Disc MITSUBISHI 3000GT 1994 2.G User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1994, Model line: 3000GT, Model: MITSUBISHI 3000GT 1994 2.GPages: 738, PDF Size: 35.06 MB

Page 471 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-25

L

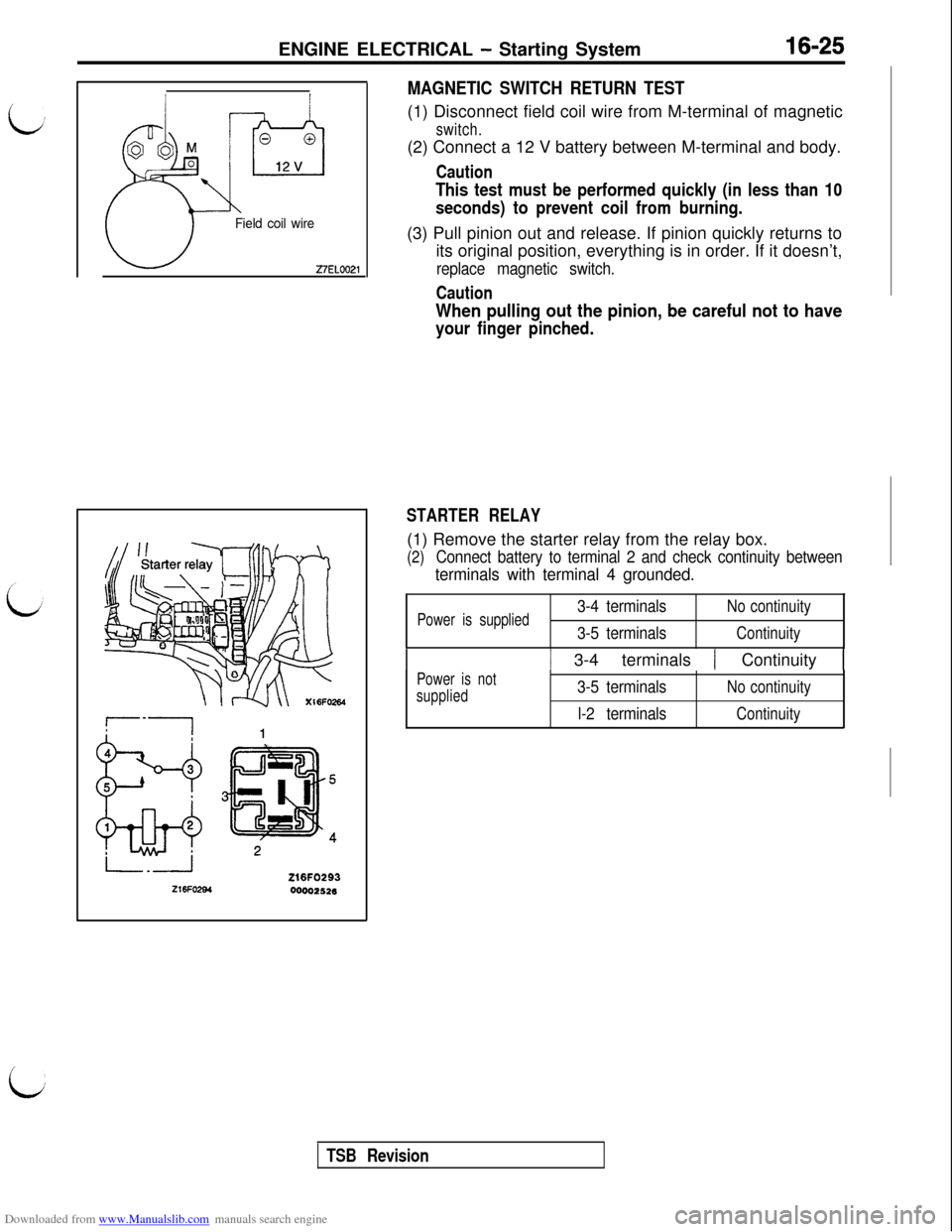

Field coil wire27EL0021216Fo264

00002526

MAGNETIC SWITCH RETURN TEST(1) Disconnect field coil wire from M-terminal of magnetic

switch.(2) Connect a 12 V battery between M-terminal and body.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.(3) Pull pinion out and release. If pinion quickly returns to

its original position, everything is in order. If it doesn’t,

replace magnetic switch.

Caution

When pulling out the pinion, be careful not to have

your finger pinched.

STARTER RELAY(1) Remove the starter relay from the relay box.

(2)Connect battery to terminal 2 and check continuity between

terminals with terminal 4 grounded.

Power is supplied3-4 terminals

3-5 terminalsNo continuity

Continuity

/ 3-4 terminals / Continuity 1

Power is not

supplied3-5 terminals

l-2 terminalsNo continuity

Continuity

i

TSB Revision

Page 482 of 738

Downloaded from www.Manualslib.com manuals search engine 16-36ENGINE ELECTRICAL - Ignition System

Defective insulation

Defective insulation’

