Coil MITSUBISHI 3000GT 1993 2.G User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1993, Model line: 3000GT, Model: MITSUBISHI 3000GT 1993 2.GPages: 738, PDF Size: 35.06 MB

Page 187 of 738

Downloaded from www.Manualslib.com manuals search engine CIRCUIT DIAGRAMS - Cooling Circuit185

OPERATIONThe engine control module controls the power

transistors (high speed and low speed) in the moduleto provide radiator fan motor and condenser fan

motor rotation controls in accordance with the engine

coolant temperature and vehicle speed.

NOTEIn the event of faulty water temperature sensor,

the engine control module commands the fan motors

(for both radiator and condenser) to rotate at high

speeds.1. Radiator Fan (Low Speed Rotation)

l

When the engine control module turns onthe power transistor (low speed) in the

module, the current flows from the ignition

switch to the engine control module throughthe radiator fan motor relay (LO) coil.

If the current flows to the fan motor relay

coil, the switch of the relay turns on to supplythe motor driving power (for low speed

rotation). This will cause the current to flow

from the battery to the ground through the

radiator fan motor, relay switch and resistor,rotating the radiator fan at low speeds.

2. Condenser Fan (Low Speed Rotation)

l

The power from the NC compressor lock

controller turns on the condenser fan motorrelay (LO) to rotate the condenser fan at

low speeds.3. Radiator Fan, Condenser Fan (High

Speed Rotation)l

When the engine control module turns onthe power transistor (high speed) in the

module. the radiator fan motor relay (HI)

and condenser fan motor relay (HI) will

operate and the motor driving power (for

high speed rotation) is sent to the radiator

fan motor and condenser fan motor to rotate

the radiator fan and condenser fan at high

speeds.

TROUBLESHOOTING HINTS1. Neither the radiator fan nor condenser

fan rotate at all.

l Check fusible link No. 5.

2. Only the condenser fan does not

operate.l Check dedicated fuse No. 8.

3. The condenser fan do not operate in the

low speed mode, but operate otherwise.

(1) The A/C compressor magnet clutch does

not enter the “ON” state.l Check whether the output of the air

conditioning compressor lock controller

unit is available.

(2) The A/C compressor magnet clutch enters

the “ON” state.l

Check the condenser fan motor relay

(LO)-4. The radiator fan and condenser fan do

not operate in the high speed mode, but

operate otherwise.l Check the engine control unit.

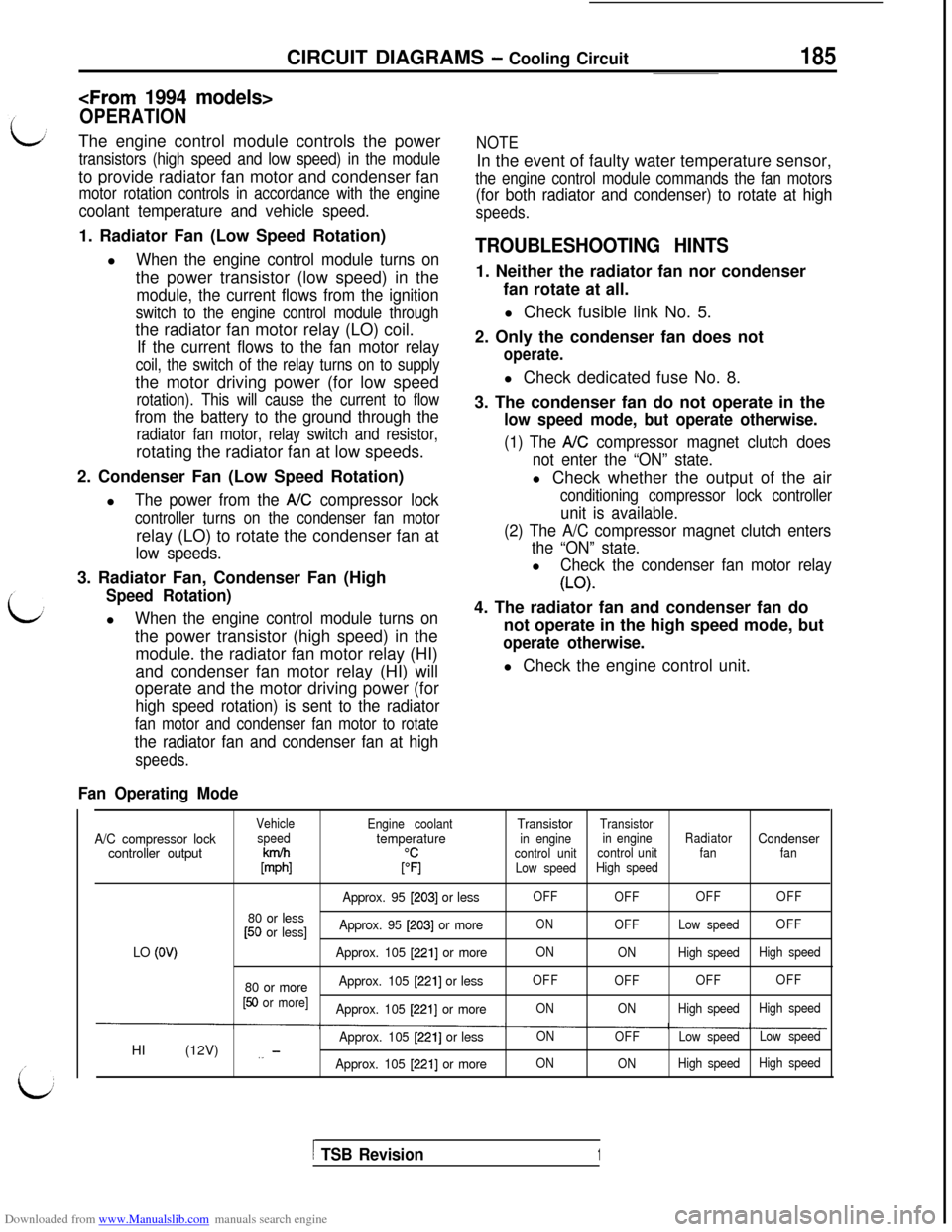

Fan Operating Mode

VehicleA/C compressor lockspeedcontroller output

k%

80 or less[50 or less]

LO

(OV)

80 or more[50 or more]HI (12V)

