brake MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1455 of 1500

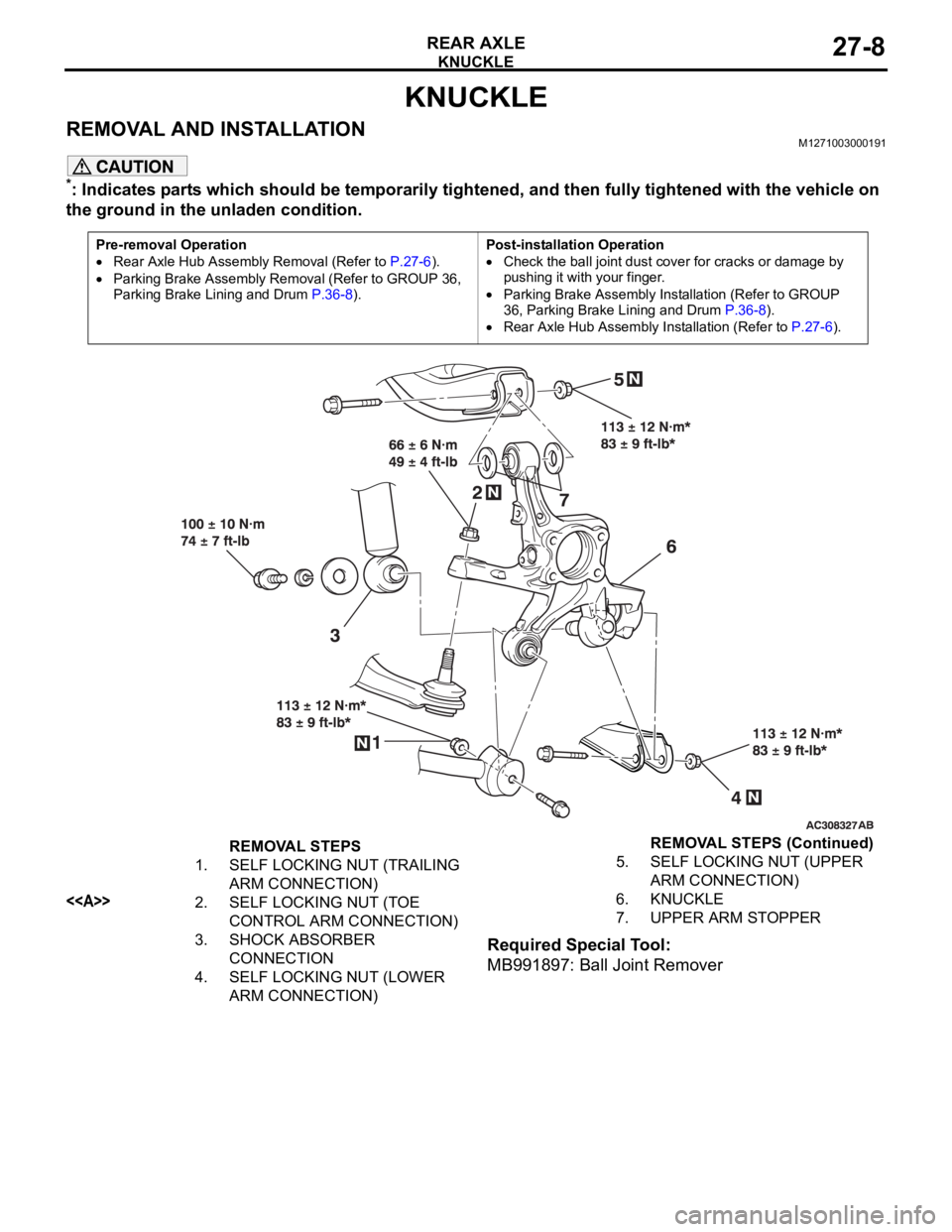

KNUCKLE

REAR AXLE27-8

KNUCKLE

REMOVAL AND INSTALLATIONM1271003000191

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the ground in the unladen condition.

Required Special Tool:

MB991897: Ball Joint Remover

Pre-removal Operation

Rear Axle Hub Assembly Removal (Refer to P.27-6).

Parking Brake Assembly Removal (Refer to GROUP 36,

Parking Brake Lining and Drum P.36-8).Post-installation Operation

Check the ball joint dust cover for cracks or damage by

pushing it with your finger.

Parking Brake Assembly Installation (Refer to GROUP

36, Parking Brake Lining and Drum P.36-8).

Rear Axle Hub Assembly Installation (Refer to P.27-6).

REMOVAL STEPS

1. SELF LOCKING NUT (TRAILING

ARM CONNECTION)

<>2. SELF LOCKING NUT (TOE

CONTROL ARM CONNECTION)

3. SHOCK ABSORBER

CONNECTION

4. SELF LOCKING NUT (LOWER

ARM CONNECTION)5. SELF LOCKING NUT (UPPER

ARM CONNECTION)

6. KNUCKLE

7. UPPER ARM STOPPERREMOVAL STEPS (Continued)

Page 1457 of 1500

SPECIFICATIONS

REAR AXLE27-10

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1271004000332

SERVICE SPECIFICATIONSM1271000300502

ITEM SPECIFICATION

Knuckle Lower arm assembly to knuckle nut 113

12 Nm (83 9 ft-lb)

Shock absorber assembly to knuckle

bolt100

10 Nm (74 7 ft-lb)

Self locking nut (toe control arm

connection)66

6 Nm (49 4 ft-lb)

Trailing arm assembly to knuckle nut 113

12 Nm (83 9 ft-lb)

Upper arm assembly to knuckle nut 113

12 Nm (83 9 ft-lb)

Rear axle hub assembly Brake caliper assembly bolt 60

5 Nm (45 3 ft-lb)

Rear hub assembly bolt 73

7 Nm (54 5 ft-lb)

ITEM LIMIT

Wheel bearing end play mm (in) 0.05 (0.002)

