switch MITSUBISHI 3000GT 1995 2.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1995, Model line: 3000GT, Model: MITSUBISHI 3000GT 1995 2.GPages: 738, PDF Size: 35.06 MB

Page 11 of 738

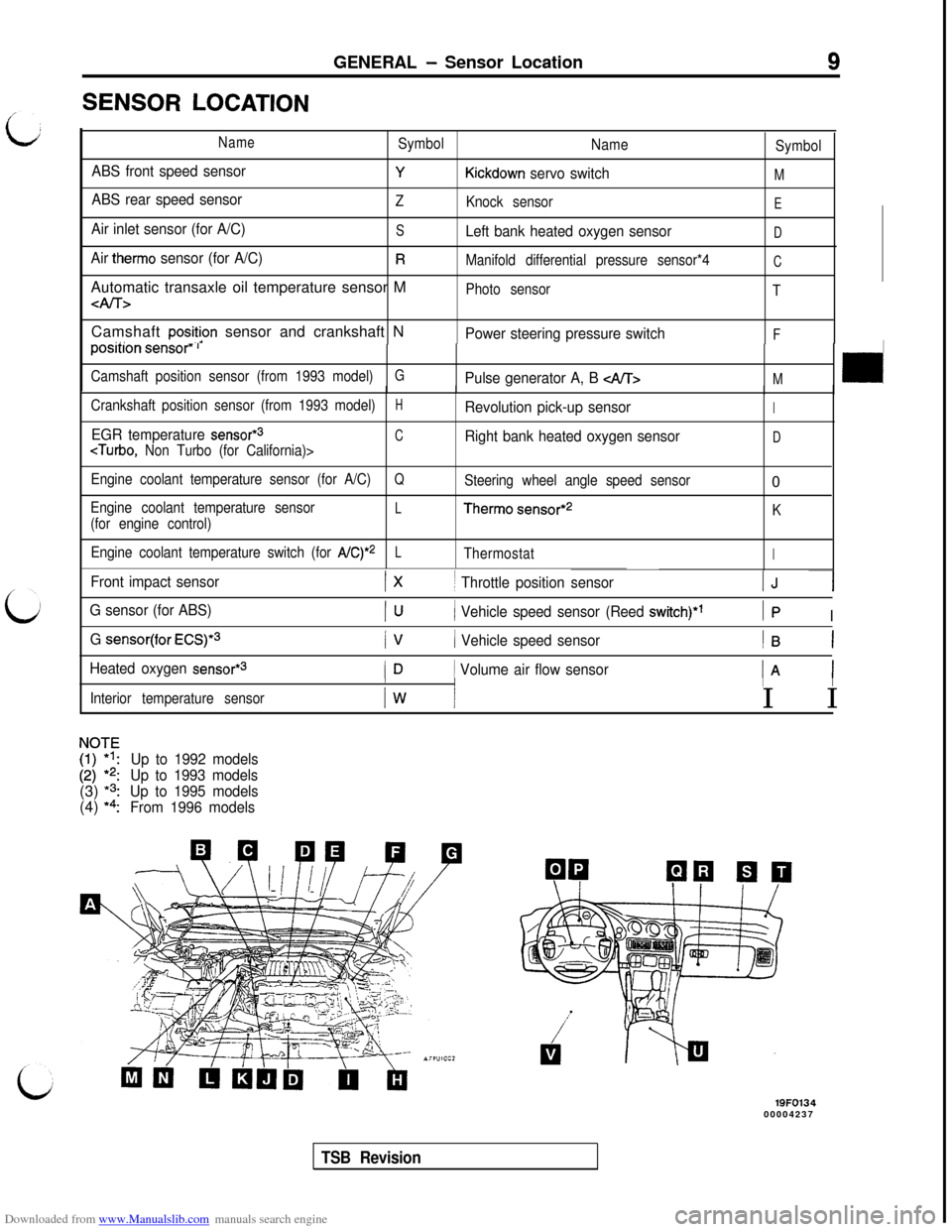

Downloaded from www.Manualslib.com manuals search engine GENERAL - Sensor Location9SENSOR

LOCATION

NameSymbol

Name

Symbol

ABS front speed sensorYKickdown servo switchM

ABS rear speed sensorZ

Knock sensorE

Air inlet sensor (for A/C)SLeft bank heated oxygen sensorD

Air therm0 sensor (for A/C)RManifold differential pressure sensor*4CAutomatic transaxle oil temperature sensor M

4lT>Photo sensor

TCamshaft

posit!on sensor and crankshaft N. . .Power steering pressure switchFposrtton sensor” I

Camshaft position sensor (from 1993 model)GPulse generator A, B M

Crankshaft position sensor (from 1993 model)HRevolution pick-up sensorI

EGR temperature sensor*3CcTurbo, Non Turbo (for California)>Right bank heated oxygen sensorD

Engine coolant temperature sensor (for A/C)QSteering wheel angle speed sensor0

Engine coolant temperature sensorL(for engine control)Therm0 sensor*2

K

Engine coolant temperature switch (for

A/C)*2LThermostatI

Front impact sensorIx1 Throttle position sensorIJ 1

G sensor (for ABS)PJ( Vehicle speed sensor (Reed switch)*’Ip I

G sensor(for ECS)*31 Vehicle speed sensorIB 1

Heated oxygen sensor*”ID( Volume air flow sensortA 1/III

Interior temperature sensorIw II I

NOIF

I:;

:

*2:

Up to 1992 models(3)

*3:

Up to 1993 models(4)

*a:

Up to 1995 models

From 1996 models

19FO13400004237

TSB Revision

Page 13 of 738

Downloaded from www.Manualslib.com manuals search engine GENERAL - Sensor Location

