check engine MITSUBISHI 3000GT 1992 2.G Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1992, Model line: 3000GT, Model: MITSUBISHI 3000GT 1992 2.GPages: 738, PDF Size: 35.06 MB

Page 452 of 738

Downloaded from www.Manualslib.com manuals search engine 16-6ENGINE ELECTRICAL - Charging System

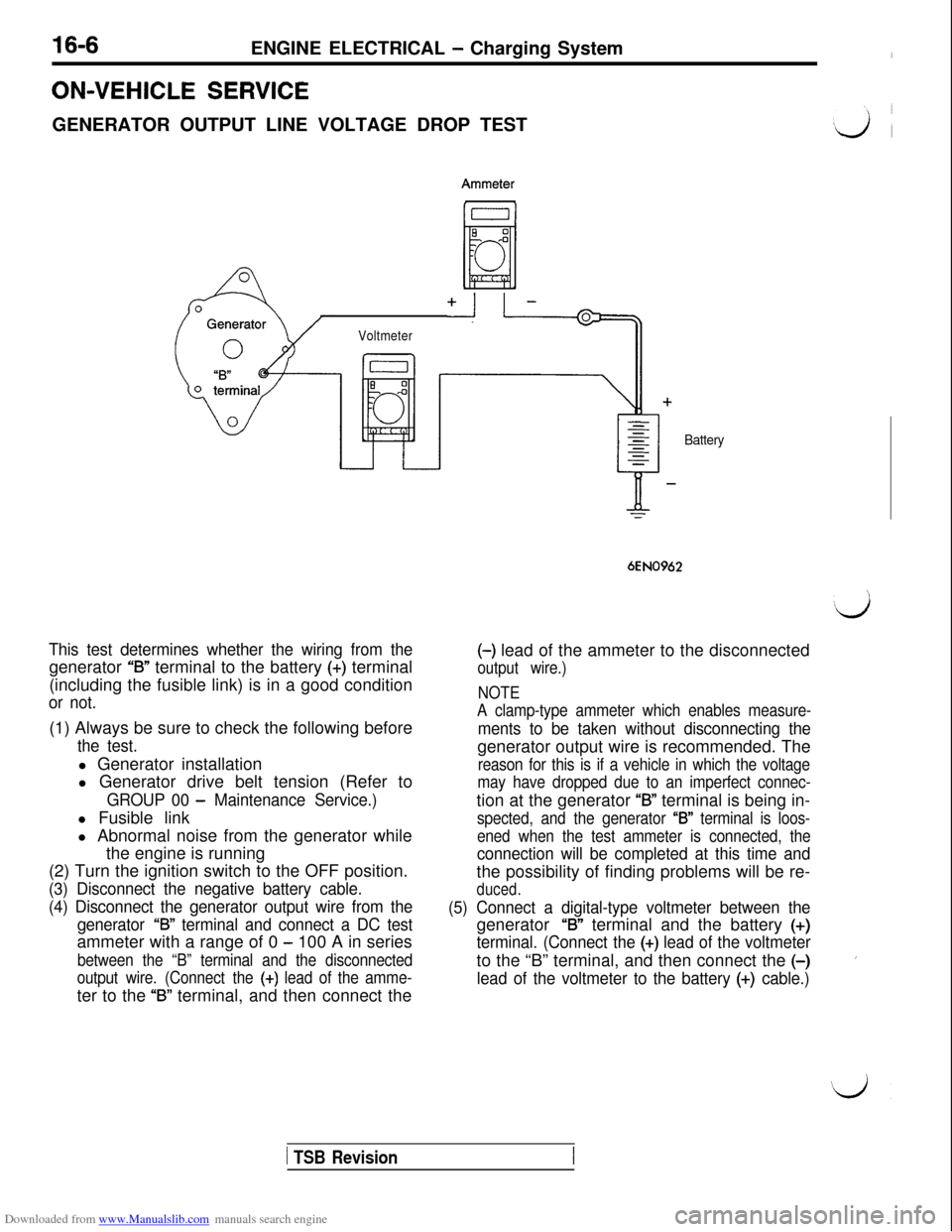

ON-VEHICLE SERVICEGENERATOR OUTPUT LINE VOLTAGE DROP TEST

+I I.=-@=

Voltmeter

This test determines whether the wiring from thegenerator

“B” terminal to the battery (+) terminal

(including the fusible link) is in a good condition

or not.(1) Always be sure to check the following before

the test.l Generator installation

l Generator drive belt tension (Refer to

GROUP 00 - Maintenance Service.)l Fusible link

l Abnormal noise from the generator while

the engine is running

(2) Turn the ignition switch to the OFF position.

(3) Disconnect the negative battery cable.

(4) Disconnect the generator output wire from the

generator

‘73” terminal and connect a DC testammeter with a range of 0

- 100 A in series

between the “B” terminal and the disconnected

output wire. (Connect the

(+) lead of the amme-ter to the

‘73” terminal, and then connect the

Battery

6EN0962(-) lead of the ammeter to the disconnected

output wire.)

NOTE

A clamp-type ammeter which enables measure-

ments to be taken without disconnecting thegenerator output wire is recommended. The

reason for this is if a vehicle in which the voltage

may have dropped due to an imperfect connec-tion at the generator

“B” terminal is being in-

spected, and the generator “B” terminal is loos-

ened when the test ammeter is connected, the

connection will be completed at this time andthe possibility of finding problems will be re-

duced.

(5) Connect a digital-type voltmeter between thegenerator

“B” terminal and the battery (+)

terminal. (Connect the (+) lead of the voltmeterto the “B” terminal, and then connect the

(-)

lead of the voltmeter to the battery (+) cable.)

’

1 TSB Revision

Page 453 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System16-7/

L

(6) Connect a tachometer. (For the procedure for

connecting the tachometer, refer to GROUP

- On-vehicle Service.)(7)

kkconnect the negative battery cable.

(8) Leave the hood open.

(9) Start the engine.

(lO)With the engine running at 2500 rpm, turn the

headlights and other lights on and off to adjust

the generator load so that the value displayed

on the ammeter is slightly above 30A.Limit value: Max. 0.3 V

NOTE

When the generator output is high and the value

displayed on the ammeter does not decreaseto

30A, set the value to 40A. Read the value

displayed on the voltmeter at this time.