Rear hub rotary-sliding resistance N (lb) 24 (5.4)

Page 1462 of 1500

GENERAL DESCRIPTION

AUTOMATIC TRANSMISSION23A-3

GENERAL DESCRIPTIONM1231000100366

ITEM SPECIFICATION

Transmission modelF5A5A-4-C5Z

Engine model 6G75-S4-MP

Torque converter Type 3-element, 1-stage, 2-phase type

Lock-up Provided

Stall torque ratio 1.71

Transmission type5 forward speeds, 1 reverse speed, fully automatic

Transmission gear

ratio1st 3.789

2nd 2.162

3rd 1.421

4th 1.000

5th 0.686

Reverse 3.117

Final reduction ratio (Differential gear ratio) 3.325

Clutch Multi-disc type 4 sets

Brake Multi-disc type 2 sets, band type 1 set

Manual control system P-R-N-D (4 position) + Sport mode (up, down)

Shift pattern control Electronic control

Hydraulic control during shifting Electronic control (Each clutch hydraulically independently

controlled)

Torque converter clutch control Electronic control

Transmission fluid Specified lubricants MITSUBISHI ELC4-SP III

Quantity (litres) 8.4

Page 1463 of 1500

GENERAL DESCRIPTION

AUTOMATIC TRANSMISSION23A-4

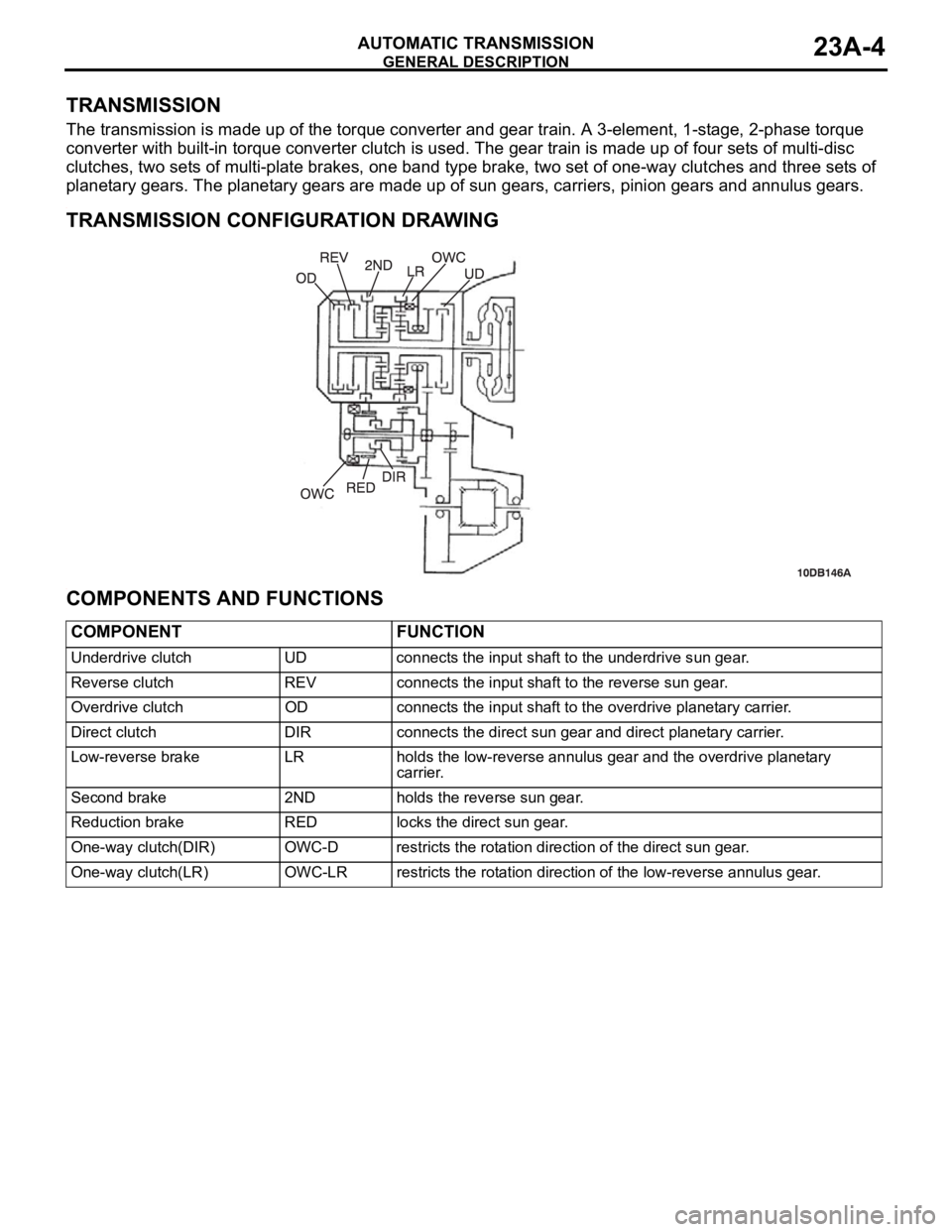

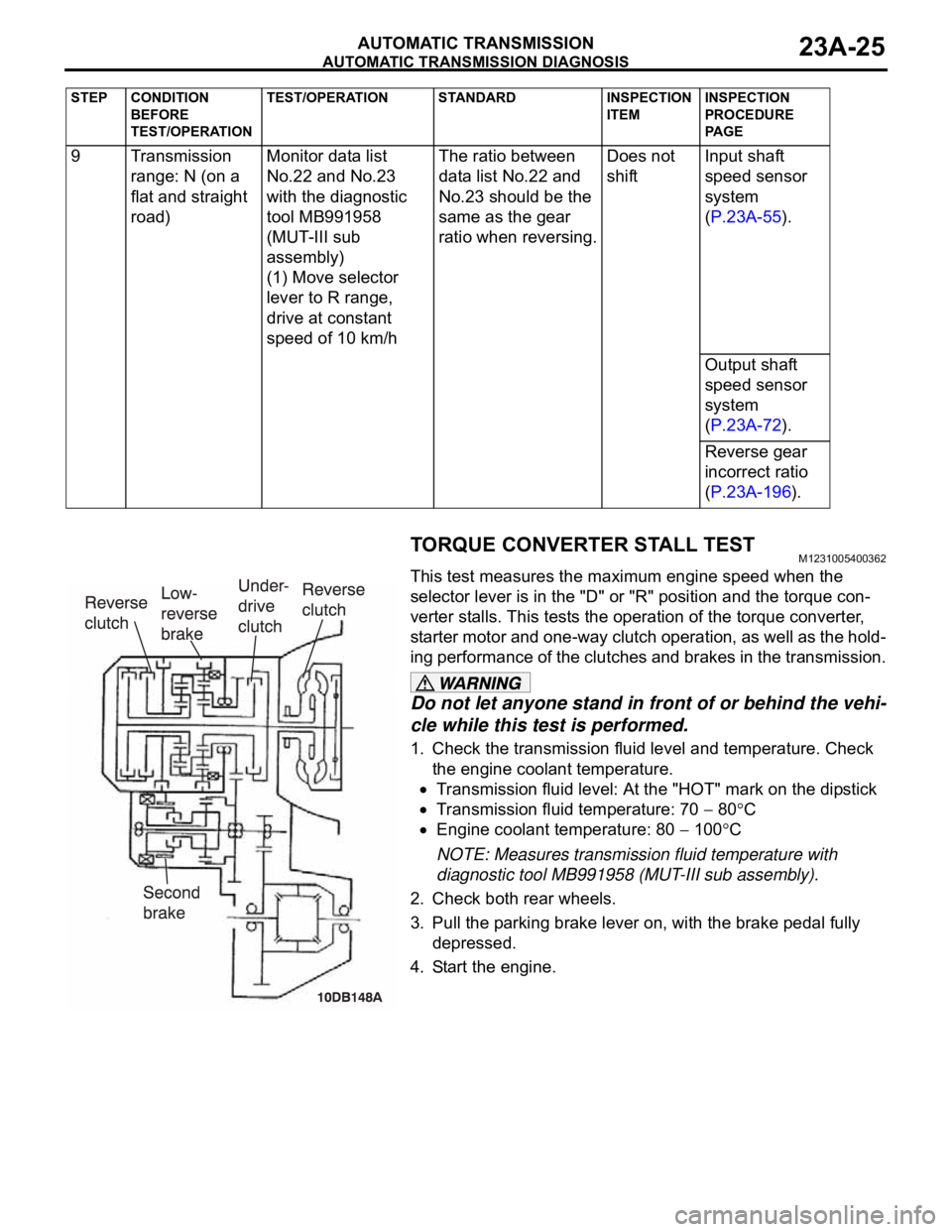

TRANSMISSION

The transmission is made up of the torque converter and gear train. A 3-element, 1-stage, 2-phase torque

converter with built-in torque converter clutch is used. The gear train is made up of four sets of multi-disc

clutches, two sets of multi-plate brakes, one band type brake, two set of one-way clutches and three sets of

planetary gears. The planetary gears are made up of sun gears, carriers, pinion gears and annulus gears.

.

TRANSMISSION CONFIGURATION DRAWING

.

COMPONENTS AND FUNCTIONS

COMPONENT FUNCTION

Underdrive clutch UD connects the input shaft to the underdrive sun gear.

Reverse clutch REV connects the input shaft to the reverse sun gear.

Overdrive clutch OD connects the input shaft to the overdrive planetary carrier.

Direct clutch DIR connects the direct sun gear and direct planetary carrier.

Low-reverse brake LR holds the low-reverse annulus gear and the overdrive planetary

carrier.

Second brake 2ND holds the reverse sun gear.

Reduction brake RED locks the direct sun gear.

One-way clutch(DIR) OWC-D restricts the rotation direction of the direct sun gear.

One-way clutch(LR) OWC-LR restricts the rotation direction of the low-reverse annulus gear.