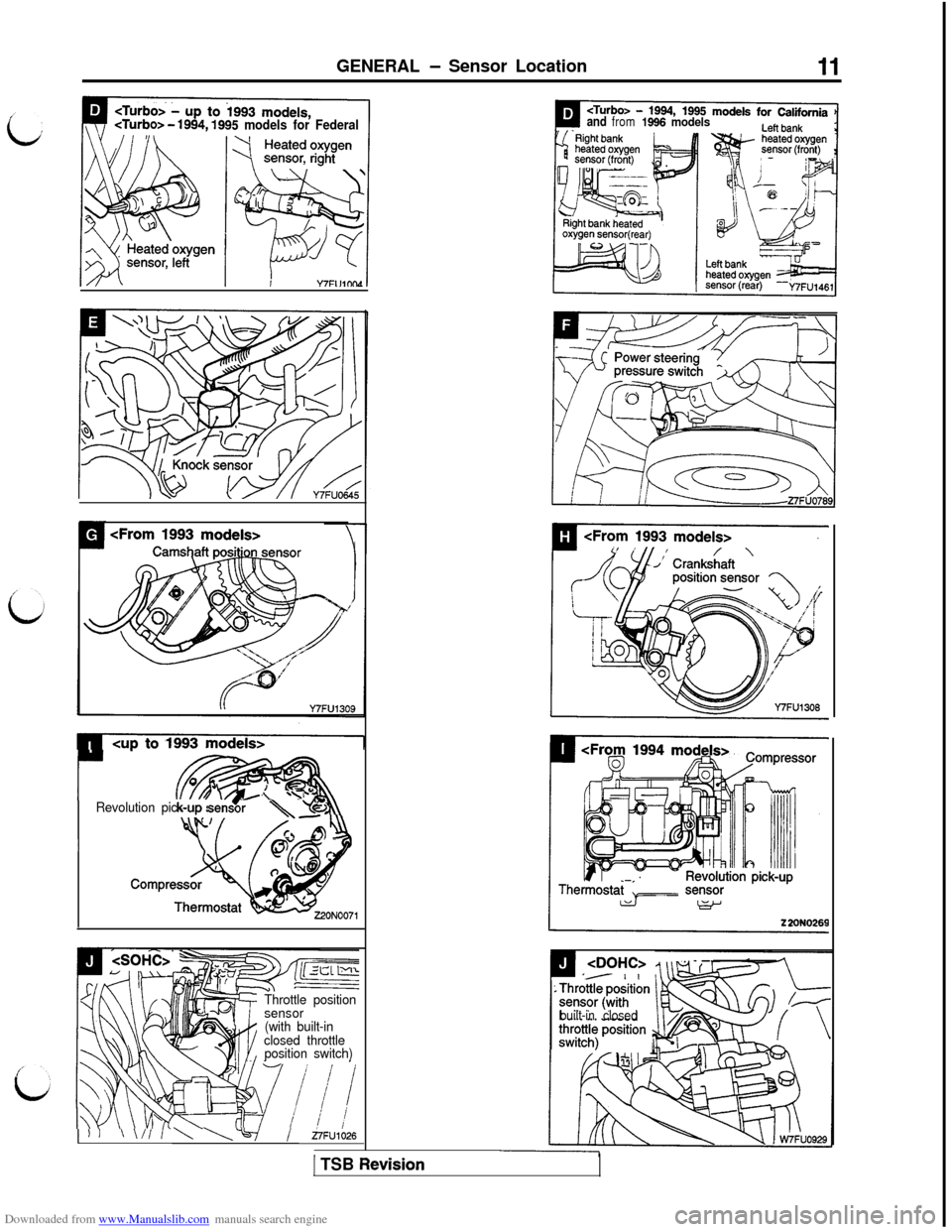

o> - 1994,1995 models for Federal

CUD to1993models>

r- m0.: \I0

wRevolution pick-up sens’or\u

/c, fdI

Throttle position

sensor

(with built-in

closed throttle

position switch)

