speed MITSUBISHI 3000GT 1992 2.G Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1992, Model line: 3000GT, Model: MITSUBISHI 3000GT 1992 2.GPages: 738, PDF Size: 35.06 MB

Page 514 of 738

Downloaded from www.Manualslib.com manuals search engine 54-18CHASSIS ELECTRICAL - Meters and Gauges

OPERATION

When the ignition key is at the “ON” position,the fuel gauge is activated.

l

When there is much fuel, the unit’s resistanceis small and the current flowing in the circuit

is great, so the gauge’s indicator indicates inthe “F” area.

l When there is little fuel, the unit’s resistance

is high and the current flowing in the circuit

is small, so the gauge’s indicator indicates inthe

“E” area.

lWhen the ignition key is at the “ON” position,

the engine coolant temperature gauge is acti-

vated.l

When the engine coolant temperature is high,

the unit’s resistance is low and there is a greatflow of current in the circuit, so the gauge’s

indicator indicates in the “H” area.

l

When the engine coolant temperature is low,

the unit’s resistance is high and there is a smallflow of current in the circuit, so the gauge’s

indicator indicates in the “C” area.

vehicle speed, and vehicle-speed signals areinput to systems (the MFI system, etc.) that

regulate according to the vehicle speed.

TROUBLESHOOTING HINTS

1.The fuel gauge doesn’t function, or shows the

incorrect indication.

(1) Disconnect the connector of the fuel pumpand gauge unit assembly; the ‘F” side is

indicated when terminal (5) is then

grounded.l Check the fuel gauge.

2.The engine coolant temperature gauge doesn’t

function, or shows the incorrect indication.

(1)The “l-l” side is indicated when the connector

of the engine coolant temperature gauge

unit is disconnected and then grounded.l

Check the engine coolant temperature

gauge unit.

3. Systems dependent upon control according to

the vehicle speed do not function correctly.l Check the reed switch (mechanical

speedometer type)l Check the speed sensor (electrical

speedometer type)

coil pressure gauge>l

When the ignition key is at the “ON” position,

the oil pressure gauge is activated.

lWhen oil pressure is high, the internal contacts

of the gauge unit are kept closed for a longerperiod of time. This causes more current to

flow in the circuit, and the gauge pointer swings

to the high pressure side.

lWhen oil pressure is low, the internal contactsof the gauge unit open in a shorter period of

time. Therefore, there is less current flowing

in the circuit and the gauge pointer swings to

the low pressure side.

lWhen the ignition key is set to the “ON” position,the gauge indicator will be at

“0”.l

When the engine is started, the indicator will

move from

“0” to the minus (-) side, and then,as the boost level increases, it will move to

the plus

(+) side.

position, the voltage gauge operates and indi-

cates a battery voltage of approximately 12 V.l

When the engine is started, the voltage gauge

indicates a battery voltage of 12 to 16 V, indicat-ing that the battery is on charge.

4. The oil pressure gauge doesn’t function, or

shows the incorrect indication.

(1)The “H” side is indicated when the connectorof the oil pressure gauge unit is discon-

nected and then grounded.l Check the oil pressure gauge unit.

5.The meter illumination light does not illuminate.

(1) The tail lights illuminate.l Check the rheostat.

6. The voltage gauge doesn’t function, or shows

the incorrect indication.l Check the voltage gauge.

TSB Revision

Page 522 of 738

Downloaded from www.Manualslib.com manuals search engine 54-26CHASSIS ELECTRICAL - Meters and Gauges

