engine MITSUBISHI 3000GT 1992 2.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1992, Model line: 3000GT, Model: MITSUBISHI 3000GT 1992 2.GPages: 738, PDF Size: 35.06 MB

Page 491 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition System16-45 l

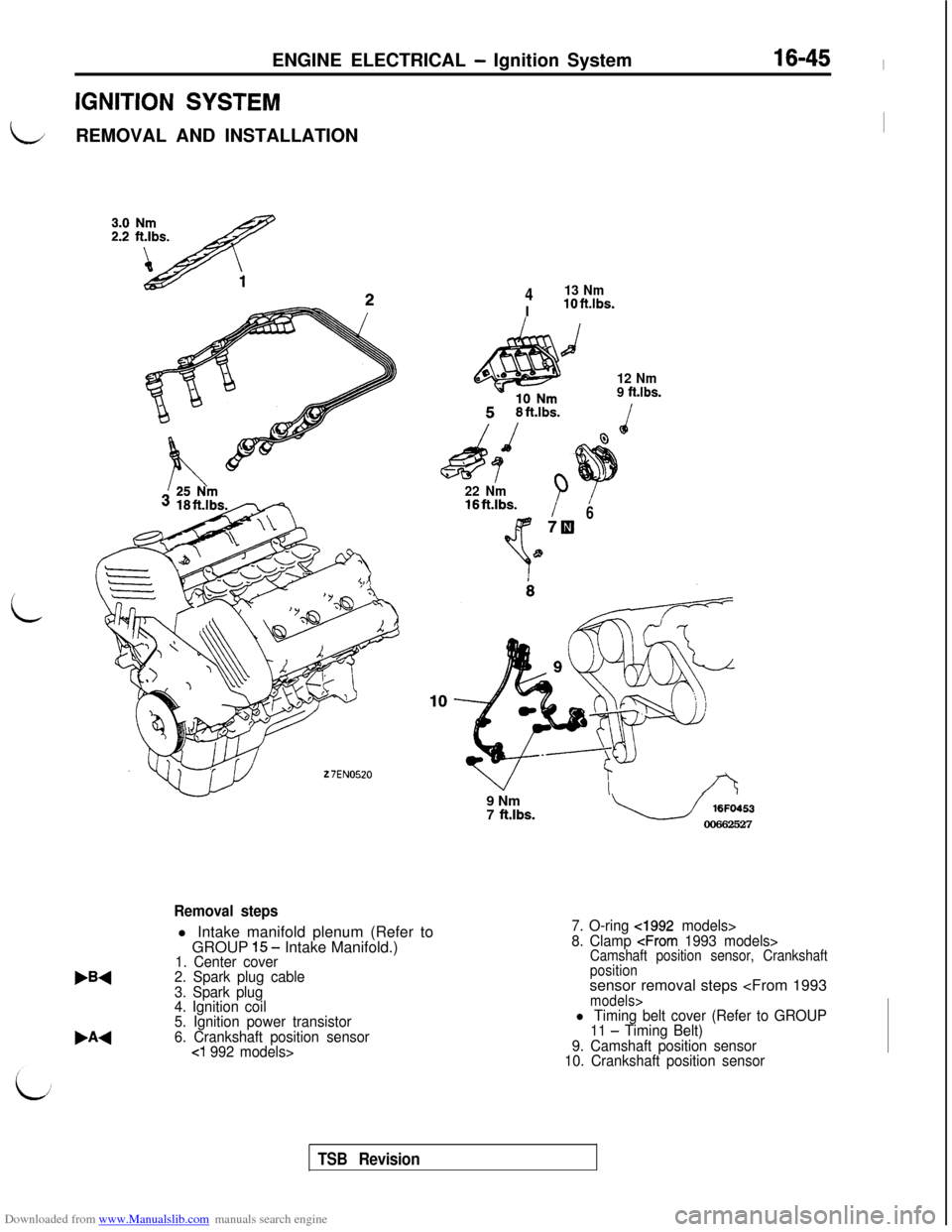

IGNITION SYSTEM

LREMOVAL AND INSTALLATIONI

i

27EN0520

413 NmIlOft.lbs.

d

12 Nm

9 ft.lbs.

22 Nm16ftAbs.B678

W1

,A4

Removal stepsl Intake manifold plenum (Refer to

GROUP

1.5 - Intake Manifold.)1. Center cover

2. Spark plug cable

3. Spark plug

4. Ignition coil

5. Ignition power transistor

6. Crankshaft position sensor

cl 992 models>9 Nm

7

ft.lbs.u 16FO453

00662527

7. O-ring cl992 models>

8. Clamp

positionsensor removal steps

11 - Timing Belt)

9. Camshaft position sensor

10. Crankshaft position sensor

TSB Revision

Page 492 of 738

Downloaded from www.Manualslib.com manuals search engine 16-46ENGINE ELECTRICAL - Ignition Svstem