and from1966 models

built-in closed

) ) 1\ \l/ / \ \v/~~1026

1 TSB Revision

Page 14 of 738

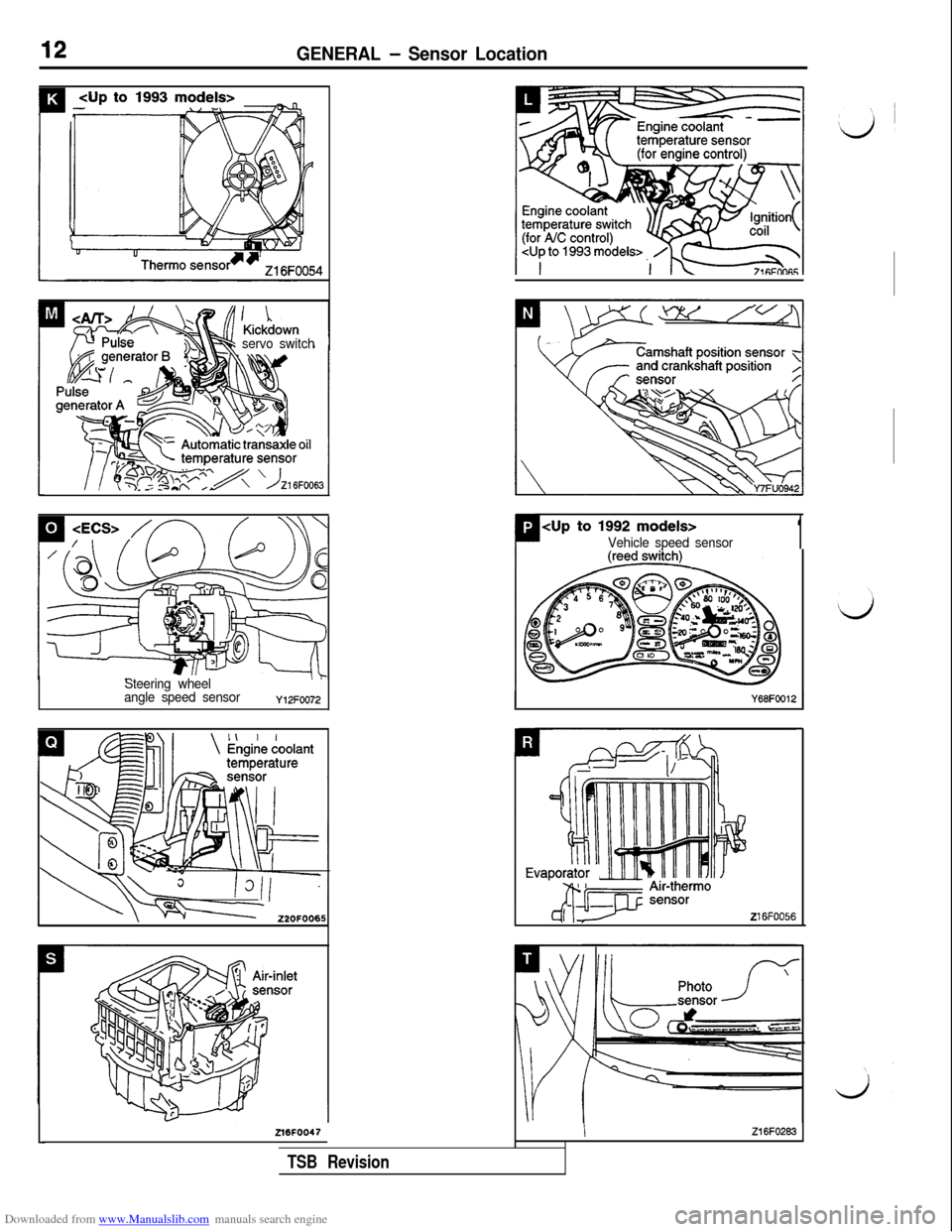

Downloaded from www.Manualslib.com manuals search engine 12GENERAL - Sensor Location

I

> servo switch

LII f$3&FZX ‘AI 6F0063

Steering wheel

angle speed sensorY12FOO72

Vehicle speed sensor1

Y66FOO12

ZWFOO47I216FO26-3

TSB Revision

Page 22 of 738

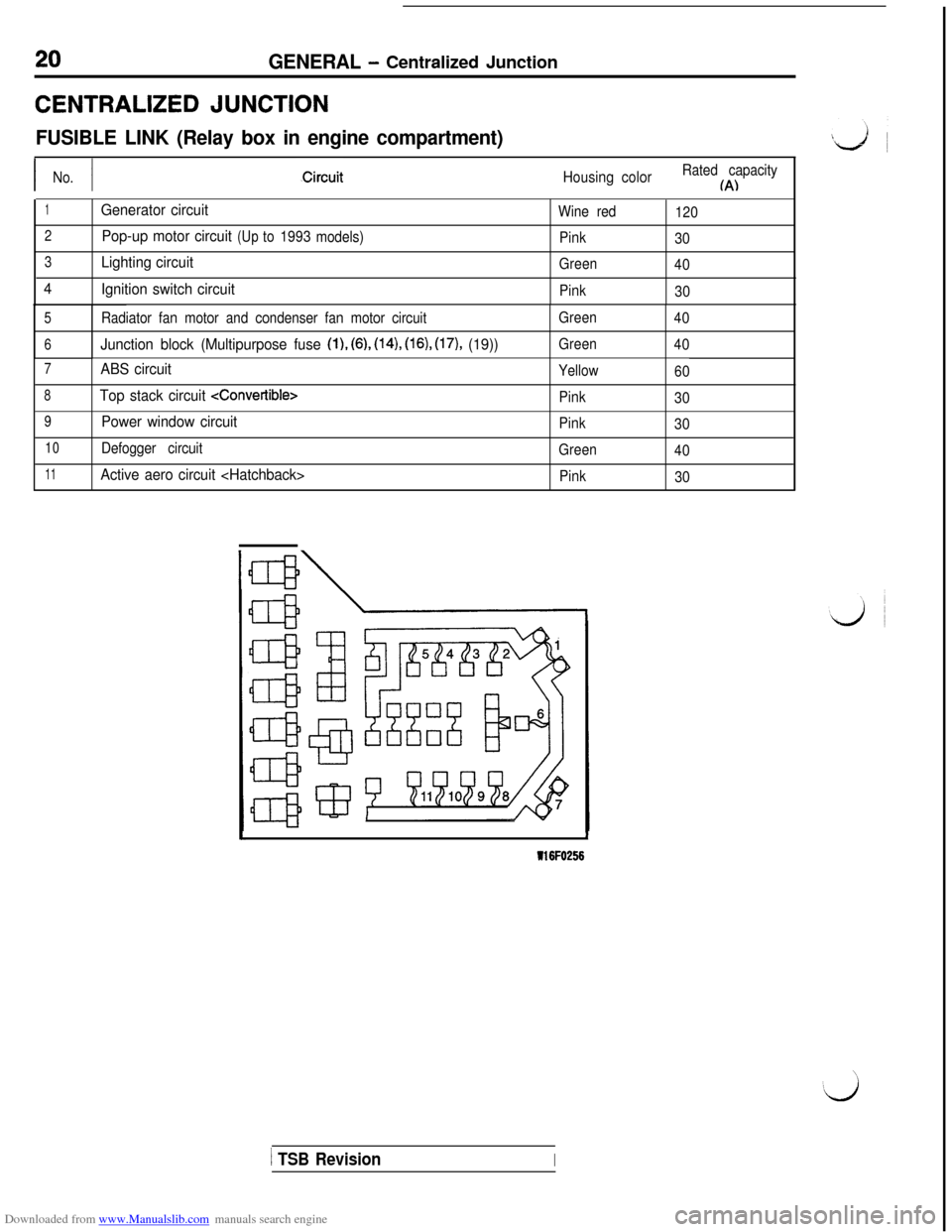

Downloaded from www.Manualslib.com manuals search engine GENERAL - Centralized JunctionCENTRALIZED

JUNCTION

FUSIBLE LINK (Relay box in engine compartment)

I INo.Housing colorRated capacityIA)

1Generator circuitWine red

120

2Pop-up motor circuit(Upto1993

models)