GoodZiELO34

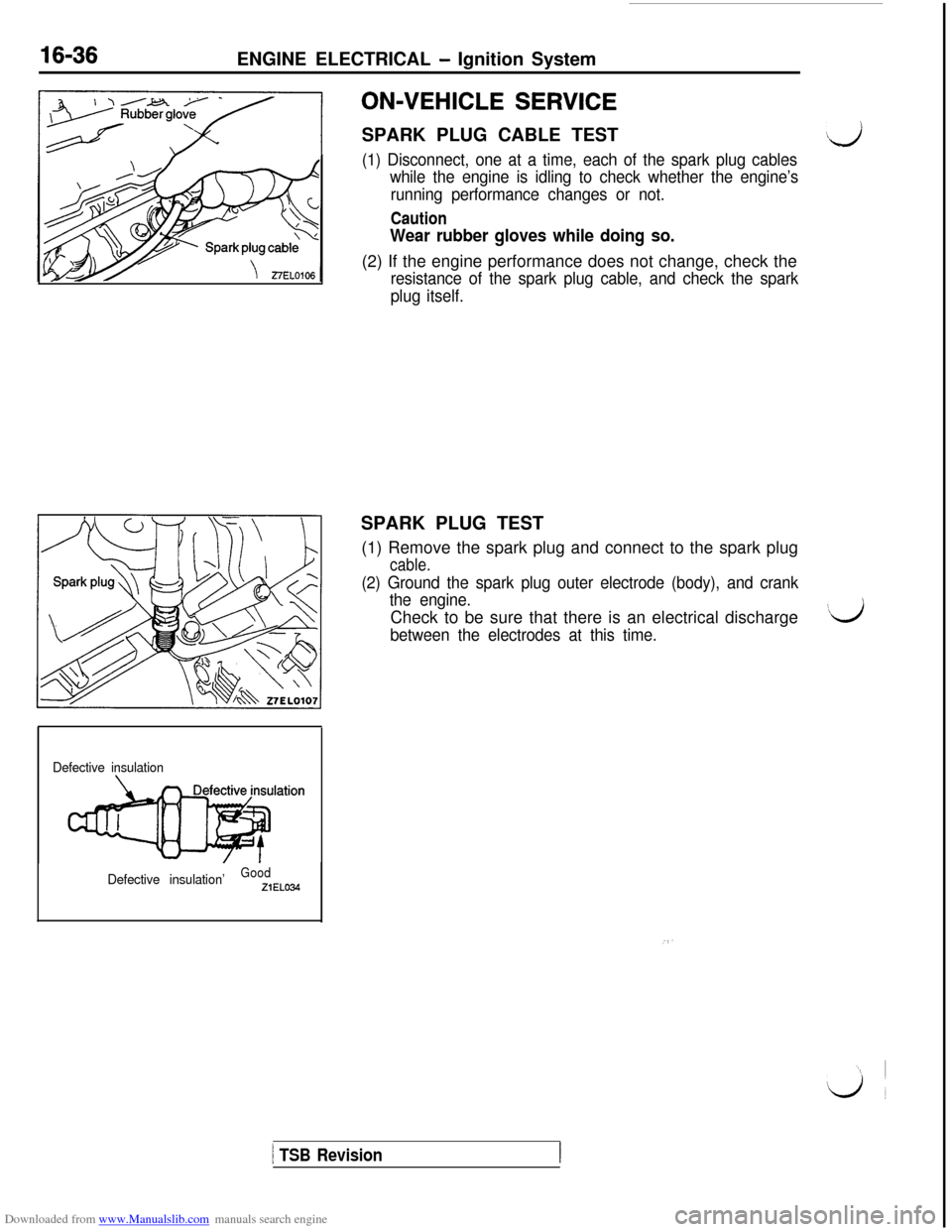

ON-VEHICLE SERVICESPARK PLUG CABLE TEST

,d

(1) Disconnect, one at a time, each of the spark plug cables

while the engine is idling to check whether the engine’s

running performance changes or not.

Caution

Wear rubber gloves while doing so.(2) If the engine performance does not change, check the

resistance of the spark plug cable, and check the spark

plug itself.SPARK PLUG TEST

(1) Remove the spark plug and connect to the spark plug

cable.

(2) Ground the spark plug outer electrode (body), and crank

the engine.Check to be sure that there is an electrical discharge

between the electrodes at this time.

‘d

1 TSB Revision

Page 494 of 738

Downloaded from www.Manualslib.com manuals search engine 16-48ENGINE ELECTRICAL - lanition Svstem