,_ -

Engine coolanttemperature

$1

Approx. 95 [203] or less

Approx. 95

[203] or more

Approx. 105

[221] or more

Approx. 105

[221] or less

Approx. 105

[221] or more

Approx. 105

[221] or less

Approx. 105

12211 or moreTransistor

Transistor

in enginein engineRadiatorCondensercontrol unitcontrol unitfanfan

Low speedHigh speed

OFF

OFFOFFOFF

ONOFFLow speedOFF

ON

ONHigh speedHigh speed

OFF

OFFOFFOFF

ONONHigh speedHigh speed

ON

OFFLow speedLow speed

ON

ONHigh speedHigh speed

1 TSB Revision1

Page 448 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging Svstem

CHARGING SYSTEM

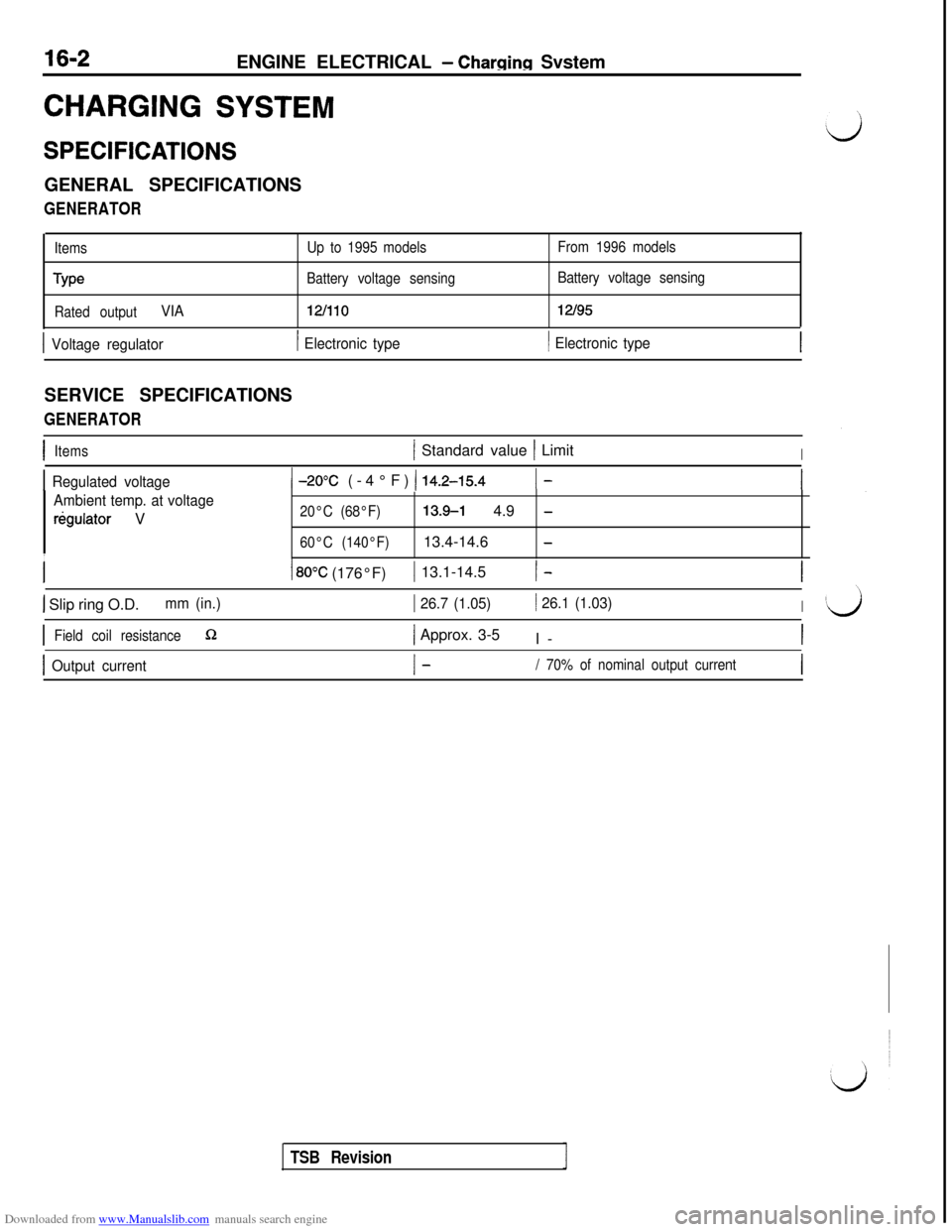

SPECIFICATIONSGENERAL SPECIFICATIONS

GENERATOR

ItemsUp to 1995 modelsFrom 1996 models

TypeBattery voltage sensingBattery voltage sensing

Rated output

VIA12fllO12l95

1 Voltage regulator1 Electronic type1 Electronic typeSERVICE SPECIFICATIONS

GENERATOR

IItems1 Standard value 1 LimitI

I Regulated voltage

Ambient temp. at voltage

rkgulator V

1 -2O’C (-4°F) ( 14.2-15.41 -I

20°C (68°F)13.9-l 4.9 -

60°C (140°F)13.4-14.6 -IIIII

1 80°C (176°F)1 13.1-14.5I-

1 Slip ring O.D.mm (in.)1 26.7 (1.05)/ 26.1 (1.03)I

IField coil resistanceQ1 Approx. 3-5

I-I

I Output currentI-/ 70% of nominal output currentI

TSB Revision

Page 450 of 738

Downloaded from www.Manualslib.com manuals search engine 16-4ENGINE ELECTRICAL - Charging System