Pink

30

3Lighting circuitGreen

40

4

Ignition switch circuitPink

30

5Radiator fan motor and condenser fan motor circuitGreen

40

6Junction block (Multipurpose fuse (l), (6), (14), (16), (17), (19))Green

40

7ABS circuitYellow

60

8Top stack circuit

Pink

30

9Power window circuitPink

30

10Defogger circuit

Green

40

11Active aero circuit

301I

116FO256

1 TSB RevisionI

Page 24 of 738

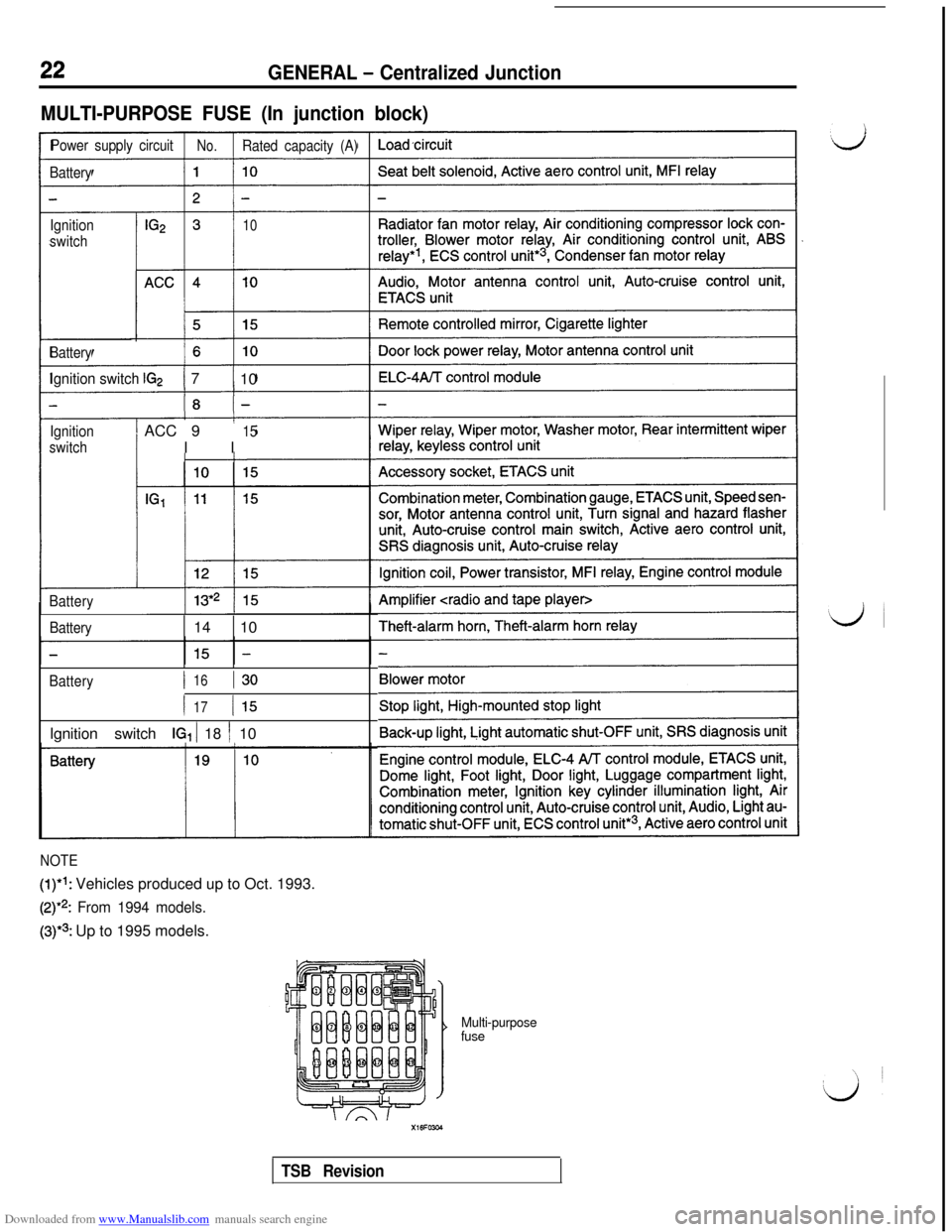

Downloaded from www.Manualslib.com manuals search engine 22GENERAL - Centralized Junction

MULTI-PURPOSE FUSE (In junction block)

Power supply circuitNo.Rated capacity (A)

Battery

Ignition

switch

10

Battery

Ignition switch IG21 7I 10

18 I-

Ignition

switch

BatteryACC 9

I I15

Battery14 10

BatteryI 13016

I 11517Ignition switch

IGl I 18 ( 10

NOTE

(l)*‘: Vehicles produced up to Oct. 1993.

(2)*2: From 1994 models.

(3)*3: Up to 1995 models.

Multi-purpose

fuse

TSB Revision

Page 29 of 738

Downloaded from www.Manualslib.com manuals search engine GENERAL - How to Diagnose27

