engine MITSUBISHI 3000GT 1992 2.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1992, Model line: 3000GT, Model: MITSUBISHI 3000GT 1992 2.GPages: 738, PDF Size: 35.06 MB

Page 471 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-25

L

Field coil wire27EL0021216Fo264

00002526

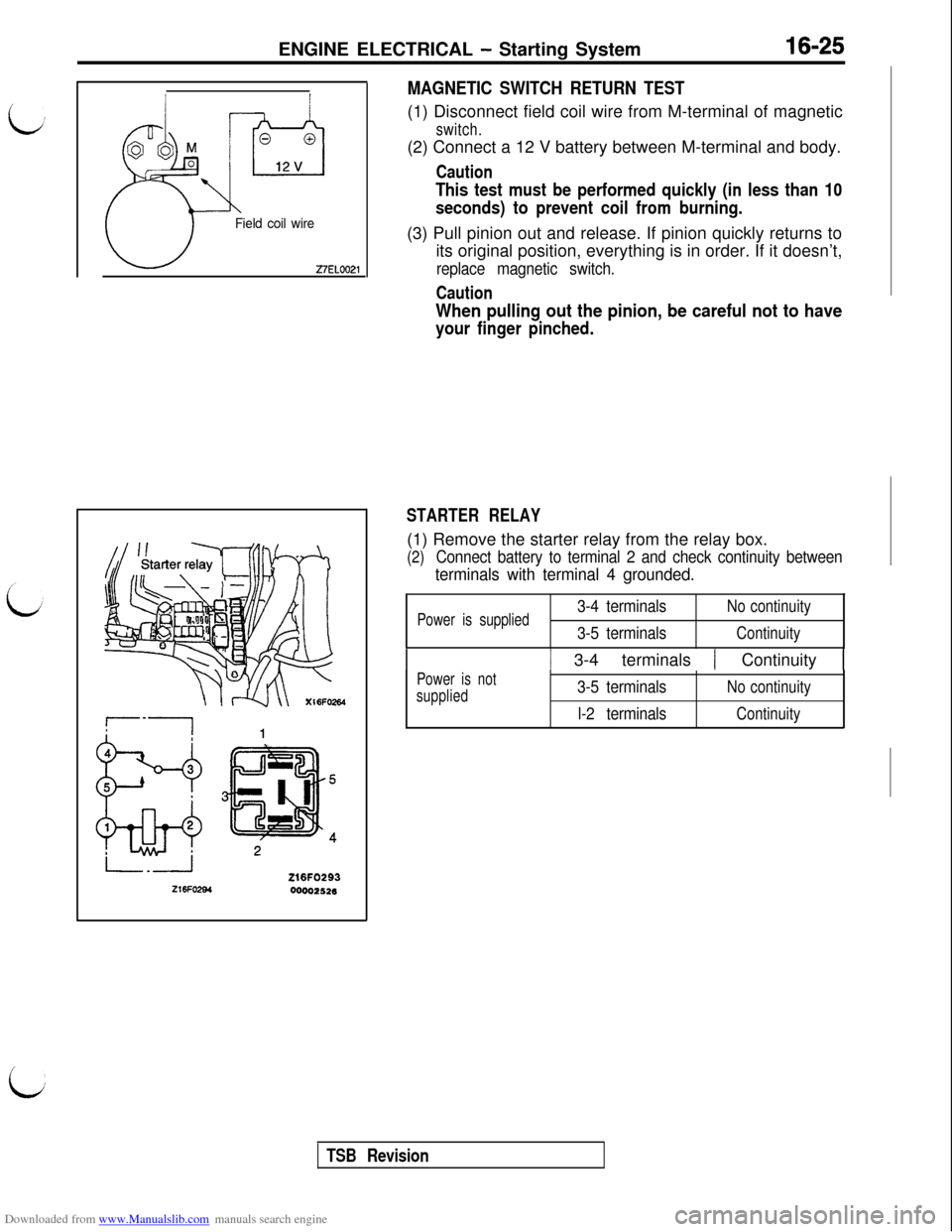

MAGNETIC SWITCH RETURN TEST(1) Disconnect field coil wire from M-terminal of magnetic

switch.(2) Connect a 12 V battery between M-terminal and body.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.(3) Pull pinion out and release. If pinion quickly returns to

its original position, everything is in order. If it doesn’t,

replace magnetic switch.

Caution

When pulling out the pinion, be careful not to have

your finger pinched.

STARTER RELAY(1) Remove the starter relay from the relay box.

(2)Connect battery to terminal 2 and check continuity between

terminals with terminal 4 grounded.

Power is supplied3-4 terminals

3-5 terminalsNo continuity

Continuity

/ 3-4 terminals / Continuity 1

Power is not

supplied3-5 terminals

l-2 terminalsNo continuity

Continuity

i

TSB Revision

Page 472 of 738

Downloaded from www.Manualslib.com manuals search engine 16-26ENGINE ELECTRICAL - Starting System

