brake MITSUBISHI 380 2005 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1379 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-48

STEP 20. Using Diagnostic Tool MB991958, check data list

item 89: Normally closed Brake Switch.

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

(1) Connect Diagnostic Tool MB991958 to the data link

connector. (Refer to P.17-11).

(2) Turn the ignition switch to the "ON" position.

(3) Set Diagnostic Tool MB991958 to data reading mode for

auto-cruise control system. (Refer to P.17-11).

Item 89, Normally closed Brake Switch.

When the brake pedal is depressed, the display on

Diagnostic Tool MB991958 should be "ON".

When the brake pedal is released, the display on

Diagnostic Tool MB991958 should be "OFF".

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect Diagnostic Tool MB991958.

Q: Is the switch operating properly?

YES : Go to Step 21.

NO : Replace the Engine ECU. [Refer to GROUP 13A,

Engine ECU 13A-675] . Then go to Step 22.

STEP 21. Using Diagnostic Tool MB991958, read the

diagnostic trouble codes.

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

(1) Connect Diagnostic Tool MB991958 to the data link

connector. (Refer to P.17-11).

(2) Turn the ignition switch to the "ON" position.

(3) Set Diagnostic Tool MB991958 to read the diagnostic

trouble codes. (Refer to P.17-11).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect Diagnostic Tool MB991958.

Q: Is DTC 1571 set?

YES : Replace the Engine ECU.[Refer to GROUP 13A,

Engine ECU 13A-675] . Then go to Step 22.

NO : It can be assumed that this malfunction is intermittent.

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunction P.00-14).