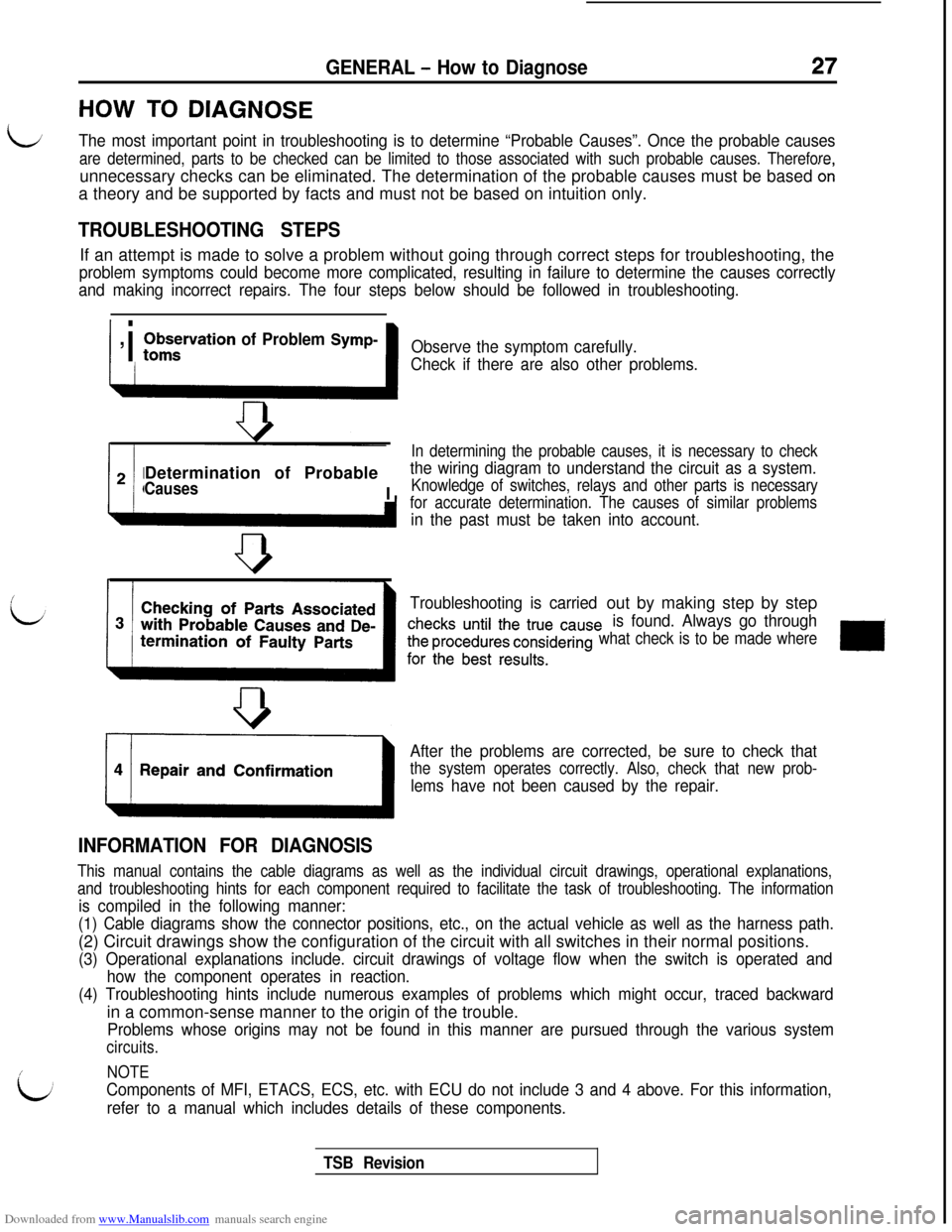

HOW TO DIAGNOSE

L;The most important point in troubleshooting is to determine “Probable Causes”. Once the probable causes

are determined, parts to be checked can be limited to those associated with such probable causes. Thereforeunnecessary checks can be eliminated. The determination of the probable causes must be based

ona theory and be supported by facts and must not be based on intuition only.

TROUBLESHOOTING STEPSIf an attempt is made to solve a problem without going through correct steps for troubleshooting, the

problem symptoms could become more complicated, resulting in failure to determine the causes correctly

and making incorrect repairs. The four steps below should be followed in troubleshooting.

I i

,;zirvation of Problem Symp-Determination of Probable

CausesI

Observe the symptom carefully.

Check if there are also other problems.

In determining the probable causes, it is necessary to check

the wiring diagram to understand the circuit as a system.

Knowledge of switches, relays and other parts is necessary

for accurate determination. The causes of similar problems

in the past must be taken into account.

After the problems are corrected, be sure to check that

the system operates correctly. Also, check that new prob-

lems have not been caused by the repair.

INFORMATION FOR DIAGNOSIS

Troubleshooting is carriedout by making step by step

is found. Always go through

what check is to be made where

/

b

This manual contains the cable diagrams as well as the individual circuit drawings, operational explanations,

and troubleshooting hints for each component required to facilitate the task of troubleshooting. The information

is compiled in the following manner:

(1) Cable diagrams show the connector positions, etc., on the actual vehicle as well as the harness path.(2) Circuit drawings show the configuration of the circuit with all switches in their normal positions.

(3) Operational explanations include. circuit drawings of voltage flow when the switch is operated and

how the component operates in reaction.

(4) Troubleshooting hints include numerous examples of problems which might occur, traced backwardin a common-sense manner to the origin of the trouble.

Problems whose origins may not be found in this manner are pursued through the various system

circuits.

NOTE

Components of MFI, ETACS, ECS, etc. with ECU do not include 3 and 4 above. For this information,

refer to a manual which includes details of these components.