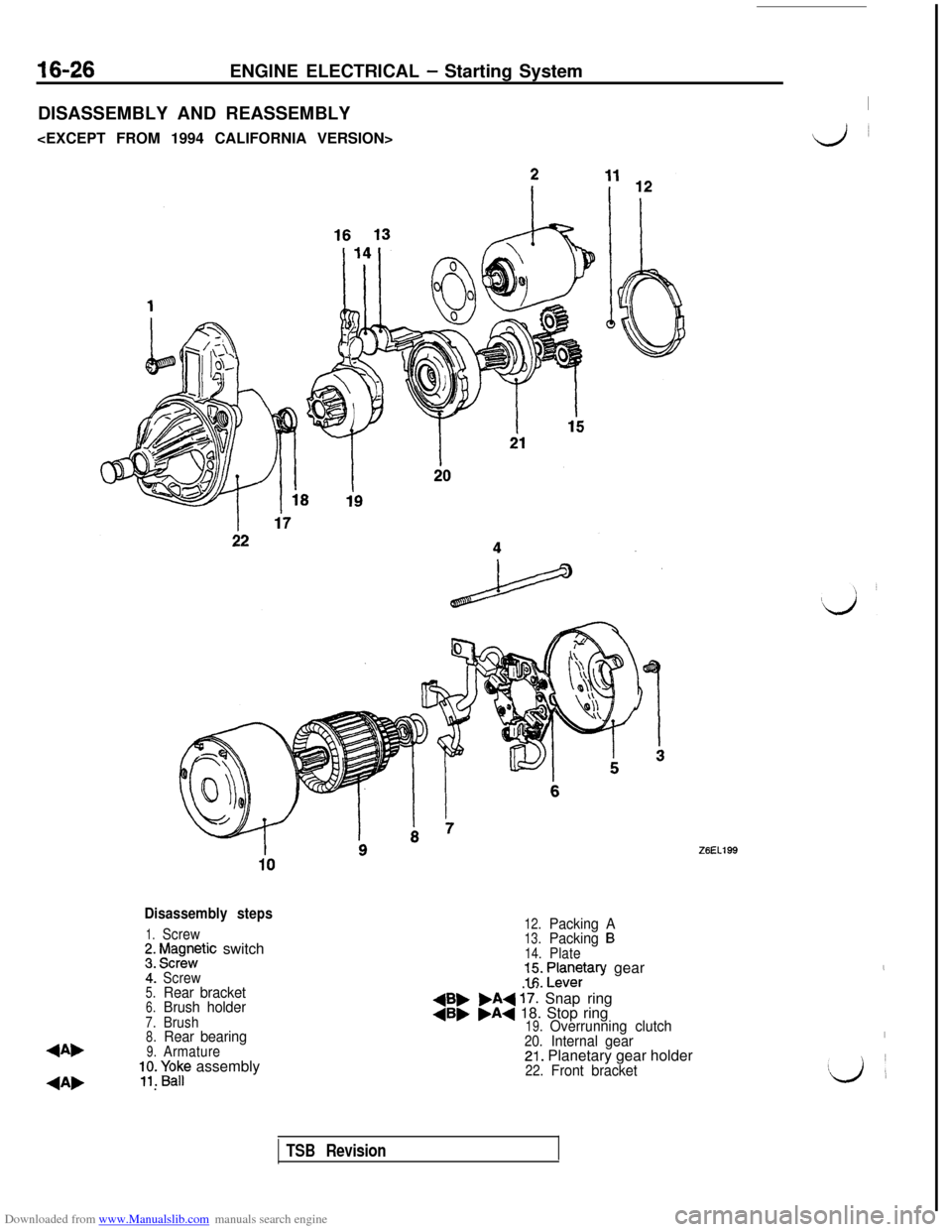

DISASSEMBLY AND REASSEMBLY

I

Lj~

Disassembly steps

1.Screw;. f$gnntic switch

4:Screw5.Rear bracket6.Brush holder7.Brush8.Rear bearing

4Ab9.Armature;;. paF assembly

4A, .

12.Packing A13.Packing B14.Plate=I:. ;an$ary gear

+B, .A+ 17: Snap ring4B, .A+ 18. Stop ring19.Overrunning clutch20.Internal gear21. Planetary gear holder22.Front bracket

,

I!Lj

’

TSB Revision

Page 473 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-27

27EN0628

1'0

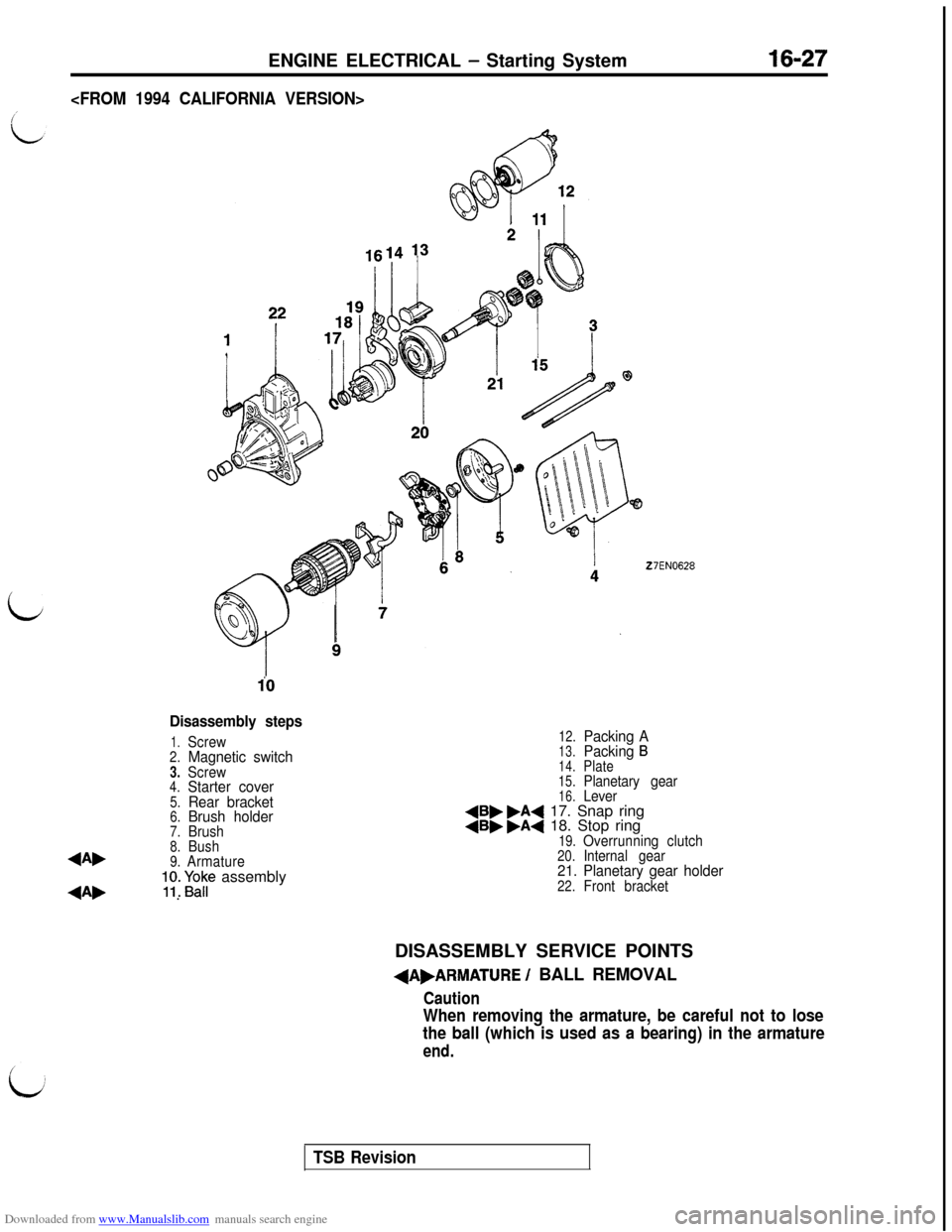

Disassembly steps

1.Screw2.Magnetic switch3.Screw4.Starter cover5.Rear bracket6.Brush holder7.Brush8.Bush4A,9.Armature;y. Fap assembly

4A, .