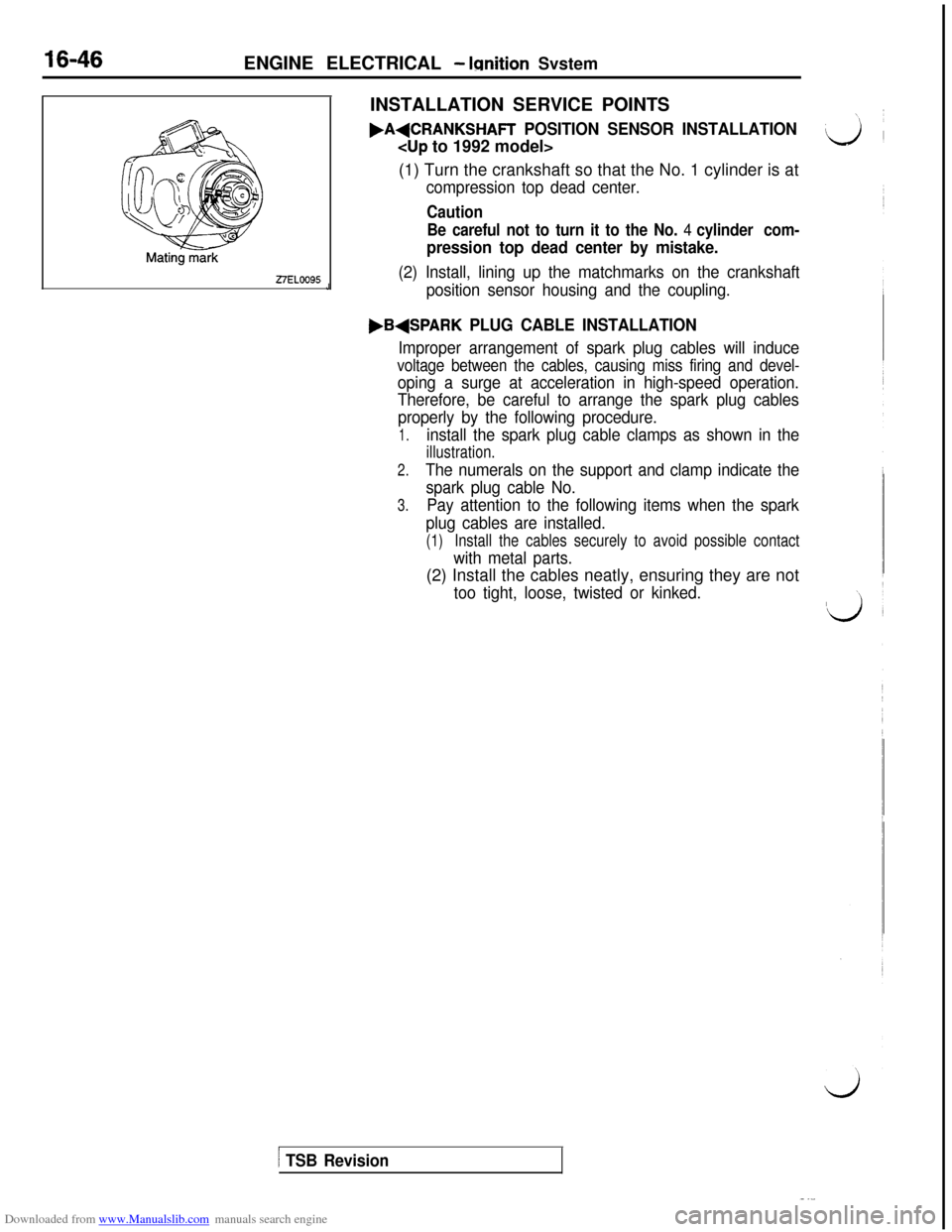

27ELOO95JINSTALLATION SERVICE POINTS.A+CRANKSHAFT

POSITION SENSOR INSTALLATION

(1) Turn the crankshaft so that the No. 1 cylinder is at

compression top dead center.

Caution

Be careful not to turn it to the No.

4 cylinder com-

pression top dead center by mistake.

(2) Install, lining up the matchmarks on the crankshaft

position sensor housing and the coupling.

