Coil MITSUBISHI 3000GT 1993 2.G Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1993, Model line: 3000GT, Model: MITSUBISHI 3000GT 1993 2.GPages: 738, PDF Size: 35.06 MB

Page 490 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition System

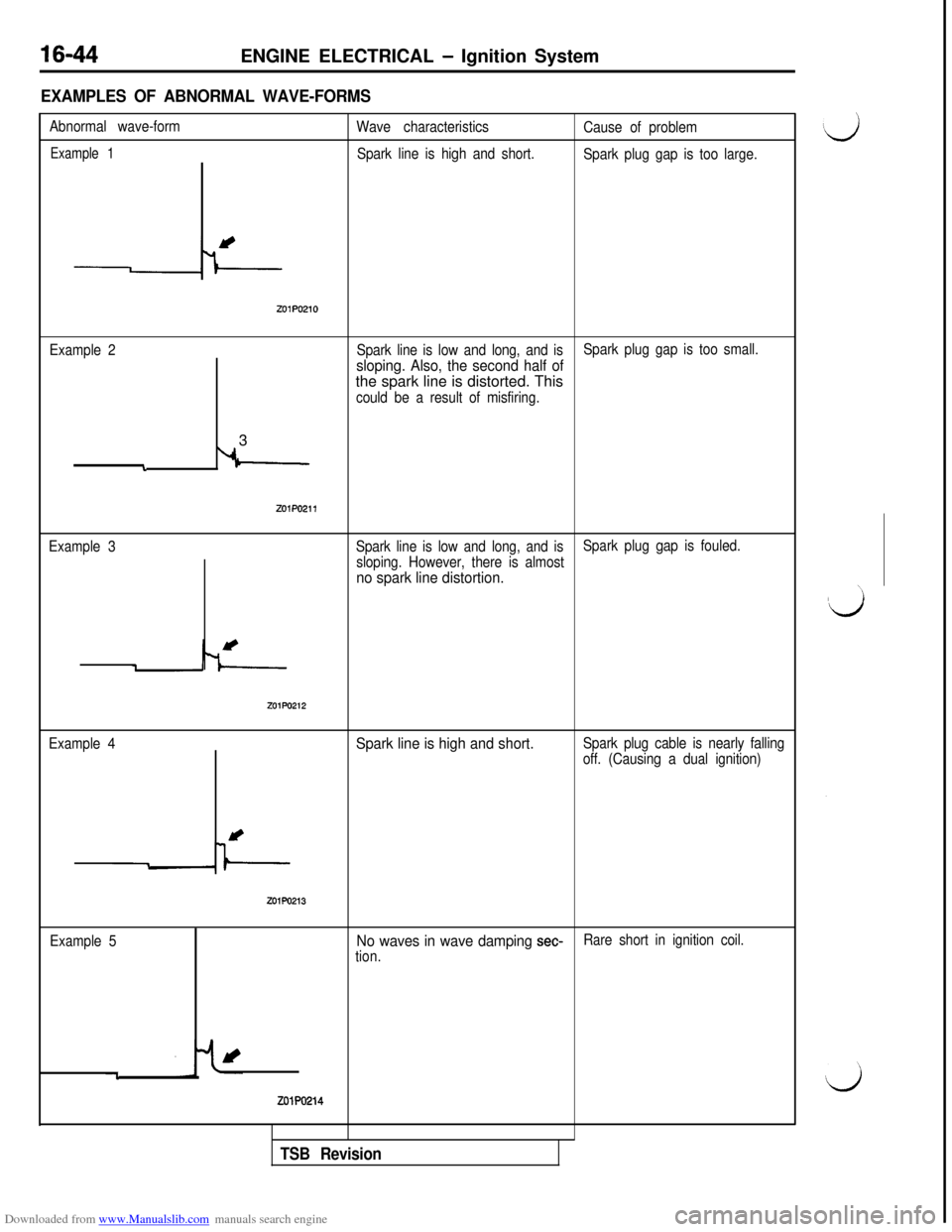

EXAMPLES OF ABNORMAL WAVE-FORMS

Abnormal wave-form

Wave characteristics

Cause of problem

Example 1Spark line is high and short.

Spark plug gap is too large.

z01P0210

Example 2Spark line is low and long, and is

sloping. Also, the second half of

Spark plug gap is too small.the spark line is distorted. This

could be a result of misfiring.3

i

Example 3

zo1Po211

Spark line is low and long, and is

sloping. However, there is almostSpark plug gap is fouled.

no spark line distortion.

ZOlPO212

Example 4Spark line is high and short.Spark plug cable is nearly falling

off. (Causing a dual ignition)

ZOlPO213

Example 5No waves in wave damping set-tion.Rare short in ignition coil.

-l

zolPo214

TSB Revision

Page 491 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition System16-45 l