12.Packing A13.Packing B

14.Plate

15.Planetary gear16.Lever4B, .A4 17. Snap ring4B, .A4 18. Stop ring19.Overrunning clutch20.Internal gear21. Planetary gear holder22.Front bracketDISASSEMBLY SERVICE POINTS

+A,ARMATURE / BALL REMOVAL

Caution

When removing the armature, be careful not to lose

the ball (which is used as a bearing) in the armature

end.

TSB Revision

Page 474 of 738

Downloaded from www.Manualslib.com manuals search engine 16-28ENGINE ELECTRICAL - Starting System

Stop ringZ6EL0097

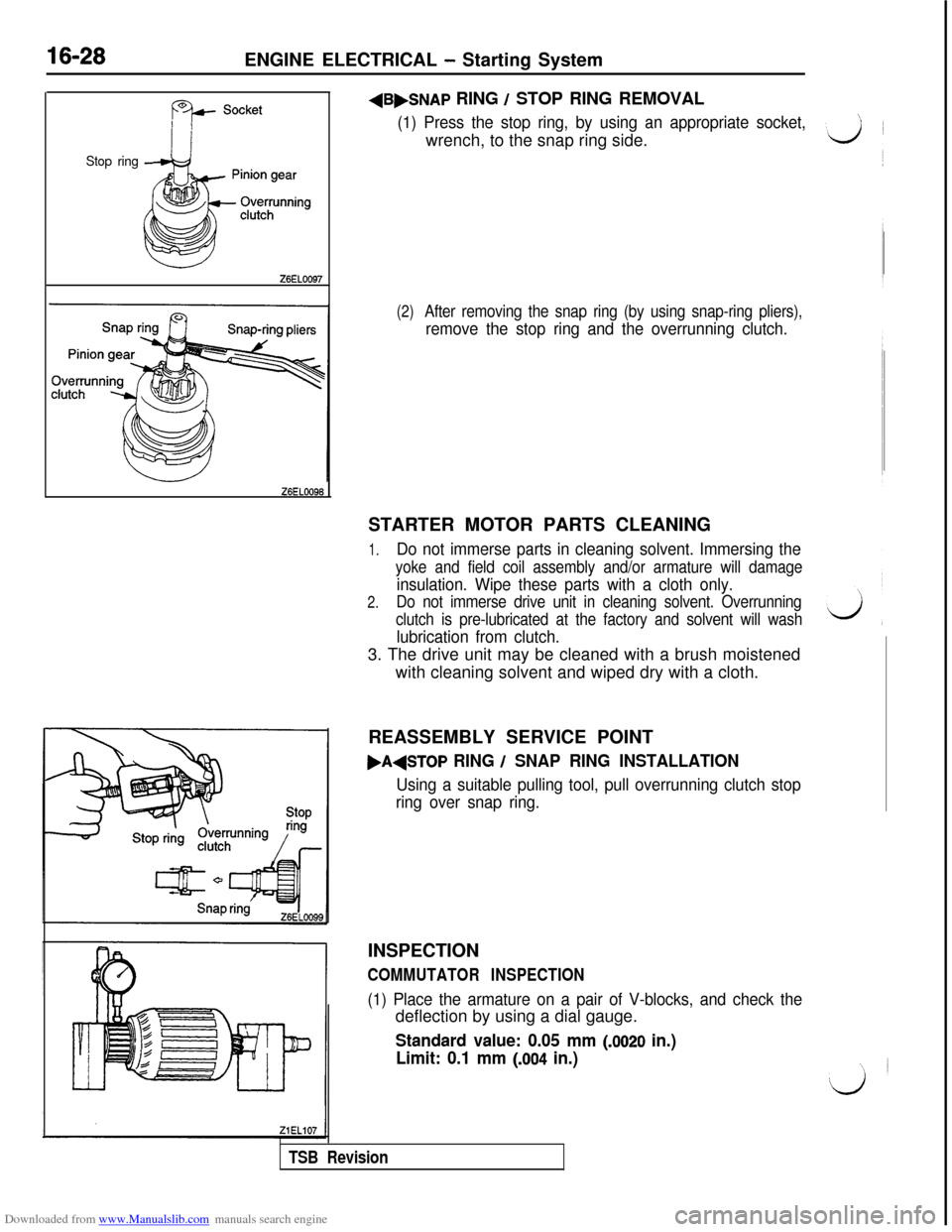

Z6ELOO96+B,SNAP

RING / STOP RING REMOVAL

(1) Press the stop ring, by using an appropriate socket,wrench, to the snap ring side.

(2)After removing the snap ring (by using snap-ring pliers),

remove the stop ring and the overrunning clutch.STARTER MOTOR PARTS CLEANING

1.Do not immerse parts in cleaning solvent. Immersing the

yoke and field coil assembly and/or armature will damage

insulation. Wipe these parts with a cloth only.

2.Do not immerse drive unit in cleaning solvent. Overrunning

clutch is pre-lubricated at the factory and solvent will wash

lubrication from clutch.3. The drive unit may be cleaned with a brush moistened

with cleaning solvent and wiped dry with a cloth.

REASSEMBLY SERVICE POINT

,A+TOP RING / SNAP RING INSTALLATION

Using a suitable pulling tool, pull overrunning clutch stop

ring over snap ring.INSPECTION

COMMUTATOR INSPECTION

(1) Place the armature on a pair of V-blocks, and check thedeflection by using a dial gauge.