In this case the limit value becomes max. 0.4V.

Adjust the engine speed by gradually decreas-

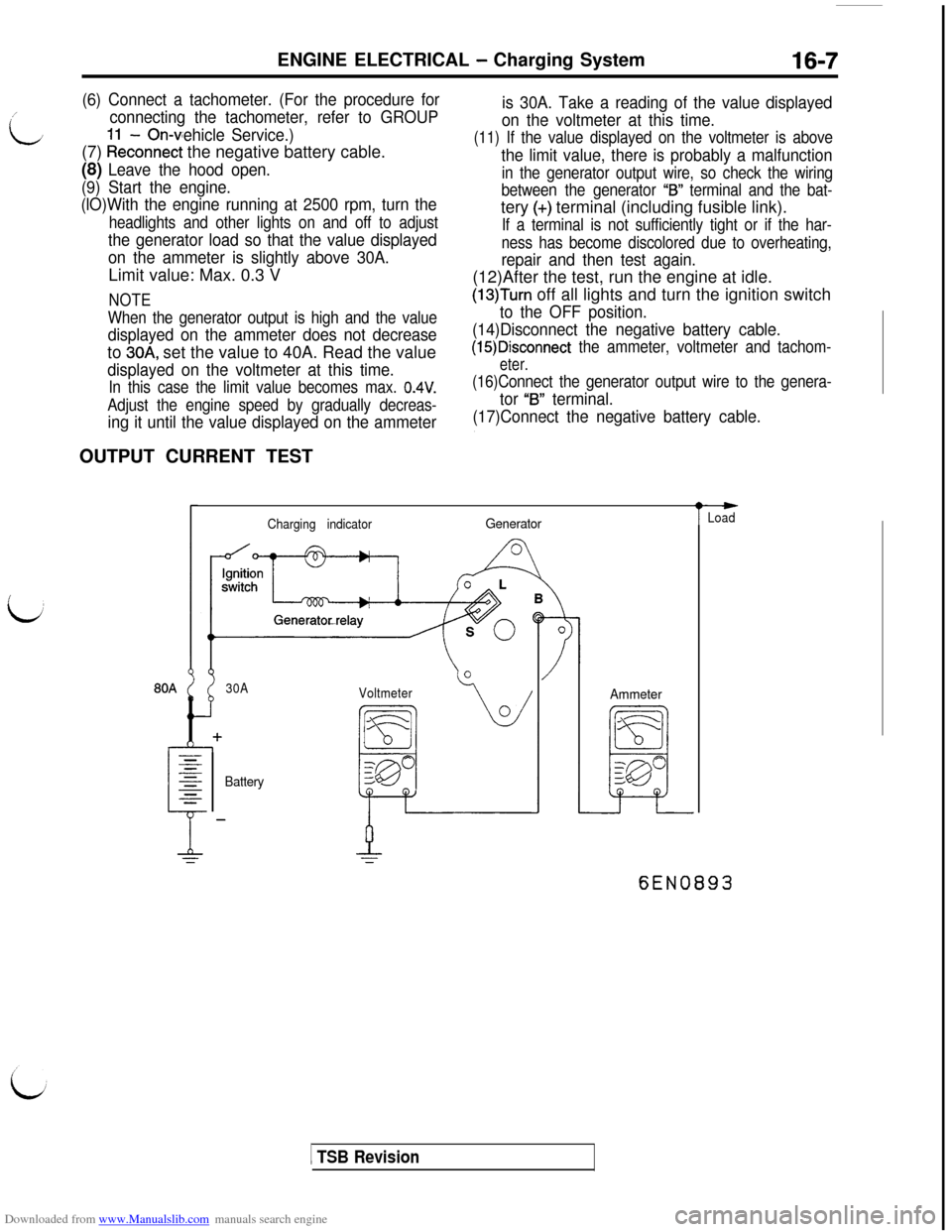

ing it until the value displayed on the ammeterOUTPUT CURRENT TEST

is 30A. Take a reading of the value displayed

on the voltmeter at this time.

(11) If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction

in the generator output wire, so check the wiring

between the generator

“IS” terminal and the bat-tery

(+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the har-

ness has become discolored due to overheating,

repair and then test again.(12)After the test, run the engine at idle.

(13)Turn off all lights and turn the ignition switch

to the OFF position.

(14)Disconnect the negative battery cable.

(15)Disconnect the ammeter, voltmeter and tachom-

eter.

(16)Connect the generator output wire to the genera-

tor “B” terminal.

(17)Connect the negative battery cable.

Charging indicatorGenerator

30A

Voltmeter

BatteryAmmeter

t

-Load

6EN0893

1 TSB Revision

Page 454 of 738

Downloaded from www.Manualslib.com manuals search engine 16-8ENGINE ELECTRICAL - Charging System

This test determines whether the generator outputs

normal current.(1) Before the test, always be sure to check the

following.l Generator installation

l

Battery (Refer to GROUP 54 - Battery.)

NOTE

The battery to be used should be slightly dis-charged. The load in a fully-charged battery

will be insufficient and the test may not be able

to be carried out correctly.l Generator drive belt tension (Refer to

GROUP 11- On-vehicle Service.)l Fusible link

l Abnormal noise from the generator while

the engine is running(2) Turn the ignition switch to the OFF position.

(3) Disconnect the negative battery cable.

(4) Disconnect the generator output wire from the

generator

“B” terminal and connect a DC testammeter with a range of O-100 A in series

between the “B” terminal and the disconnected

output wire. (Connect the

(+) lead of the amme-ter to the

“B” terminal, and then connect the(-) lead of the ammeter to the disconnected

output wire.)

Caution

Never use clips but tighten bolts and nutsto connect the line.

Otherwise loose

connections (e.g. using clips) will lead to

a serious accident because of high current.

NOTE

A clamp-type ammeter which enables measure-

ments to be taken without disconnecting the

generator output wire is recommended.(5) Connect a voltmeter with a range of 0

- 20

V between the generator “B” terminal and the

ground. (Connect the

(+) lead of the voltmeterto the “B” terminal, and then connect the (-)

lead of the voltmeter to the ground.)