\/27EL0086

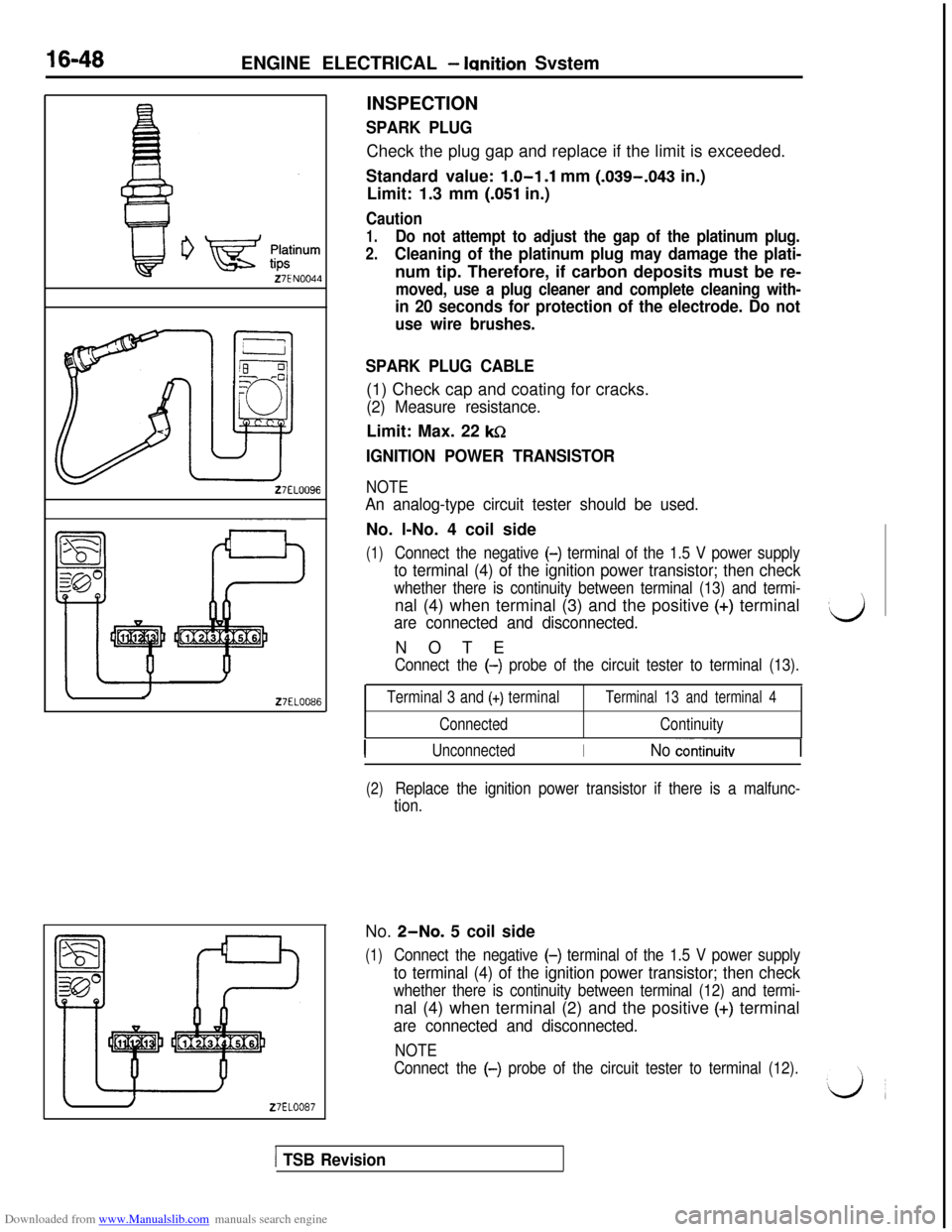

/DEL0087INSPECTION

SPARK PLUGCheck the plug gap and replace if the limit is exceeded.

Standard value:

1.0-l .l mm (.039-.043 in.)

Limit: 1.3 mm

(.051 in.)

Caution

1.Do not attempt to adjust the gap of the platinum plug.

2.Cleaning of the platinum plug may damage the plati-num tip. Therefore, if carbon deposits must be re-

moved, use a plug cleaner and complete cleaning with-

in 20 seconds for protection of the electrode. Do not

use wire brushes.

SPARK PLUG CABLE(1) Check cap and coating for cracks.

(2) Measure resistance.Limit: Max. 22

ksZ

IGNITION POWER TRANSISTOR

NOTE

An analog-type circuit tester should be used.No. l-No. 4 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (13) and termi-nal (4) when terminal (3) and the positive

(+) terminal

are connected and disconnected.NOTE

Connect the (-) probe of the circuit tester to terminal (13).

Terminal 3 and (+) terminal

ConnectedTerminal 13 and terminal 4

Continuity

IUnconnectedINo continuitv

(2)Replace the ignition power transistor if there is a malfunc-

tion.No. ~-NO. 5 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (12) and termi-nal (4) when terminal (2) and the positive

(+) terminal

are connected and disconnected.

NOTE

Connect the (-)

probe of the circuit tester to terminal (12).

[ TSB Revision

Page 495 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL b Ignition System16-49

27EL0089

Z7ELOOQO

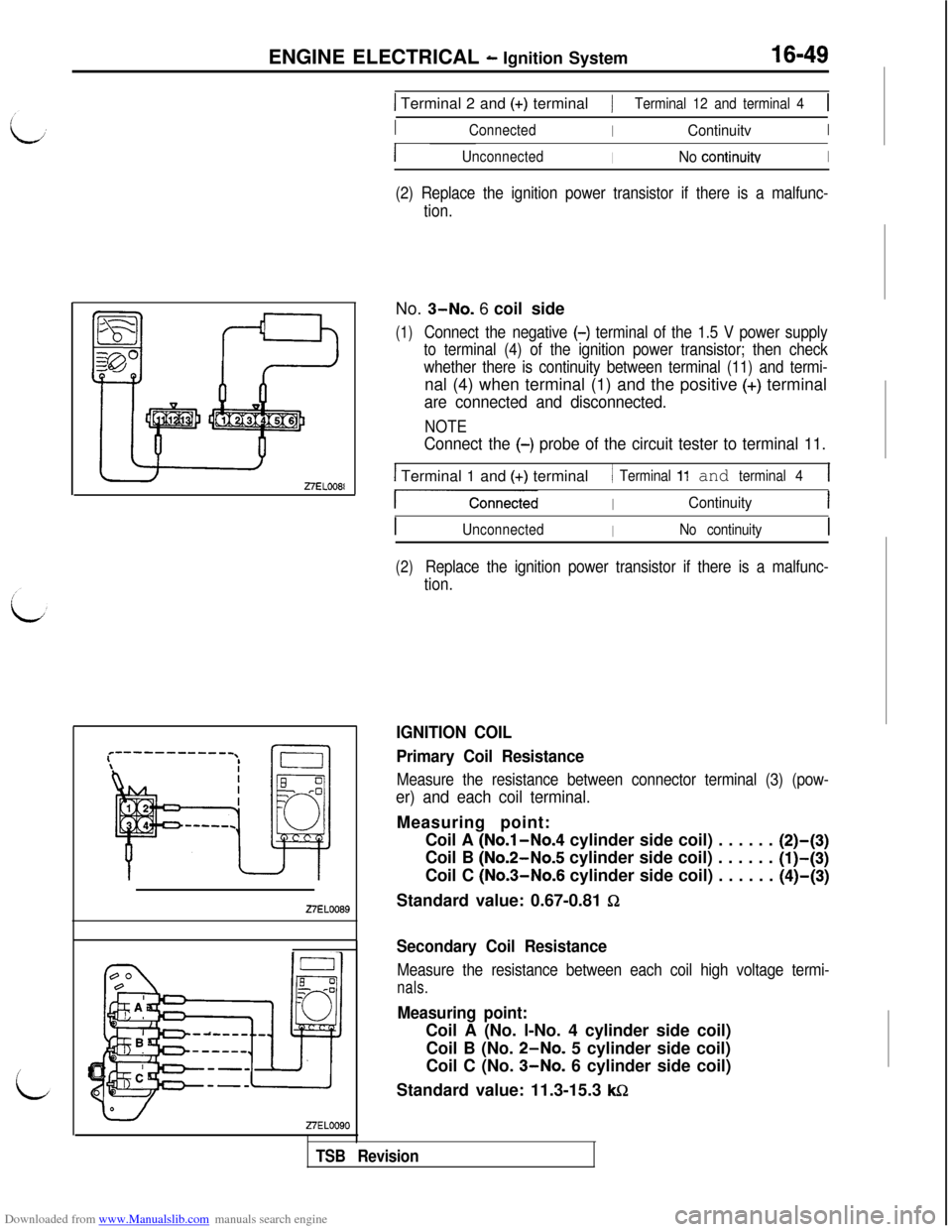

1 Terminal 2 and (+) terminal/Terminal 12 and terminal 41

IConnectedIContinuitvI

IUnconnectedINo continuitvI

(2) Replace the ignition power transistor if there is a malfunc-

tion.No. ~-NO. 6 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (11) and termi-nal (4) when terminal (1) and the positive

(+) terminal

are connected and disconnected.