Standard value: 0.05 mm (JO20 in.)

Limit: 0.1 mm

(.004 in.)

TSB Revision

Page 475 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-29

ZiELllS

UndercutI

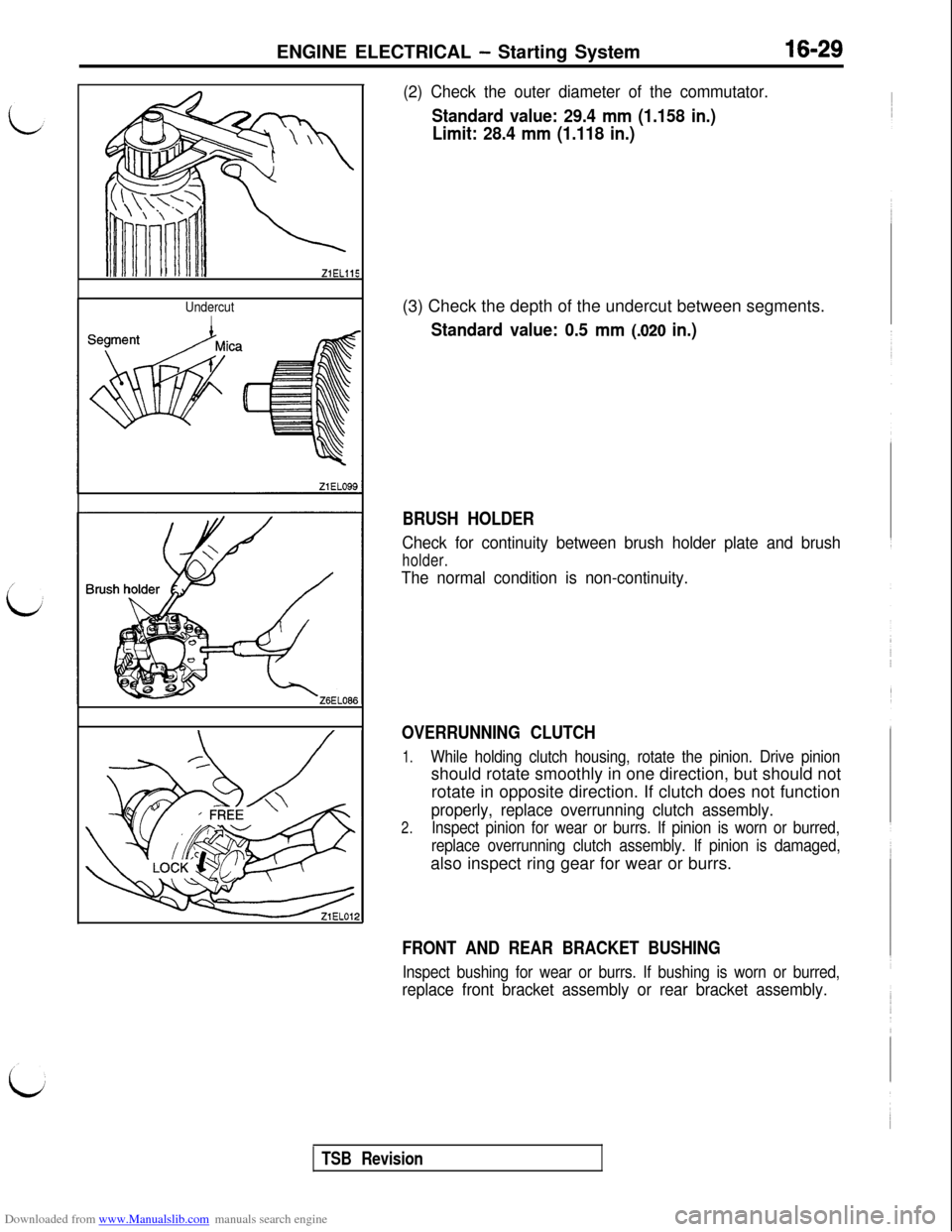

(2) Check the outer diameter of the commutator.

Standard value: 29.4 mm (1.158 in.)

Limit: 28.4 mm (1.118 in.)(3) Check the depth of the undercut between segments.

Standard value: 0.5 mm (.020 in.)

BRUSH HOLDER

Check for continuity between brush holder plate and brush

holder.

The normal condition is non-continuity.

OVERRUNNING CLUTCH

1.While holding clutch housing, rotate the pinion. Drive pinionshould rotate smoothly in one direction, but should not

rotate in opposite direction. If clutch does not function

properly, replace overrunning clutch assembly.

2.Inspect pinion for wear or burrs. If pinion is worn or burred,

replace overrunning clutch assembly. If pinion is damaged,also inspect ring gear for wear or burrs.

FRONT AND REAR BRACKET BUSHING

Inspect bushing for wear or burrs. If bushing is worn or burred,

replace front bracket assembly or rear bracket assembly.

TSB Revision

Page 476 of 738

Downloaded from www.Manualslib.com manuals search engine 16-30ENGINE ELECTRICAL - Starting System

Eq

C-- Wear limit line

-

New brush

Soldered

(Make sure that

there is no

excess solder on

brush surface)