TSB Revision

Page 31 of 738

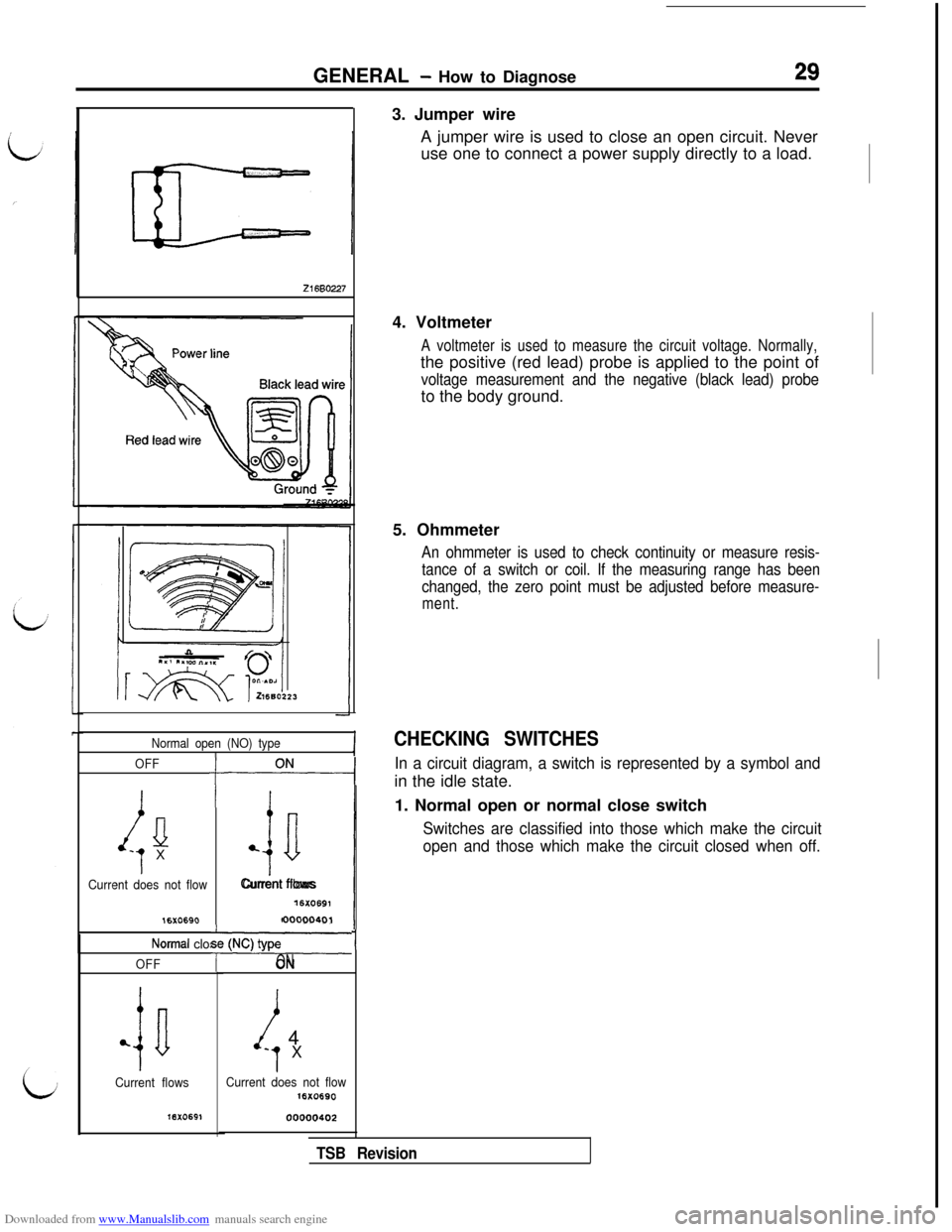

Downloaded from www.Manualslib.com manuals search engine GENERAL - How to Diagnose293. Jumper wire

A jumper wire is used to close an open circuit. Never

use one to connect a power supply directly to a load.

Z16602274. Voltmeter

A voltmeter is used to measure the circuit voltage. Normally,the positive (red lead) probe is applied to the point of

voltage measurement and the negative (black lead) probeto the body ground.

5. Ohmmeter

An ohmmeter is used to check continuity or measure resis-

tance of a switch or coil. If the measuring range has been

changed, the zero point must be adjusted before measure-

ment.

CHECKING SWITCHES

In a circuit diagram, a switch is represented by a symbol andin the idle state.

1. Normal open or normal close switch

Switches are classified into those which make the circuit

open and those which make the circuit closed when off.

INormal open (NO) typeIOFF

/4-

1X

t

Current does not flow

16X0690

ON

1

a

ia

Current flows

16X0691

00000401

Normal close (NC) type

i===ONOFF

1

/4-

1X

Current does not flow16X0690

00000402

a

III

Current flows

16X0691

TSB Revision

Page 32 of 738

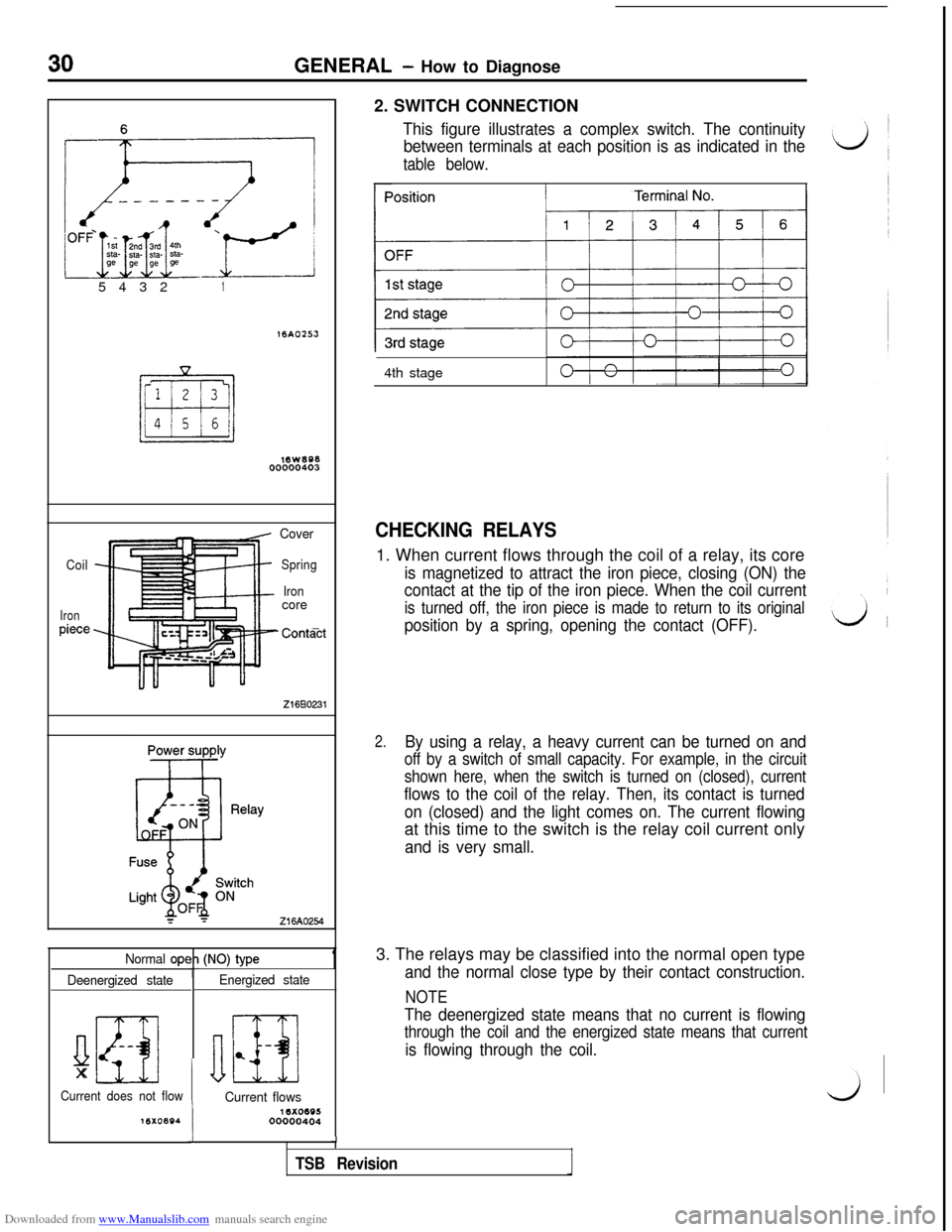

Downloaded from www.Manualslib.com manuals search engine 30GENERAL - How to Diagnose

5432

1

18AO253

10W80800000403

Coil

Iron

Cover

Spring

Iron

core

- ContZt

21680231

(NO) type

Energized state1Normal op6

Deenergized state

--

nKilX

Current does not flow

lSXO804

!