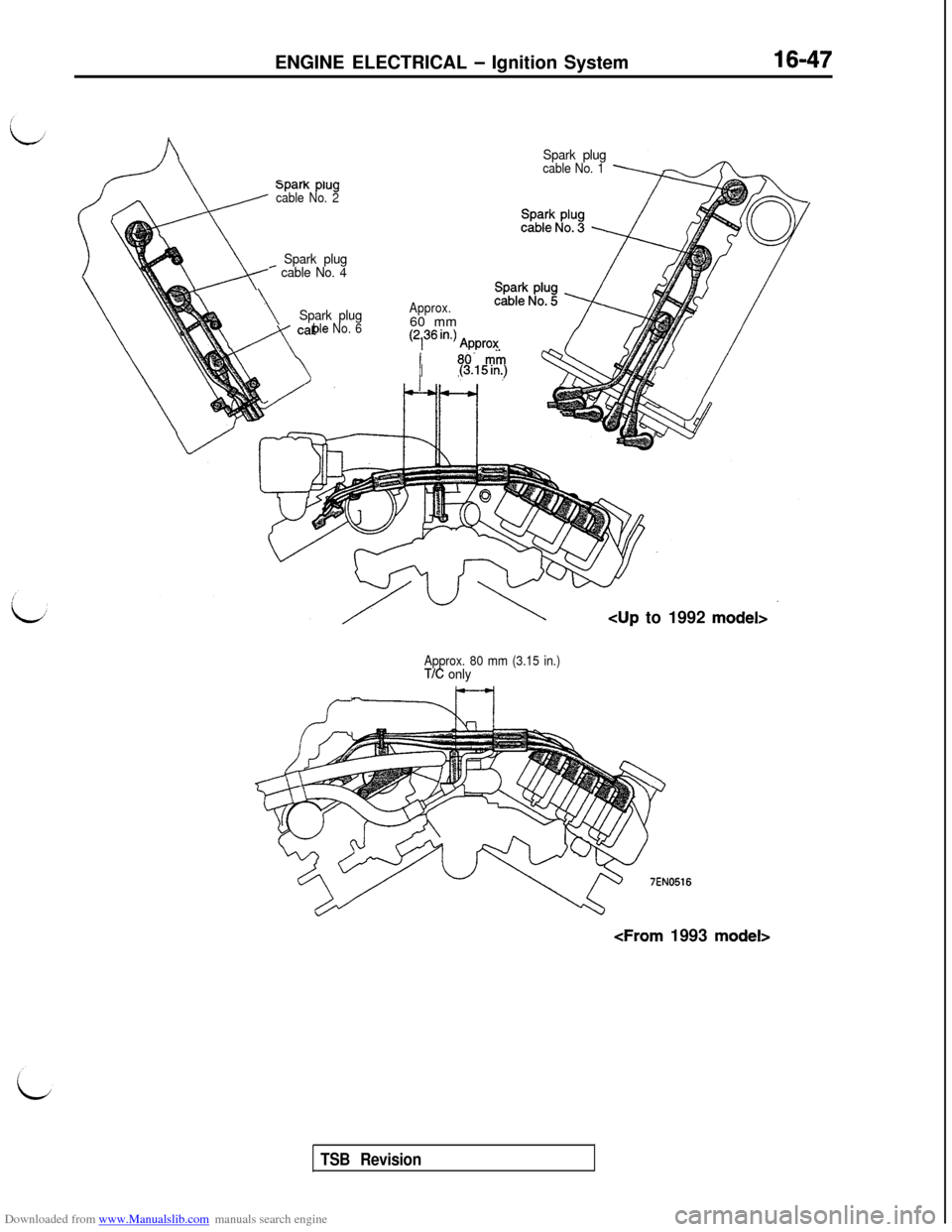

,B+SPARK PLUG CABLE INSTALLATION

Improper arrangement of spark plug cables will induce

voltage between the cables, causing miss firing and devel-

oping a surge at acceleration in high-speed operation.

Therefore, be careful to arrange the spark plug cables

properly by the following procedure.

1.install the spark plug cable clamps as shown in the

illustration.

2.The numerals on the support and clamp indicate the

spark plug cable No.

3.Pay attention to the following items when the spark

plug cables are installed.

(1)Install the cables securely to avoid possible contact

with metal parts.(2) Install the cables neatly, ensuring they are not

too tight, loose, twisted or kinked.

/ TSB Revision

Page 493 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition System16-47

Spark plugcable No. 1

Spark plugr cable No. 4

\Spark plug‘de No. 6

sparK piug

cable No. 2

Approx.60 mm

(2,36in.) Approx

I(3.15in.)cup to 1992

model>

Approx. 80 mm (3.15 in.)TIC only

TSB Revision

Page 494 of 738

Downloaded from www.Manualslib.com manuals search engine 16-48ENGINE ELECTRICAL - lanition Svstem