NOTE

Connect the (-) probe of the circuit tester to terminal 11.

I Terminal 1 and (+) terminal/ Terminal 11 and terminal 41

-ConnectedIContinuityI

IUnconnectedINo continuityI

(2)Replace the ignition power transistor if there is a malfunc-

tion.

IGNITION COIL

Primary Coil Resistance

Measure the resistance between connector terminal (3) (pow-

er) and each coil terminal.Measuring point:

Coil A

(No.l-No.4 cylinder side coil) . . . . . . (2)-(3)Coil B (No.2-No.5 cylinder side coil) . . . . . .

(l)-(3)Coil C (No.3-No.6 cylinder side coil) . . . . . .

(4)-(3)Standard value: 0.67-0.81

Sz

TSB Revision

Secondary Coil Resistance

Measure the resistance between each coil high voltage termi-

nals.

Measuring point:Coil A (No. l-No. 4 cylinder side coil)

Coil B (No. ~-NO. 5 cylinder side coil)

Coil C (No. ~-NO. 6 cylinder side coil)

Standard value: 11.3-15.3

Wz

Page 499 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Battery54-3

BATTERY

LSPECIFICATIONSGENERAL SPECIFICATIONS

ItemsUp to 1993 modelsFrom 1994 models

Type75D26R-MF75D23R-MF

Ampere hours

(5HR) Ah5252

Cranking rating [at -18°C (O’F)] A490520

Reserve capacity min.123118

NOTES

1.CRANKING RATING is the current a battery can deliver for 30 seconds and maintain a terminal voltage of

7.2 volts or greater at a specified temperature.

2.RESERVE CAPACITY RATING is the amount of time a battery can deliver 25A and maintain a minimum terminal

voltage of 10.5 at

27% (80°F).

L

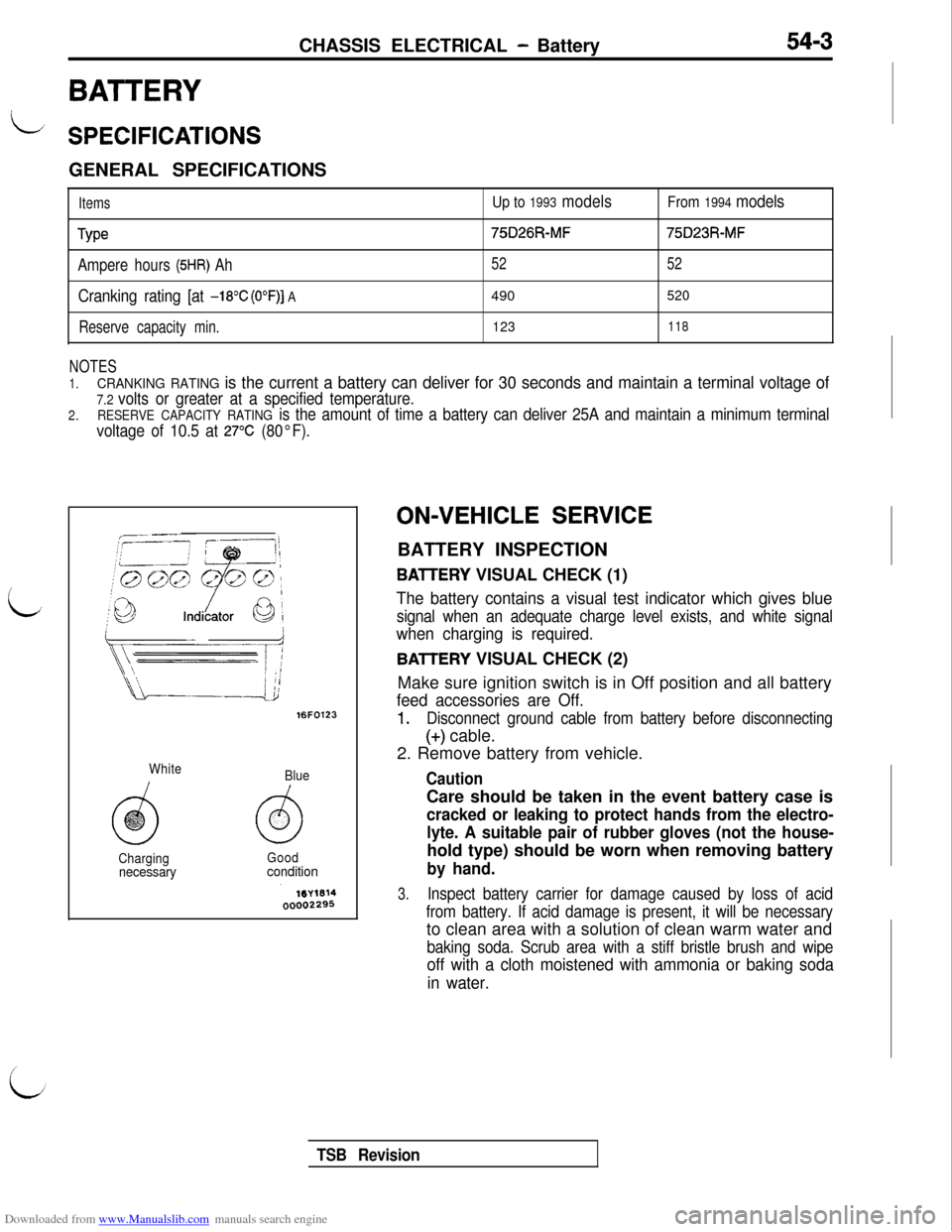

16FO123

White

Blue

ChargingGood

necessaryconditionON-VEHICLE

SERVICE

BATTERY INSPECTION

BAlTERY VISUAL CHECK (1)

The battery contains a visual test indicator which gives blue

signal when an adequate charge level exists, and white signal

when charging is required.