Current flows10x0095000004042. SWITCH CONNECTION

This figure illustrates a complex switch. The continuity

between terminals at each position is as indicated in the

table below.4th stage

CHECKING RELAYS1. When current flows through the coil of a relay, its core

is magnetized to attract the iron piece, closing (ON) the

contact at the tip of the iron piece. When the coil current

is turned off, the iron piece is made to return to its original

position by a spring, opening the contact (OFF).

2.By using a relay, a heavy current can be turned on and

off by a switch of small capacity. For example, in the circuit

shown here, when the switch is turned on (closed), current

flows to the coil of the relay. Then, its contact is turned

on (closed) and the light comes on. The current flowingat this time to the switch is the relay coil current only

and is very small.3. The relays may be classified into the normal open type

and the normal close type by their contact construction.

NOTE

The deenergized state means that no current is flowing

through the coil and the energized state means that current

is flowing through the coil.

JI

TSB Revision

Page 33 of 738

Downloaded from www.Manualslib.com manuals search engine iGENERAL

- How to Diagnose31

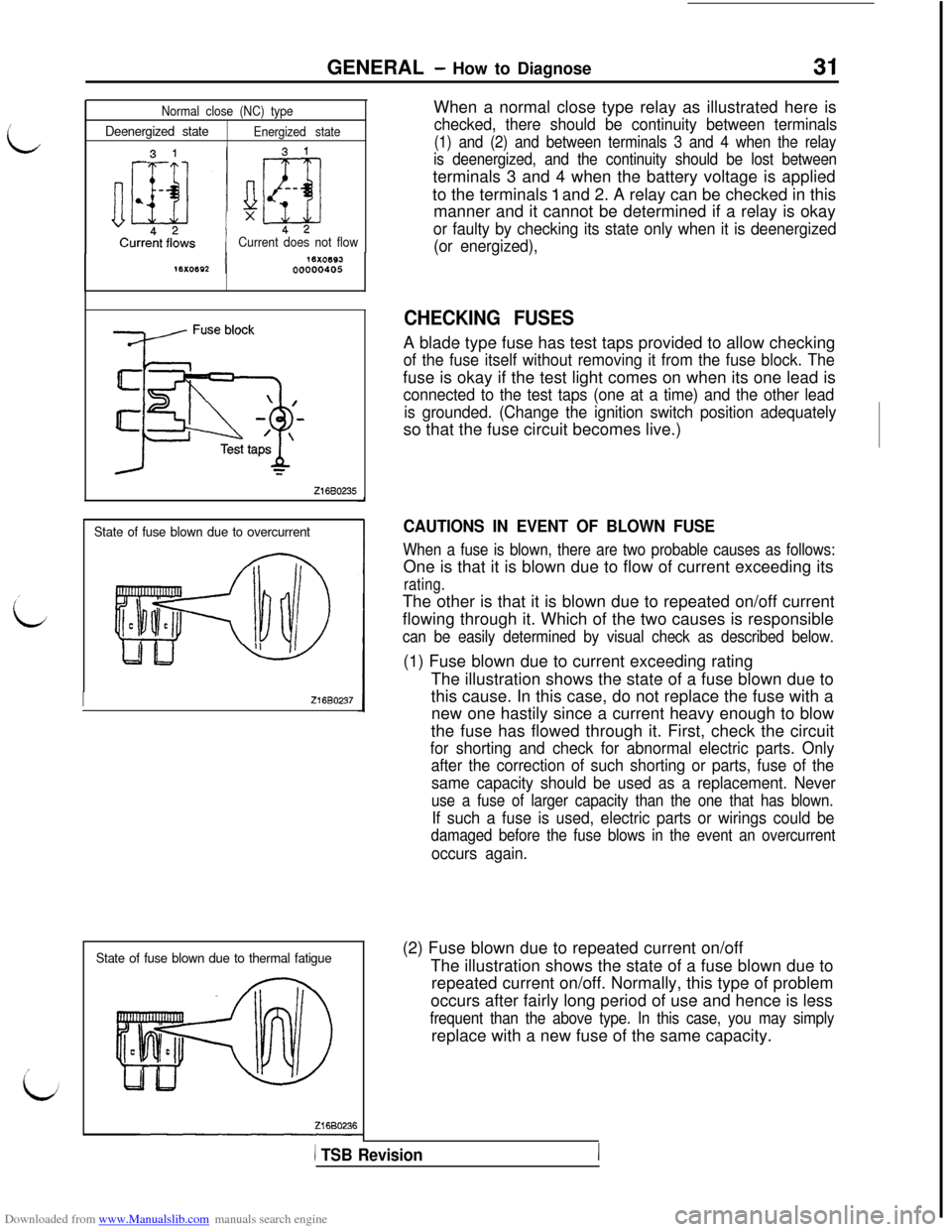

Normal close (NC) type

Deenergized stateEnergized state

Current does not flow

Z1680235

State of fuse blown due to overcurrent

/

L

I21680237

State of fuse blown due to thermal fatigue

Z1660236When a normal close type relay as illustrated here is

checked, there should be continuity between terminals

(1) and (2) and between terminals 3 and 4 when the relay

is deenergized, and the continuity should be lost betweenterminals 3 and 4 when the battery voltage is applied

to the terminals

1 and 2. A relay can be checked in this

manner and it cannot be determined if a relay is okay

or faulty by checking its state only when it is deenergized

(or energized),

CHECKING FUSESA blade type fuse has test taps provided to allow checking

of the fuse itself without removing it from the fuse block. Thefuse is okay if the test light comes on when its one lead is

connected to the test taps (one at a time) and the other lead

is grounded. (Change the ignition switch position adequatelyso that the fuse circuit becomes live.)

CAUTIONS IN EVENT OF BLOWN FUSE

When a fuse is blown, there are two probable causes as follows:One is that it is blown due to flow of current exceeding its

rating.The other is that it is blown due to repeated on/off current

flowing through it. Which of the two causes is responsible

can be easily determined by visual check as described below.(1) Fuse blown due to current exceeding rating

The illustration shows the state of a fuse blown due to

this cause. In this case, do not replace the fuse with a

new one hastily since a current heavy enough to blow

the fuse has flowed through it. First, check the circuit

for shorting and check for abnormal electric parts. Only

after the correction of such shorting or parts, fuse of the

same capacity should be used as a replacement. Never

use a fuse of larger capacity than the one that has blown.