Free

r&Hers -

Sear wheels raised on jack>

?qi&%!g

Rigid rack oooo2297

Anchor plate

-w216AO864

bracket

/IZ16FO13300002298ON-VEHICLE

SERVICEINSPECTION

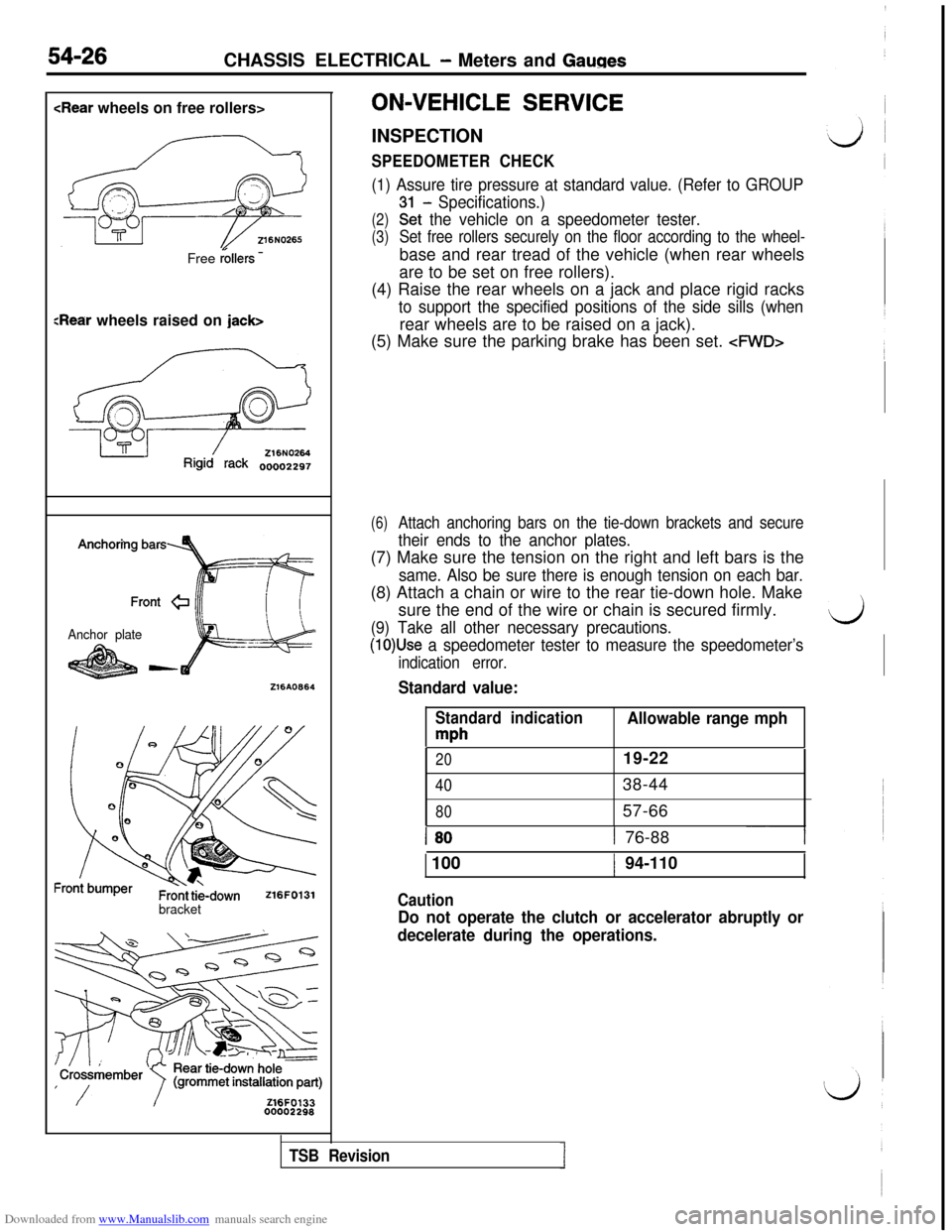

SPEEDOMETER CHECK

(1) Assure tire pressure at standard value. (Refer to GROUP

- Specifications.)

(2)Gt the vehicle on a speedometer tester.

(3)Set free rollers securely on the floor according to the wheel-base and rear tread of the vehicle (when rear wheels

are to be set on free rollers).

(4) Raise the rear wheels on a jack and place rigid racks

to support the specified positions of the side sills (whenrear wheels are to be raised on a jack).

(5) Make sure the parking brake has been set.

cPWD>

(6)Attach anchoring bars on the tie-down brackets and secure

their ends to the anchor plates.(7) Make sure the tension on the right and left bars is the

same. Also be sure there is enough tension on each bar.(8) Attach a chain or wire to the rear tie-down hole. Make

sure the end of the wire or chain is secured firmly.

(9) Take all other necessary precautions.

(1O)Use a speedometer tester to measure the speedometer’s

indication error.

Standard value:

Standard indication

mph

Allowable range mph

2019-22

4038-44

8057-66

1 801 76-88--I

1 100

Caution

1 94-110

Do not operate the clutch or accelerator abruptly or

decelerate during the operations.

d

TSB Revision

Page 523 of 738

Downloaded from www.Manualslib.com manuals search engine I,;CHASSIS ELECTRICAL

- Meters and Gauges54-27

c I\\ zl6F024;