Surface

Amarked

Zl EL049

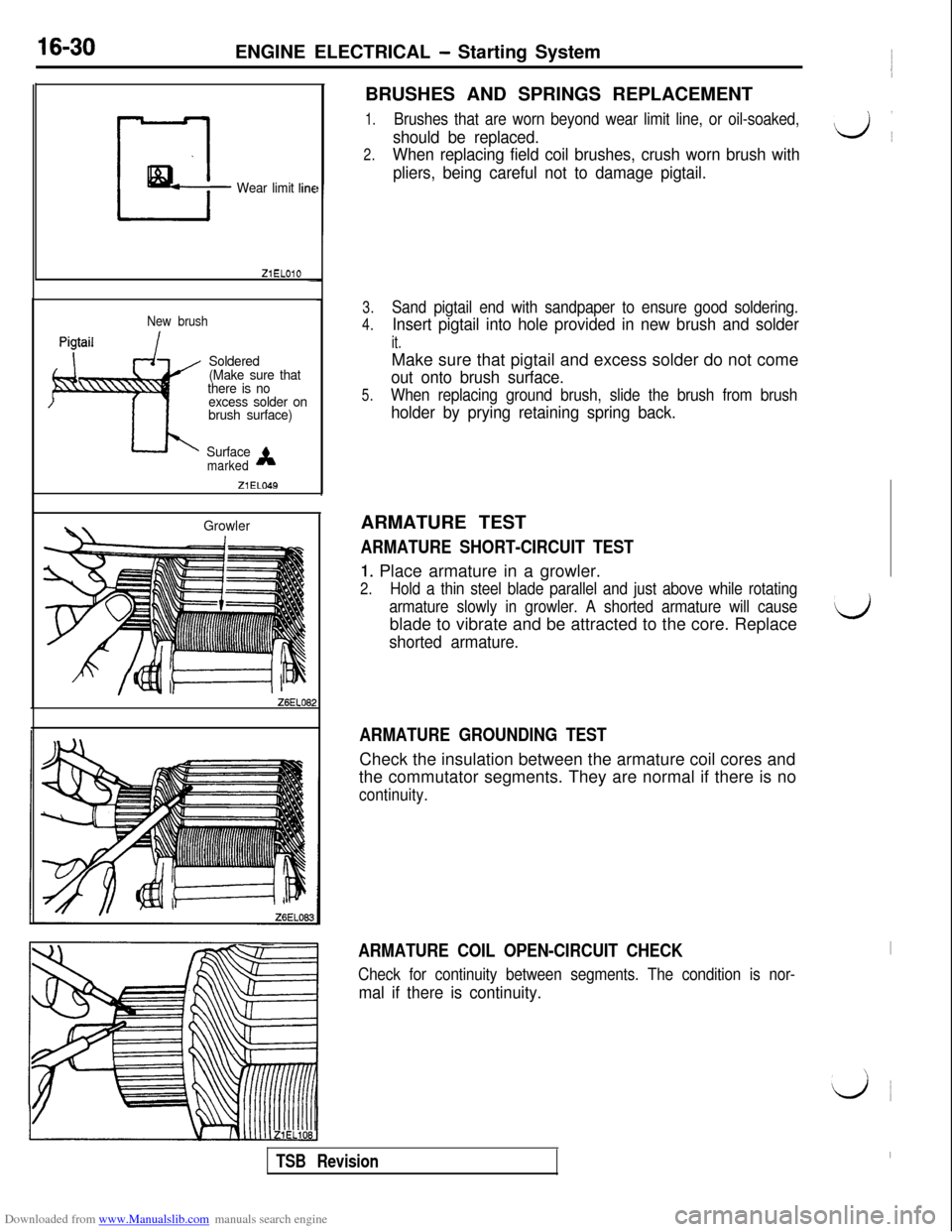

GrowlerBRUSHES AND SPRINGS REPLACEMENT

1.Brushes that are worn beyond wear limit line, or oil-soaked,

should be replaced.do

2.When replacing field coil brushes, crush worn brush with

pliers, being careful not to damage pigtail.

3.

4.Sand pigtail end with sandpaper to ensure good soldering.

Insert pigtail into hole provided in new brush and solder

it.Make sure that pigtail and excess solder do not come

out onto brush surface.

5.When replacing ground brush, slide the brush from brush

holder by prying retaining spring back.ARMATURE TEST

ARMATURE SHORT-CIRCUIT TEST

1. Place armature in a growler.

2.Hold a thin steel blade parallel and just above while rotating

armature slowly in growler. A shorted armature will causeblade to vibrate and be attracted to the core. Replace

shorted armature.

ARMATURE GROUNDING TESTCheck the insulation between the armature coil cores and

the commutator segments. They are normal if there is no

continuity.

ARMATURE COIL OPEN-CIRCUIT CHECK

Check for continuity between segments. The condition is nor-

mal if there is continuity.