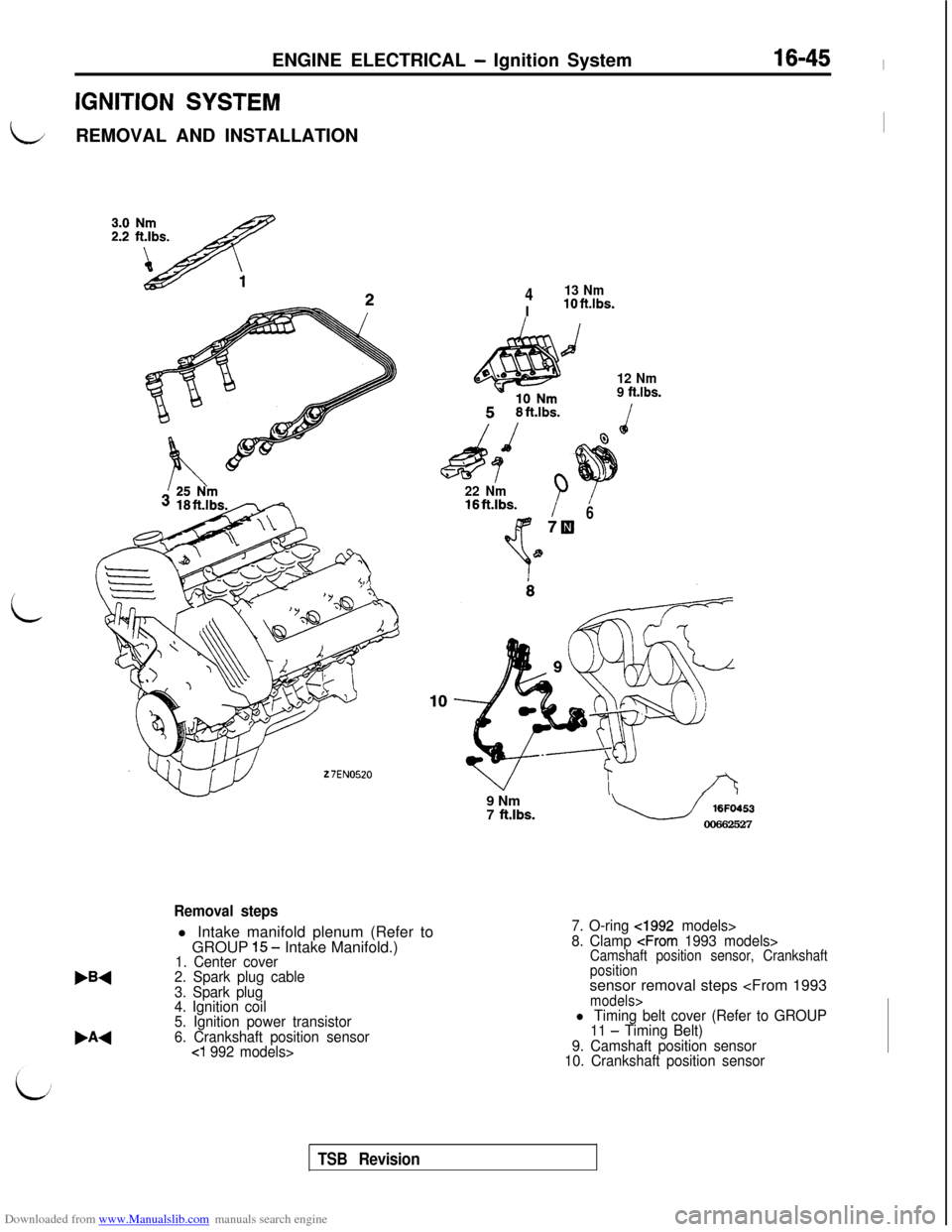

IGNITION SYSTEM

LREMOVAL AND INSTALLATIONI

i

27EN0520

413 NmIlOft.lbs.

d

12 Nm

9 ft.lbs.

22 Nm16ftAbs.B678

W1

,A4

Removal stepsl Intake manifold plenum (Refer to

GROUP

1.5 - Intake Manifold.)1. Center cover

2. Spark plug cable

3. Spark plug

4. Ignition coil

5. Ignition power transistor

6. Crankshaft position sensor

cl 992 models>9 Nm

7

ft.lbs.u 16FO453

00662527

7. O-ring cl992 models>

8. Clamp

positionsensor removal steps

11 - Timing Belt)

9. Camshaft position sensor

10. Crankshaft position sensor

TSB Revision

Page 494 of 738

Downloaded from www.Manualslib.com manuals search engine 16-48ENGINE ELECTRICAL - lanition Svstem