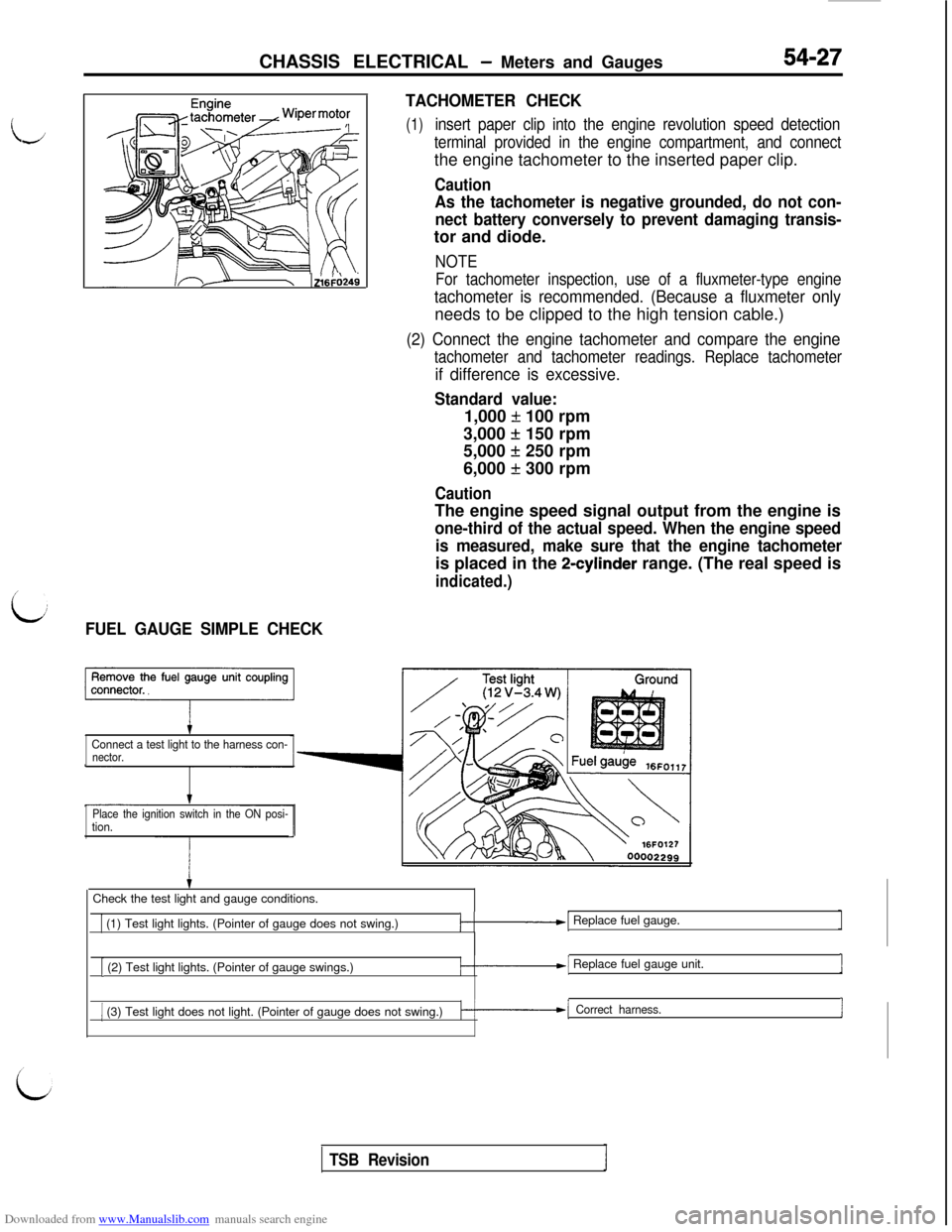

L:FUEL GAUGE SIMPLE CHECKTACHOMETER CHECK

(1)insert paper clip into the engine revolution speed detection

terminal provided in the engine compartment, and connectthe engine tachometer to the inserted paper clip.

Caution

As the tachometer is negative grounded, do not con-

nect battery conversely to prevent damaging transis-tor and diode.

NOTE

For tachometer inspection, use of a fluxmeter-type engine

tachometer is recommended. (Because a fluxmeter onlyneeds to be clipped to the high tension cable.)

(2) Connect the engine tachometer and compare the engine

tachometer and tachometer readings. Replace tachometer

if difference is excessive.

Standard value:1,000

f 100 rpm

3,000

+ 150 rpm

5,000

f 250 rpm

6,000

f 300 rpm

CautionThe engine speed signal output from the engine is

one-third of the actual speed. When the engine speed

is measured, make sure that the engine tachometeris placed in the

2-cylinder range. (The real speed is

indicated.)

Connect a test light to the harness con-nector.

Place the ignition switch in the ON posi-

tion.Check the test light and gauge conditions.

1 (1) Test light lights. (Pointer of gauge does not swing.)/-.-I Replace fuel gauge.

[ (2) Test light lights. (Pointer of gauge swings.)/-.--I Replace fuel gauge unit.1

1 (3) Test light does not light. (Pointer of gauge does not swing.)k-1 Correct harness.I

TSB Revision

Page 527 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Meters and Gauges54-31

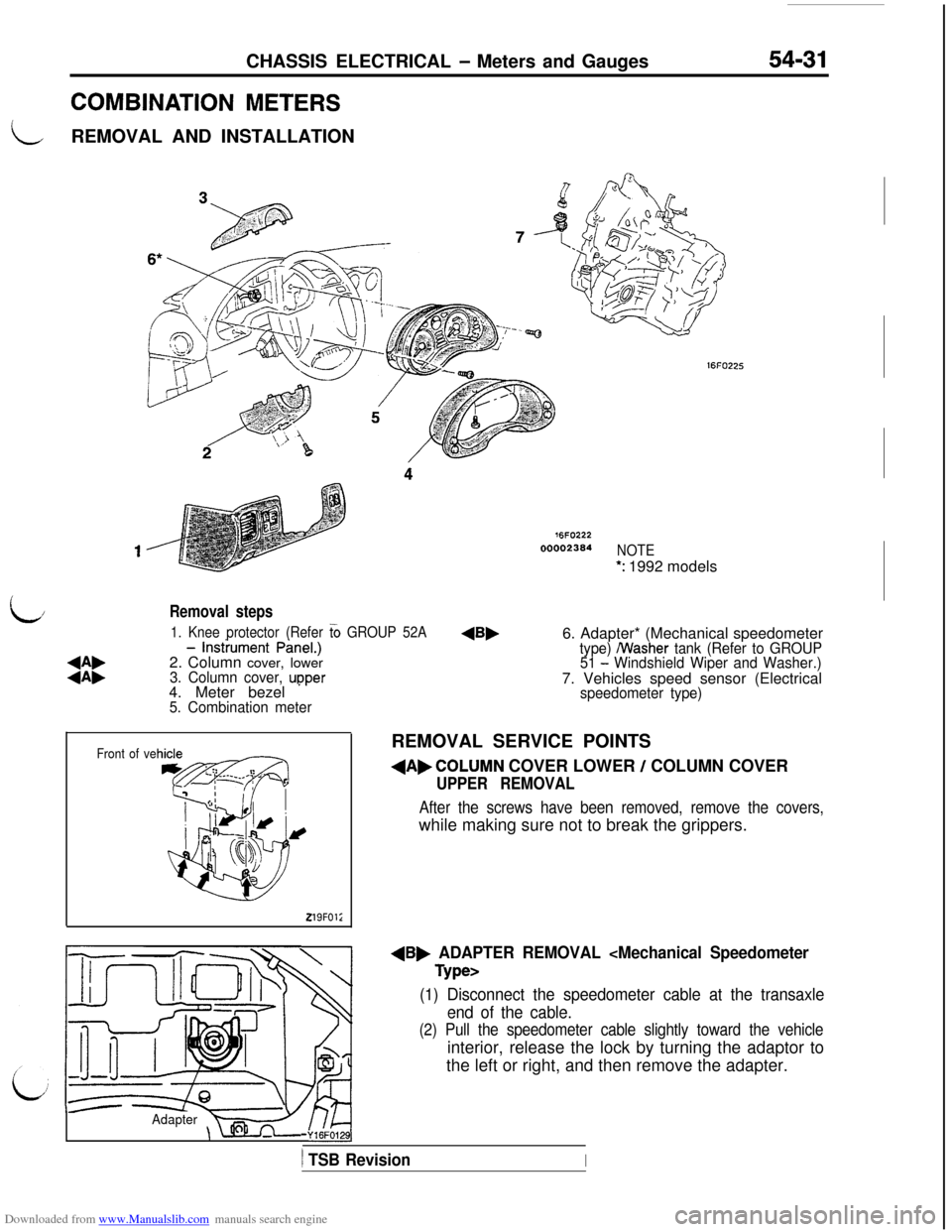

COMBINATION METERS

LREMOVAL AND INSTALLATION

76FO22200002364

NOTE

*: 1992 models

L/

:i:

- lnstiument PineI.)