\/27EL0086

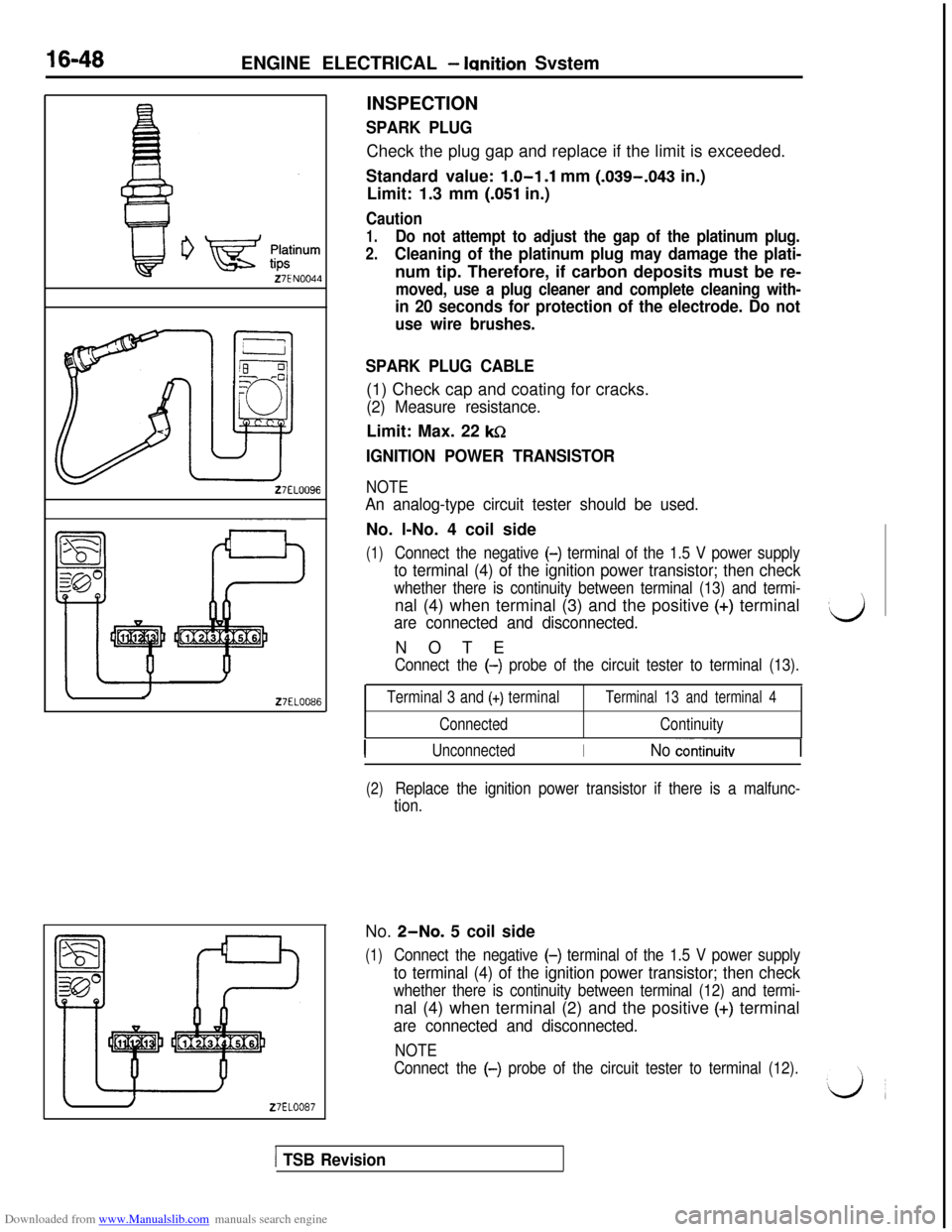

/DEL0087INSPECTION

SPARK PLUGCheck the plug gap and replace if the limit is exceeded.

Standard value:

1.0-l .l mm (.039-.043 in.)

Limit: 1.3 mm

(.051 in.)

Caution

1.Do not attempt to adjust the gap of the platinum plug.

2.Cleaning of the platinum plug may damage the plati-num tip. Therefore, if carbon deposits must be re-

moved, use a plug cleaner and complete cleaning with-

in 20 seconds for protection of the electrode. Do not

use wire brushes.

SPARK PLUG CABLE(1) Check cap and coating for cracks.

(2) Measure resistance.Limit: Max. 22

ksZ

IGNITION POWER TRANSISTOR

NOTE

An analog-type circuit tester should be used.No. l-No. 4 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (13) and termi-nal (4) when terminal (3) and the positive

(+) terminal

are connected and disconnected.NOTE

Connect the (-) probe of the circuit tester to terminal (13).

Terminal 3 and (+) terminal

ConnectedTerminal 13 and terminal 4

Continuity

IUnconnectedINo continuitv

(2)Replace the ignition power transistor if there is a malfunc-

tion.No. ~-NO. 5 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (12) and termi-nal (4) when terminal (2) and the positive

(+) terminal

are connected and disconnected.

NOTE

Connect the (-)

probe of the circuit tester to terminal (12).

[ TSB Revision

Page 495 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL b Ignition System16-49