(6) Connect a tachometer. (For the procedure forconnecting the tachometer, refer to GROUP

11 - On-vehicle Service.)

(7) Connect the negative battery cable.

(8) Leave the hood open.(9) Check to be sure that the reading on the

voltmeter is equal to the battery voltage.

NOTE

If the voltage is 0 V, the cause is probably an

open circuit in the wire or fusible link between

the generator “B” terminal and the battery

(+)

terminal.

(1O)After turning the light switch on and turning on

the headlights, start the engine.

(1l)lmmediately after setting the headlights to high

beam and turning the heater blower switch to

the high revolution position, increase the enginespeed to 2,500

r/min and read the maximum

current output value displayed on the ammeter.

Limit value: 70% of nominal current output

NOTEl

For the nominal current output, refer to the

Generator Specifications.l

Because the current from the battery will

soon drop after the engine is started, the

above step should be carried out as quickly

as possible in order to obtain the maximum

current output value.l The current output value will depend on

the electrical load and the temperature of

the generator body.l

If the electrical load is small while testing,the specified level of current may not be

output even though the generator is normal.

In such cases, increase the electrical load

by leaving the headlights turned on for sometime to discharge the battery or by using

the lighting system in another vehicle, and

then test again.l

The specified level of current also may not

be output if the temperature of the generator

body or the ambient temperature is too high.

In such cases, cool the generator and then

test again.

(12)The reading on the ammeter should be above

the limit value. If the reading is below the limit

value and the generator output wire is normal,

remove the generator from the engine and check

the generator.(13)Run the engine at idle speed after the test.

(14)Turn the ignition switch to the OFF position.

(15)Disconnect the negative battery cable.

(16)Disconnect the ammeter, voltmeter and

tachometer.(17)Connect the generator output wire to the

generator “B” terminal.

(18)Connect the negative battery cable.

TSB Revision

Page 455 of 738

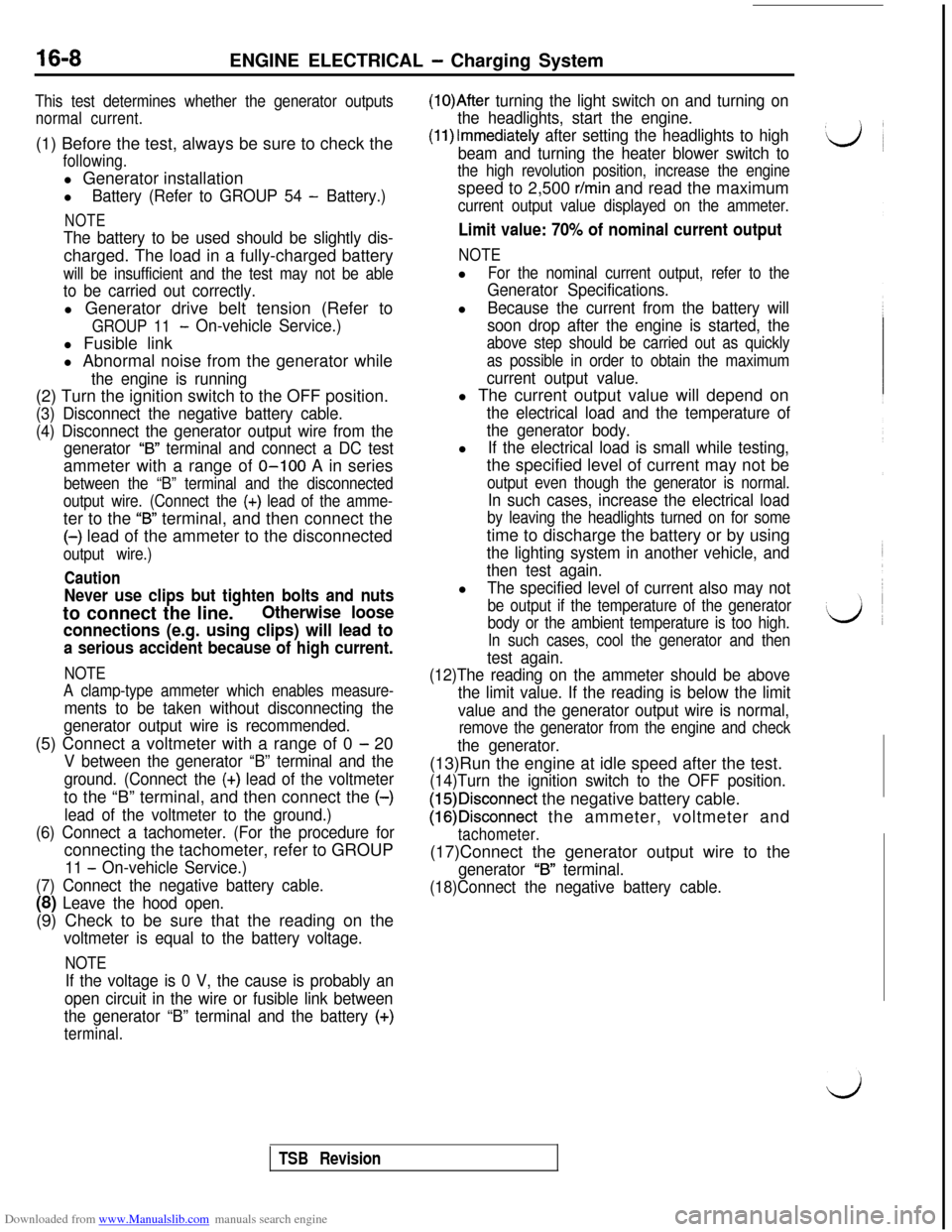

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging Svstem16-9REGULATED VOLTAGE TEST

\:

b

Ignitionswitch (IGl)Generator

This test determines whether the voltage regulator

is correctly controlling the generator output voltage.

(1) Always be sure to check the following before

the test.l Generator installation

lCheck to be sure that the battery installedin the vehicle is fully charged. (Refer to

GROUP 54 - Battery.)l Generator drive belt tension (Refer to

GROUP 00 - Maintenance Service.)l Fusible link

l Abnormal noise from the generator while

the engine is running(2) Turn the ignition switch to the OFF position.