2. Column cover, lower

3. Column cover, upper 1. Knee protector (Refer

G GROUP 52A4. Meter bezel

* ’5. Combination meter

Removal steps6. Adapter* (Mechanical speedometer

type) /Washer tank (Refer to GROUP

51 - Windshield Wiper and Washer.)7. Vehicles speed sensor (Electrical

Front of ve

219FOl;

speedometer type)REMOVAL SERVICE POINTS

dAbCOLUMN COVER LOWER / COLUMN COVER

UPPER REMOVAL

After the screws have been removed, remove the covers,while making sure not to break the grippers.

dB, ADAPTER REMOVAL

(1) Disconnect the speedometer cable at the transaxle

end of the cable.

(2) Pull the speedometer cable slightly toward the vehicleinterior, release the lock by turning the adaptor to

the left or right, and then remove the adapter.

Adapter-Y16FO129],

) TSB RevisionI

Page 528 of 738

Downloaded from www.Manualslib.com manuals search engine 54-32CHASSIS ELECTRICAL - Meters and Gauges

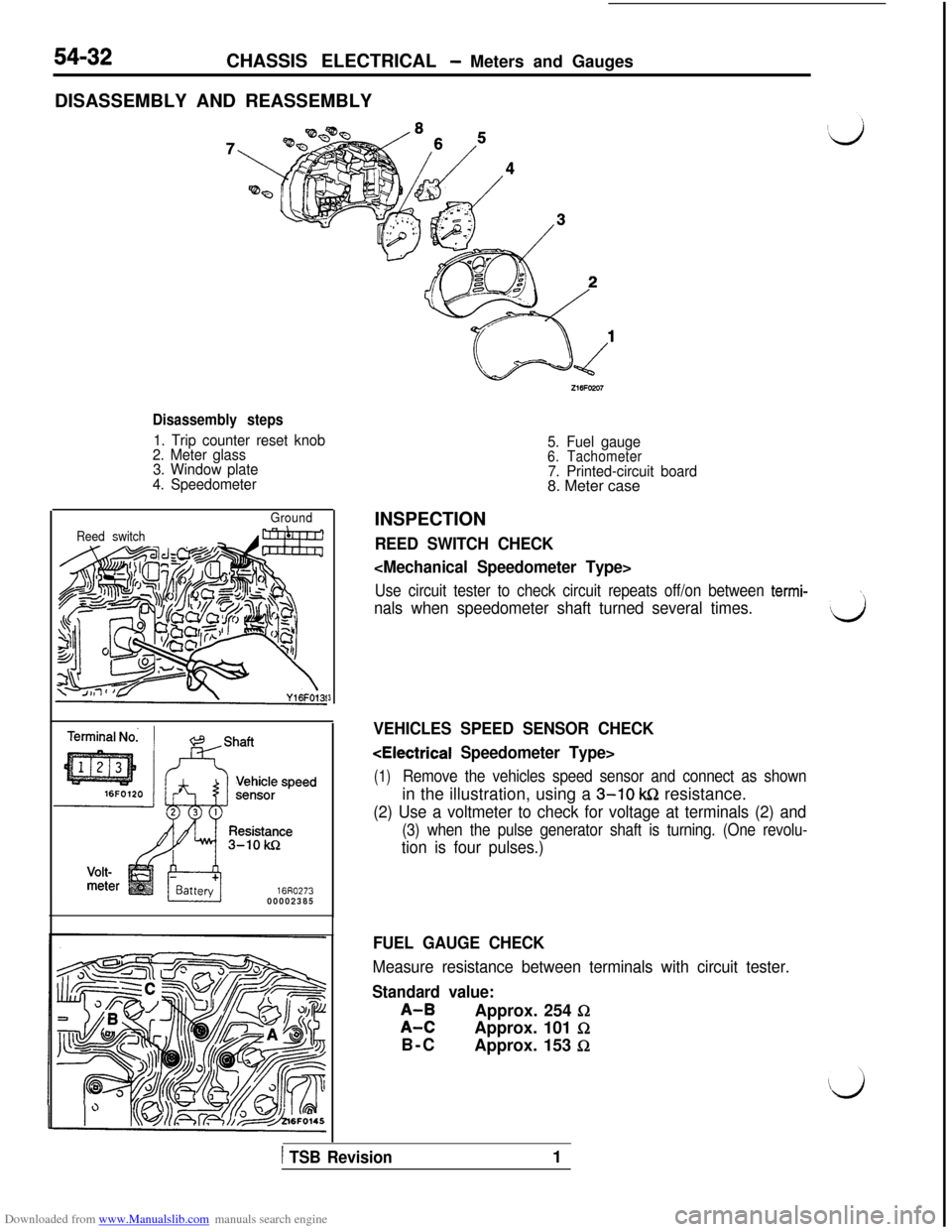

DISASSEMBLY AND REASSEMBLY

Disassembly steps

1. Trip counter reset knob

2. Meter glass

3. Window plate

4. Speedometer

Ground

Reed switch

16R027300002385

3

5. Fuel gauge6. Tachometer7. Printed-circuit board8. Meter case

INSPECTION

REED SWITCH CHECK

Use circuit tester to check circuit repeats off/on between termi-\

nals when speedometer shaft turned several times.d

VEHICLES SPEED SENSOR CHECK

(1)Remove the vehicles speed sensor and connect as shownin the illustration, using a

3-10 k&2 resistance.