Page 1464 of 1500

GENERAL DESCRIPTION

AUTOMATIC TRANSMISSION23A-5

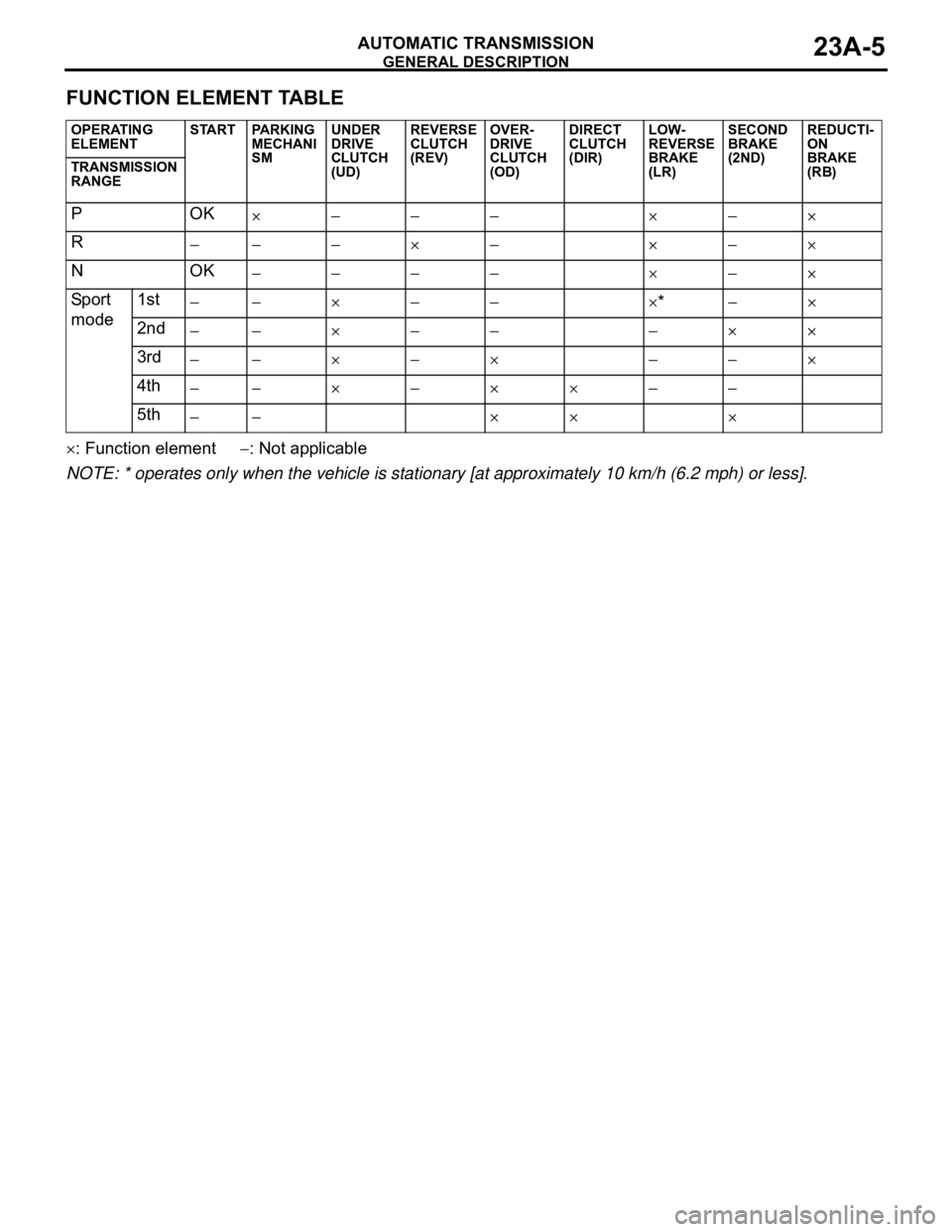

FUNCTION ELEMENT TABLE

: Function element : Not applicable

NOTE: * operates only when the vehicle is stationary [at approximately 10 km/h (6.2 mph) or less].