\/27EL0086

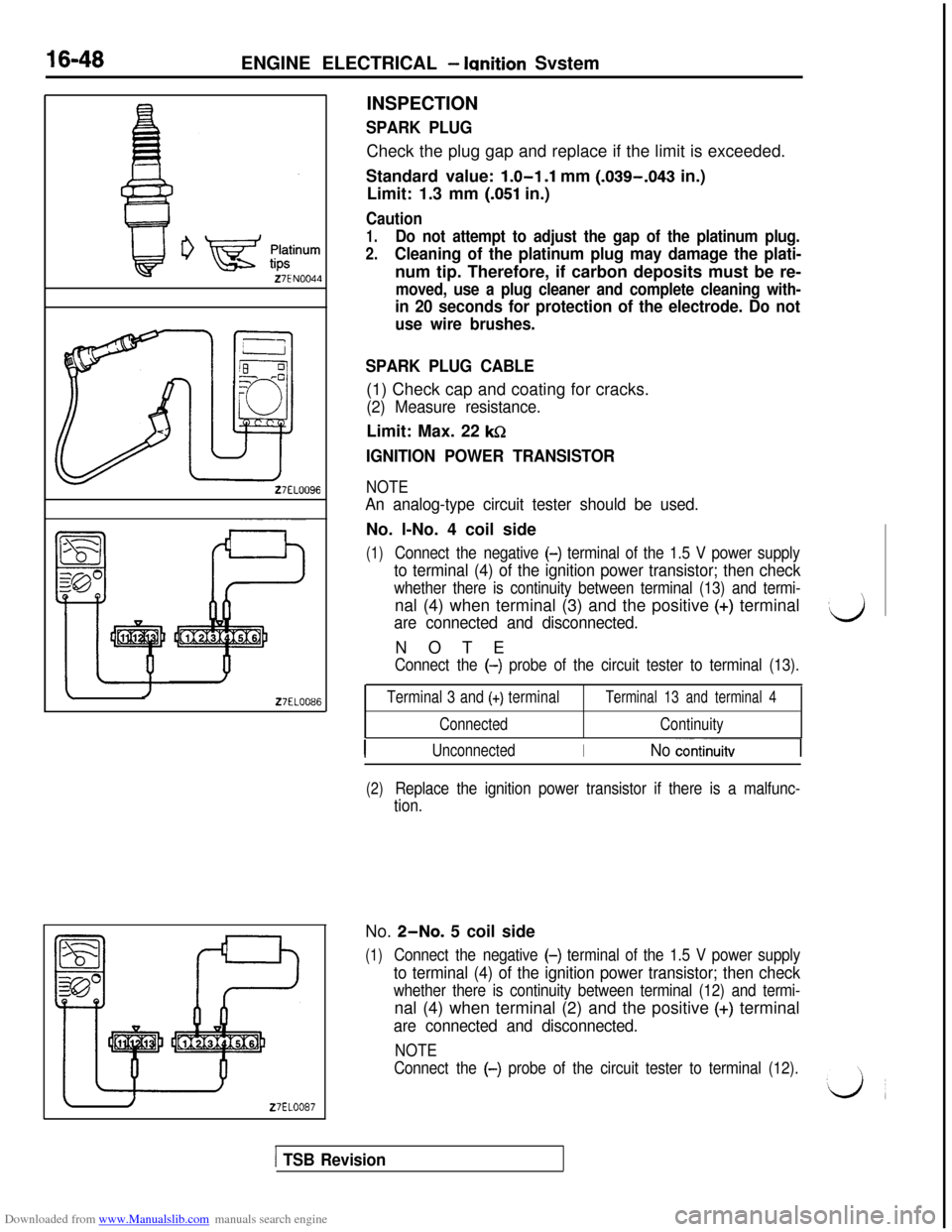

/DEL0087INSPECTION

SPARK PLUGCheck the plug gap and replace if the limit is exceeded.

Standard value:

1.0-l .l mm (.039-.043 in.)

Limit: 1.3 mm

(.051 in.)

Caution

1.Do not attempt to adjust the gap of the platinum plug.

2.Cleaning of the platinum plug may damage the plati-num tip. Therefore, if carbon deposits must be re-

moved, use a plug cleaner and complete cleaning with-

in 20 seconds for protection of the electrode. Do not

use wire brushes.

SPARK PLUG CABLE(1) Check cap and coating for cracks.

(2) Measure resistance.Limit: Max. 22

ksZ

IGNITION POWER TRANSISTOR

NOTE

An analog-type circuit tester should be used.No. l-No. 4 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (13) and termi-nal (4) when terminal (3) and the positive

(+) terminal

are connected and disconnected.NOTE

Connect the (-) probe of the circuit tester to terminal (13).

Terminal 3 and (+) terminal

ConnectedTerminal 13 and terminal 4

Continuity

IUnconnectedINo continuitv

(2)Replace the ignition power transistor if there is a malfunc-

tion.No. ~-NO. 5 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (12) and termi-nal (4) when terminal (2) and the positive

(+) terminal

are connected and disconnected.

NOTE

Connect the (-)

probe of the circuit tester to terminal (12).

[ TSB Revision

Page 495 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL b Ignition System16-49