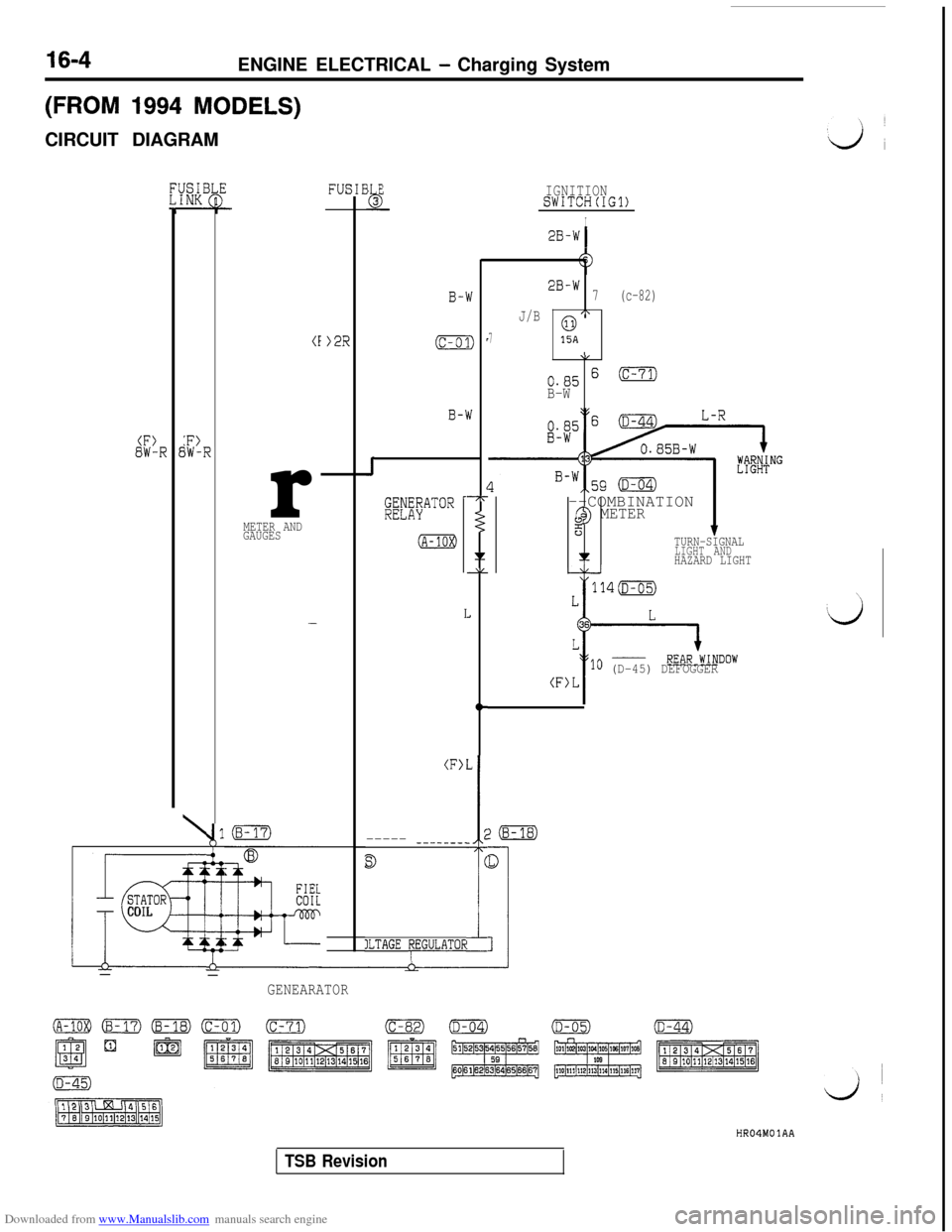

(FROM 1994 MODELS)CIRCUIT DIAGRAM

(F)8W-:F>IW-F

\

1

1-8

COIL

-

i

~

i

-

(Ir

METER AND

GAUGES

-

3 Eb3-

B-\

(c-01

B-\

J

gfF;E$ATOR r

(A-1OX)

I

nr

D r

hJ

s-77

3

ILJL

_)

tc

(F>

----- -------.

3

ILTAGE YEGULATOS

L

;

:

(

L

2B-W7(c-82)

J/B,\

0715A

\,0.85

6(c-71)

B-W

--COMBINATION@ METER

z7TURN-SIGNAL

?LIGHT ANDHAZARD LIGHT

GENEARATOR

IGNITIONSWITCH(IG1)

I2B-WI

(Flo (D-45) DEFOGGER

HR04MOlAA

TSB Revision

Page 451 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System16-5

OPERATION

When engine is stoppedWhen the ignition switch is switched to the “ON”

position, electricity flows from the

‘I” terminal of

the generator to the field coil, and at the same time

the charging warning light illuminates.

When engine is being started/has started

When the engine is started, charging voltage is ap-

plied to the ‘I” terminal of the generator, with the

result that the charging warning light is extinguished.

In addition, because battery voltage is applied to

the “S” terminal of the generator, this battery voltage

is monitored at the

IC voltage regulator, thus switch-ing ON and OFF the current to the field coil and

thereby controlling the output voltage of the genera-

tor.

Power is supplied to each load from the “B” terminal

of the generator.

NOTE

The generator relay functions as a back-up for the

flow of electricity to the field coil if there is a discon-

nection or damaged wiring of the charging warning

light.