OPERATING

ELEMENTSTART PARKING

MECHANI

SMUNDER

DRIVE

CLUTCH

(UD)REVERSE

CLUTCH

(REV)OVER-

DRIVE

CLUTCH

(OD)DIRECT

CLUTCH

(DIR)LOW-

REVERSE

BRAKE

(LR)SECOND

BRAKE

(2ND)REDUCTI-

ON

BRAKE

(RB) TRANSMISSION

RANGE

POK

R

NOK

Sport

mode1st*

2nd

3rd

4th

5th

Page 1465 of 1500

GENERAL DESCRIPTION

AUTOMATIC TRANSMISSION23A-6

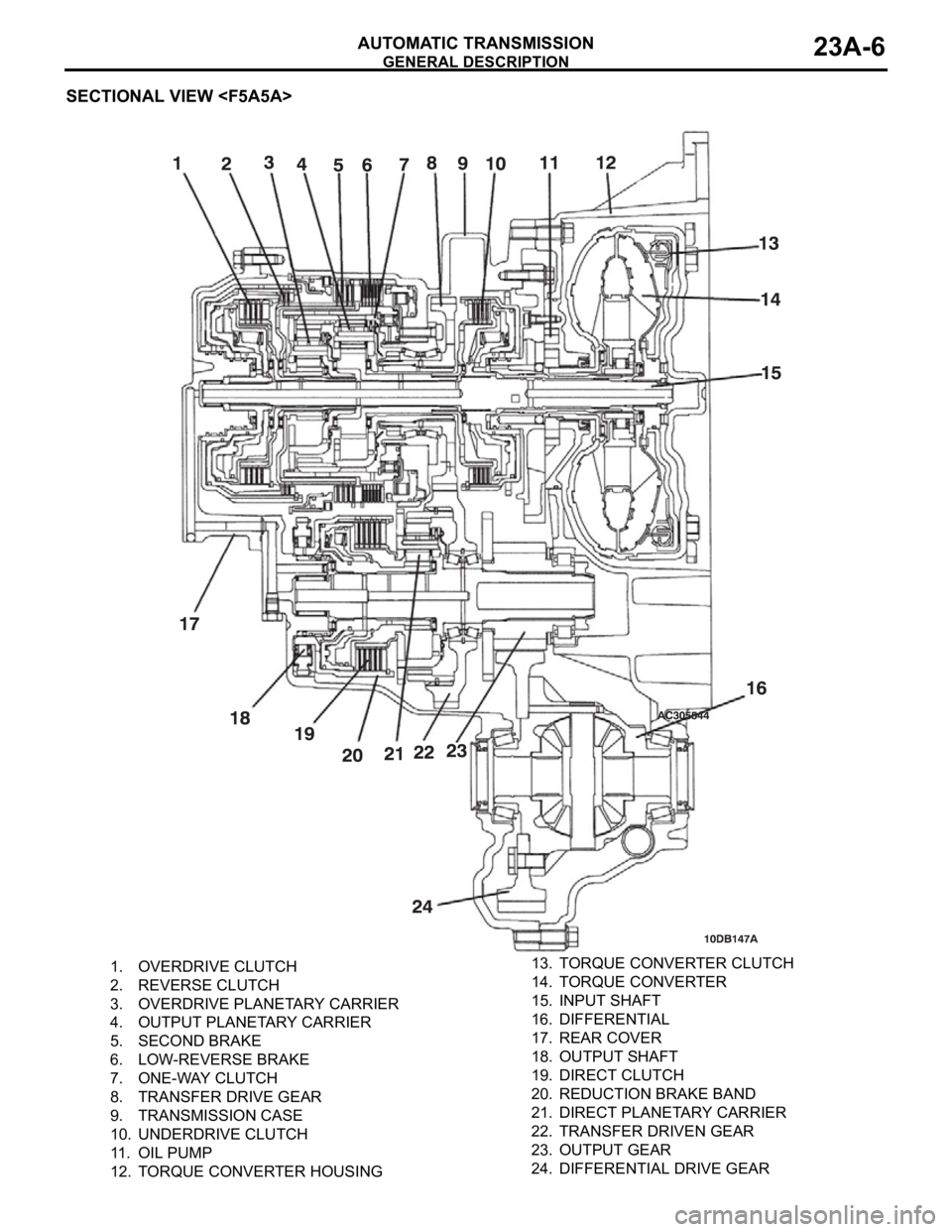

SECTIONAL VIEW

1. OVERDRIVE CLUTCH

2. REVERSE CLUTCH

3. OVERDRIVE PLANETARY CARRIER

4. OUTPUT PLANETARY CARRIER

5. SECOND BRAKE

6. LOW-REVERSE BRAKE

7. ONE-WAY CLUTCH

8. TRANSFER DRIVE GEAR

9. TRANSMISSION CASE

10. UNDERDRIVE CLUTCH

11. OIL PUMP

12. TORQUE CONVERTER HOUSING13. TORQUE CONVERTER CLUTCH

14. TORQUE CONVERTER

15. INPUT SHAFT

16. DIFFERENTIAL

17. REAR COVER

18. OUTPUT SHAFT

19. DIRECT CLUTCH

20. REDUCTION BRAKE BAND

21. DIRECT PLANETARY CARRIER

22. TRANSFER DRIVEN GEAR

23. OUTPUT GEAR

24. DIFFERENTIAL DRIVE GEAR

Page 1467 of 1500

GENERAL DESCRIPTION

AUTOMATIC TRANSMISSION23A-8

FEATURES

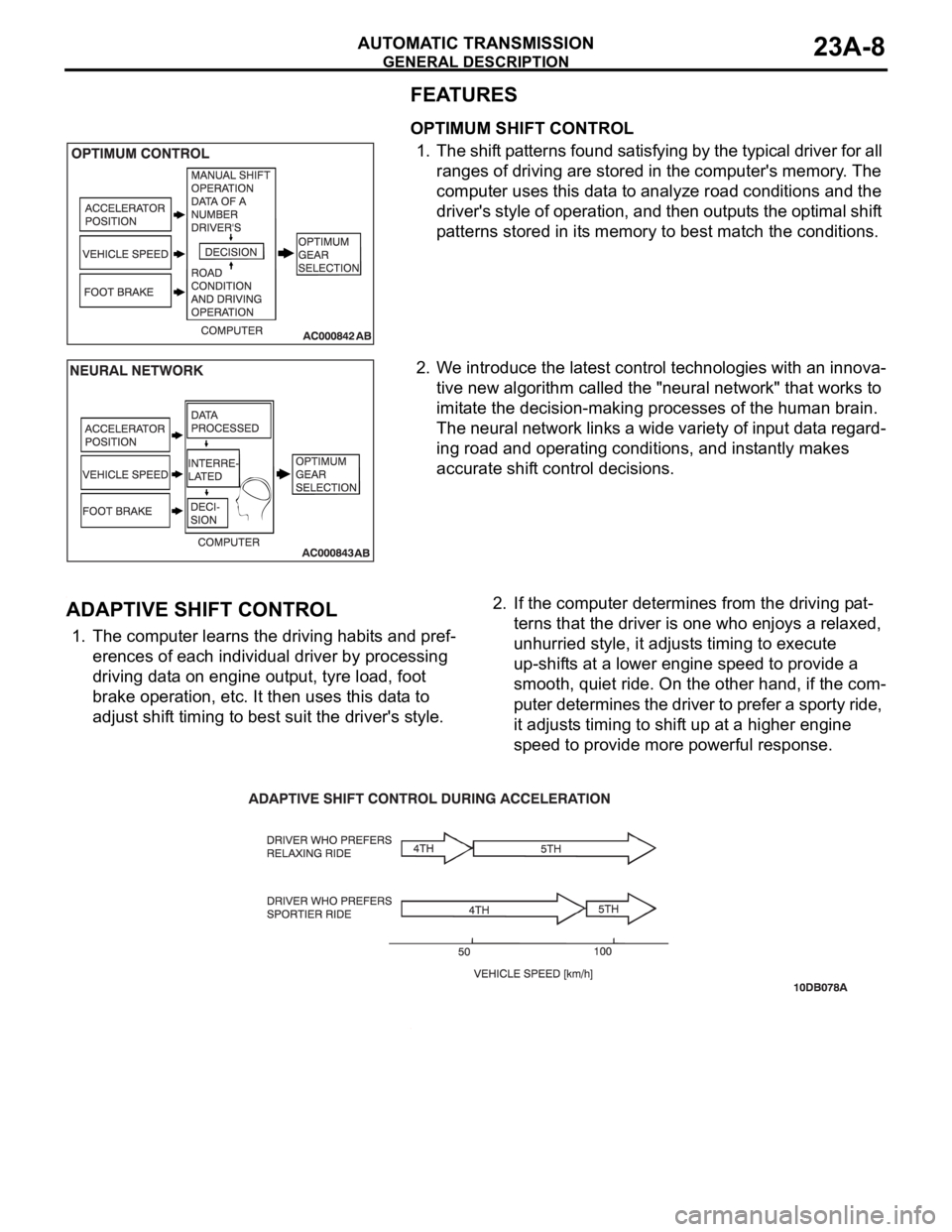

OPTIMUM SHIFT CONTROL

1. The shift patterns found satisfying by the typical driver for all

ranges of driving are stored in the computer's memory. The

computer uses this data to analyze road conditions and the

driver's style of operation, and then outputs the optimal shift

patterns stored in its memory to best match the conditions.

2. We introduce the latest control technologies with an innova-

tive new algorithm called the "neural network" that works to

imitate the decision-making processes of the human brain.

The neural network links a wide variety of input data regard-

ing road and operating conditions, and instantly makes

accurate shift control decisions.

.

ADAPTIVE SHIFT CONTROL

1. The computer learns the driving habits and pref-

erences of each individual driver by processing

driving data on engine output, tyre load, foot

brake operation, etc. It then uses this data to

adjust shift timing to best suit the driver's style.2. If the computer determines from the driving pat-

terns that the driver is one who enjoys a relaxed,

unhurried style, it adjusts timing to execute

up-shifts at a lower engine speed to provide a

smooth, quiet ride. On the other hand, if the com-

puter determines the driver to prefer a sporty ride,

it adjusts timing to shift up at a higher engine

speed to provide more powerful response.

.