27EL0089

Z7ELOOQO

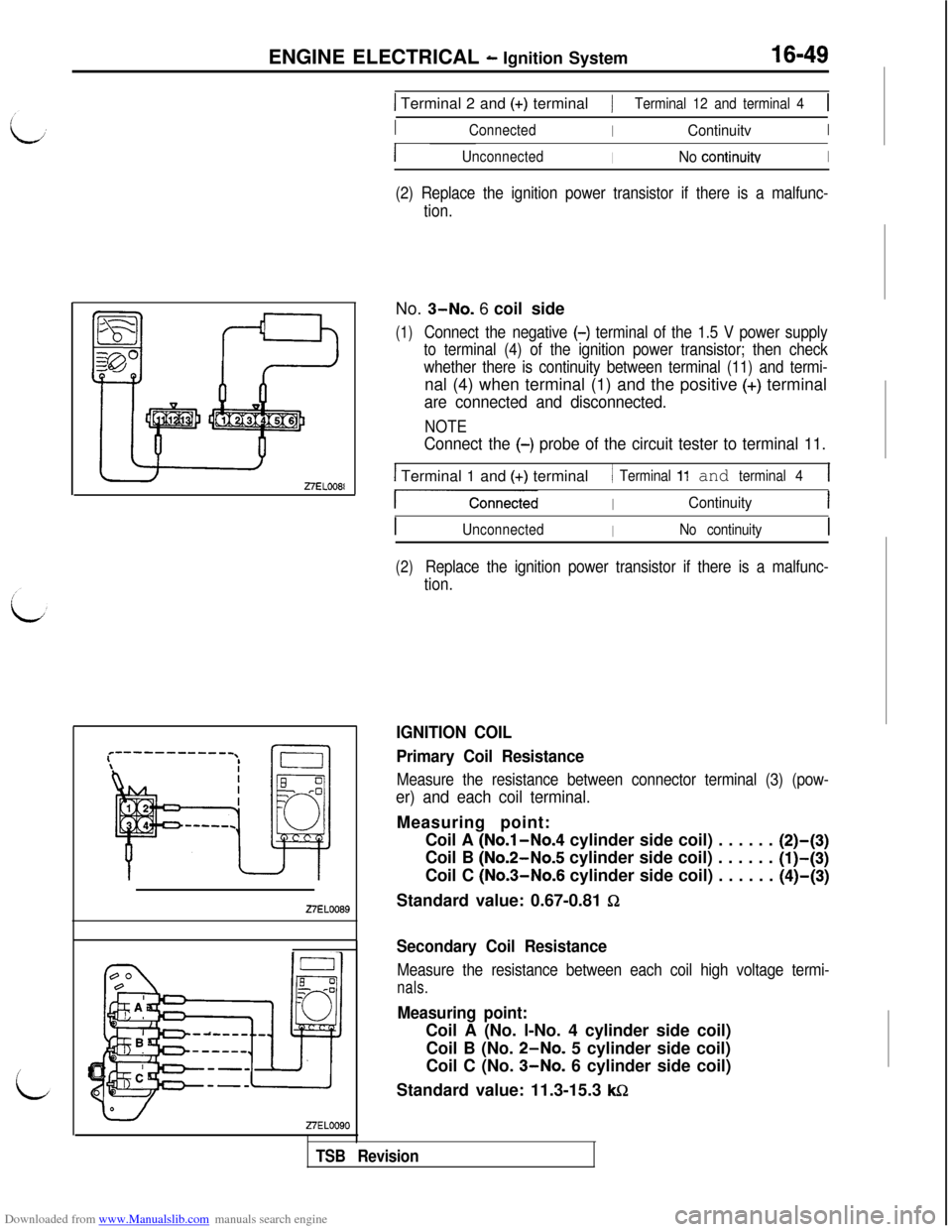

1 Terminal 2 and (+) terminal/Terminal 12 and terminal 41

IConnectedIContinuitvI

IUnconnectedINo continuitvI

(2) Replace the ignition power transistor if there is a malfunc-

tion.No. ~-NO. 6 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (11) and termi-nal (4) when terminal (1) and the positive

(+) terminal

are connected and disconnected.

NOTE

Connect the (-) probe of the circuit tester to terminal 11.

I Terminal 1 and (+) terminal/ Terminal 11 and terminal 41

-ConnectedIContinuityI

IUnconnectedINo continuityI

(2)Replace the ignition power transistor if there is a malfunc-

tion.

IGNITION COIL

Primary Coil Resistance

Measure the resistance between connector terminal (3) (pow-

er) and each coil terminal.Measuring point:

Coil A

(No.l-No.4 cylinder side coil) . . . . . . (2)-(3)Coil B (No.2-No.5 cylinder side coil) . . . . . .

(l)-(3)Coil C (No.3-No.6 cylinder side coil) . . . . . .

(4)-(3)Standard value: 0.67-0.81

Sz

TSB Revision

Secondary Coil Resistance

Measure the resistance between each coil high voltage termi-

nals.

Measuring point:Coil A (No. l-No. 4 cylinder side coil)

Coil B (No. ~-NO. 5 cylinder side coil)

Coil C (No. ~-NO. 6 cylinder side coil)

Standard value: 11.3-15.3

Wz

Page 514 of 738

Downloaded from www.Manualslib.com manuals search engine 54-18CHASSIS ELECTRICAL - Meters and Gauges

OPERATION

When the ignition key is at the “ON” position,the fuel gauge is activated.

l

When there is much fuel, the unit’s resistanceis small and the current flowing in the circuit

is great, so the gauge’s indicator indicates inthe “F” area.

l When there is little fuel, the unit’s resistance

is high and the current flowing in the circuit

is small, so the gauge’s indicator indicates inthe

“E” area.

lWhen the ignition key is at the “ON” position,

the engine coolant temperature gauge is acti-

vated.l

When the engine coolant temperature is high,

the unit’s resistance is low and there is a greatflow of current in the circuit, so the gauge’s

indicator indicates in the “H” area.

l

When the engine coolant temperature is low,

the unit’s resistance is high and there is a smallflow of current in the circuit, so the gauge’s

indicator indicates in the “C” area.

vehicle speed, and vehicle-speed signals areinput to systems (the MFI system, etc.) that

regulate according to the vehicle speed.

TROUBLESHOOTING HINTS

1.The fuel gauge doesn’t function, or shows the

incorrect indication.

(1) Disconnect the connector of the fuel pumpand gauge unit assembly; the ‘F” side is

indicated when terminal (5) is then

grounded.l Check the fuel gauge.

2.The engine coolant temperature gauge doesn’t

function, or shows the incorrect indication.

(1)The “l-l” side is indicated when the connector

of the engine coolant temperature gauge

unit is disconnected and then grounded.l

Check the engine coolant temperature

gauge unit.

3. Systems dependent upon control according to

the vehicle speed do not function correctly.l Check the reed switch (mechanical

speedometer type)l Check the speed sensor (electrical

speedometer type)

coil pressure gauge>l

When the ignition key is at the “ON” position,

the oil pressure gauge is activated.

lWhen oil pressure is high, the internal contacts

of the gauge unit are kept closed for a longerperiod of time. This causes more current to

flow in the circuit, and the gauge pointer swings

to the high pressure side.

lWhen oil pressure is low, the internal contactsof the gauge unit open in a shorter period of

time. Therefore, there is less current flowing

in the circuit and the gauge pointer swings to

the low pressure side.

lWhen the ignition key is set to the “ON” position,the gauge indicator will be at

“0”.l

When the engine is started, the indicator will

move from

“0” to the minus (-) side, and then,as the boost level increases, it will move to

the plus

(+) side.

position, the voltage gauge operates and indi-

cates a battery voltage of approximately 12 V.l

When the engine is started, the voltage gauge

indicates a battery voltage of 12 to 16 V, indicat-ing that the battery is on charge.

4. The oil pressure gauge doesn’t function, or

shows the incorrect indication.

(1)The “H” side is indicated when the connectorof the oil pressure gauge unit is discon-

nected and then grounded.l Check the oil pressure gauge unit.

5.The meter illumination light does not illuminate.

(1) The tail lights illuminate.l Check the rheostat.

6. The voltage gauge doesn’t function, or shows

the incorrect indication.l Check the voltage gauge.