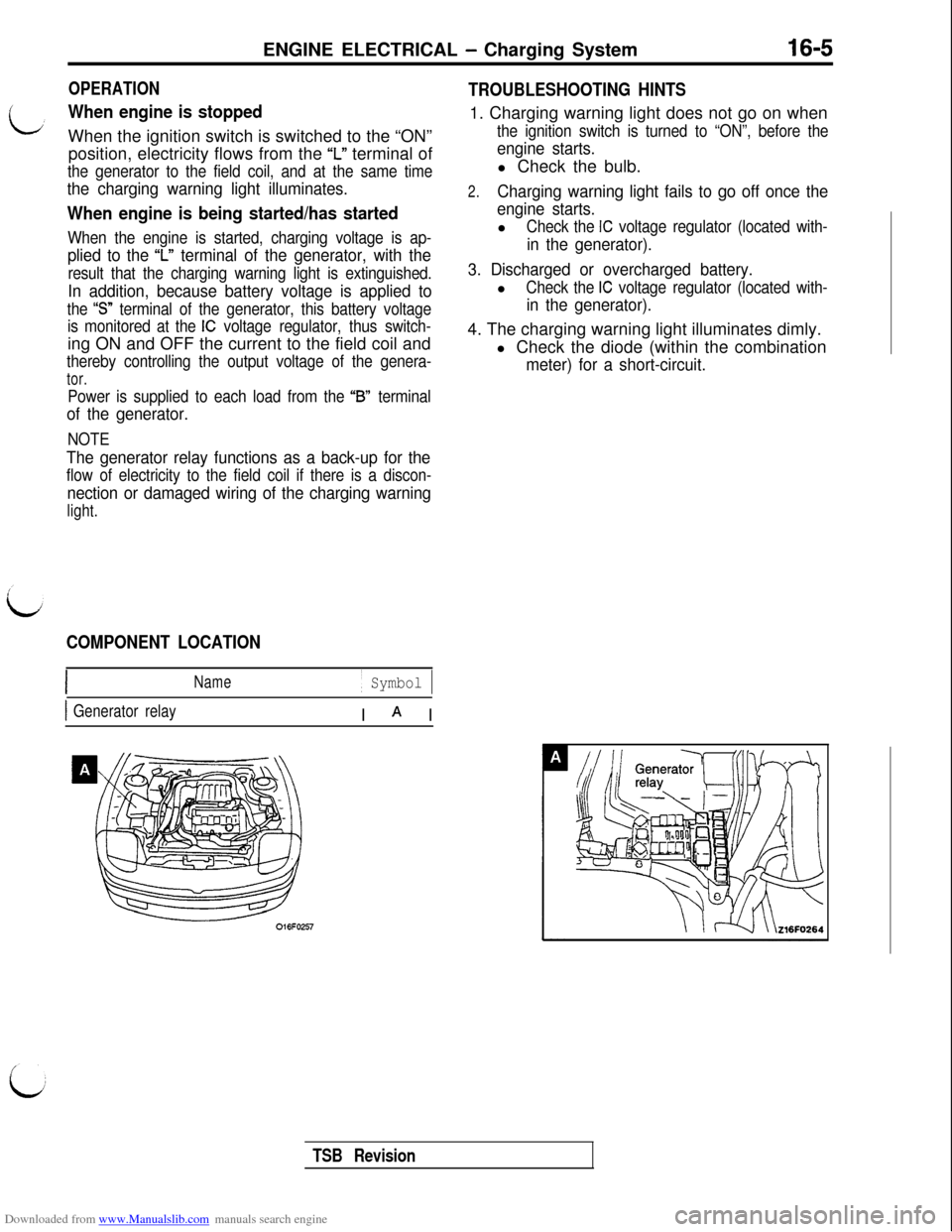

COMPONENT LOCATION

Name/ Symbol 1

1 Generator relayI A I

TROUBLESHOOTING HINTS1. Charging warning light does not go on when

the ignition switch is turned to “ON”, before the

engine starts.l Check the bulb.

2.Charging warning light fails to go off once the

engine starts.l

Check the IC voltage regulator (located with-

in the generator).

3. Discharged or overcharged battery.l

Check the IC voltage regulator (located with-

in the generator).4. The charging warning light illuminates dimly.

l Check the diode (within the combination

meter) for a short-circuit.

TSB Revision

Page 457 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System16-11

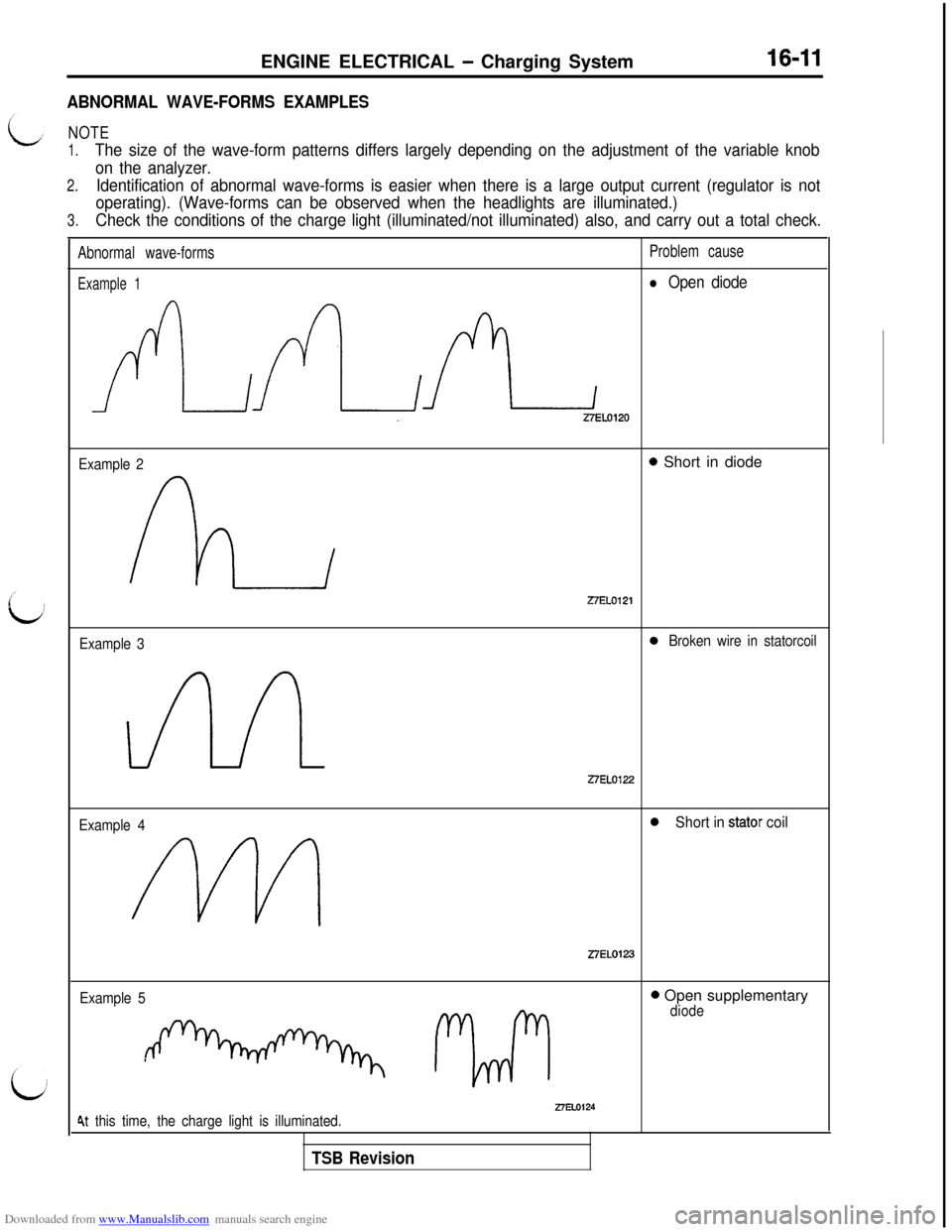

ABNORMAL WAVE-FORMS EXAMPLES

NOTE

1.The size of the wave-form patterns differs largely depending on the adjustment of the variable knob

on the analyzer.