Page 1478 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-19

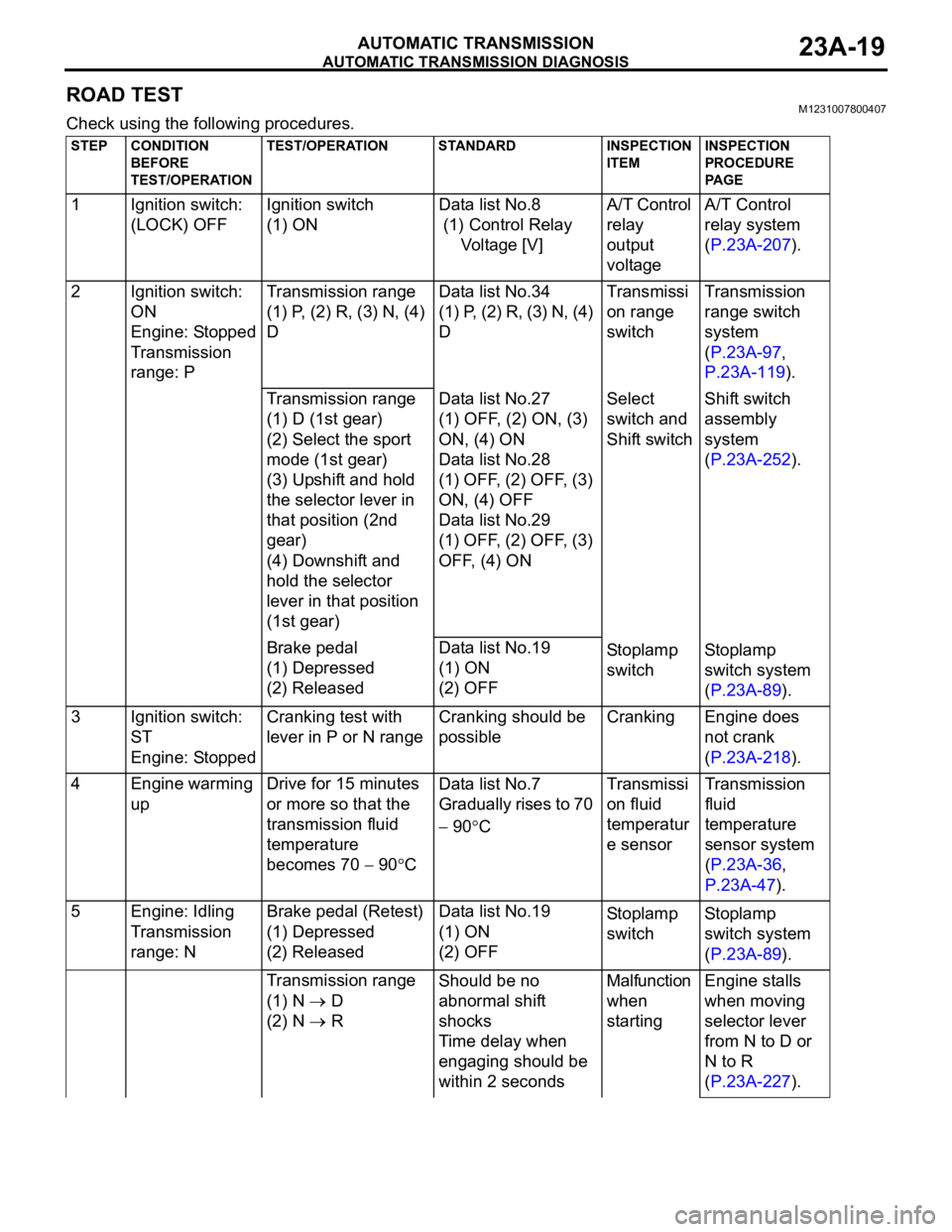

ROAD TESTM1231007800407

Check using the following procedures.

STEP CONDITION

BEFORE

TEST/OPERATIONTEST/OPERATION STANDARD INSPECTION

ITEMINSPECTION

PROCEDURE

PA G E

1 Ignition switch:

(LOCK) OFFIgnition switch

(1) ONData list No.8

(1) Control Relay

Voltage [V]A/T Control

relay

output

voltageA/T Control

relay system

(P.23A-207).

2 Ignition switch:

ON

Engine: Stopped

Transmission

range: PTransmission range

(1) P, (2) R, (3) N, (4)

DData list No.34

(1) P, (2) R, (3) N, (4)

DTransmissi

on range

switchTransmission

range switch

system

(P.23A-97,

P.23A-119).

Transmission range

(1) D (1st gear)

(2) Select the sport

mode (1st gear)

(3) Upshift and hold

the selector lever in

that position (2nd

gear)

(4) Downshift and

hold the selector

lever in that position

(1st gear)Data list No.27

(1) OFF, (2) ON, (3)

ON, (4) ON

Data list No.28

(1) OFF, (2) OFF, (3)

ON, (4) OFF

Data list No.29

(1) OFF, (2) OFF, (3)

OFF, (4) ONSelect

switch and

Shift switchShift switch

assembly

system

(P.23A-252).

Brake pedal

(1) Depressed

(2) ReleasedData list No.19

(1) ON

(2) OFFSto pl amp

switchSt o pla mp

switch system

(P.23A-89).

3 Ignition switch:

ST

Engine: StoppedCranking test with

lever in P or N rangeCranking should be

possibleCranking Engine does

not crank

(P.23A-218).

4 Engine warming

upDrive for 15 minutes

or more so that the

transmission fluid

temperature

becomes 70

90CData list No.7

Gradually rises to 70

90CTransmissi

on fluid

temperatur

e sensorTransmission

fluid

temperature

sensor system

(P.23A-36,

P.23A-47).

5 Engine: Idling

Transmission

range: NBrake pedal (Retest)

(1) Depressed

(2) ReleasedData list No.19

(1) ON

(2) OFFSto pl amp

switchSt o pla mp

switch system

(P.23A-89).

Transmission range

(1) N

D

(2) N

RShould be no

abnormal shift

shocks

Time delay when

engaging should be

within 2 secondsMalfunction

when

startingEngine stalls

when moving

selector lever

from N to D or

N to R

(P.23A-227).