TSB Revision

Page 533 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Lighting System54-37

i

TROUBLESHOOTING

LHEADLIGHT

OPERATION

lTurn the lighting switch to “HEAD”, and the con-

tact point of the headlight relay will be closedto turn “ON” the headlight relay.

lWhen the dimmer switch is placed in the LO

position, the headlight low-beams go on. On

vehicles up to 1993 model, when the switch

is placed in the HI position, the headlight high-

beams go on. On vehicles from 1994 model,when the switch is placed in the HI position,

the headlight high-beams and low-beams go

on.

When the high-beam is lit or when the passing

switch is activated, the high-beam indicator lightwill be lit.

If the driver’s door is opened after the ignition

switch is turned to “OFF” or the ignition switchis turned to “OFF” after the driver’s door is

opened when the headlights are lit, the currentwhich flows to the coil side of the headlight

relay will be cut off by the light automatic shut-OFF unit opening the contact point, and the

headlight relay will be turned “OFF” to automati-

cally shut off the headlights.l

To turn the headlights on again after they are

automatically shut off, turn the lighting switchto “OFF” once and then back to “HEAD”, or

turn the ignition switch to “ACC” or “ON”, and

the

aut0mati.c shut-OFF will be cancelled andthe current will flow from the light automatic

shut-OFF unit to the coil side of the headlightrelay again to close the contact point. Thus,

the headlight relay will be turned “ON” to turnon the headlights.

NOTEWhen the lighting switch is at “HEAD”, the light

automatic shut-OFF system is valid for tail lights,

parking and side marker lights, license plate light,

illumination light, etc.(Refer to

P.54-70.)

l

When the lighting switch is placed in the HEAD

position, current flows through multi-purpose

fuse (6) to the lighting switch, and the ETACScontrol unit. Then the UP timer circuit in the

LETACS control unit is operated, and currentflows from the ETACS control unit to the U con-tact of the pop-up motor U/D (UP/DOWN)

switch, the coil of the pop-up motor relay and

ground, causing the contacts of the pop-up mo-

tor relay to close.

When the contacts of the pop-up motor relay

close, current flows through the contacts of the

pop-up motor relay to the pop-up motor and

ground, causing the pop-up motor to rotate,

which brings the headlights to the UP position.

The pop-up motor rotates until the automatic

UP stop position is reached, then the contactsof the interlocked U/D (UP/DOWN) switch

change from the U to D contacts. As a result,

the contacts of the pop-up motor relay opento cut off the current supplied to the pop-up

motor. Then the pop-up motor ceases to rotate,

holding the headlights in the UP position.l

When the lighting switch is placed in the TAIL

or OFF position, current flows through the multi-

purpose fuse (6) to the lighting switch, and the

ETACS control unit. Then the DOWN timer cir-

cuit in the ETACS control unit is operated and

current flows from the ETACS control unit to

the DOWN contacts of the pop-up motor U/D

(UP/DOWN) switch, the coil of the pop-up motor

relay and ground, causing the contacts of the

pop-up motor relay to close.

When the contacts of the pop-up motor relay

close, current flows through the contacts of the

pop-up motor relay to the pop-up motor andground, causing the pop-up motor to rotate,

which brings the headlights to the DOWN posi-

tion.

The pop-up motor rotates until the automatic

DOWN stop position is reached, then the con-

tacts of the interlocked U/D (UP/DOWN) switch

change from the D to U contacts. As a result,

the contacts of the pop-up motor relay open

to cut off current supply to the pop-up motor.

Then the pop-up motor ceases to rotate, holding

the headlights in the DOWN position.

When the pop-up switch is placed in the UP

position, current flows through multi-purpose

fuse (6) to the lighting switch, the pop-up switch

and the ETACS control unit, which brings the

headlights to the UP position and holds them

in the UP position just like when they are oper-

ated by the lighting switch.l

When the pop-up switch is placed in the DOWN

position, current flows through the multi-purpose

fuse (6) to the lighting switch, the pop-up switch

and the ETACS control unit, which brings the

headlights to the DOWN position and holds them

in the DOWN position just like when they are

operated by the lighting switch.

TSB Revision

Page 558 of 738

Downloaded from www.Manualslib.com manuals search engine 54-62CHASSIS ELECTRICAL - Lighting System