TSB Revision

Page 477 of 738

Downloaded from www.Manualslib.com manuals search engine i/ENGINE ELECTRICAL

- Ignition System

IGNITION SYSTEM

16-31

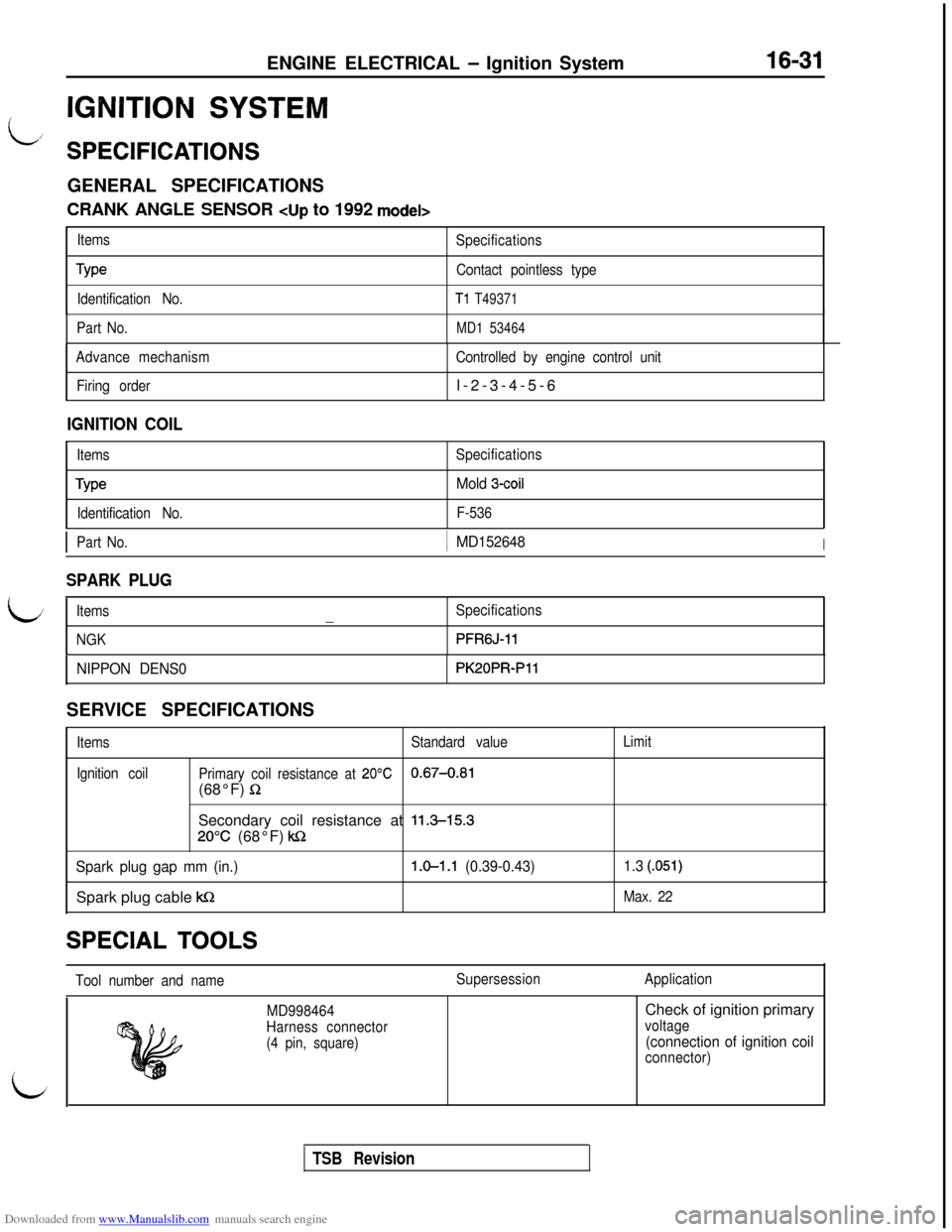

SPECIFICATIONSGENERAL SPECIFICATIONS

CRANK ANGLE SENSOR cup to 1992 model>

Items

Specifications

TypeContact pointless type

Identification No.

Tl T49371

Part No.MD1 53464

Advance mechanism

Firing orderControlled by engine control unitl-2-3-4-5-6

IGNITION COILrItems

Type

Identification No.SpecificationsMold 3-coil

F-536

L

IPart No.j MD152648I

SPARK PLUG

Items

NGK-Specifications

PFRGJ-11

NIPPON DENS0PK20PRPllSERVICE SPECIFICATIONS

Items

Ignition coilStandard valueLimit

Primary coil resistance at

20°C0.67-0.81(68°F)

RSecondary coil resistance at

11.3-15.3

20°C (68°F) kc2

Spark plug gap mm (in.)1.0-l .l (0.39-0.43)Spark plug cable

kQ

1.3 (.051)

Max. 22SPECIAL

TOOLS

Tool number and nameSupersessionApplication

i

MD998464

Harness connector

(4 pin, square)Check of ignition primaryvoltage

(connection of ignition coil

connector)

i

TSB Revision

Page 478 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - lanition Svstem

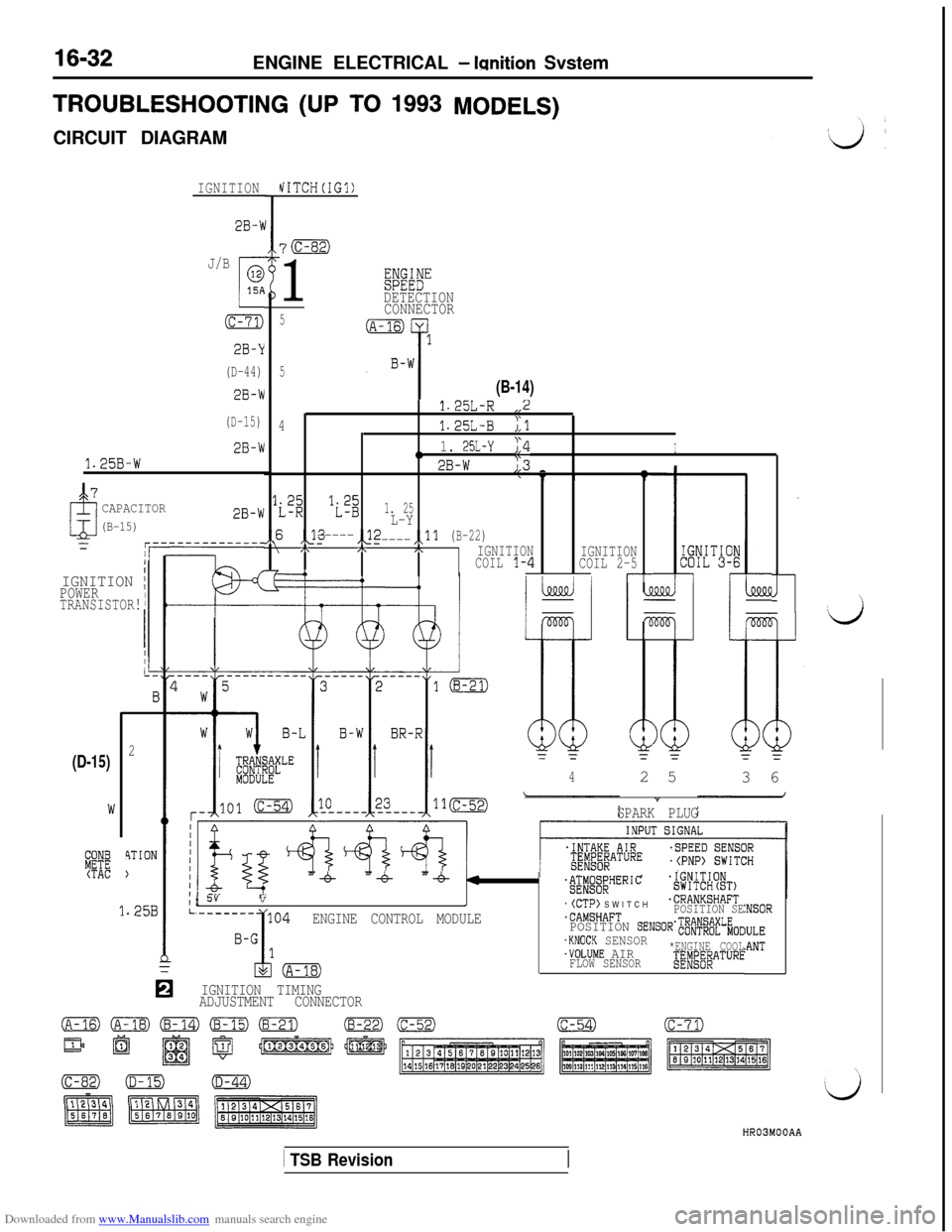

TROUBLESHOOTING (UP TO 1993MODELS)CIRCUIT DIAGRAM

IGNITIONhiITCH(IG1)