BAlTERY VISUAL CHECK (2)

Make sure ignition switch is in Off position and all battery

feed accessories are Off.

1.Disconnect ground cable from battery before disconnecting

(+) cable.

2. Remove battery from vehicle.

CautionCare should be taken in the event battery case is

cracked or leaking to protect hands from the electro-

lyte. A suitable pair of rubber gloves (not the house-hold type) should be worn when removing battery

by hand.

3.Inspect battery carrier for damage caused by loss of acid

from battery. If acid damage is present, it will be necessaryto clean area with a solution of clean warm water and

baking soda. Scrub area with a stiff bristle brush and wipe

off with a cloth moistened with ammonia or baking soda

in water.

TSB Revision

Page 501 of 738

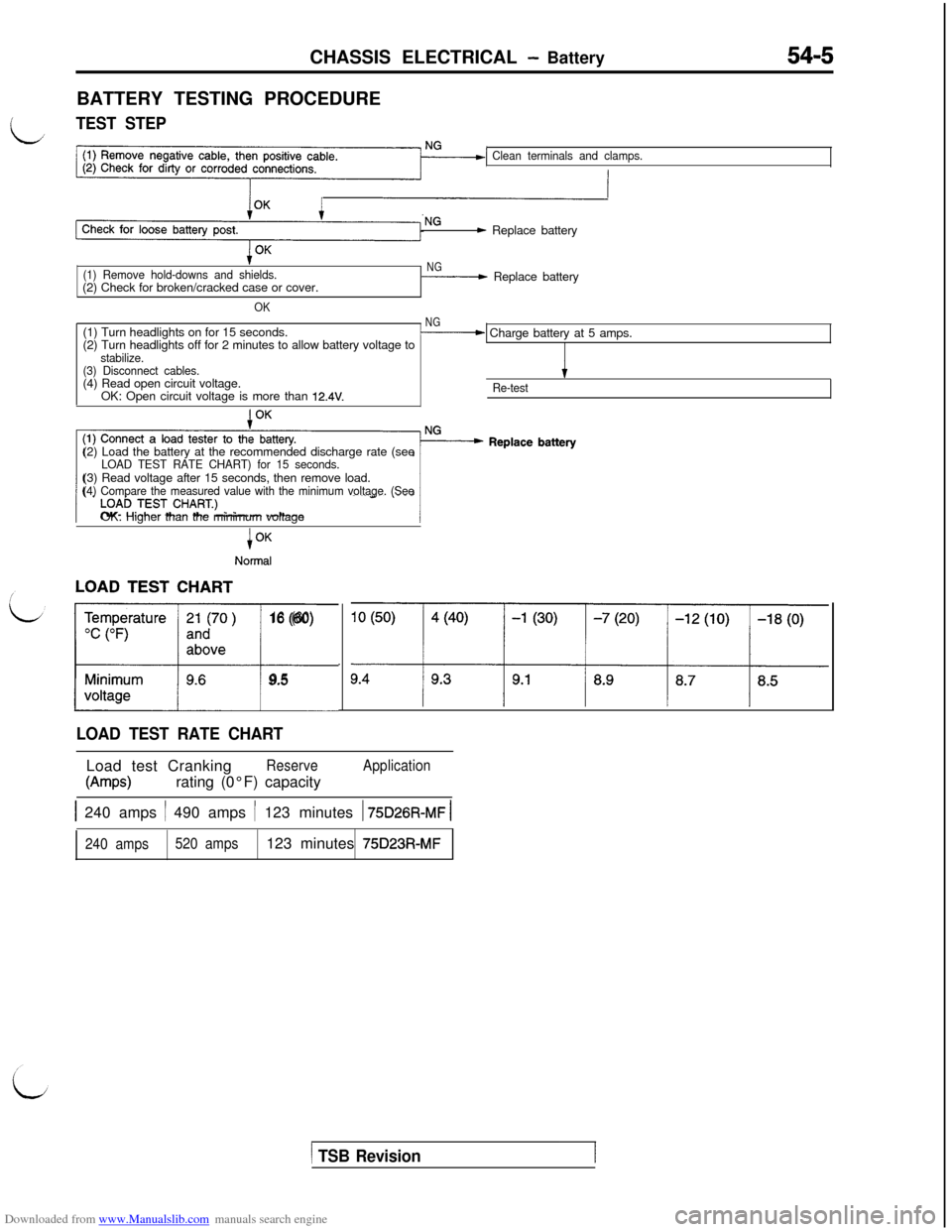

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Battery54-5BATTERY TESTING PROCEDURE

LTEST STEP

Clean terminals and clamps.

- Replace battery

(1) Remove hold-downs and shields.(2) Check for broken/cracked case or cover.

OK

NG- Replace battery

(1) Turn headlights on for 15 seconds.

NG(2) Turn headlights off for 2 minutes to allow battery voltage to- Charge battery at 5 amps.

stabilize.

(3) Disconnect cables.(4) Read open circuit voltage.

IOK: Open circuit voltage is more than

12.4V.Re-test(2) Load the battery at the recommended discharge rate (see

LOAD TEST RATE CHART) for 15 seconds.(3) Read voltage after 15 seconds, then remove load.