(3) Disconnect the negative battery cable.

(4) Connect a digital-type voltmeter between the

generator “S” terminal and the ground. (Connect

the

(+) lead of the voltmeter to the “s” terminal,

and then connect the (-) lead of the voltmeter

to a secure ground or to the battery (-) terminal.)

(5) Disconnect the generator output wire from the

generator

“B” terminal.(6) Connect a DC test ammeter with a range of

O-100A in series between the “B” terminal andthe disconnected output wire. (Connect the

(+) lead of the ammeter to the “B” terminal,

and then connect the (-) lead of the ammeter

to the disconnected output wire.)

(7) Connect a tachometer. (Refer to GROUP 11

- On-vehicle Service.)

(8) Reconnect the negative battery cable.

VOLTAGE REGULATION TABLE

Ammeter

- Load

6EN1029

(9) Turn the ignition switch to the ON position and

check that the reading on the voltmeter is equal

to the battery voltage.

NOTE

If the voltage is 0 V, the cause is probably an

open circuit in the wire or fusible link between

the generator

“S” terminal and the battery (+)

terminal.

(1O)Check to be sure that all lights and accessories

are off.

(11) Start the engine.(12)lncrease the engine speed to 2,500

r/min.

(13)Read the value displayed on the voltmeter when

the current output by the generator becomes

10A or less.

(14)lf the voltage reading conforms to the value

in the voltage regulation table, then the voltage

regulator is operating normally.If the voltage is outside the standard value,

there is a malfunction of the voltage regulator

or of the generator.

(15)After the test, lower the engine speed to the

idle speed.

(16)Turn the ignition switch to the “OFF” position.

(17)Disconnect the negative battery cable.

(18)Disconnect the ammeter, voltmeter and

tachometer.(19)Connect the generator output wire to the

generator “B” terminal.

(20)Connect the negative battery cable.

Inspection

terminal

Terminal “S”

Voltage regula-Standard value Inspection

torambient (V)terminal

temperature

(“C PI)-20 (-4)14.2-15.4

Terminal “S”

20 (68)13.9-14.9

TSB Revision

Voltage regula- Standard value

torambient (V)

temperature(“c

PI)

60 (140)13.4-14.5

80 (176)13.1-14.5

I

Page 456 of 738

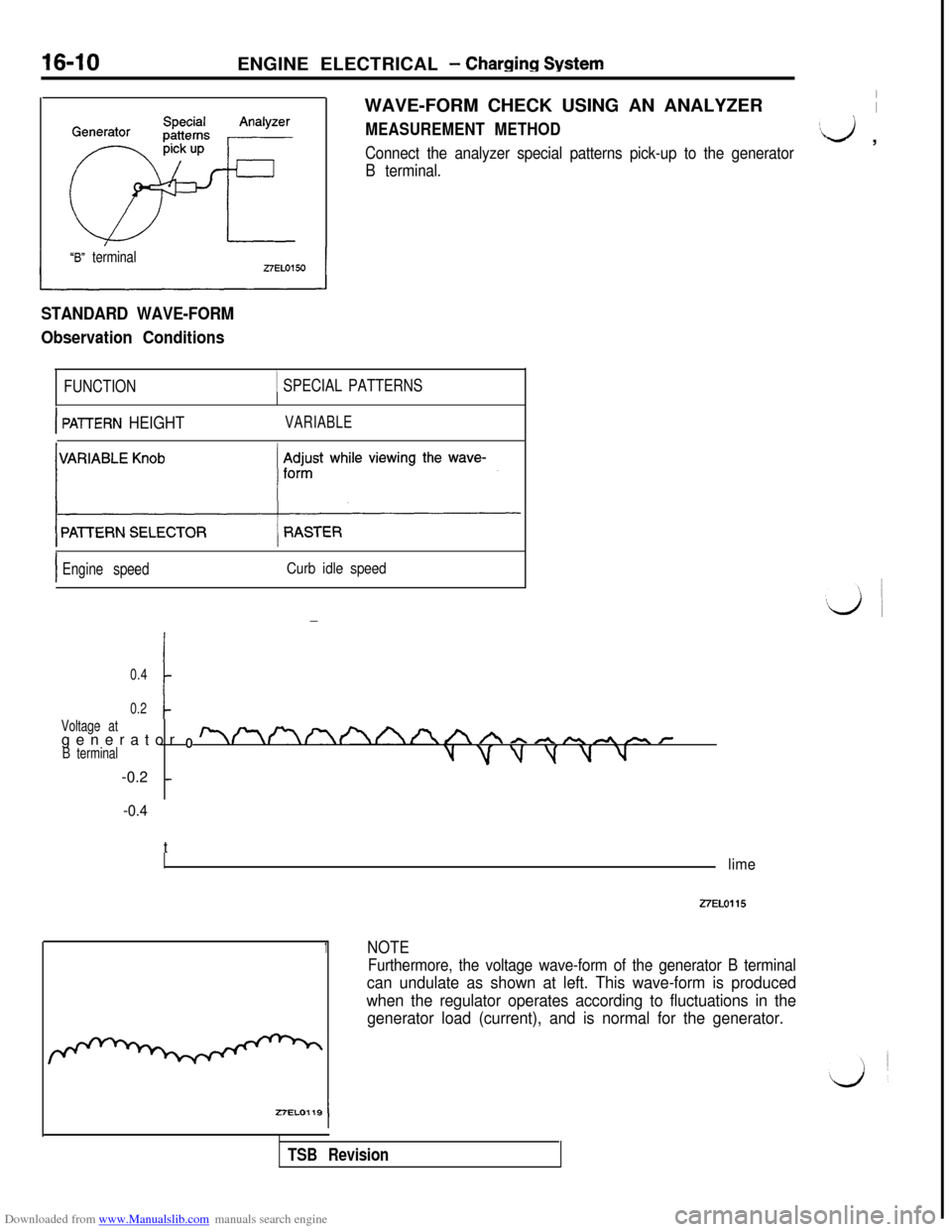

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charqinq SystemWAVE-FORM CHECK USING AN ANALYZER

II

MEASUREMENT METHOD

Connect the analyzer special patterns pick-up to the generator

:L.J ,

B terminal.