2.Identification of abnormal wave-forms is easier when there is a large output current (regulator is not

operating). (Wave-forms can be observed when the headlights are illuminated.)

3.Check the conditions of the charge light (illuminated/not illuminated) also, and carry out a total check.

Abnormal wave-formsProblem cause

Example 1l Open diode

AALZELOlZO

Example 20 Short in diodeZ7EL0121

Example 30Broken wire in statorcoil

27EL0122

Example 40Short in stator coil

Z7EL0123

Example 5

1 r2rrirl

0 Open supplementarydiode

27EL01244t this time, the charge light is illuminated.

TSB Revision

Page 460 of 738

Downloaded from www.Manualslib.com manuals search engine 16-14ENGINE ELECTRICAL - Charging System

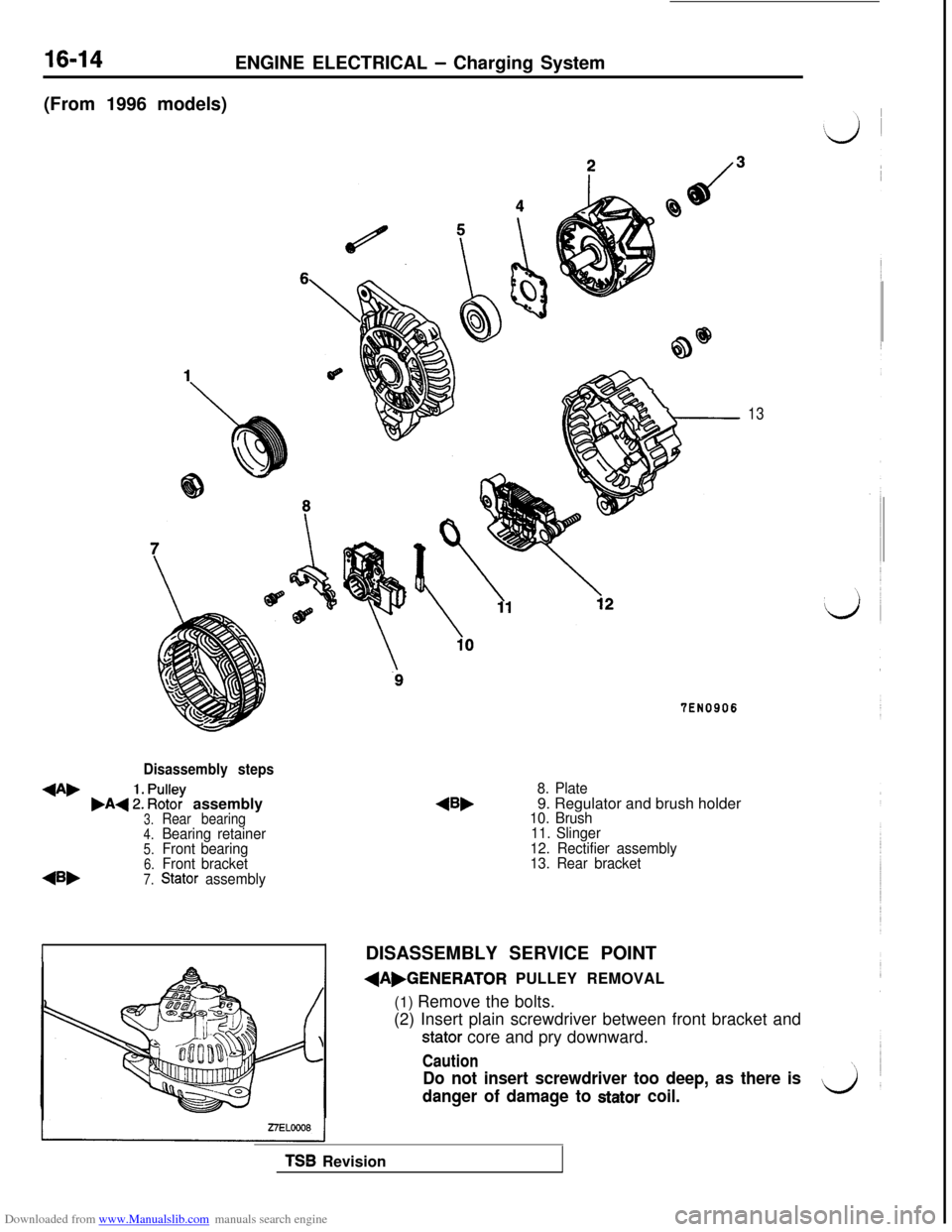

(From 1996 models)

Disassembly steps

+A,,A+ :: ~%? assembly3.Rear bearing4.Bearing retainer5.Front bearing6.Front bracket

45,7.Stator assembly

13

TEN0906

8. Plate9. Regulator and brush holder

10. Brush

11. Slinger

12. Rectifier assembly

13. Rear bracket

IDISASSEMBLY SERVICE POINT

dAbGENERATOR PULLEY REMOVAL

(1) Remove the bolts.

(2) Insert plain screwdriver between front bracket and

stator core and pry downward.

Caution

Do not insert screwdriver too deep, as there is

danger of damage to

stator coil.