Page 1484 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-25

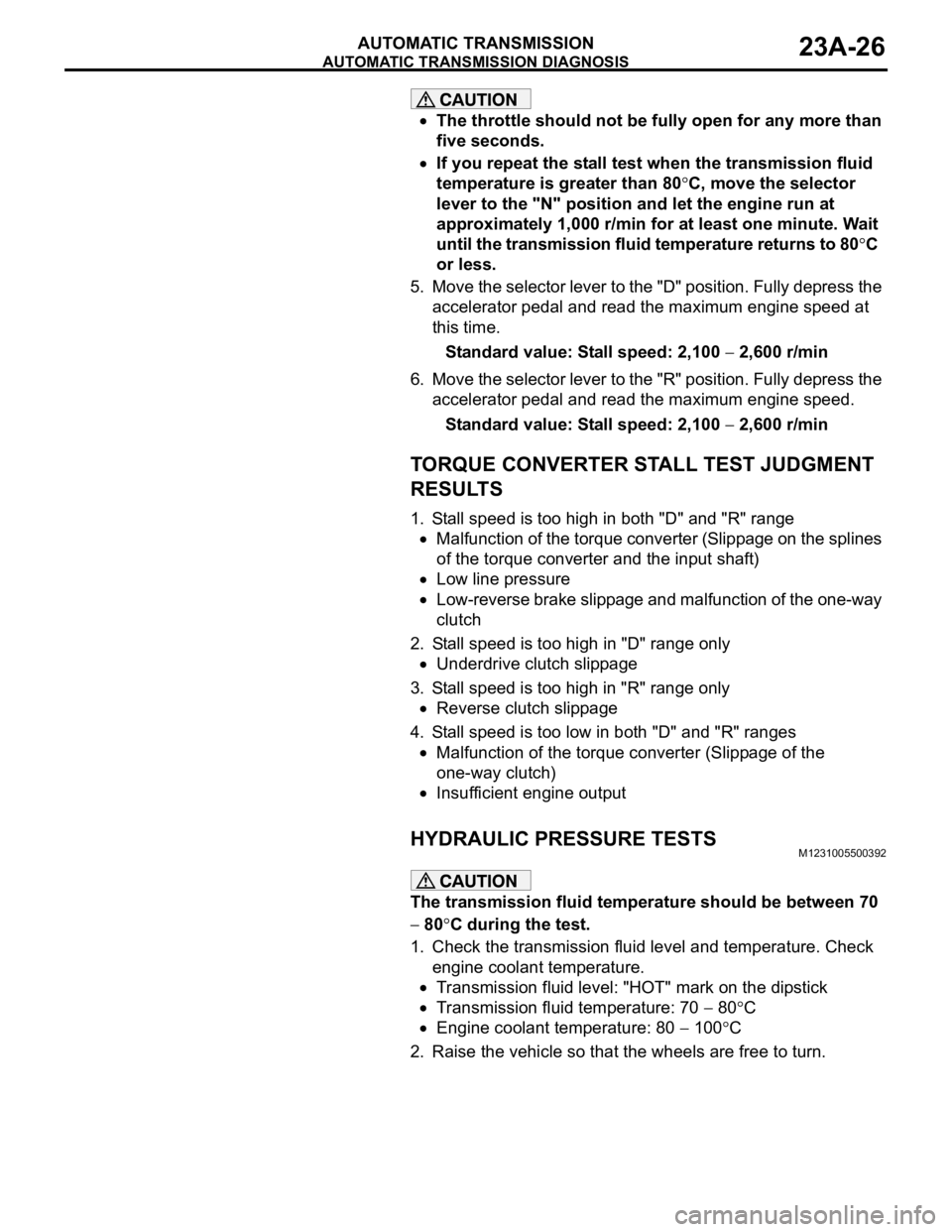

TORQUE CONVERTER STALL TESTM1231005400362

This test measures the maximum engine speed when the

selector lever is in the "D" or "R" position and the torque con-

verter stalls. This tests the operation of the torque converter,

starter motor and one-way clutch operation, as well as the hold-

ing performance of the clutches and brakes in the transmission.

Do not let anyone stand in front of or behind the vehi-

cle while this test is performed.

1. Check the transmission fluid level and temperature. Check

the engine coolant temperature.

Transmission fluid level: At the "HOT" mark on the dipstick

Transmission fluid temperature: 70 80C

Engine coolant temperature: 80 100C

NOTE: Measures transmission fluid temperature with

diagnostic tool MB991958 (MUT-III sub assembly).

2. Check both rear wheels.

3. Pull the parking brake lever on, with the brake pedal fully

depressed.

4. Start the engine. 9 Transmission

range: N (on a

flat and straight

road)Monitor data list

No.22 and No.23

with the diagnostic

tool MB991958

(MUT-III sub

assembly)

(1) Move selector

lever to R range,

drive at constant

speed of 10 km/hThe ratio between

data list No.22 and

No.23 should be the

same as the gear

ratio when reversing.Does not

shiftInput shaft

speed sensor

system

(P.23A-55).

Output shaft

speed sensor

system

(P.23A-72).

Reverse gear

incorrect ratio

(P.23A-196).

STEP CONDITION

BEFORE

TEST/OPERATIONTEST/OPERATION STANDARD INSPECTION

ITEMINSPECTION

PROCEDURE

PA G E

Page 1485 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-26

The throttle should not be fully open for any more than

five seconds.

If you repeat the stall test when the transmission fluid

temperature is greater than 80

C, move the selector

lever to the "N" position and let the engine run at

approximately 1,000 r/min for at least one minute. Wait

until the transmission fluid temperature returns to 80

C

or less.

5. Move the selector lever to the "D" position. Fully depress the

accelerator pedal and read the maximum engine speed at

this time.

Standard value: Stall speed: 2,100

2,600 r/min

6. Move the selector lever to the "R" position. Fully depress the

accelerator pedal and read the maximum engine speed.

Standard value: Stall speed: 2,100

2,600 r/min

TORQUE CONVERTER STALL TEST JUDGMENT

RESULTS

1. Stall speed is too high in both "D" and "R" range

Malfunction of the torque converter (Slippage on the splines

of the torque converter and the input shaft)

Low line pressure

Low-reverse brake slippage and malfunction of the one-way

clutch

2. Stall speed is too high in "D" range only

Underdrive clutch slippage

3. Stall speed is too high in "R" range only

Reverse clutch slippage

4. Stall speed is too low in both "D" and "R" ranges

Malfunction of the torque converter (Slippage of the

one-way clutch)

Insufficient engine output

HYDRAULIC PRESSURE TESTSM1231005500392

The transmission fluid temperature should be between 70

80C during the test.

1. Check the transmission fluid level and temperature. Check

engine coolant temperature.

Transmission fluid level: "HOT" mark on the dipstick

Transmission fluid temperature: 70 80C

Engine coolant temperature: 80 100C

2. Raise the vehicle so that the wheels are free to turn.