I“B” terminalZ7ELOlSlI

STANDARD WAVE-FORM

Observation Conditions

FUNCTION1 SPECIAL PATTERNS

IPATTERN HEIGHTVARIABLEAdjust while viewing the

wave-

{

IEngine speedCurb idle speed

-

0.4

0.2

IVoltage atgenerator 0 p7r-\fTfTfi/\AJ\ I+ h A fi 4 n rB terminal-0.2

-

-0.4t

lime

27ELOl15

1NOTE

Furthermore, the voltage wave-form of the generator B terminal

can undulate as shown at left. This wave-form is produced

when the regulator operates according to fluctuations in the

generator load (current), and is normal for the generator.

TSB Revision

Page 457 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System16-11

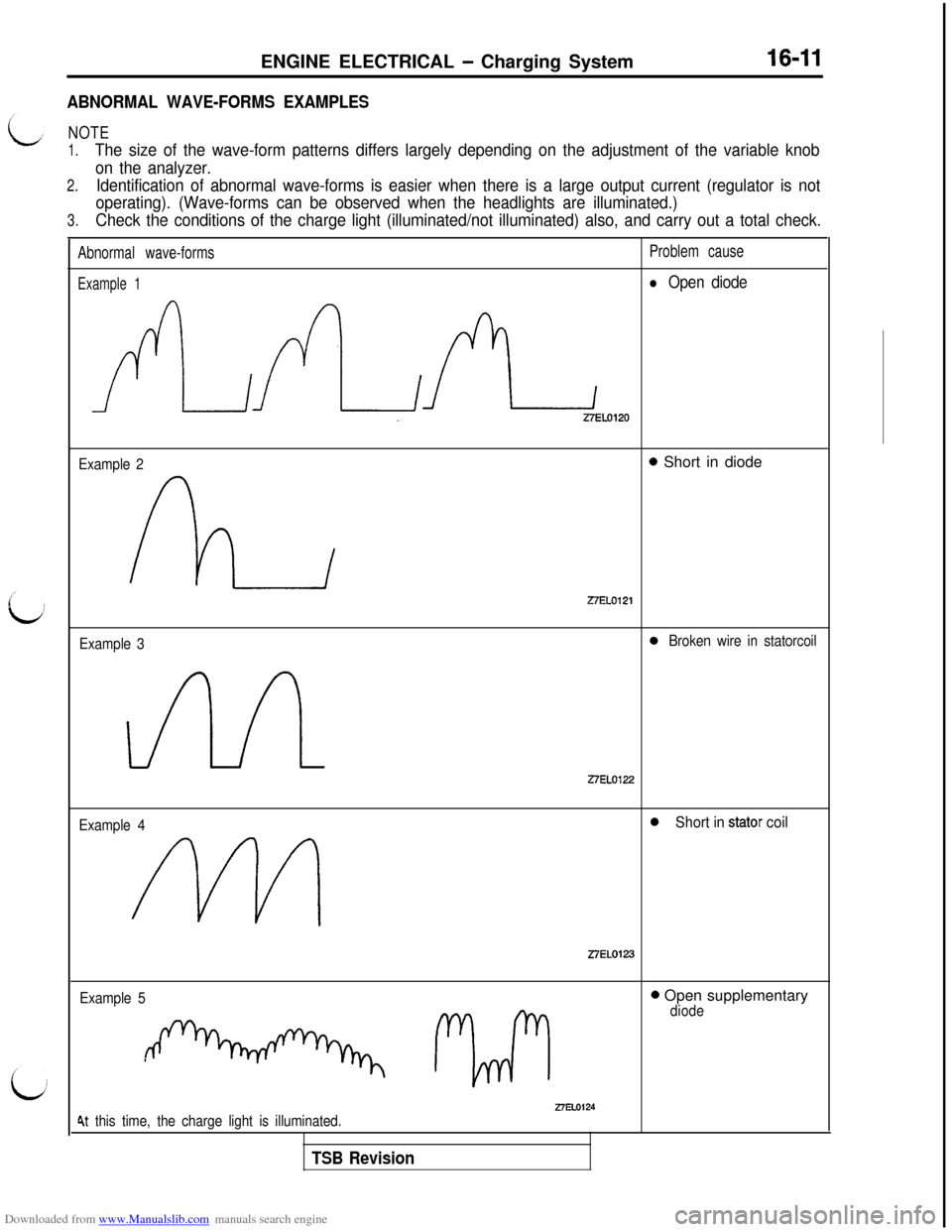

ABNORMAL WAVE-FORMS EXAMPLES

NOTE

1.The size of the wave-form patterns differs largely depending on the adjustment of the variable knob

on the analyzer.

2.Identification of abnormal wave-forms is easier when there is a large output current (regulator is not

operating). (Wave-forms can be observed when the headlights are illuminated.)

3.Check the conditions of the charge light (illuminated/not illuminated) also, and carry out a total check.

Abnormal wave-formsProblem cause

Example 1l Open diode

AALZELOlZO

Example 20 Short in diodeZ7EL0121

Example 30Broken wire in statorcoil

27EL0122

Example 40Short in stator coil

Z7EL0123

Example 5

1 r2rrirl

0 Open supplementarydiode

27EL01244t this time, the charge light is illuminated.