TSB Revision

Page 462 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System

h\Z3ELOlO

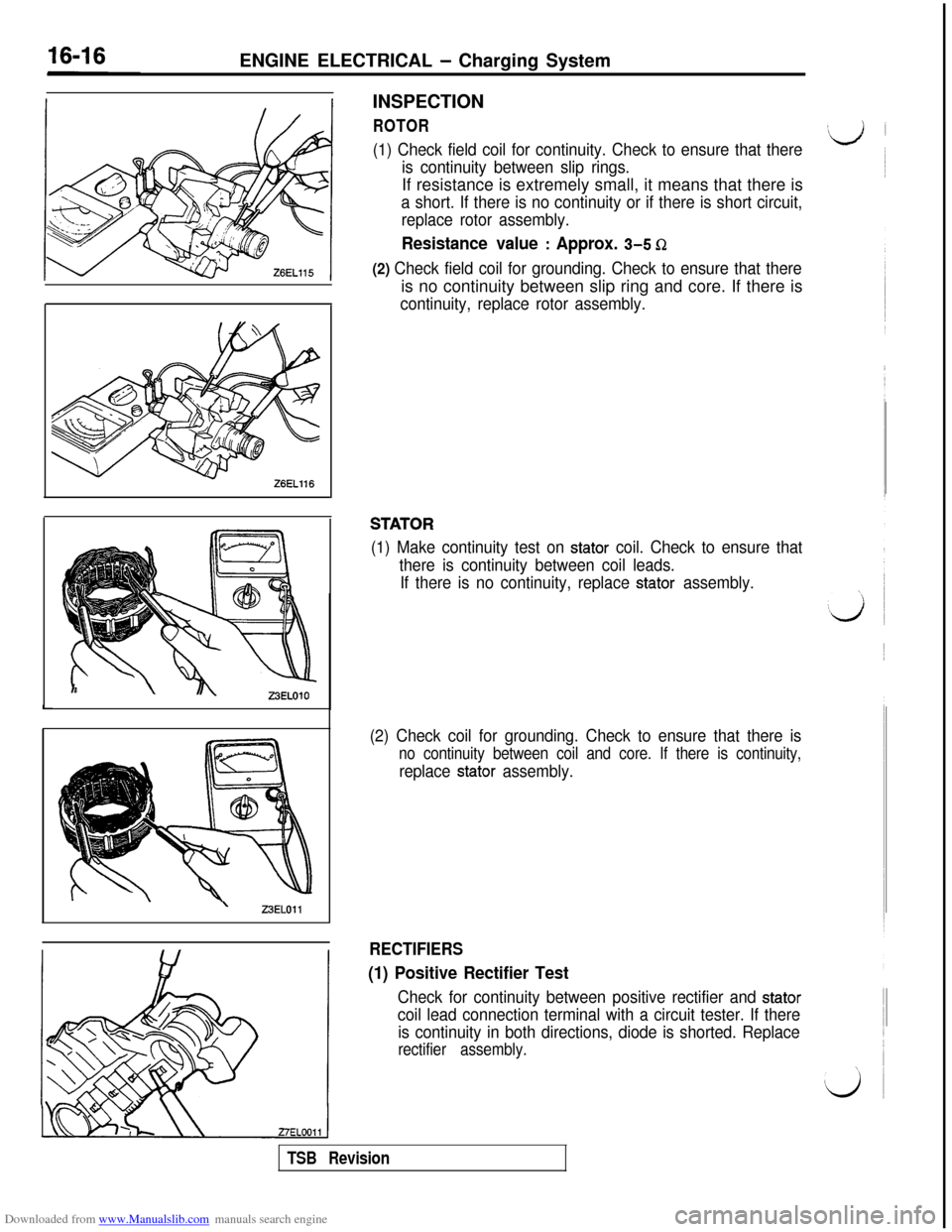

\23ELOllINSPECTION

ROTOR

(1) Check field coil for continuity. Check to ensure that there

is continuity between slip rings.If resistance is extremely small, it means that there is

a short. If there is no continuity or if there is short circuit,

replace rotor assembly.

Resistance value : Approx. 3-5 Q

(2) Check field coil for grounding. Check to ensure that thereis no continuity between slip ring and core. If there is

continuity, replace rotor assembly.

STATOR

(1) Make continuity test on stator coil. Check to ensure that

there is continuity between coil leads.

If there is no continuity, replace

stator assembly.

(2) Check coil for grounding. Check to ensure that there is

no continuity between coil and core. If there is continuity,

replace stator assembly.

RECTIFIERS

(1) Positive Rectifier Test

Check for continuity between positive rectifier and stator

coil lead connection terminal with a circuit tester. If there

is continuity in both directions, diode is shorted. Replace

rectifier assembly.