(4) Compare the measured value with the minimum voltage. (SeeOK: Higher than the minimum voltage

i

Normal

LL16 (60)

9.5

LOAD TEST RATE CHARTLoad test Cranking

Reserve

W-w)rating (0°F) capacity

Application

1 240 amps / 490 amps / 123 minutes 1 75D26R-MF 1

240 amps520 amps123 minutes 75D23R-MF

1 TSB Revision1

Page 504 of 738

Downloaded from www.Manualslib.com manuals search engine 54-8CHASSIS ELECTRICAL - Ignition Switch

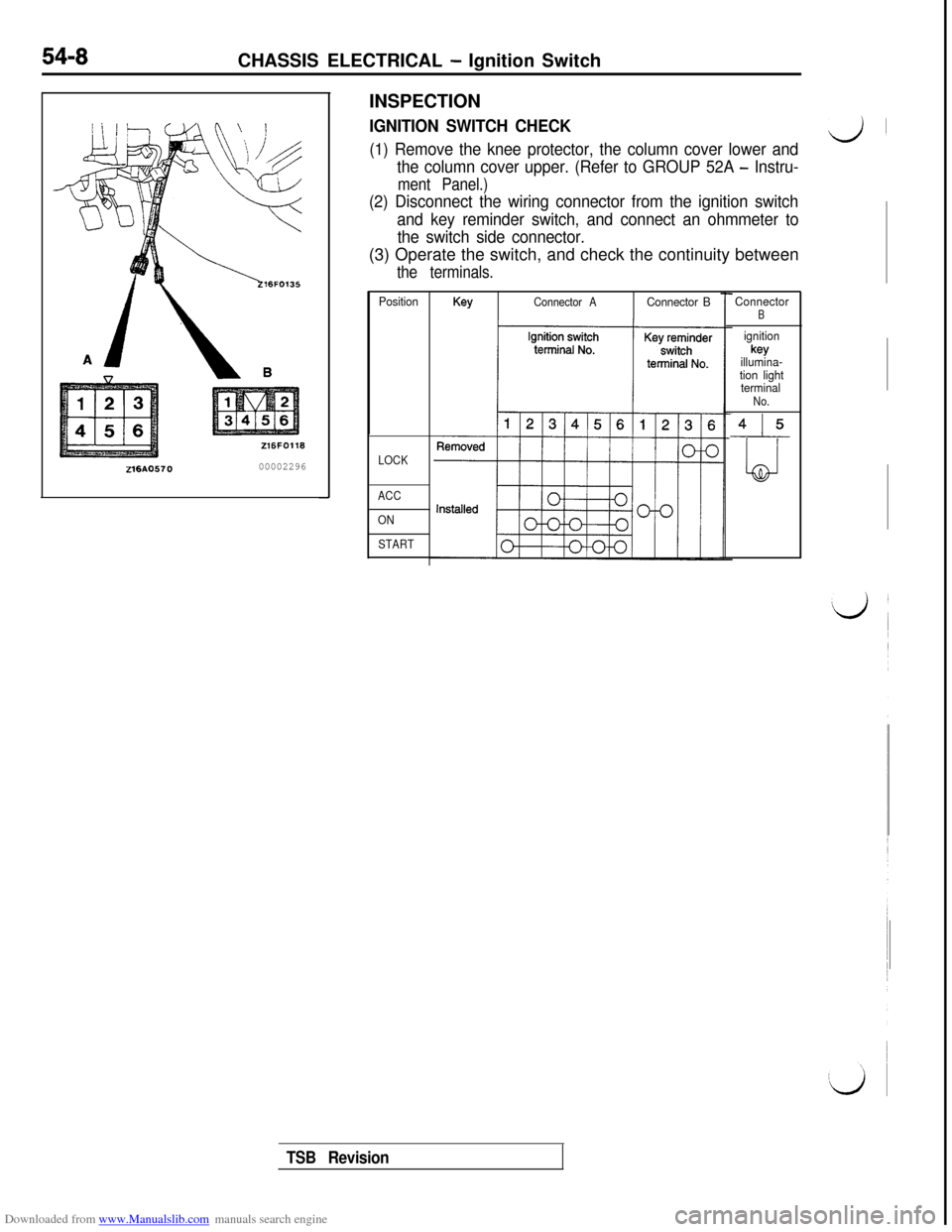

216AO57000002296INSPECTION

IGNITION SWITCH CHECK

(1) Remove the knee protector, the column cover lower andd’

the column cover upper. (Refer to GROUP 52A - Instru-

ment Panel.)

(2) Disconnect the wiring connector from the ignition switch

and key reminder switch, and connect an ohmmeter to

the switch side connector.(3) Operate the switch, and check the continuity between

the terminals.

PositionKeyConnector AConnector B

LOCK

ACC

ON

START

ConnectorB

ignitionkey

illumina-

tion light

terminal

No.

415

LJ

TSB Revision

Page 514 of 738

Downloaded from www.Manualslib.com manuals search engine 54-18CHASSIS ELECTRICAL - Meters and Gauges

OPERATION

When the ignition key is at the “ON” position,the fuel gauge is activated.

l

When there is much fuel, the unit’s resistanceis small and the current flowing in the circuit

is great, so the gauge’s indicator indicates inthe “F” area.

l When there is little fuel, the unit’s resistance

is high and the current flowing in the circuit

is small, so the gauge’s indicator indicates inthe

“E” area.

lWhen the ignition key is at the “ON” position,

the engine coolant temperature gauge is acti-

vated.l

When the engine coolant temperature is high,

the unit’s resistance is low and there is a greatflow of current in the circuit, so the gauge’s

indicator indicates in the “H” area.

l

When the engine coolant temperature is low,

the unit’s resistance is high and there is a smallflow of current in the circuit, so the gauge’s

indicator indicates in the “C” area.

vehicle speed, and vehicle-speed signals areinput to systems (the MFI system, etc.) that

regulate according to the vehicle speed.

TROUBLESHOOTING HINTS

1.The fuel gauge doesn’t function, or shows the

incorrect indication.

(1) Disconnect the connector of the fuel pumpand gauge unit assembly; the ‘F” side is

indicated when terminal (5) is then

grounded.l Check the fuel gauge.

2.The engine coolant temperature gauge doesn’t

function, or shows the incorrect indication.

(1)The “l-l” side is indicated when the connector

of the engine coolant temperature gauge

unit is disconnected and then grounded.l

Check the engine coolant temperature

gauge unit.