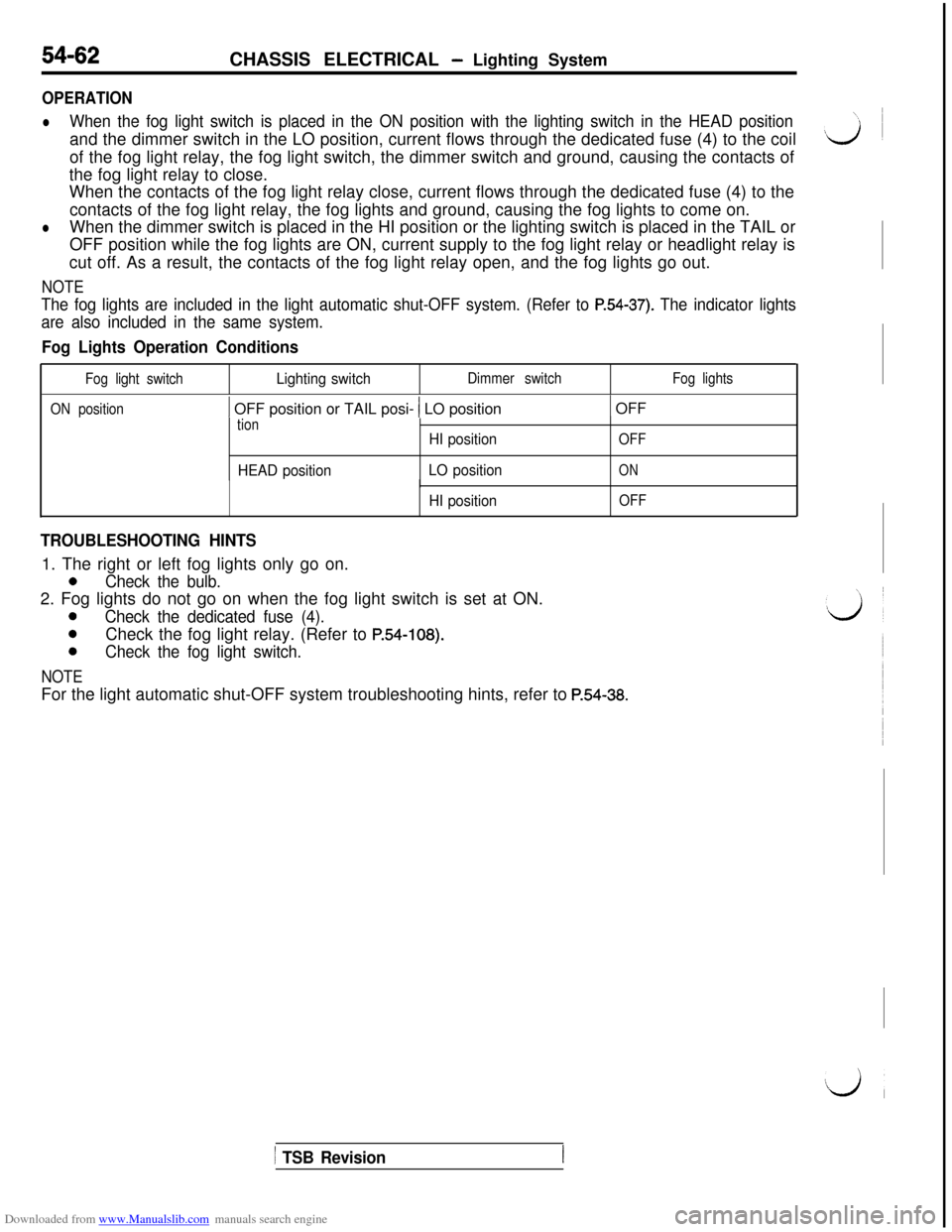

OPERATION

lWhen the fog light switch is placed in the ON position with the lighting switch in the HEAD positionand the dimmer switch in the LO position, current flows through the dedicated fuse (4) to the coil

of the fog light relay, the fog light switch, the dimmer switch and ground, causing the contacts of

the fog light relay to close.

When the contacts of the fog light relay close, current flows through the dedicated fuse (4) to the

contacts of the fog light relay, the fog lights and ground, causing the fog lights to come on.

lWhen the dimmer switch is placed in the HI position or the lighting switch is placed in the TAIL or

OFF position while the fog lights are ON, current supply to the fog light relay or headlight relay is

cut off. As a result, the contacts of the fog light relay open, and the fog lights go out.

NOTE

The fog lights are included in the light automatic shut-OFF system. (Refer to P.54-37). The indicator lights

are also included in the same system.

Fog Lights Operation Conditions

Fog light switchLighting switchDimmer switchFog lights

ON position

1 OFF position or TAIL posi- 1 LO position1 OFF

tion

HEAD positionHI position

LO position

OFF

ON

HI position

I

OFF

TROUBLESHOOTING HINTS1. The right or left fog lights only go on.

0Check the bulb.2. Fog lights do not go on when the fog light switch is set at ON.

0Check the dedicated fuse (4).

0Check the fog light relay. (Refer to P.54-108).

0Check the fog light switch.

NOTEFor the light automatic shut-OFF system troubleshooting hints, refer to

P.54-38.

1 TSB Revision

Page 566 of 738

Downloaded from www.Manualslib.com manuals search engine 54-70CHASSIS ELECTRICAL - Lighting System

OPERATION

0When the lighting switch is placed in the TAILor HEAD position, current flows through the

coil of the tail light relay to the lighting switchand ground, causing the contacts of the tail

light relay to close.

Then current flows through the contacts of thetail light relay to the dedicated fuse

(2) the

individual lights and ground, causing the tail

lights, parking/side marker lights and licenseplate lights to go ON.

lIf the driver’s door is opened after the ignition

switch is turned to “OFF” or the ignition switchis turned to “OFF” after the driver’s door is

opened when the tail lights are lit, the current

which flows to the coil side of the tail light relaywill be cut off by the light automatic shut-off

unit opening the contact point, and the tail light

relay will be turned “OFF’ to automatically shut

off the tail lights, parking and front side marker

lights and license plate light.

lTo turn on the tail lights, parking and front side

marker lights and license plate light again after

they are automatically shut off, turn the lightingswitch to “OFF” once and to “HEAD” again,

or turn the ignition switch to “ACC” or “ON”,

and the automatic shut-OFF will be cancelled

and the current will flow from the light automaticshut-OFF unit to the coil side of the tail light

relay to close the contact point. Thus, the taillight relay will be turned “ON” to turn on the

tail lights, parking and front marker lights and

license plate light.

NOTE

When the lighting switch is at the “HEAD” position,

the light automatic shut-OFF system will be also

activated for the headlights. (Refer to P.54-37.) The

same system will also be activated for the illumina-

tion lights, etc.

TROUBLESHOOTING HINTS1. All lights don’t illuminate.

(1) The headlights don’t illuminate, either.l Check the fusible link (3).

(2) The headlights illuminate.l Check the tail light relay. (Refer to

P.54-108.)l Check the dedicated fuse (2).

l Check the lighting switch. (Refer to

P.54-113.)l Check the light automatic shut-OFF

unit. (Refer to

P.54-108.)2. Some light does not come on.

l Check the bulb.

l Check the grounding circuit.