TSB Revision

Page 463 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System16-17

Limit line

WELO

,Soldered

27EL0014

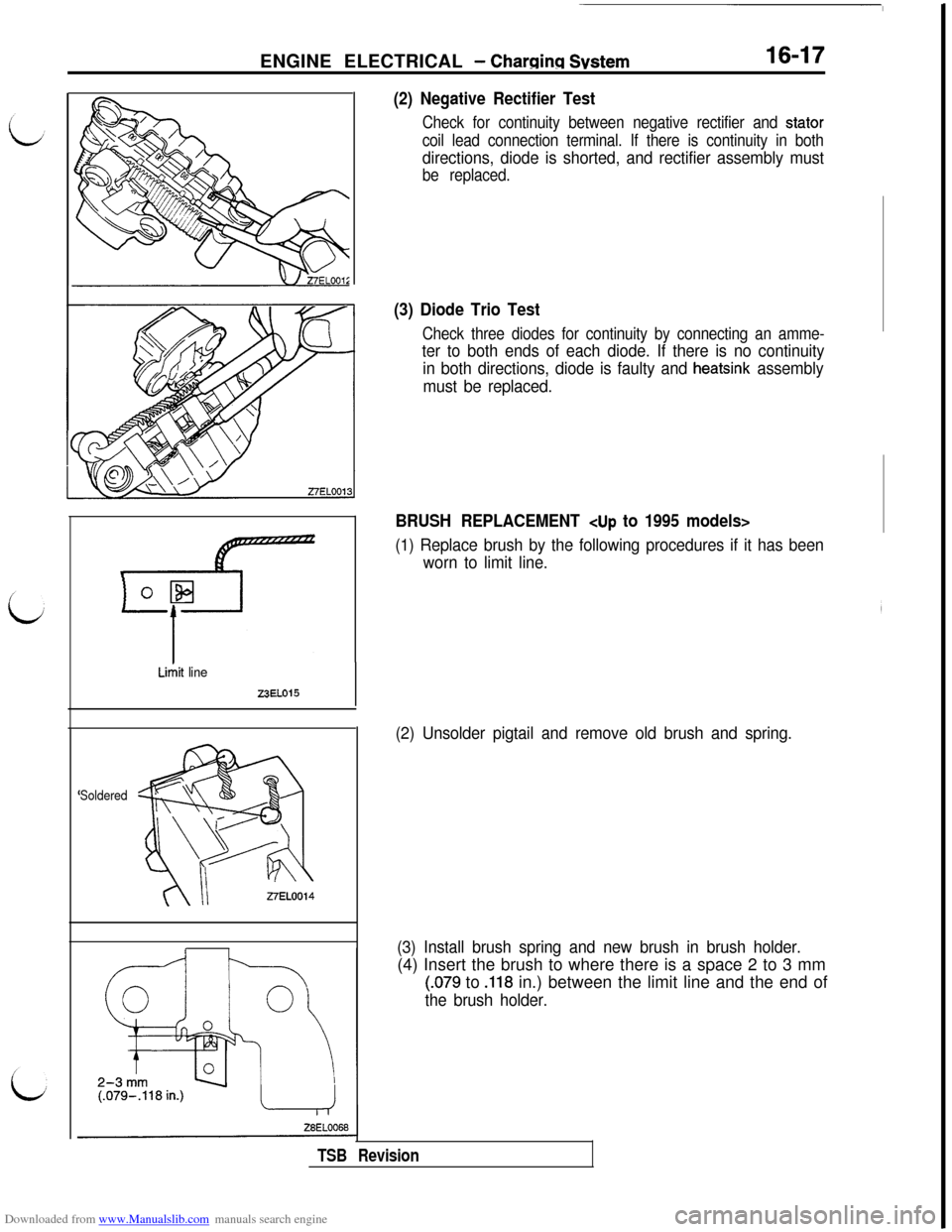

(2) Negative Rectifier Test

Check for continuity between negative rectifier and stator

coil lead connection terminal. If there is continuity in both

directions, diode is shorted, and rectifier assembly must

be replaced.

(3) Diode Trio Test

Check three diodes for continuity by connecting an amme-

ter to both ends of each diode. If there is no continuity

in both directions, diode is faulty and

heatsink assembly

must be replaced.

BRUSH REPLACEMENT

(1) Replace brush by the following procedures if it has been

worn to limit line.

(2) Unsolder pigtail and remove old brush and spring.

(3) Install brush spring and new brush in brush holder.(4) Insert the brush to where there is a space 2 to 3 mm

(.079 to .118 in.) between the limit line and the end of

the brush holder.

TSB Revision

Page 469 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-23

OPERATION

L

0For models equipped with the M/T, the clutch

pedal position switch contact is switched OFF

when the clutch pedal is depressed; when the

ignition switch is then switched to the “ST’ posi-tion, electricity flows to the starter relay and

the starter motor, the contact (magnetic switch)of the starter is switched ON and the starter

motor is activated.

NOTEIf the ignition switch is switched to the “ST

position without the clutch pedal being de-

pressed, electricity flows to the starter relay

(coil), the clutch pedal position switch (contacts)

and to ground, with the result that the contacts

of the starter relay are switched OFF, and, be-

cause the power to the starter motor is thereby

interrupted, the starter motor is not activated.lFor models equipped with the

AIT, when the

ignition switch is switched to the “ST’ position

while the selector lever is at the “P” or “N” posi-

tion, the contact (magnetic switch) of the starter

is switched ON and the starter motor is activated.

TROUBLESHOOTING HINTSThe starter motor does not operate at all.

l Check the starter (coil).

lCheck for poor contact at the battery terminals

and starter.l Check Park/Neutral position switch.

l Check clutch pedal position switch.

l Check starter relay.

l Check theft-alarm starter relay.

l Check key reminder switch.

i

/’

L&J

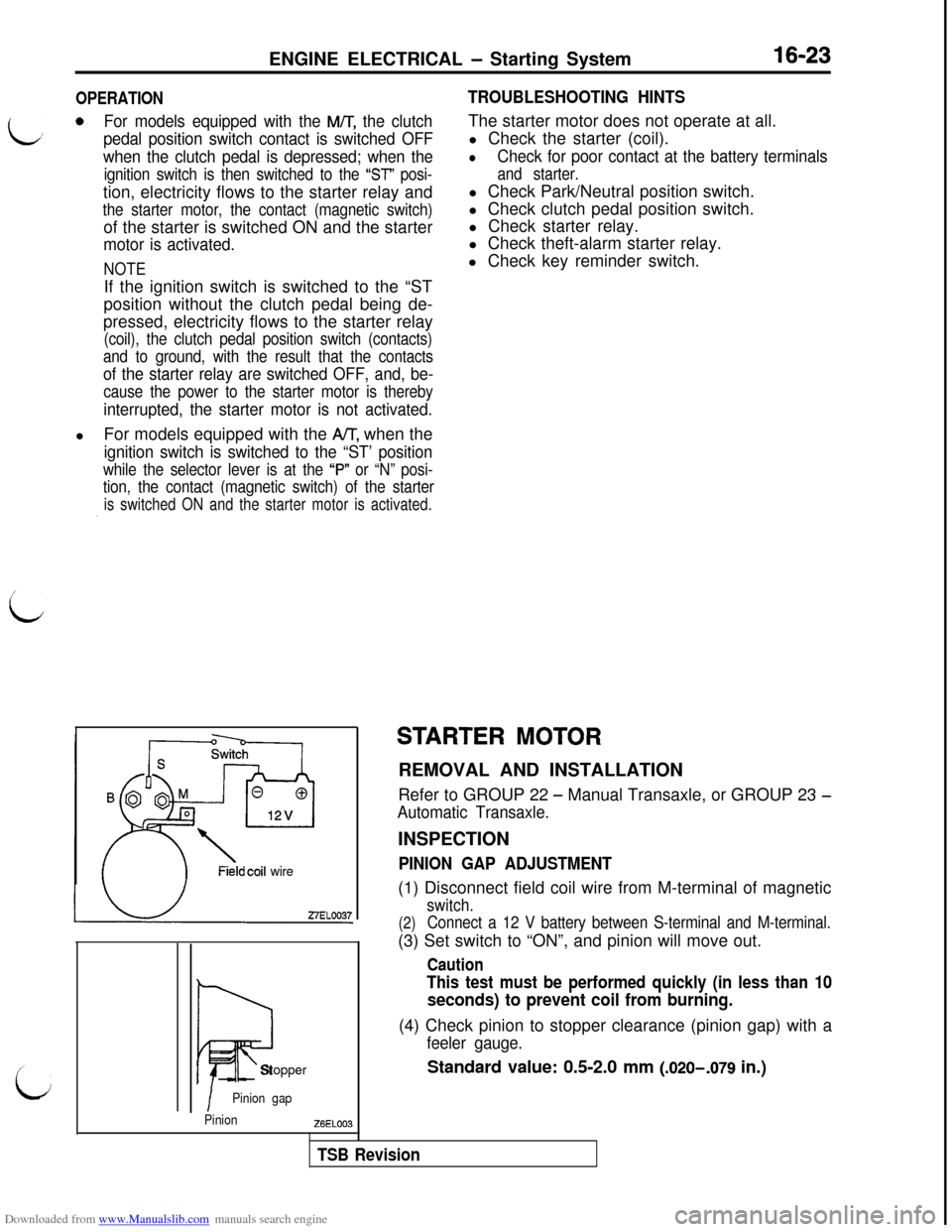

Fieldcoil wire

Iii?Stopper

IPinion gap

PinionZ6EL003

STARTER MOTORREMOVAL AND INSTALLATION

Refer to GROUP 22

- Manual Transaxle, or GROUP 23 -

Automatic Transaxle.INSPECTION

PINION GAP ADJUSTMENT(1) Disconnect field coil wire from M-terminal of magnetic

switch.