If such a fuse is used, electric parts or wirings could be

damaged before the fuse blows in the event an overcurrent

occurs again.(2) Fuse blown due to repeated current on/off

The illustration shows the state of a fuse blown due to

repeated current on/off. Normally, this type of problem

occurs after fairly long period of use and hence is less

frequent than the above type. In this case, you may simplyreplace with a new fuse of the same capacity.

1 TSB Revision

Page 34 of 738

Downloaded from www.Manualslib.com manuals search engine 32GENERAL - How to Diaanose

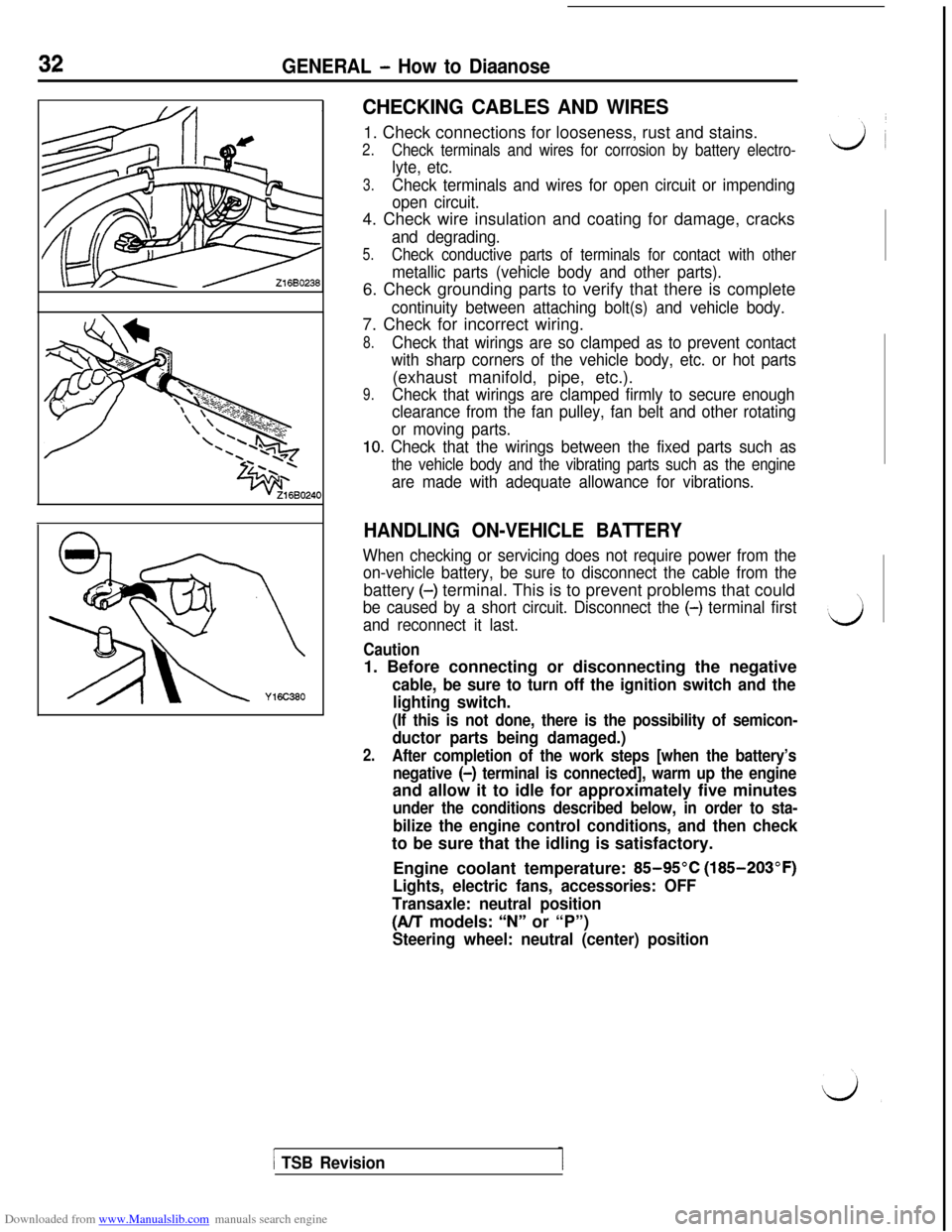

CHECKING CABLES AND WIRES1. Check connections for looseness, rust and stains.

2.Check terminals and wires for corrosion by battery electro-

lyte, etc.

3.Check terminals and wires for open circuit or impending

open circuit.4. Check wire insulation and coating for damage, cracks

and degrading.

5.Check conductive parts of terminals for contact with other

metallic parts (vehicle body and other parts).6. Check grounding parts to verify that there is complete

continuity between attaching bolt(s) and vehicle body.7. Check for incorrect wiring.

8.Check that wirings are so clamped as to prevent contact

with sharp corners of the vehicle body, etc. or hot parts(exhaust manifold, pipe, etc.).

9.Check that wirings are clamped firmly to secure enough

clearance from the fan pulley, fan belt and other rotating

or moving parts.

10. Check that the wirings between the fixed parts such as

the vehicle body and the vibrating parts such as the engine

are made with adequate allowance for vibrations.

HANDLING ON-VEHICLE BATTERY

When checking or servicing does not require power from the

on-vehicle battery, be sure to disconnect the cable from thebattery

(-) terminal. This is to prevent problems that could

be caused by a short circuit. Disconnect the (-) terminal first

and reconnect it last.

Caution1. Before connecting or disconnecting the negative

cable, be sure to turn off the ignition switch and the

lighting switch.

(If this is not done, there is the possibility of semicon-

ductor parts being damaged.)

2.After completion of the work steps [when the battery’s

negative (-)

terminal is connected], warm up the engineand allow it to idle for approximately five minutes

under the conditions described below, in order to sta-

bilize the engine control conditions, and then checkto be sure that the idling is satisfactory.

Engine coolant temperature:

85-95°C (185-203°F)

Lights, electric fans, accessories: OFF

Transaxle: neutral position

(A/T models: “N” or “P”)

Steering wheel: neutral (center) position

1 TSB Revision