(2) Use a voltmeter to check for voltage at terminals (2) and

(3) when the pulse generator shaft is turning. (One revolu-

tion is four pulses.)

FUEL GAUGE CHECK

Measure resistance between terminals with circuit tester.

Standard value:

;I;Approx. 254 0Approx. 101

I2B-C

Approx. 153

fi

1 TSB Revision1

Page 660 of 738

Downloaded from www.Manualslib.com manuals search engine 54-164CHASSIS ELECTRICAL - Radio and Tape Player

A-6There is noise when starting the engine.

Noise type

Sounds are in pa-

rentheses ( ).

AM, FM:

Ignition noise

(Popping, Snap-

ping,Cracking,

Buzzing)

Otherelectrical

components

Static electricity

(Cracking, Crin-

kling)

Conditions

0Increasing the engine speedcausing the popping sound tospeed up, and volume de-creases.0Disappears when the ignitionswitch is turned to ACC.

-

lDisappears when the vehicle is

completely stopped.Occurs when parts or wir-

Severe when the clutch is en-ing move for some reasonlgaged.and contact metal parts of

the body.

lVarious noises are produced de-pending on the body part of thevehicle.

Due to detachment from

the body of the front hood,

bumpers, exhaust pipe

and muffler, suspension,

etc.

Causel

Mainly due to the

spark plugs.l Due to the enginenoise.

Noise may appear as

electrical components be-

come older.

Parts to be Location of

inspectedparts

or remedy(next page)

Noise con- 1

denser

Ground

cable2, 3

Repair or replace electricalcomponents.

Return parts or wiring to

their proper position.

Caution

1.Connecting a high tension cable to the noise

filter may destroy the noise filter and shouldnever be done.

2.Check that there is no external noise. Since

failure to do this may result in misdiagnosis

due to inability to identify the noise source,

this operation must be performed.3. Noise prevention should be performed by

suppressing strong sources of noise step

by step.

NOTE

1. Condenser

The condenser does not pass D.C. current, butas the number of waves increases when it

passes A.C. current, impedance (resistanceagainst A.C.) decreases, and current flow is

facilitated. A noise suppressing condenser

which takes advantage of this property is in-

serted between the power line for the noise

source and the ground. This suppresses noiseby grounding the noise component (A.C. or

pulse signal) to the body of the vehicle.

2. Coil

The coil passes D.C. current, but impedance

rises as the number of waves increases relativeto the A.C. current. A noise suppressing coil

which takes advantage of this property is in-

serted into the power line for the noise source,

and works by preventing the noise componentfrom flowing or radiating out of the line.

1 TSB Revision

Ground parts by bonding.

Cases where the problem

is not eliminated by a single

response to one area are

common, due to several

bodypartsbeing

imperfectly grounded.

Page 672 of 738

Downloaded from www.Manualslib.com manuals search engine 54-176CHASSIS ELECTRICAL - Radio and Tape Player