3. Systems dependent upon control according to

the vehicle speed do not function correctly.l Check the reed switch (mechanical

speedometer type)l Check the speed sensor (electrical

speedometer type)

coil pressure gauge>l

When the ignition key is at the “ON” position,

the oil pressure gauge is activated.

lWhen oil pressure is high, the internal contacts

of the gauge unit are kept closed for a longerperiod of time. This causes more current to

flow in the circuit, and the gauge pointer swings

to the high pressure side.

lWhen oil pressure is low, the internal contactsof the gauge unit open in a shorter period of

time. Therefore, there is less current flowing

in the circuit and the gauge pointer swings to

the low pressure side.

lWhen the ignition key is set to the “ON” position,the gauge indicator will be at

“0”.l

When the engine is started, the indicator will

move from

“0” to the minus (-) side, and then,as the boost level increases, it will move to

the plus

(+) side.

position, the voltage gauge operates and indi-

cates a battery voltage of approximately 12 V.l

When the engine is started, the voltage gauge

indicates a battery voltage of 12 to 16 V, indicat-ing that the battery is on charge.

4. The oil pressure gauge doesn’t function, or

shows the incorrect indication.

(1)The “H” side is indicated when the connectorof the oil pressure gauge unit is discon-

nected and then grounded.l Check the oil pressure gauge unit.

5.The meter illumination light does not illuminate.

(1) The tail lights illuminate.l Check the rheostat.

6. The voltage gauge doesn’t function, or shows

the incorrect indication.l Check the voltage gauge.

TSB Revision

Page 527 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Meters and Gauges54-31

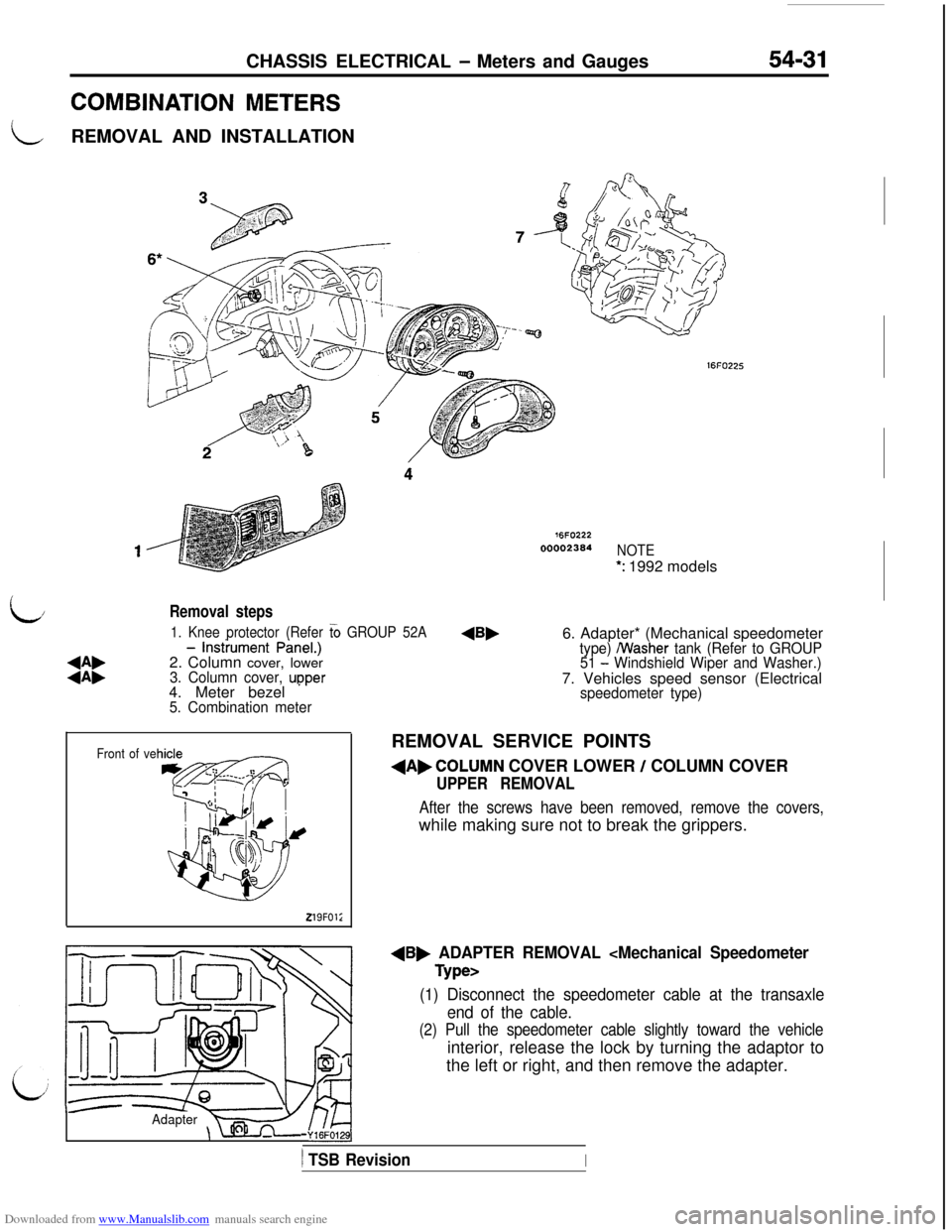

COMBINATION METERS

LREMOVAL AND INSTALLATION

76FO22200002364

NOTE

*: 1992 models

L/

:i:

- lnstiument PineI.)

2. Column cover, lower

3. Column cover, upper 1. Knee protector (Refer

G GROUP 52A4. Meter bezel

* ’5. Combination meter

Removal steps6. Adapter* (Mechanical speedometer

type) /Washer tank (Refer to GROUP

51 - Windshield Wiper and Washer.)7. Vehicles speed sensor (Electrical

Front of ve

219FOl;

speedometer type)REMOVAL SERVICE POINTS

dAbCOLUMN COVER LOWER / COLUMN COVER

UPPER REMOVAL

After the screws have been removed, remove the covers,while making sure not to break the grippers.

dB, ADAPTER REMOVAL

(1) Disconnect the speedometer cable at the transaxle

end of the cable.