3. Some light is not automatically shut off.

lCheck the driver’s side door switch.

(Refer to GROUP 42- Door Assembly.)l Check the automatic shut-OFF unit.

(Refer to

P.54-108.)

1 TSB Revision

Page 611 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Horn54-115

HORN

SPECIFICATIONS

GENERAL SPECIFICATIONS

Horn (Except for theft-alarm horn)

ItemsI Specifications

Type

Effective sounding voltage V

Power consumption A

Sound level dB

Fundamental frequency Hz

“low” sound

“high” sound

“low” sound

“high” sound

Fiat type

11.5-15

3.0

100-112

100-112350-390395-435

Theft-alarm horn

1 ItemsI Specifications

1 Type1 Flat typeI

Effective sounding voltage V

Power consumption A

Sound level dB

Fundamental frequency Hz

11-14.5

Max. 3.5

105-120I

I 405-435

TROUBLESHOOTING

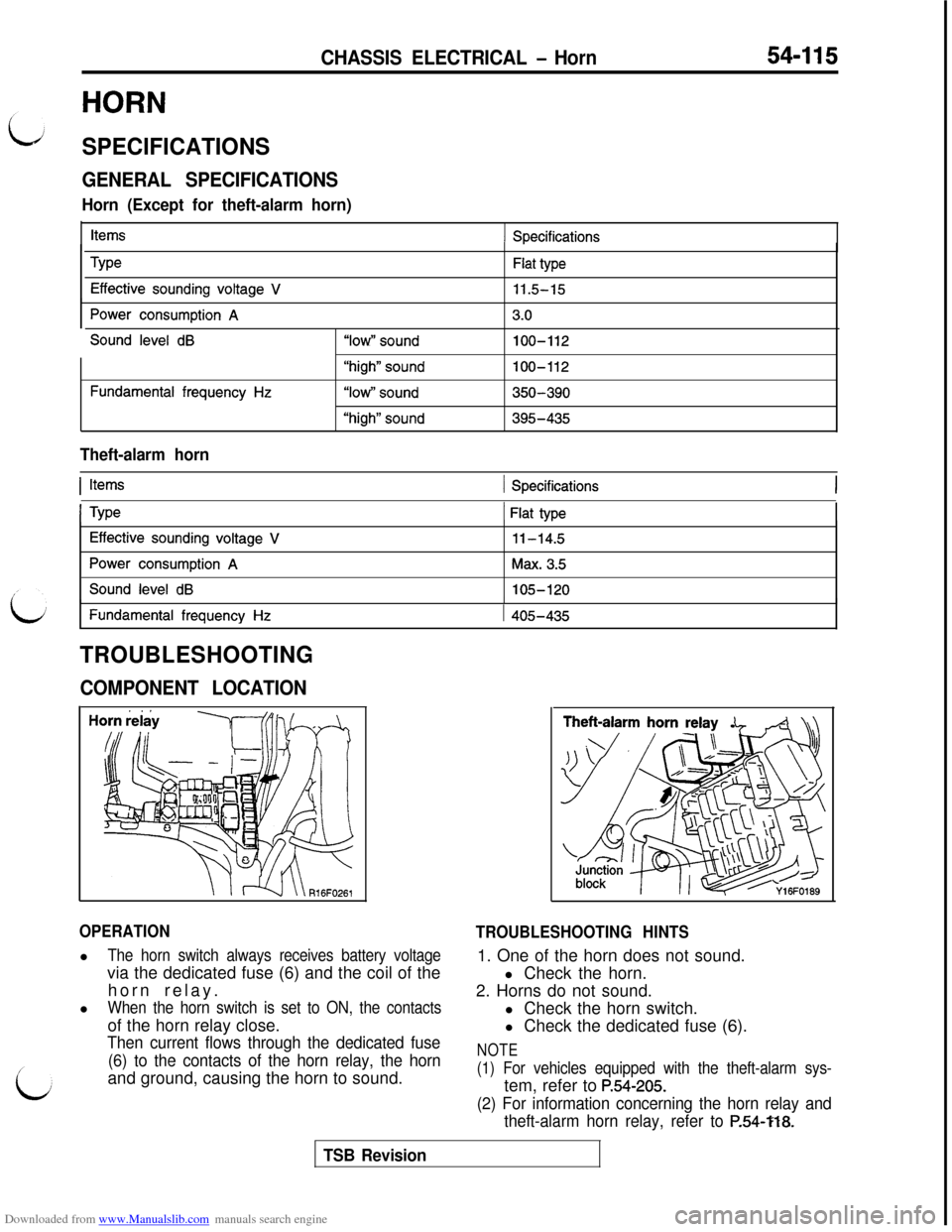

COMPONENT LOCATION

OPERATIONl

The horn switch always receives battery voltagevia the dedicated fuse (6) and the coil of the

horn relay.

l

When the horn switch is set to ON, the contactsof the horn relay close.

Then current flows through the dedicated fuse

(6) to the contacts of the horn relay, the hornand ground, causing the horn to sound.1. One of the horn does not sound.

TROUBLESHOOTING HINTSl Check the horn.

2. Horns do not sound.

l Check the horn switch.

l Check the dedicated fuse (6).

NOTE

(1) For vehicles equipped with the theft-alarm sys-tem, refer to

P.54-205.

(2) For information concerning the horn relay and

theft-alarm horn relay, refer to

P.54-?18.