(2)Connect a 12 V battery between S-terminal and M-terminal.(3) Set switch to “ON”, and pinion will move out.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.(4) Check pinion to stopper clearance (pinion gap) with a

feeler gauge.

Standard value: 0.5-2.0 mm (.020-,079 in.)

TSB Revision

Page 470 of 738

Downloaded from www.Manualslib.com manuals search engine 16-24ENGINE ELECTRICAL - Starting System

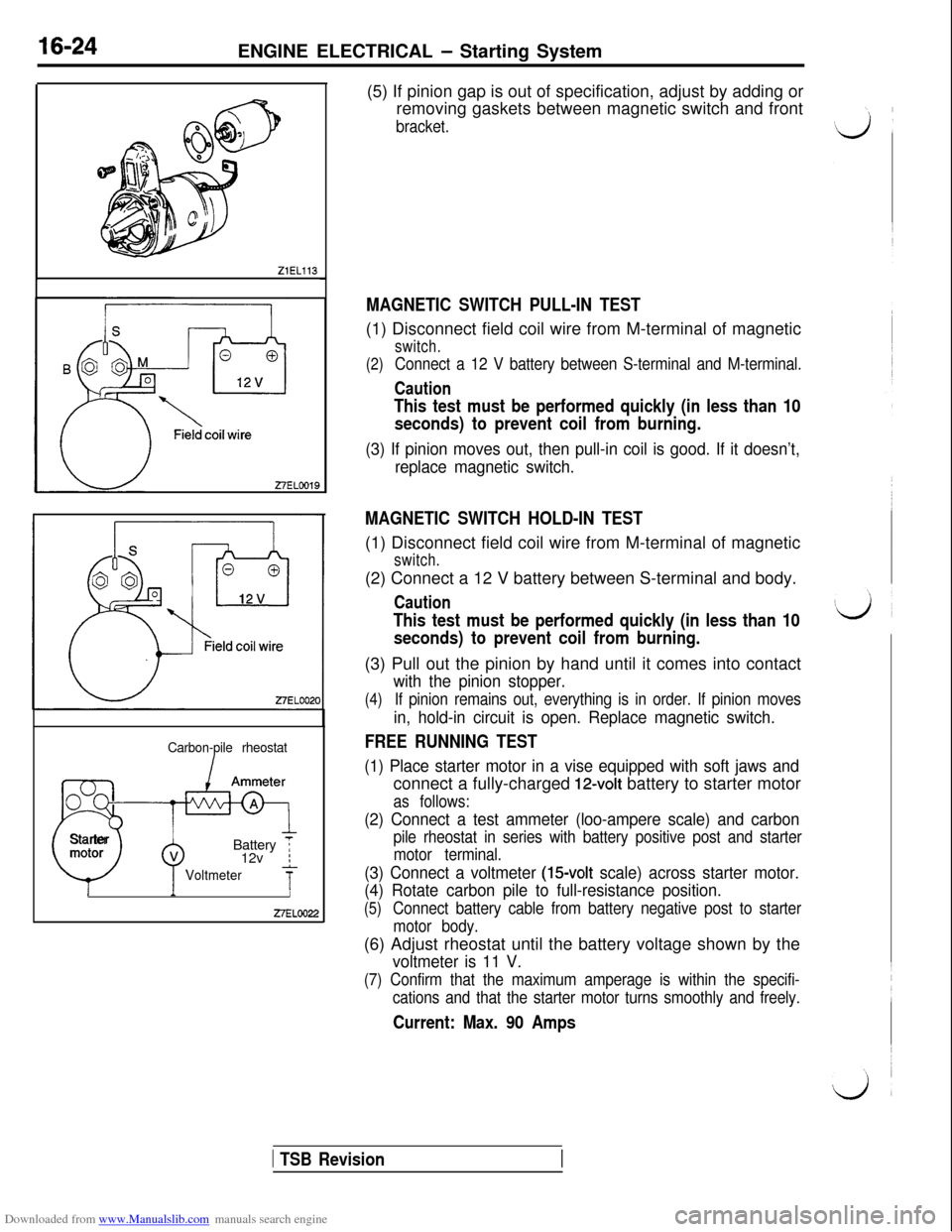

ZlEL11327ELOOlQ

0

5

Startermotor

Carbon-pile rheostat

-I-Battery

i12v I

Voltmeter7-II27ELOO22(5) If pinion gap is out of specification, adjust by adding or

removing gaskets between magnetic switch and front

bracket.

MAGNETIC SWITCH PULL-IN TEST(1) Disconnect field coil wire from M-terminal of magnetic

switch.

(2)

Connect a 12 V battery between S-terminal and M-terminal.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.

(3) If pinion moves out, then pull-in coil is good. If it doesn’t,

replace magnetic switch.

MAGNETIC SWITCH HOLD-IN TEST(1) Disconnect field coil wire from M-terminal of magnetic

switch.(2) Connect a 12 V battery between S-terminal and body.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.(3) Pull out the pinion by hand until it comes into contact

with the pinion stopper.

(4)If pinion remains out, everything is in order. If pinion moves

in, hold-in circuit is open. Replace magnetic switch.

FREE RUNNING TEST

(1) Place starter motor in a vise equipped with soft jaws andconnect a fully-charged

12-volt battery to starter motor

as follows:

(2) Connect a test ammeter (loo-ampere scale) and carbon

pile rheostat in series with battery positive post and starter

motor terminal.

(3) Connect a voltmeter (15volt scale) across starter motor.

(4) Rotate carbon pile to full-resistance position.

(5)Connect battery cable from battery negative post to starter

motor body.(6) Adjust rheostat until the battery voltage shown by the

voltmeter is 11 V.

(7) Confirm that the maximum amperage is within the specifi-

cations and that the starter motor turns smoothly and freely.

Current: Max. 90 Amps

1 TSB Revision