2B-X

7m

1

J/B

c

015A

(c-71)

2B-Y

(D-44)

2B-W

(D-15)

2B-W

1.25B-W

@%t”DETECTION

CONNECTOR

5

5

(B-14)

1.25L-R,,2

41.25L-B;,l

,,1. 25L-Y;,4I

2B-W23_

y;'$1. 25L-Y

A6 ,P-----,\22-----,,ll(B-22) /\,h,\IGNITION

IGNITIONCOIL1-4COIL2-5-r--

CAPACITOR

(B-15)2B-W

1/IGNITION IPOWERTRANSISTOR!rl

2

4TION

)

(D-15)

3%(TAC

42 5

3 6

”

SPARK PLUG

1.25B

IIIIIIII1IL

“-6% “-6 “-4%4;ig;f;HERIC.IGNITIONSWITCHtST)/ 5vv.(CTP) SWITCH.CRANKSHAFT

.CAMSHAFTPOSITION SEENGINE CONTROL MODULEPOSITION SENSOR';#$;~L;oc.KNOCK SENSOR.VOLUME AIR*ENGINE COOL

FLOW SENSOR;ED&f$AT"RE

:NSOR

IULE:ANT

IGNITION TIMING

ADJUSTMENT CONNECTOR

HR03MOOAA

1 TSB Revision

Page 479 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition Svstem

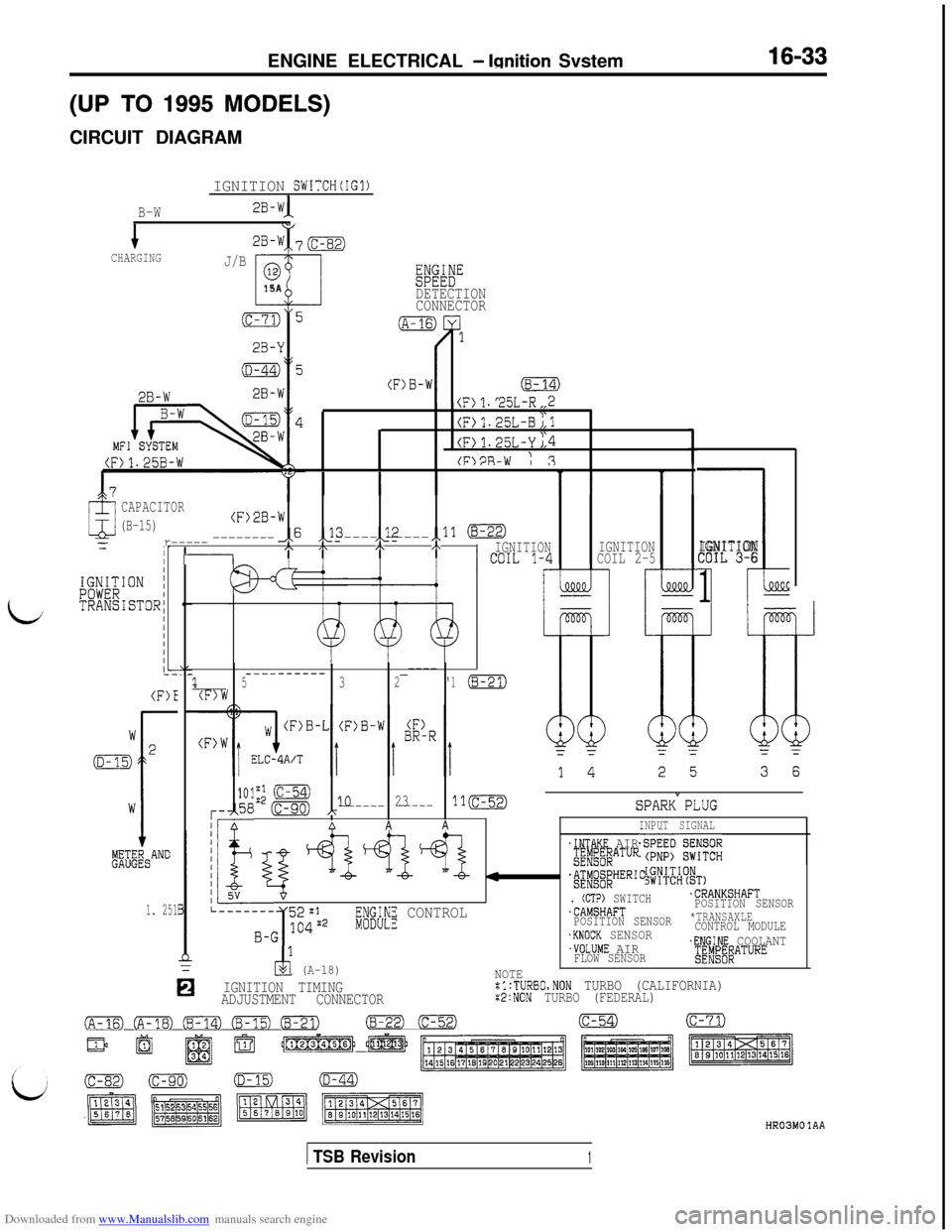

(UP TO 1995 MODELS)CIRCUIT DIAGRAM

IGNITION SWITCH(IG1)

B-W

1CHARGING33-W 70

J/B0

t15A

(c-71)5

2B-Y

2B-W

WEDETECTION

CONNECTOR

\I/1. c5L-R,,2

(F)1.25L-B;,lI'(F>1.25L-Y J,4

(FlPR-W : 3

CAPACITOR

(B-15)(F)2B-W

,x6 ,J3,_12=r------------------ -----,,ll (B-22)

iI -,\ I\,\,\IGNITION' ""TL 1-4IGNITION

COIL 2-5

i

IGNITION

COIL 3-6

1

(F)E_________-----------_----1532'1(8-21)(F)W

101;; (C-54)

r-,58 (c-90) A

1o23-----------ll(c-52)

