.

TSB Revision

Page 527 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Meters and Gauges54-31

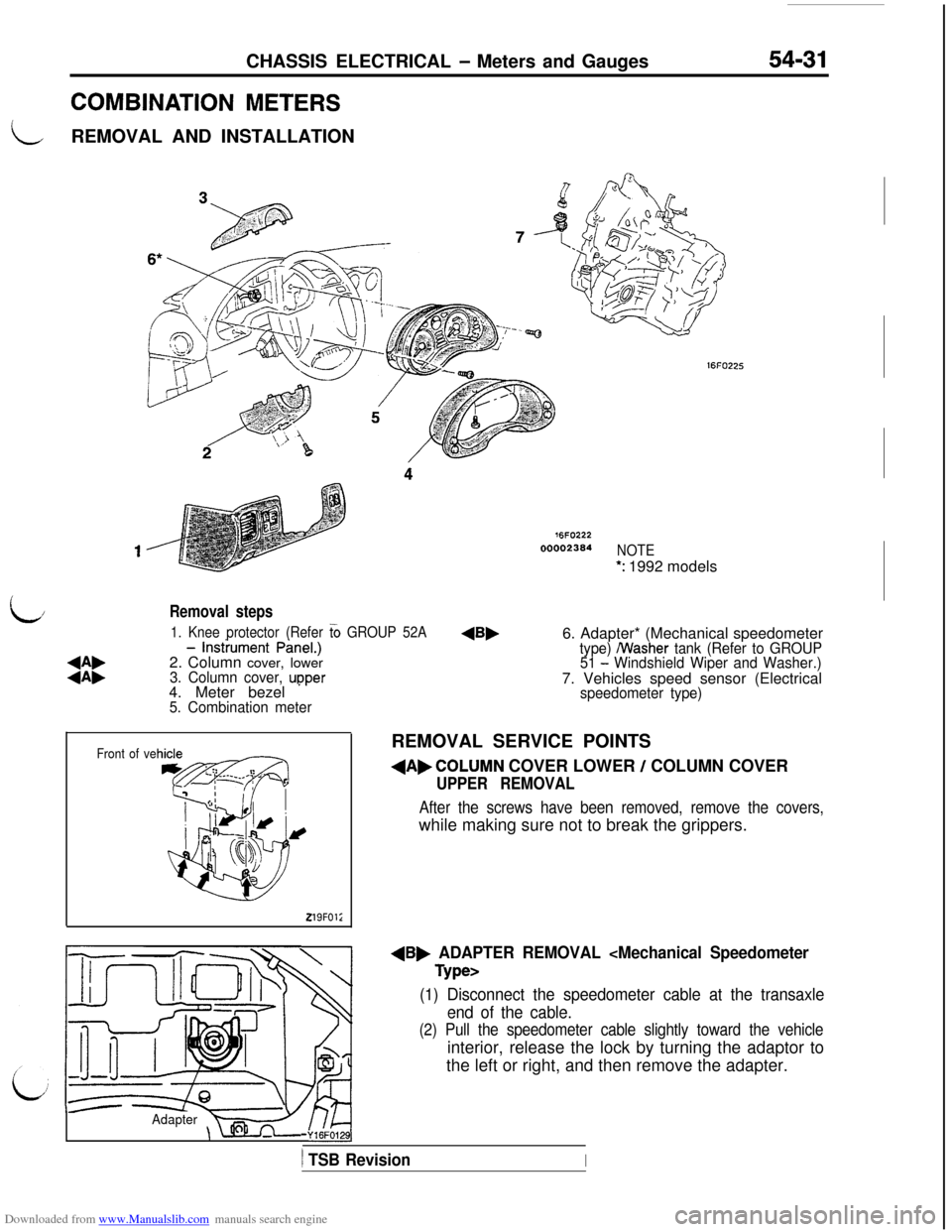

COMBINATION METERS

LREMOVAL AND INSTALLATION

76FO22200002364

NOTE

*: 1992 models

L/

:i:

- lnstiument PineI.)

2. Column cover, lower

3. Column cover, upper 1. Knee protector (Refer

G GROUP 52A4. Meter bezel

* ’5. Combination meter

Removal steps6. Adapter* (Mechanical speedometer

type) /Washer tank (Refer to GROUP

51 - Windshield Wiper and Washer.)7. Vehicles speed sensor (Electrical

Front of ve

219FOl;

speedometer type)REMOVAL SERVICE POINTS

dAbCOLUMN COVER LOWER / COLUMN COVER

UPPER REMOVAL

After the screws have been removed, remove the covers,while making sure not to break the grippers.

dB, ADAPTER REMOVAL

(1) Disconnect the speedometer cable at the transaxle

end of the cable.

(2) Pull the speedometer cable slightly toward the vehicleinterior, release the lock by turning the adaptor to

the left or right, and then remove the adapter.

Adapter-Y16FO129],

) TSB RevisionI