27EL0089

Z7ELOOQO

1 Terminal 2 and (+) terminal/Terminal 12 and terminal 41

IConnectedIContinuitvI

IUnconnectedINo continuitvI

(2) Replace the ignition power transistor if there is a malfunc-

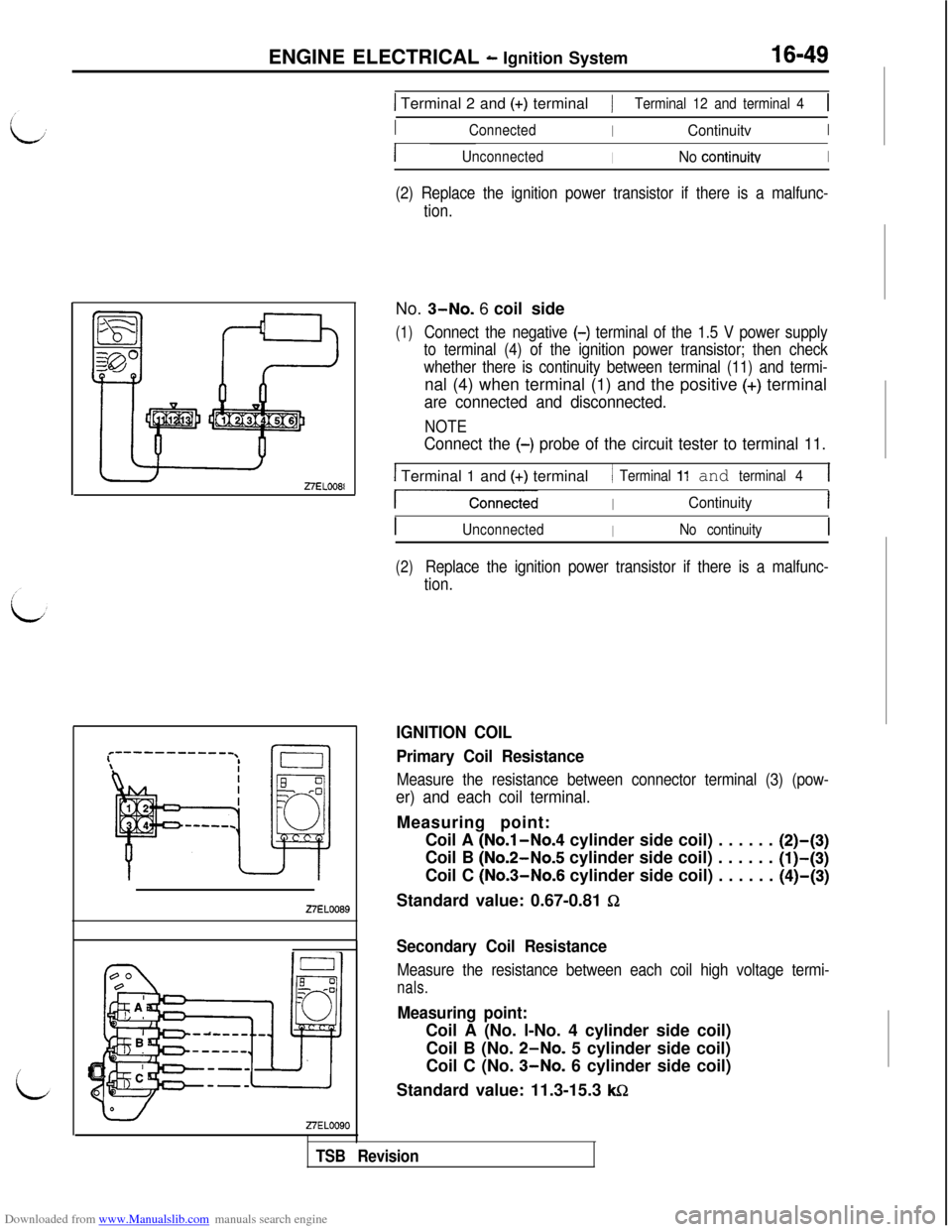

tion.No. ~-NO. 6 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (11) and termi-nal (4) when terminal (1) and the positive

(+) terminal

are connected and disconnected.

NOTE

Connect the (-) probe of the circuit tester to terminal 11.

I Terminal 1 and (+) terminal/ Terminal 11 and terminal 41

-ConnectedIContinuityI

IUnconnectedINo continuityI

(2)Replace the ignition power transistor if there is a malfunc-

tion.

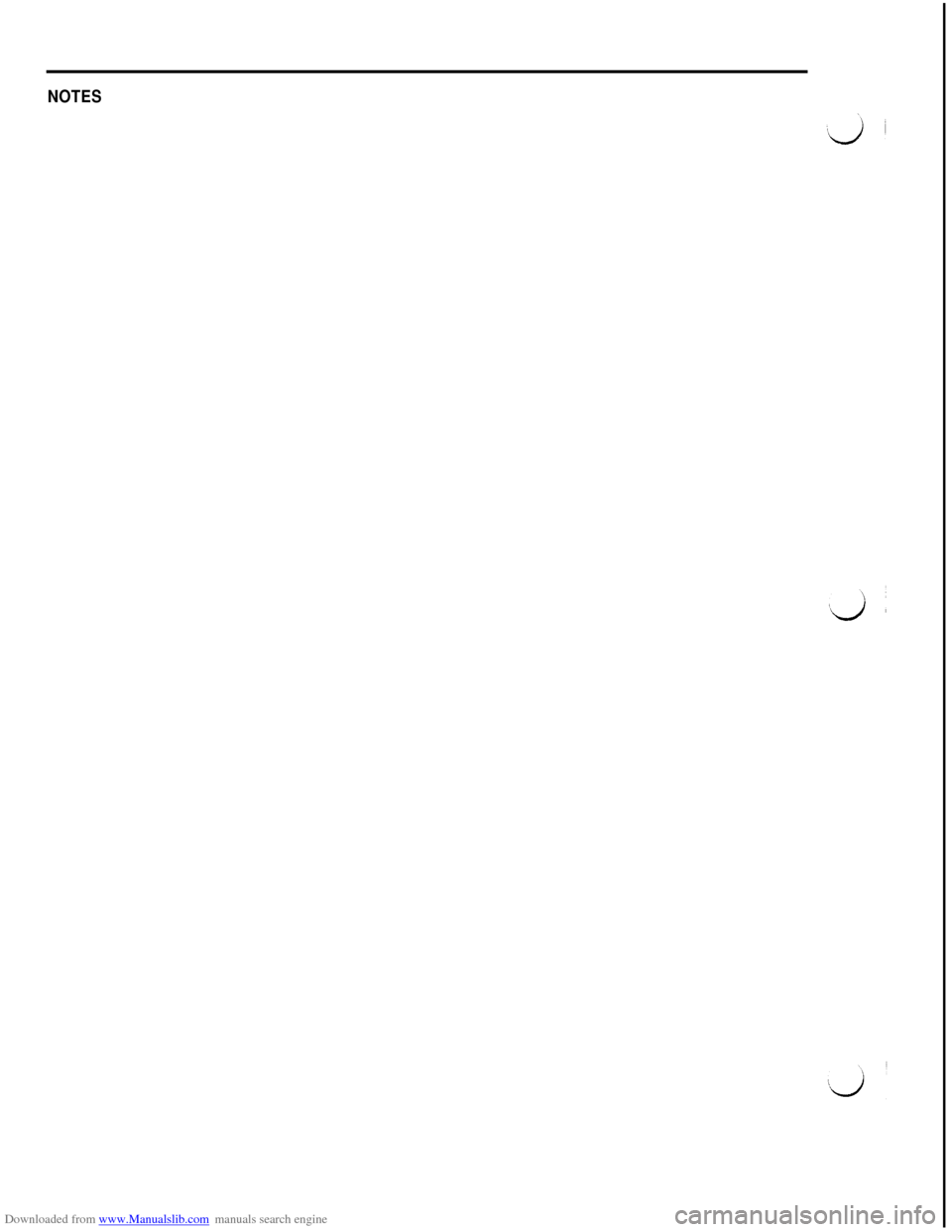

IGNITION COIL

Primary Coil Resistance

Measure the resistance between connector terminal (3) (pow-

er) and each coil terminal.Measuring point:

Coil A

(No.l-No.4 cylinder side coil) . . . . . . (2)-(3)Coil B (No.2-No.5 cylinder side coil) . . . . . .

(l)-(3)Coil C (No.3-No.6 cylinder side coil) . . . . . .

(4)-(3)Standard value: 0.67-0.81

Sz

TSB Revision

Secondary Coil Resistance

Measure the resistance between each coil high voltage termi-

nals.