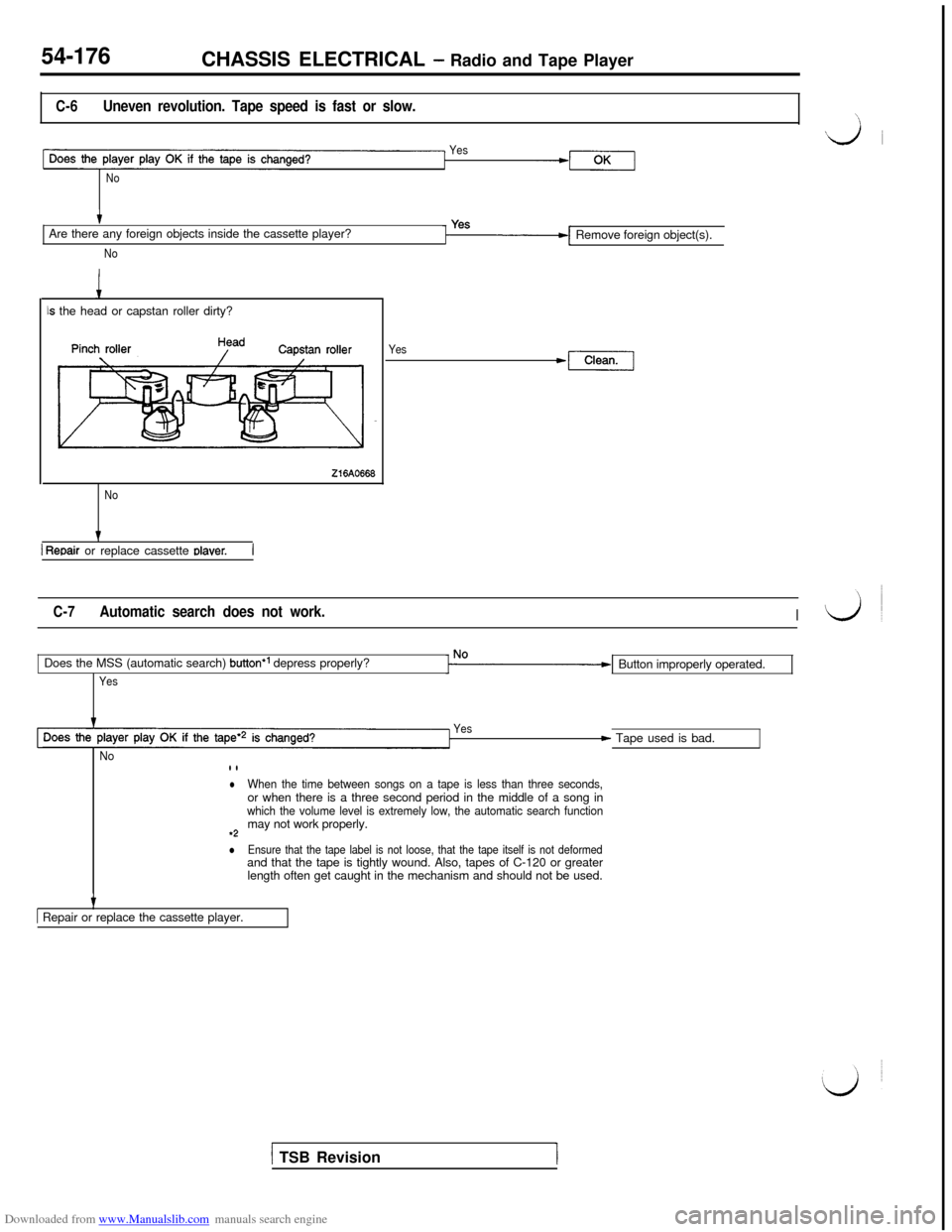

C-6Uneven revolution. Tape speed is fast or slow.

NoYesAre there any foreign objects inside the cassette player?

Remove foreign object(s).

No

Is the head or capstan roller dirty?

I-

Z16AO668

No

j Reoair or replace cassette olaver.

Yes

C-7Automatic search does not work.IDoes the MSS (automatic search) button” depress properly?

YesButton improperly operated.

1Yesc Tape used is bad.

Nol l

lWhen the time between songs on a tape is less than three seconds,or when there is a three second period in the middle of a song in

which the volume level is extremely low, the automatic search function

*2may not work properly.

lEnsure that the tape label is not loose, that the tape itself is not deformedand that the tape is tightly wound. Also, tapes of C-120 or greater

length often get caught in the mechanism and should not be used.

t1 Repair or replace the cassette player.

1 TSB Revision

Page 731 of 738

Downloaded from www.Manualslib.com manuals search engine ALPHABETICAL INDEX1

A

iiABSPOWER RELAY, Check . . . . . . . . . . . . . . . . . . . . , . . .

35-82-lRELAY.............................................35-110-1SIGNAL, On-vehicle Inspection.................13A-176,277-iACCELERATOR

CABLE..............................................

17-4-l

SWITCH

ACTIVE AERO SYSTEM, Check.........................

51-7-l

ACTIVE EXHAUST

CONTROL UNIT, On-vehicle Inspection..........13A-173,274-lSYSTEM............................................15-40-l

AERO PARTS........................................51-19-lAIR BAG..........................................520-74-lMODULE......................................528-82, 87-lAIR CLEANER.........................................15-9-l

ELEMENT, Maintenance..............................00-45-lAIR CONDITIONING...................................55-3-l

55-18-lCONTROL PANEL...................................55-73-lCONTROL UNIT.....................................55-73-lENGINE COOLANT TEMPERATURE SWITCHEngine Cooling.....................................14-13-l

ASSIST LINK

Maintenance

.........................................00-49-IAXLE

Rear

HUB, Rear -&VD>

....................................

27-4-lSHAFT

B

BALL JOINT SEALS, Maintenance. . . .

BAROMETRIC PRESSURE SENSOR

On-vehicle Inspection . . . . . . . . . . . .BASIC IDLE SPEED, Adjustment . . . . . .

BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . .

Discharged, Remedy . . . . . . . . . . . .

BELT LOCK CONTROLLER . . . . . . . . .

BLOWER. . . . . . . . . . . . . . . . . .

BOOSTER, Clutch

Parking. . . . . . . . . . ..*.............

BOOSTER . . . . . . . . . . . . . . . .

Operating Check . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .00-52-l

..........13A-91,217-l..............

13A-55-l................64-3-11................35-82-l............55-32,74-t................

55-35-l.................21-6-l.........13A-171,273-l

.................36-8-l................35-87-l................35-64-l

DISC..........................................35-93,103-l

Front, Check.......................................35-70-IRear, Check........................................35-73-lFLUID LEVEL SENSOR, Check........................35-64-l

HOSES, Maintenance.................................00-52-I

LINE................................................35-91-lLINING.............................................35-74-lPAD

Disc, Front.........................................

35-66-l

Disc, Rear.............~..................>..........35-71-lPEDAL.............................................35-84-l

Check and Adjustment......................

:........35-63-lBUMPERFront...............................................51-8-lRear...............................................51-13-l

CAMSHAFT

OIL SEALS..........................................

11-21-lPOSITION SENSOR, On-vehicle Inspection......13A-103,225-lCATALYTIC CONVERTER..............................17-71-l

..........................................

15-33-lCD AUTO CHANGER................................54-191-11CENTER PILLAR GLASS..............................42-33-l

CENTRAL DOOR LOCKING SYSTEM...................42-49-lCHARGE AIR COOLER................................15-11-l

CHARGING SYSTEM..................................l.6-2-11CIGARETTE LIGHTER..............................54-123-k

CLOCK SPRING, SRS..............................528-74-I

CLOSED THROTTLE POSITION SWITCH

Adjustment.......................................