TSB Revision

Page 462 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System

h\Z3ELOlO

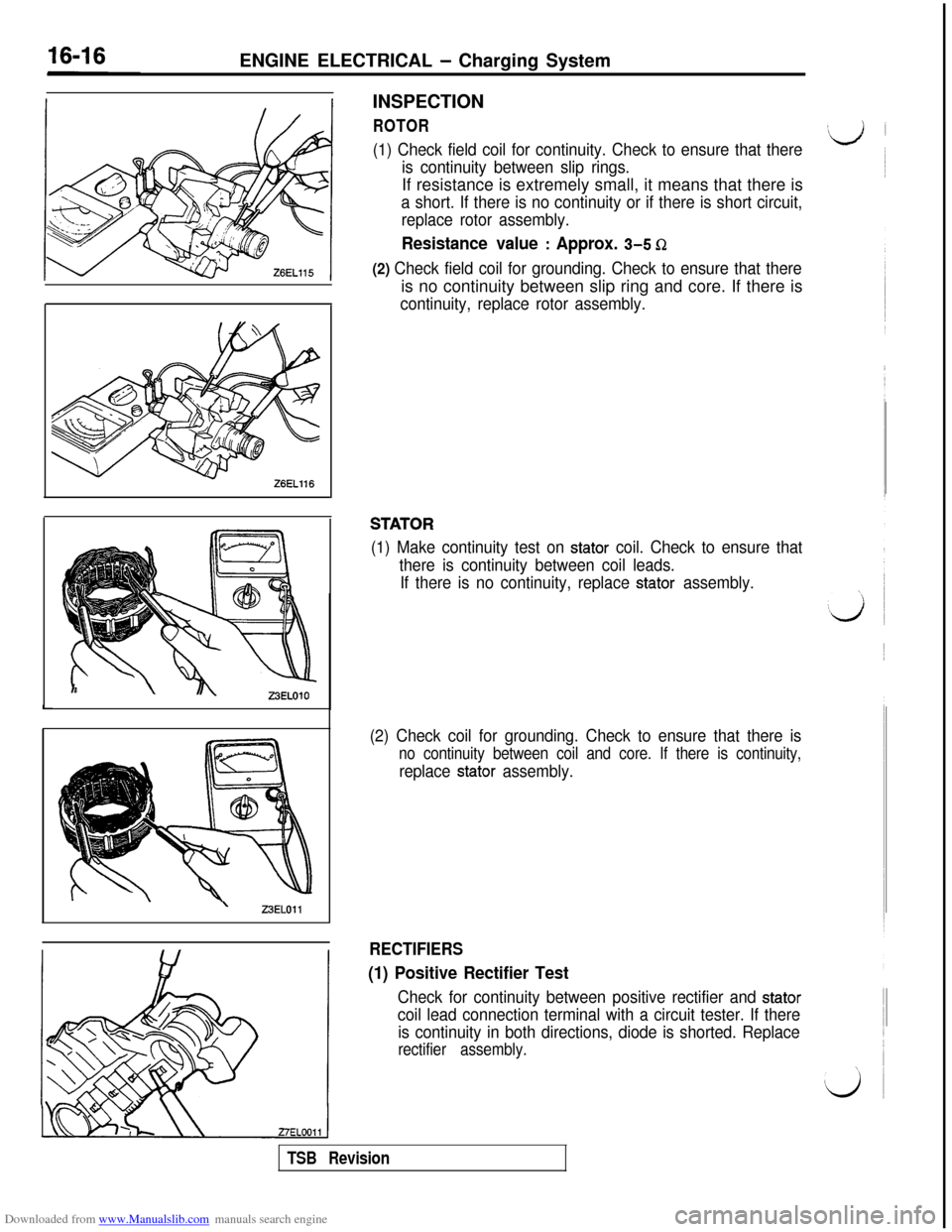

\23ELOllINSPECTION

ROTOR

(1) Check field coil for continuity. Check to ensure that there

is continuity between slip rings.If resistance is extremely small, it means that there is

a short. If there is no continuity or if there is short circuit,

replace rotor assembly.

Resistance value : Approx. 3-5 Q

(2) Check field coil for grounding. Check to ensure that thereis no continuity between slip ring and core. If there is

continuity, replace rotor assembly.

STATOR

(1) Make continuity test on stator coil. Check to ensure that

there is continuity between coil leads.

If there is no continuity, replace

stator assembly.

(2) Check coil for grounding. Check to ensure that there is

no continuity between coil and core. If there is continuity,

replace stator assembly.

RECTIFIERS

(1) Positive Rectifier Test

Check for continuity between positive rectifier and stator

coil lead connection terminal with a circuit tester. If there

is continuity in both directions, diode is shorted. Replace

rectifier assembly.