(2) Pull the speedometer cable slightly toward the vehicleinterior, release the lock by turning the adaptor to

the left or right, and then remove the adapter.

Adapter-Y16FO129],

) TSB RevisionI

Page 552 of 738

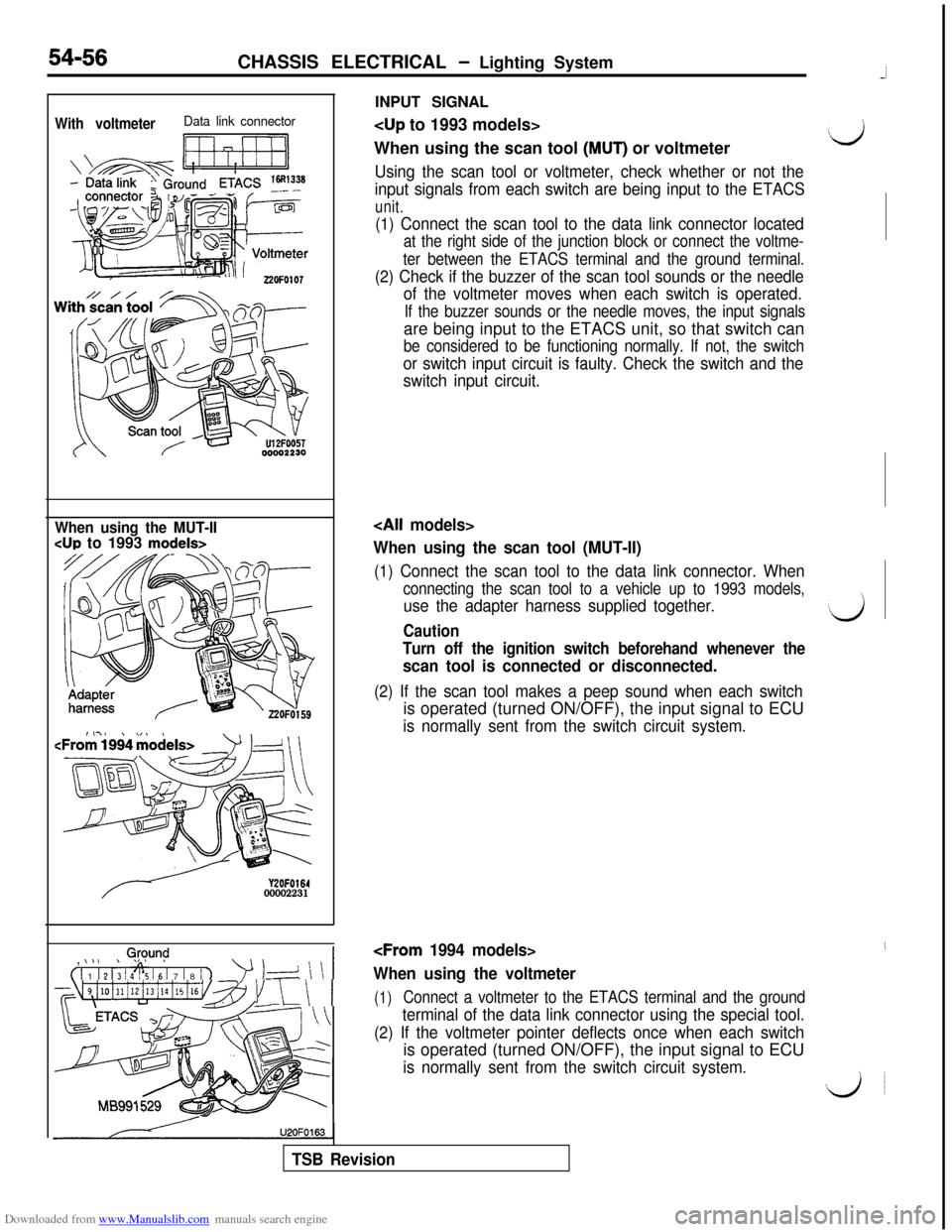

Downloaded from www.Manualslib.com manuals search engine INPUT SIGNALWith voltmeterData link connector

Ii ri7-11

When using the scan tool (MUT) or voltmeter‘d

Using the scan tool or voltmeter, check whether or not the

input signals from each switch are being input to the ETACS

unit.

54-56CHASSIS ELECTRICAL - Lighting System

(1) Connect the scan tool to the data link connector located

at the right side of the junction block or connect the voltme-

ter between the ETACS terminal and the ground terminal.

(2) Check if the buzzer of the scan tool sounds or the needle

of the voltmeter moves when each switch is operated.

If the buzzer sounds or the needle moves, the input signalsare being input to the ETACS unit, so that switch can

be considered to be functioning normally. If not, the switch

or switch input circuit is faulty. Check the switch and the

switch input circuit.

When using the MUT-II

CUP to 1993 models>

Y2OFO16400002231,

0,@y.m$

( 1 1 1 2 1; 1 4% 16 1 7 1 8 / 1

’ 1-d \ \ 1

~~~4i10illi12i13illi15i16v~~~1 \ \ 1U2OFO163

When using the scan tool (MUT-II)

(1) Connect the scan tool to the data link connector. When

connecting the scan tool to a vehicle up to 1993 models,

use the adapter harness supplied together.‘dCaution

Turn off the ignition switch beforehand whenever the

scan tool is connected or disconnected.

(2) If the scan tool makes a peep sound when each switchis operated (turned ON/OFF), the input signal to ECU

is normally sent from the switch circuit system.

When using the voltmeter

(1)Connect a voltmeter to the ETACS terminal and the ground

terminal of the data link connector using the special tool.

(2) If the voltmeter pointer deflects once when each switchis operated (turned ON/OFF), the input signal to ECU

is normally sent from the switch circuit system.

do

TSB Revision