13A-57-lOn-vehicle Inspection.........................13A-101,223-lCLUTCH

BOOSTER OPERATING, Check

MASTER CYLINDER.................................21-14-lPEDAL..............................................21-8-lCheck and Adjustment................................21-5-l

RELEASE CYLINDER................................21-16-IVACUUM LINE cAWD>...............................21-18-I

COLUMN SWITCH..................................54-112-11COMBINATION GAUGES.............................54-33-kCOMBINATION LIGHT...............................54-106-11COMBINATION METERS.............................54-31-11COMPRESSOR CLUTCH RELAY,On-vehicle Inspection...........................13A-123,236-lCONDENSER

Active Exhaust, On-vehicle Inspection...........13A-173,274-lECS.............................................338-20-I

Electronic CABS>..................................35-119-l

CONTROL VALVE.....................................37B-9-l

Fuel Tank Pressure..................................13F-6-IInspection..

........................................17-65-l

CRANKSHAFT

FRONT OIL SEAL....................................

11-25-lPOSITION SENSOR, On-vehicle Inspection......13A-107,227-l

REAR QIL SEAL.....................................11-26-l

Page 732 of 738

Downloaded from www.Manualslib.com manuals search engine ALPHABETICAL INDEX

CROSSMEMBER......................................32-8-lCRUISE CONTROL......................................17-t

CABLE, Check and Adjustment........................17-31-l

SYSTEM............................................17-38-i

Check.............................................

17-32-l

CURB IDLE SPEED, Check............................11-11-l

CYLINDER HEAD GASKET............................11-28-l

D

DAMPER CONTROL MOTOR..........................55-75-lDAMPING FORCE CHANGEOVER ACTUATOR........338-19-I

DASHPOT, Check And Adjustment......................11-l 3-lDEFOGGER

Rear Window.....................................54-192-11

RELAY............................................54-204-11

SWITCH, Rear Window.............................54-203-11

DIFFERENTIALCase, Limited Slip cAWD>...........................27-40-ILimited Slip, Check cAWD>..........................27-15-tCARRIER

DISC BRAKEFront..............................................35-93-lRear..............................................35-103-I

PADS, Maintenance..................................00-52-I

DOOR...............................................42-41-l

Adjustment.........................................42-12-lGLASS.............................................42-43-l

HANDLE............................................42-47-l

INSIDE HANDLE, Play Check..........................42-16-l

LATCH..............................................42-47-lMIRROR............................................51-31-l

REGULATOR........................................42-43-l

TRIM...............................................42-42- 1WATERPROOF FILM.................................42-42-lWINDOW GLASS, Adjustment.........................42-12-l

DRIP LINE WEATHERSTRIP...........................42-63-lDRIVE BELTCompressor, Adjustment.............................55-18-l

Maintenance.......................................00-47-I

Tension, Adjustment..................................11-7-l

Tension, Check.....................................37A-9-l

DRIVE SHAFTFront..............................................26-12-lRear...............................................27-19- I

BOOTS, Maintenance.................................00-52-l

OIL SEALS, Replacement

.......................23-53-l

E

ECSOn-vehicle Inspection..............................,338-l 1 -I

CONTROL UNIT...................................338-20-IINDICATOR LIGHT.................................338-19-ISWITCH..........................................338-18-I

EGR

SOLENOID..........................................17-70-l

On-vehicle Inspection.........................13A-164,269-l

SYSTEM, Inspection..................................17-67-l

TEMPERATURE SENSOR............................17-68-l

On-vehicle Inspection.........................13A-i35,246-I

VALVE..............................................17-68-l

VALVE CONTROL VACUUM, Check....................17-67-l

ELECTRICAL LOAD SWITCH, On-vehicle Inspection 13A-127,238-l

ELECTRONIC CONTROL UNIT

CABS>.................35-119-l

ENGINE.............................................11-18-l

CONTROL...........................................17-5-lCOOLANT

Maintenance.......................................00-51 -IReplacement........................................14-4-l

COOLANT TEMPERATURE GAUGE UNIT..............14-13-l

COOLANT TEMPERATURE SENSOR

Engine and Emission Control.........................17-65-l

Engine Cooling.....................................14-13-IOn-vehicle Inspection..........................13A-93,219-lHOOD..............................................42-18-l

MOUNTING..........................................32-3-lOIL, Maintenance....................................00-47-l

OIL COOLER........................................11-36-lOIL FILTER, Maintenance.............................00-48-l

ROLL STOPPER......................................32-6-l

SPEED ADJUSTING SCREW, Adjustment.............

13A-59-l

EVAPORATIVE EMISSION

CANISTER..........................................

17-65-l

CONTROL SYSTEM.................................17-57-l

Check for Leaks and Clogging........................00-46-l

PURGE SOLENOID..................................17-64-lOn-vehicle Inspection.........................13A-162,268-lEVAPORATOR........................................55-37-lEXHAUSTGAS RECIRCULATION (EGR) SYSTEM................17-66-l

MANIFOLD

PIPE

SYSTEM

Active.............................................15-40-l

Maintenance.......................................00-60-l

F

FAN MOTORCondenser

RELAY, On-vehicle Inspection...................13A-129.240-t

FEEDER CABLE, Antenna...........................54-188-11FENDER.............................................42-24-l

FILLER TUBE CAP, Fuel Tank, Check....................17-65-lFLOOR CONSOLE..................................52A-1 O-I

FLOOR PAN, Check...................................42-16-l

FOG LIGHT........................................54-105-11

SWITCH..........................................54-109-11FRONT IMPACT SENSORS..........................526-68-l

FUELFILLER DOOR, Adjustment............................42-12-l

FILTER............................................13F-10-I

GAUGE UNIT........................................13F-6-IHOSES, Maintenance.................................00-45-l

LINE................................................13F-8-I

PRESSURE SOLENOID, On-vehicle Inspection...13A-166,270-l

PRESSURE TEST, On-vehicle Inspection........13A-180,279-lPUMP..............................................13F-6-I

On-vehicle Inspection..........................13A-72,200-l

PUMP CIRCUIT RESISTOR, On-vehicle Inspection .