TSB Revision

Page 463 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System16-17

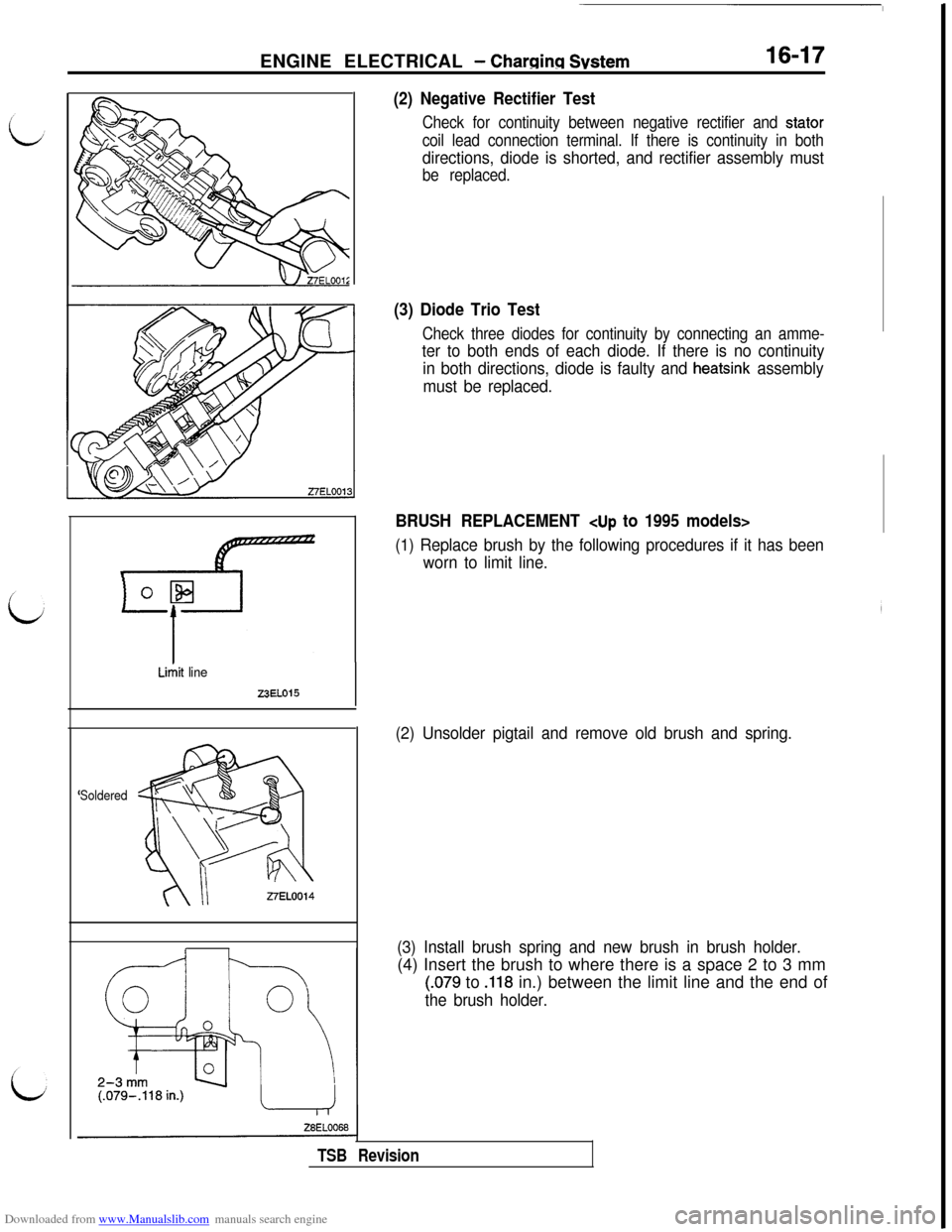

Limit line

WELO

,Soldered

27EL0014

(2) Negative Rectifier Test

Check for continuity between negative rectifier and stator

coil lead connection terminal. If there is continuity in both

directions, diode is shorted, and rectifier assembly must

be replaced.

(3) Diode Trio Test

Check three diodes for continuity by connecting an amme-

ter to both ends of each diode. If there is no continuity

in both directions, diode is faulty and

heatsink assembly

must be replaced.

BRUSH REPLACEMENT

(1) Replace brush by the following procedures if it has been

worn to limit line.

(2) Unsolder pigtail and remove old brush and spring.

(3) Install brush spring and new brush in brush holder.(4) Insert the brush to where there is a space 2 to 3 mm

(.079 to .118 in.) between the limit line and the end of

the brush holder.

TSB Revision

Page 469 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-23

OPERATION

L

0For models equipped with the M/T, the clutch

pedal position switch contact is switched OFF

when the clutch pedal is depressed; when the

ignition switch is then switched to the “ST’ posi-tion, electricity flows to the starter relay and

the starter motor, the contact (magnetic switch)of the starter is switched ON and the starter

motor is activated.

NOTEIf the ignition switch is switched to the “ST

position without the clutch pedal being de-

pressed, electricity flows to the starter relay

(coil), the clutch pedal position switch (contacts)

and to ground, with the result that the contacts

of the starter relay are switched OFF, and, be-

cause the power to the starter motor is thereby

interrupted, the starter motor is not activated.lFor models equipped with the

AIT, when the

ignition switch is switched to the “ST’ position

while the selector lever is at the “P” or “N” posi-

tion, the contact (magnetic switch) of the starter

is switched ON and the starter motor is activated.

TROUBLESHOOTING HINTSThe starter motor does not operate at all.

l Check the starter (coil).

lCheck for poor contact at the battery terminals

and starter.l Check Park/Neutral position switch.

l Check clutch pedal position switch.

l Check starter relay.

l Check theft-alarm starter relay.

l Check key reminder switch.

i

/’