Measuring point:Coil A (No. l-No. 4 cylinder side coil)

Coil B (No. ~-NO. 5 cylinder side coil)

Coil C (No. ~-NO. 6 cylinder side coil)

Standard value: 11.3-15.3

Wz

Page 496 of 738

Downloaded from www.Manualslib.com manuals search engine NOTES

Page 497 of 738

Downloaded from www.Manualslib.com manuals search engine 54-1

CHASSIS

ELECTRICAL

CONTENTS

AERO PARTS (ACTIVE AERO).....Refer to GROUP 51

ANTI-LOCK BRAKING SYSTEM....

Refer to GROUP 35

BATTERY...........................................-3

ON-VEHICLE SERVICE............................3

Battery Charging.................................4Battery Inspection................................3Battery Testing Procedure........................5

SPECIFICATIONS................................-3

General Specifications............................3

CIGARETTE LIGHTER.............................119

CIGARETTE LIGHTER..........................123

SPECIFICATIONS..............................

119

General Specifications............I...........119

TROUBLESHOOTING............................120

COLUMN SWITCH.................................

.lll

COLUMN SWITCH*............................112

SPECIAL TOOL.................................111

SPECIFICATIONS...............................111

General Specifications..........................111

CRUISE CONTROL SYSTEM . . . . . . . Refer to GROUP 17

DOOR GLASS AND REGULATOR

(POWER WINDOWS) . . . . . . . . . . . . . .Refer to GROUP 42

DOOR HANDLE AND LATCH

(CENTRAL DOOR LOCKING) . . . . . . Refer to GROUP 42

DOOR MIRROR (ELECTRONIC

CONTROLLED MIRROR). . . . . . . . . . .Refer to GROUP 51

ELECTRONIC CONTROL

SUSPENSION . . . . . . . . . . . . . . . . . . . . Refer to GROUP

338

FRONT SEAT (POWER SEAT) . . . . Refer to GROUP 52A

HEATER AND AIR CONDITIONING . Refer to GROUP 55

HORN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

115

HORN SWITCH* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

RELAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

118

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

115

General Specifications . . . . . . . . . . . . . . . . . . . . . . . .115

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . .115

KEYLESS ENTRY SYSTEM

(CENTRAL DOOR LOCKING) . . . . . . Refer to GROUP 42

CONTINUED ON NEXT PAGE

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the

SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from render-

ing the SRS inoperative).

(2) Service or maintenance of any SRS component or

SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3)MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

TSupplemental Re-

straint System (SRS) and GROUP 00 -Maintenance Service before beginning any service or maintenance of any com-

ponent of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: impact sensors, SRS diagnosis unit, SRS warning light, air bag module, clock spring

and interconnecting wiring. Other SRS-related components (that may

h,a”” to be removed/installed in connection with SRS serviceor maintenance) are indicated in the table of contents by an asterisk ( ).

Page 498 of 738

Downloaded from www.Manualslib.com manuals search engine 54-2

IGNITION SWITCH*..................................6

IGNITION SWITCH.................................

SPECIAL TOOL...................................6

LIGHTING SYSTEM................................35

FOG LIGHT....................................105

FRONT COMBINATION LIGHT AND

OPTICAL HORN LENS.........................106

HAZARD SWITCH..............................

110

HEADLIGHT...................................103

HIGH MOUNTED STOP LIGHT..................107

ON-VEHICLE SERVICE.........................100

POP-UP SWITCH AND FOG LIGHT SWITCH....109

REAR COMBINATION LIGHT AND

LICENSE PLATE LIGHT........................106

RELAY........................................108

RHEOSTAT....................................

110

SPECIAL TOOLS................................36

SPECIFICATIONS...............................

35

General Specifications..........................35Service Specifications..........................35

TROUBLESHOOTING............................37

METERS AND GAUGES..............................9

COMBINATION GAUGES........................33

COMBINATION METERS.........................31

ON-VEHICLE SERVICE...........................26

SPECIFICATIONS.................................

9

General Specifications............................9Sealant........................................ll

Service Specifications...........................11

TROUBLESHOOTING............................12

RADIO AND TAPE PLAYER.......................124

CD AUTO CHANGER..........................191

RADIO AND TAPE PLAYER WITH ANTI-THEFTSYSTEM.......................................156

MOTOR ANTENNA/ANTENNA FEEDERCABLE/AMPLIFIER.............................188

RADIO AND TAPE PLAYER....................186

RADIO REMOTE-CONTROL*...................186

SPEAKER.....................................

187

TROUBLESHOOTING...........................

124

REAR WINDOW DEFOGGER. . . . . . . . . . . . . . . . . . . . . .192

DEFOGGER RELAY. . . . . . . . . . . . . . . . . . . . . . . . . . . .204

ON-VEHICLE SERVICE. . . . . . . . . . . . . . . . . ~ ~. . . . . .203

REAR WINDOW DEFOGGER SWITCH . . . . . . -. . . 203

SPECIAL TOOLS.. . . s.. . . . . . . . . . . . . . . . . . . . . . . . .192

TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . .193

REAR WIPER AND WASHER . . ~ *. . Refer to GROUP 51

SEAT BELT (BUZZER). . . . . . . . . . . . Refer to GROUP 52A

SEAT BELT (TENSION-REDUCERTYPE SEAT BELT) . . . . . . . . . . . . . . . Refer to GROUP 52A

SUPPLEMENTAL RESTRAINTSYSTEM (SRS)..-...............Refer to GROUP 52B

THEFT-ALARM SYSTEM . . . . . . . . . . . . . . . . . e . . . . . m.. s205

SPECIAL TOOLS.. . . . . . . . . . . . . . . . . . . .

m . . . . . . . .e205

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . .206

WINDSHIELD WIPER ANDWASHER. . . . . . . . . . . . . . . . . . . . . ~. . .Refer to GROUP 51

Page 499 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Battery54-3

BATTERY

LSPECIFICATIONSGENERAL SPECIFICATIONS

ItemsUp to 1993 modelsFrom 1994 models

Type75D26R-MF75D23R-MF

Ampere hours

(5HR) Ah5252

Cranking rating [at -18°C (O’F)] A490520

Reserve capacity min.123118

NOTES

1.CRANKING RATING is the current a battery can deliver for 30 seconds and maintain a terminal voltage of

7.2 volts or greater at a specified temperature.