13A-84,211-lPUMP OPERATION CHECK, On-vehicle Inspection 13A-179,279-lPUMP RELAY N0.2, On-vehicle Inspection........13A-84,211-l

SYSTEM, Maintenance...............................00-45-I

FUEL TANK..........................................13F-3-IFILLER DOOR.......................................42-23-lFILLER TUBE CAP, Check............................17-65-l

PRESSURE CONTROL VALVE........................

13F-6-IInspection..........................................17-65-l

FULL AUTO AIR CONDITIONING.......................55-54-l

Page 733 of 738

Downloaded from www.Manualslib.com manuals search engine ALPHABETICAL INDEX3FUNCTION, Check (4WS) .

. . . . . . . . . . . .37B-5-l

GARNISHES . . . . . . . . .

GENERATOR . .

GLASSCenter Pillar .

Door.....................

Door Window, Adjustment

Liftgate . .Quarter Window.Window. . . . . . . . . . . . . . . .G SENSOR.. . . . . .

G

.........................51-15-l........................16-12-11

.....................42-33-l.....................42-43-l......42-12-l......42-38-l......42-34-l......42-26-l....338-l 8-l.....35-117-l

H

HAZARD SWITCH..................................54-110-11

HEADLIGHT........................................54-103-11

HEADLINING.......................................52A-16-l

HEATED OXYGEN SENSOROn-vehicle Inspection.........................13A-137,247-l

HEATER..............................................55-3-l

HEATER CONTROL...................................55-30-I

HEATER UNIT........................................55-34-l

HIGH MOUNTED STOP LIGHT.......................54-107-11

HOOD...............................................42-18-lAdjustment.........................................42-11 -I

HORN.............................................54-115-11RELAY..

..........................................54-118-11

SWITCH..........................................54-118-11

HYDRAULIC UNIT CABS>.............................35-110-I

Check

.............................................35-76-lI

IDLE AIR CONTROL MOTOR (Stepper Motor Type)

On-vehicle Inspection.........................13A-153,263-l

IDLE MIXTURE, Check................................11-12-l

IDLE SPEED

Basic, Adjustment.................................13A-55-lCurb,Check........................................11-11-l

IGNITION

CABLES, Maintenance................................00-46-l

COIL, On-vehicle Inspection....................

13A-158,264-l

POWER TRANSISTOR, On-vehicle Inspection....13&158,264-l

SWITCH............................................54-6-11

SWITCH-IG, On-vehicle Inspection...............13A-65, 193-l

SWITCH-ST, On-vehicle Inspection

......................................13A-113,230-l

SYSTEM...........................................16-45-11

TIMING,‘Check.......................................11-9-l

IMPACT SENSORS, Front............................528-68-I

INDUCTION CONTROL VALVE POSITION SENSOROn-vehicle Inspection.........................13A-133,242-l

INJECTOR........................................13A-286-l

On-vehicle Inspection.........................

13A-144,257-l

INSTRUMENT PANEL.................................52A-5-lINTAKE

AIR TEMPERATURE SENSOR........................17-65-l

On-vehicle Inspection..........................13A-88,215-l

CHARGE PRESSURE CONTROL SYSTEM, Check.......15-7-l

INTAKE MANIFOLD...................................15-17-l

PLENUM

K

KEY INTERLOCK MECHANISM....KEYLESS ENTRY SYSTEM........KICKDOWN SERVO...............KNOCK SENSOR.................On-vehicle Inspection............KNUCKLE........................

.................23-51-l.................42-52-l.................23-47-l..............13A-289-l..........

13A-125,237-l..................26-6-l

L

LASH ADJUSTERSCheck.............................................11-15-lReplacement.......................................11-l 7-l

LATCH, Door.........................................42-47-lLEFT MEMBER........................................32-8-l

LEVER, Shift

cFWD>.............................................22-8-lLICENSE PLATE LIGHT.............................54-106-11

LIFTGATE............................................42-20-I

Adjustment.........................................42-11-l

GLASS.............................................42-38-lLIGHT

Indicator, ECS....................................338-19-IFog.............................................54-105-11Front Combination.................................54-106-11High Mounted Stop................................54-107-11License Plate.....................................54-106-11

Rear Combination.................................54-106-11Switch, Stop......................................33B-19-l

LIGHTING SYSTEM..................................54-35-11LIMITED SLIP DIFFERENTIALCheck cAWD>......................................27-l 5-l

Rear Axle, Oil Change, Maintenance...................00-52-I

CASE

LOOSE PANEL.......................................42-25-l

LOWER ARM

Front Suspension.................................33A-10-I

Rear Suspension

M

MAIN MUFFLER

MANUAL AIR CONDITIONING .

MANUAL TRANSAXLE

cFWD> . . . . . . . . . . . .Maintenance. . . . .

MASTER CYLINDER . . .

Clutch . . . . . . . .

MIRROR, Door..

_. .MIXTURE CONTROL (MFI) SystemMOTOR ANTENNA.. . . .

MOTOR RELAY

CABS>, Check .MOULDINGS . . . . . . . . . . . . .MUFFLER, Main

.....................

.......

...............................................................

..........15-30-I..........

15-33-l...........55-6-l..........

22-13-l...........22-2-l..........00-48-I..........35-87-l..........21-14-l..........51-31-l..........17-70-I........54-188-11..........35-83-l..........51-15-l...........

15-30-I..........15-33-l...

13A-131,241-l