TSB Revision

Page 660 of 738

Downloaded from www.Manualslib.com manuals search engine 54-164CHASSIS ELECTRICAL - Radio and Tape Player

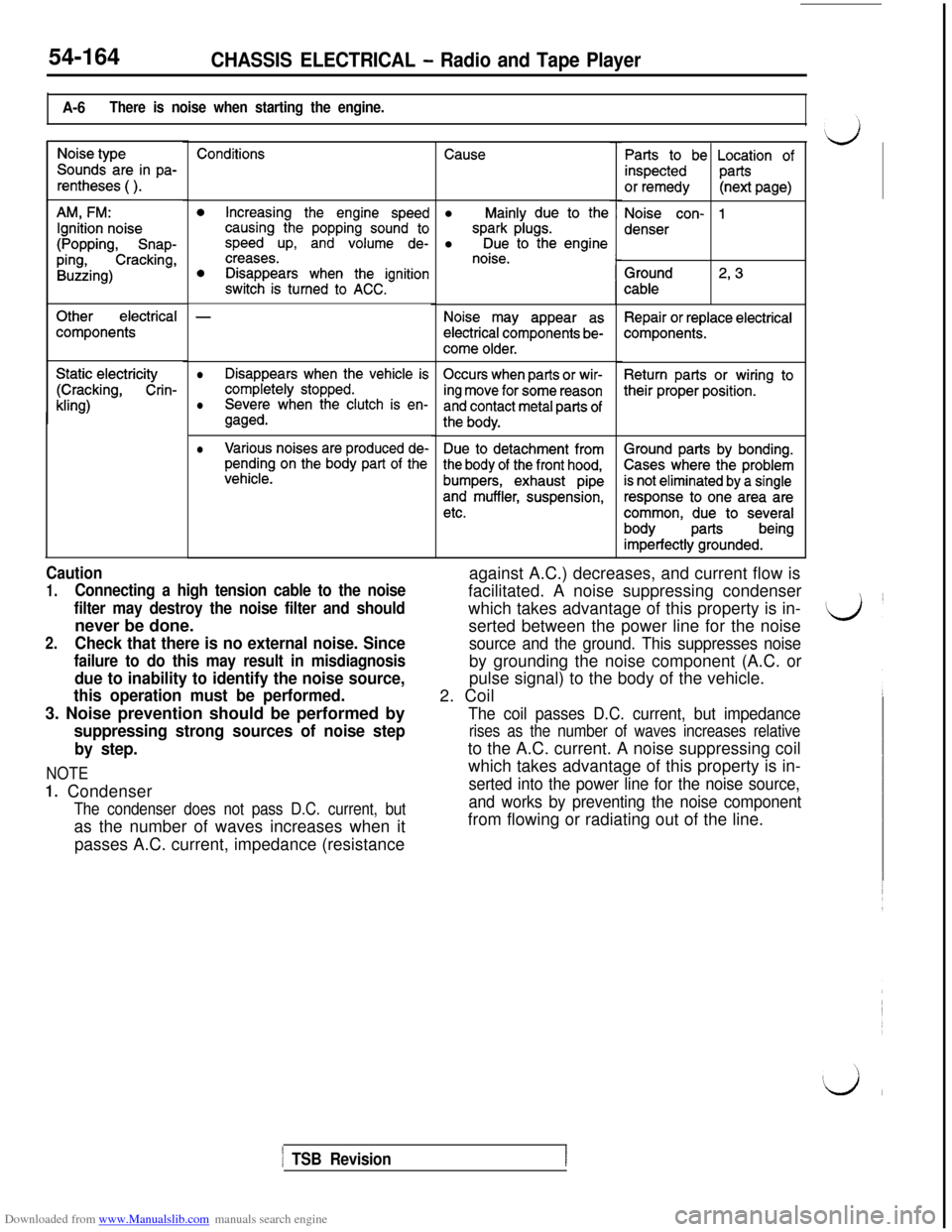

A-6There is noise when starting the engine.

Noise type

Sounds are in pa-

rentheses ( ).

AM, FM:

Ignition noise

(Popping, Snap-

ping,Cracking,

Buzzing)

Otherelectrical

components

Static electricity

(Cracking, Crin-

kling)

Conditions

0Increasing the engine speedcausing the popping sound tospeed up, and volume de-creases.0Disappears when the ignitionswitch is turned to ACC.

-

lDisappears when the vehicle is

completely stopped.Occurs when parts or wir-

Severe when the clutch is en-ing move for some reasonlgaged.and contact metal parts of

the body.

lVarious noises are produced de-pending on the body part of thevehicle.

Due to detachment from

the body of the front hood,

bumpers, exhaust pipe

and muffler, suspension,

etc.

Causel

Mainly due to the

spark plugs.l Due to the enginenoise.

Noise may appear as

electrical components be-

come older.

Parts to be Location of

inspectedparts

or remedy(next page)

Noise con- 1

denser

Ground

cable2, 3

Repair or replace electricalcomponents.

Return parts or wiring to

their proper position.

Caution

1.Connecting a high tension cable to the noise

filter may destroy the noise filter and shouldnever be done.

2.Check that there is no external noise. Since

failure to do this may result in misdiagnosis

due to inability to identify the noise source,

this operation must be performed.3. Noise prevention should be performed by

suppressing strong sources of noise step

by step.

NOTE

1. Condenser

The condenser does not pass D.C. current, butas the number of waves increases when it

passes A.C. current, impedance (resistanceagainst A.C.) decreases, and current flow is

facilitated. A noise suppressing condenser

which takes advantage of this property is in-

serted between the power line for the noise

source and the ground. This suppresses noiseby grounding the noise component (A.C. or

pulse signal) to the body of the vehicle.

2. Coil

The coil passes D.C. current, but impedance

rises as the number of waves increases relativeto the A.C. current. A noise suppressing coil

which takes advantage of this property is in-

serted into the power line for the noise source,

and works by preventing the noise componentfrom flowing or radiating out of the line.

1 TSB Revision

Ground parts by bonding.

Cases where the problem

is not eliminated by a single

response to one area are

common, due to several

bodypartsbeing

imperfectly grounded.