2.RESERVE CAPACITY RATING is the amount of time a battery can deliver 25A and maintain a minimum terminal

voltage of 10.5 at

27% (80°F).

L

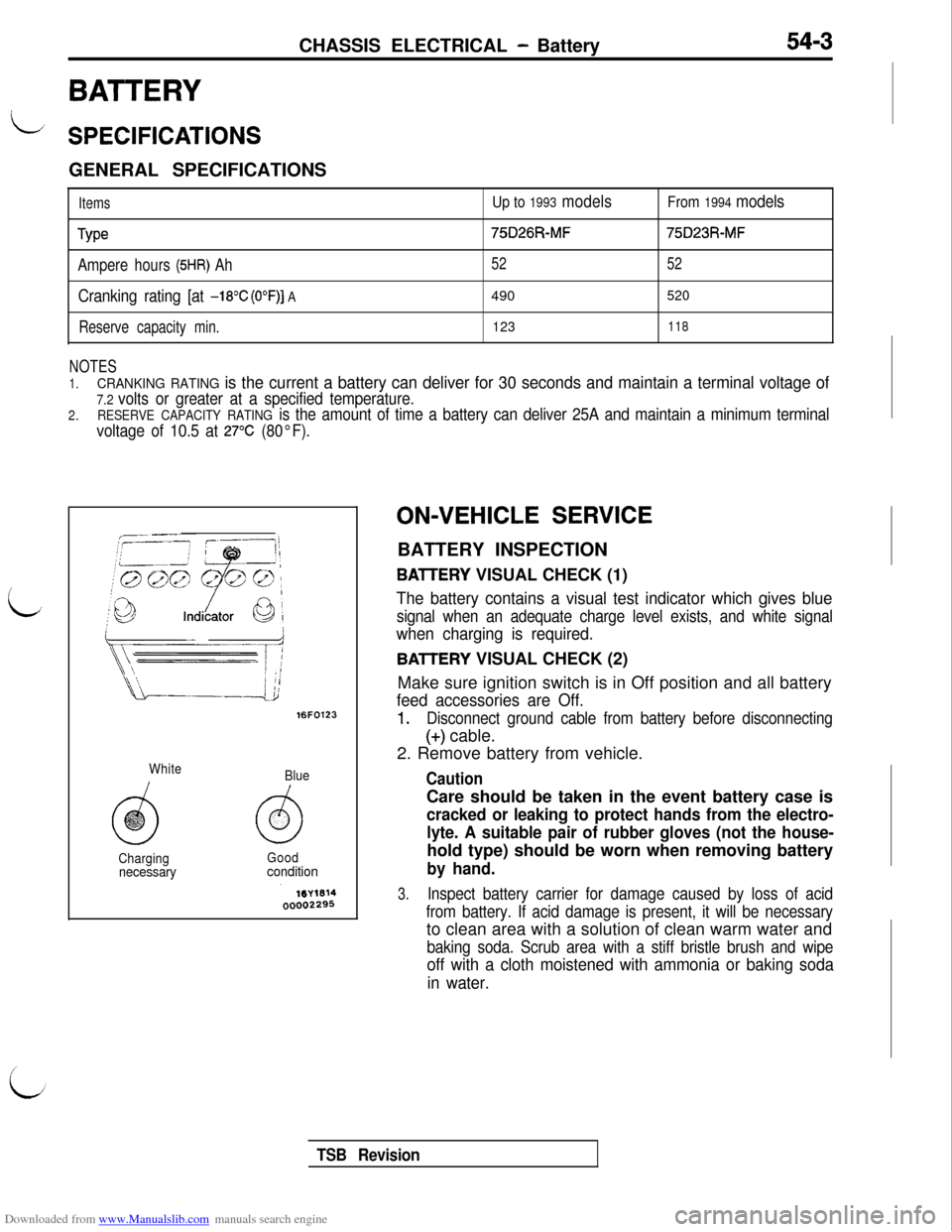

16FO123

White

Blue

ChargingGood

necessaryconditionON-VEHICLE

SERVICE

BATTERY INSPECTION

BAlTERY VISUAL CHECK (1)

The battery contains a visual test indicator which gives blue

signal when an adequate charge level exists, and white signal

when charging is required.

BAlTERY VISUAL CHECK (2)

Make sure ignition switch is in Off position and all battery

feed accessories are Off.

1.Disconnect ground cable from battery before disconnecting

(+) cable.

2. Remove battery from vehicle.

CautionCare should be taken in the event battery case is

cracked or leaking to protect hands from the electro-

lyte. A suitable pair of rubber gloves (not the house-hold type) should be worn when removing battery

by hand.

3.Inspect battery carrier for damage caused by loss of acid

from battery. If acid damage is present, it will be necessaryto clean area with a solution of clean warm water and

baking soda. Scrub area with a stiff bristle brush and wipe

off with a cloth moistened with ammonia or baking soda

in water.