L&J

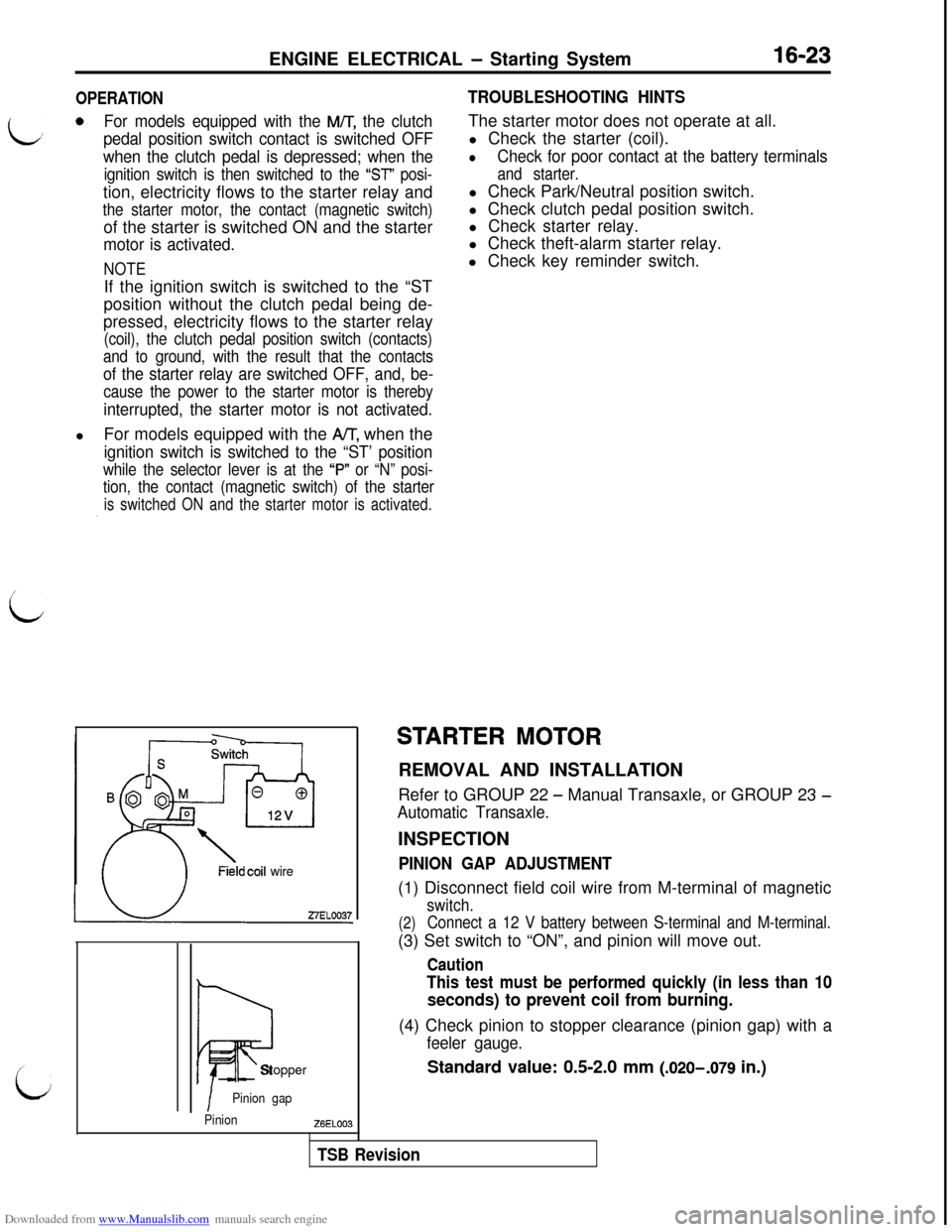

Fieldcoil wire

Iii?Stopper

IPinion gap

PinionZ6EL003

STARTER MOTORREMOVAL AND INSTALLATION

Refer to GROUP 22

- Manual Transaxle, or GROUP 23 -

Automatic Transaxle.INSPECTION

PINION GAP ADJUSTMENT(1) Disconnect field coil wire from M-terminal of magnetic

switch.

(2)Connect a 12 V battery between S-terminal and M-terminal.(3) Set switch to “ON”, and pinion will move out.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.(4) Check pinion to stopper clearance (pinion gap) with a

feeler gauge.

Standard value: 0.5-2.0 mm (.020-,079 in.)

TSB Revision

Page 471 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-25

L

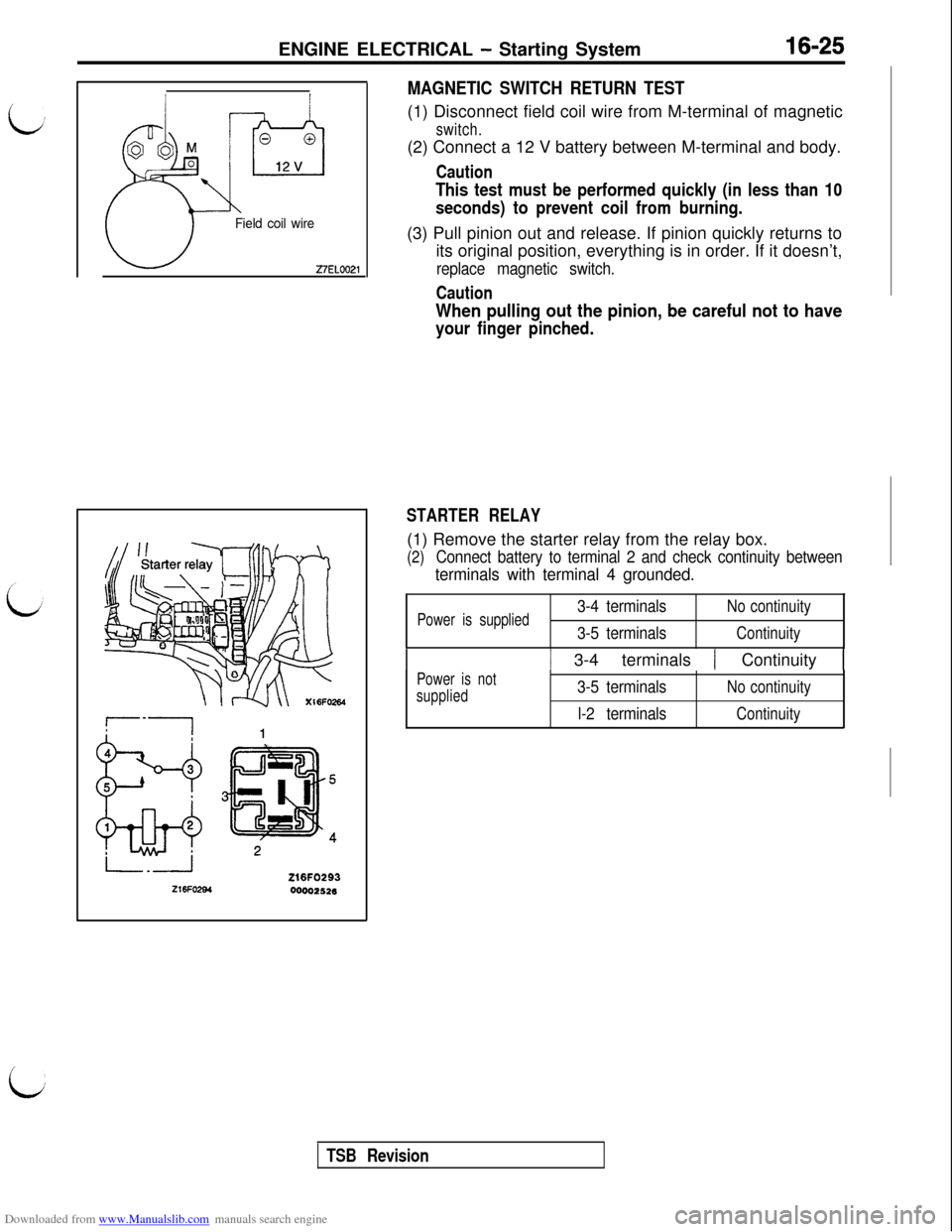

Field coil wire27EL0021216Fo264

00002526

MAGNETIC SWITCH RETURN TEST(1) Disconnect field coil wire from M-terminal of magnetic

switch.(2) Connect a 12 V battery between M-terminal and body.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.(3) Pull pinion out and release. If pinion quickly returns to

its original position, everything is in order. If it doesn’t,

replace magnetic switch.

Caution

When pulling out the pinion, be careful not to have

your finger pinched.

STARTER RELAY(1) Remove the starter relay from the relay box.

(2)Connect battery to terminal 2 and check continuity between

terminals with terminal 4 grounded.

Power is supplied3-4 terminals

3-5 terminalsNo continuity

Continuity

/ 3-4 terminals / Continuity 1

Power is not

supplied3-5 terminals

l-2 terminalsNo continuity

Continuity

i

TSB Revision