I/ AAAA

SPARK"PLUG

INPUT SIGNAL

&i&AND

1. 251

!I

~~$yqppQ.INTAKE AIRgE;g;EATUREsiKz&G

'&$AT~~;HER'C

k-_""_---- 52~1. (CTP) SWITCH.CRANKSHAFT

3.CAMSHAFTPOSITION SENSOR

B-G 104g2

I

if;INE CONTROLPOSITION SENSOR*TRANSAXLE

.KNOCK SENSORCONTROL MODULE

2 (A-18)

.VOLUME AIR.ENGINE COOLANT

FLOW SENSOR$~~~~~ATURE

0

NOTEIGNITION TIMING:l:TURBO,NON TURBO (CALIFORNIA)ADJUSTMENT CONNECTORx2:NON TURBO (FEDERAL)

FE) CFm) (B-14) Em3 EFZTJ(B-22)-(c-54)(c-71)

/$J$mb @f-@

ok4 Oh,

( TSB Revision1

HR03MO 1AA

Page 480 of 738

Downloaded from www.Manualslib.com manuals search engine 16-34ENGINE ELECTRICAL - Ignition System

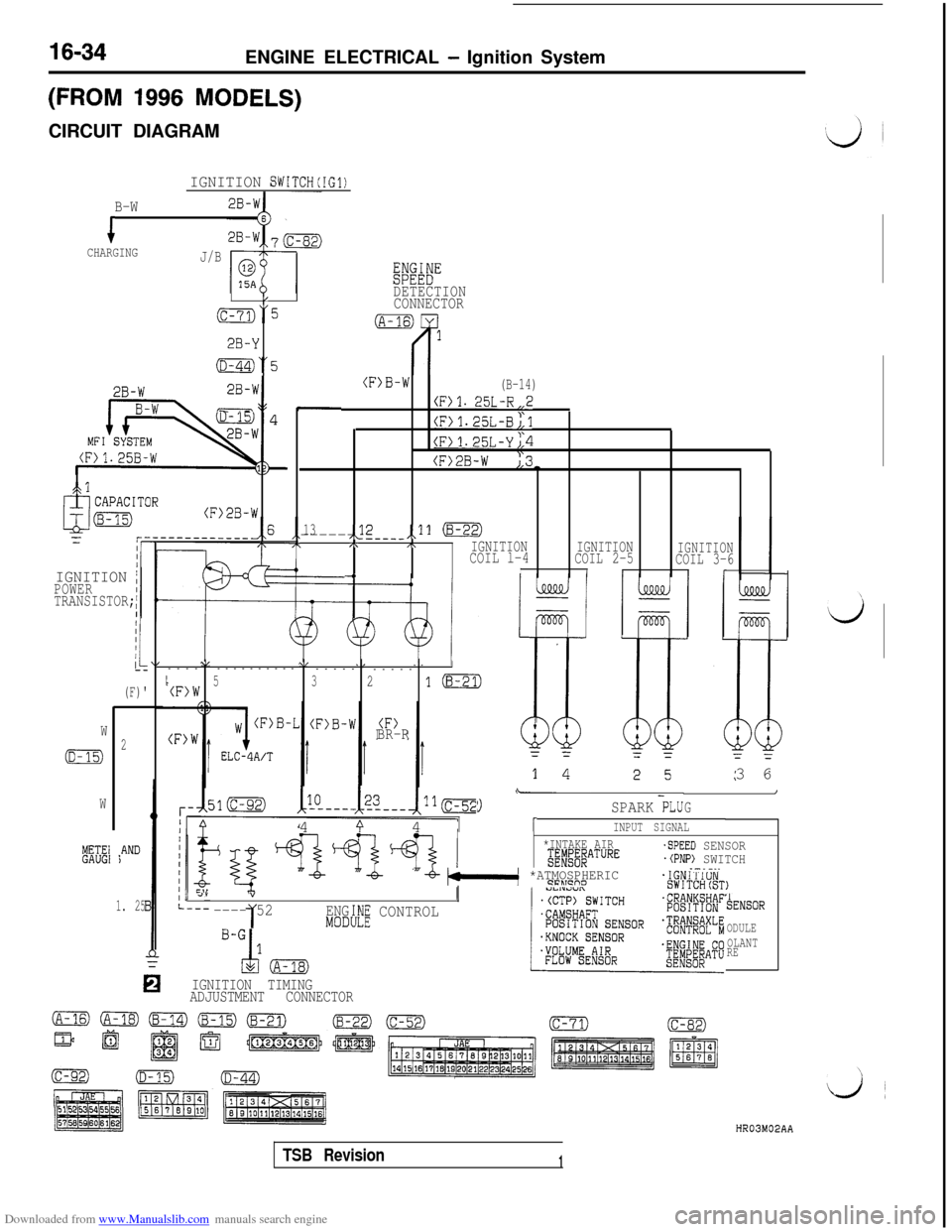

(FROM 1996 MODELS)CIRCUIT DIAGRAM

IGNITION SWITCH(IG1)

B-W

iCHARGINGJ/B

Eiwi"

/DETECTION

(c-73)“5CONNECTOR

2B-Y

(D-44)“5

2B-W-I

2B-W

MFILS - --

(F>B-W(B-14)

(F)l. 25L-R,,2

(F)1.25L-B;,l

(F>1.25L-Yj,4

(F>2B-W ),3-

.

13,<2------ ---__,,11 (8-22),\,\IGNITIONCOIL l-4IGNITION

COIL 2-5IGNITIONCOIL 3-6-4III(r

,cl

(F>2B-W

IGNITION /POWER

TRANSISTOR;

I

(F)'

\I\/,I--------------

-----

-----

I5(F)W321m

BR-RW

(D-15)2

W

METE1GAUGI*AND)3 6

\-I

G9SPARK PLU4

9 41INPUT SIGNAL

*INTAKE AIRg;#j#ATURE

"-b- bkl *ATMOSPHERIC9FLTcno

-SPEED SENSOR.(PNP) SWITCH.-.-..

, 4””

---- 521ENG:h!E CONTROLMODI

TENSOR

ODULE

OLANT

RE

IGNITION TIMING

ADJUSTMENT CONNECTOR

1. 25

HR03M02AA

TSB Revision1