TSB Revision

Page 500 of 738

Downloaded from www.Manualslib.com manuals search engine 54-4CHASSIS ELECTRICAL - Battery

4. Clean top of battery with same solutions as described

in step (3).

5.Inspect battery case and cover for cracks. If cracks are

present, battery must be replaced.

6.Clean the battery post with a suitable battery post cleaning

tool.7. Clean the inside surfaces of the terminal clamps with a

suitable battery terminal cleaning tool. Replace damaged

or frayed cables and broken terminals clamps.8. Install the battery in vehicle.

9.Connect (+) and (-) cables to battery in the order of men-

tion.

10. Tighten the clamp nut securely.BATTERY

CHARGLNG

Caution

When batteries are being charged, an explosive gas forms

beneath the cover of each cell. Do not smoke near batteries

on charge or which have recently been charged. Do notbreak live circuits at the terminals of the batteries on

charge. A spark will occur where the live circuit is broken.

Keep all open flames away from the battery.

Battery electrolyte temperature may temporarily be allowed

to rise to 55°C (131°F). Increase of electrolyte temperature

above 55°C (131 OF) is harmful to the battery, causing deforma-tion of battery cell, decrease in life of battery, etc.

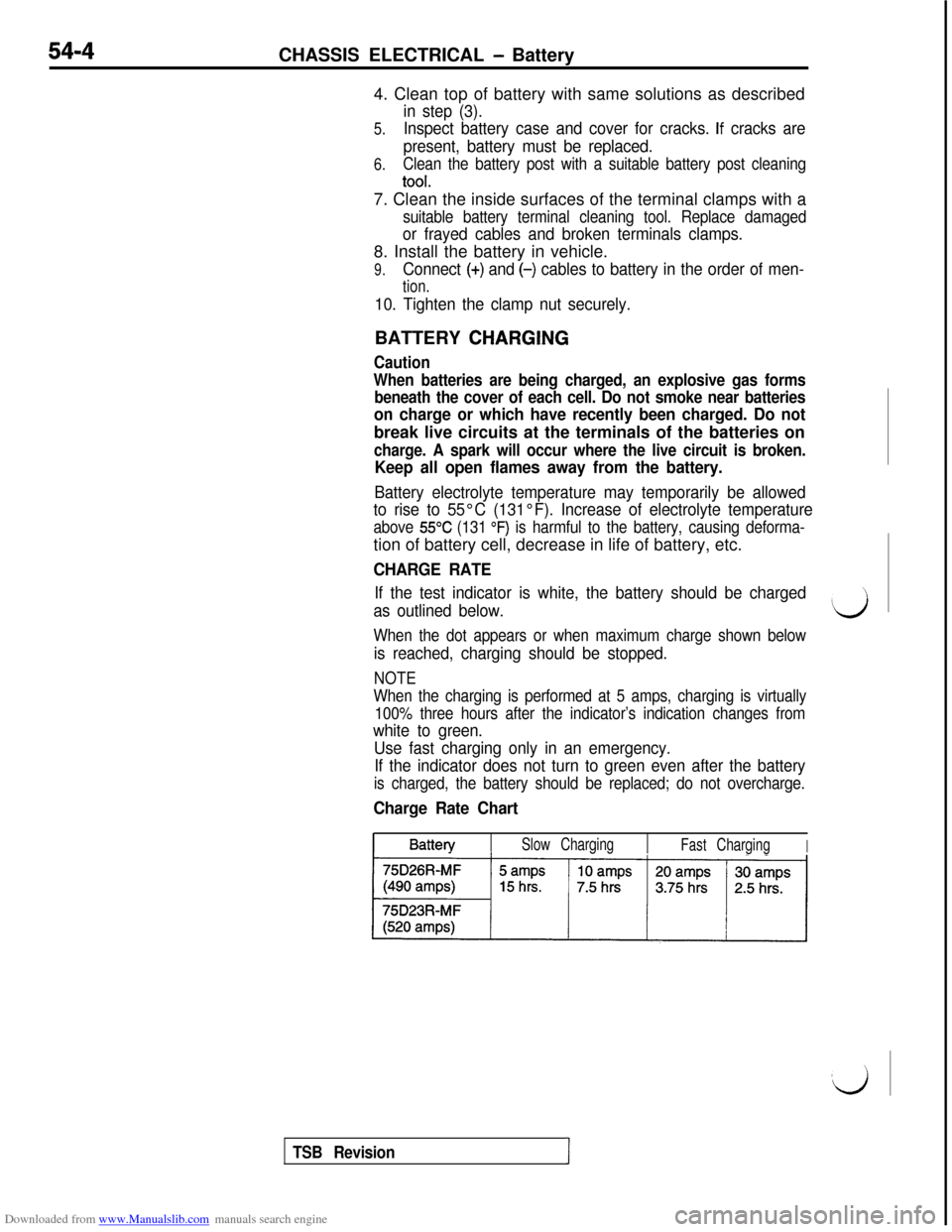

CHARGE RATE

If the test indicator is white, the battery should be charged

as outlined below.

When the dot appears or when maximum charge shown below

is reached, charging should be stopped.

NOTE

When the charging is performed at 5 amps, charging is virtually

100% three hours after the indicator’s indication changes from

white to green.

Use fast charging only in an emergency.

If the indicator does not turn to green even after the battery

is charged, the battery should be replaced; do not overcharge.

Charge Rate Chart

Batten/Slow Charging

Fast ChargingI

TSB RevisionI