Page 1384 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-53

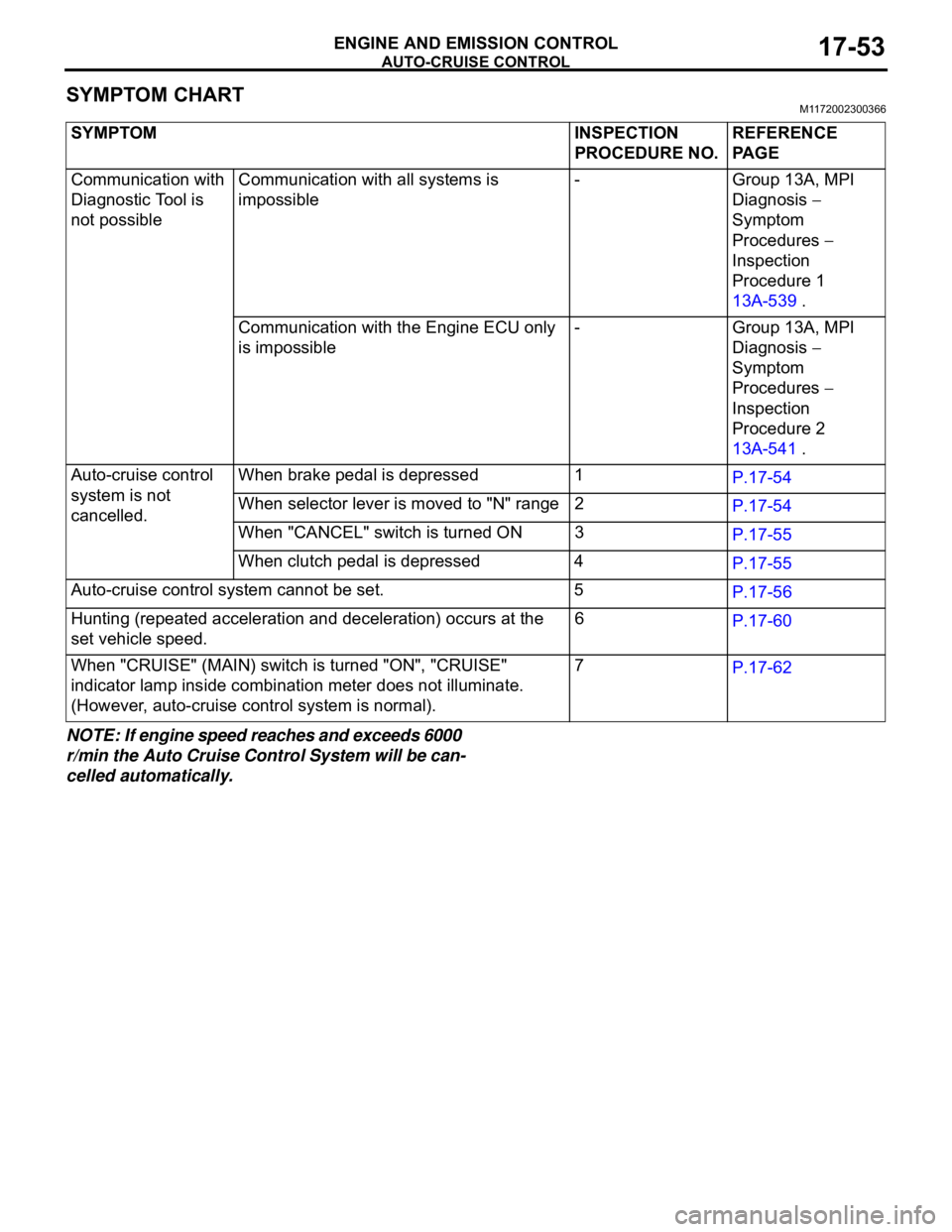

SYMPTOM CHARTM1172002300366

NOTE: If engine speed reaches and exceeds 6000

r/min the Auto Cruise Control System will be can-

celled automatically.SYMPTOM INSPECTION

PROCEDURE NO.REFERENCE

PA G E

Communication with

Diagnostic Tool is

not possibleCommunication with all systems is

impossible- Group 13A, MPI

Diagnosis

Symptom

Procedures

Inspection

Procedure 1

13A-539 .

Communication with the Engine ECU only

is impossible- Group 13A, MPI

Diagnosis

Symptom

Procedures

Inspection

Procedure 2

13A-541 .

Auto-cruise control

system is not

cancelled.When brake pedal is depressed 1

P.17-54

When selector lever is moved to "N" range 2

P.17-54

When "CANCEL" switch is turned ON 3

P.17-55

When clutch pedal is depressed 4

P.17-55

Auto-cruise control system cannot be set. 5

P.17-56

Hunting (repeated acceleration and deceleration) occurs at the

set vehicle speed.6

P.17-60

When "CRUISE" (MAIN) switch is turned "ON", "CRUISE"

indicator lamp inside combination meter does not illuminate.

(However, auto-cruise control system is normal).7

P.17-62

Page 1385 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-54

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: When the Brake Pedal is Depressed, Auto-cruise Control System is not

Cancelled.

.

COMMENT

The stoplamp switch circuit is suspected.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THIS CASE:)

Malfunction of the stoplamp switch.

Damaged harness or connector.

Malfunction of the Engine ECU.

Circuit drawings

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Refer to component locations GROUP-70

DIAGNOSIS

Refer to P.17-35, Diagnostic Trouble Code Procedures DTC

22: Stoplamp Switch System.

INSPECTION PROCEDURE 2: When the Selector Lever is Moved to "N" Range, Auto-cruise Control

System is not Cancelled.

.

COMMENT

The transmission inhibitor switch circuit is suspected.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THIS CASE:)

Malfunction of the transmission inhibitor switch.

Damaged harness or connector.

Malfunction of the Engine ECU.

Malfunction of A/T ECU.

Circuit drawings

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Refer to component locations GROUP-70

DIAGNOSIS

Refer to GROUP 23A, A/T Diagnosis Diagnostic Trouble

Code Procedures

DTC 0705: Transmission Inhibitor Switch

System (Open/short Circuit) P.23A-97.

Page 1389 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-58

STEP 3. Using Diagnostic ToolDiagnostic Tool MB991958,

check data list item 74: Stoplamp Switch and data list item

89: Brake switch.

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

(1) Connect Diagnostic Tool MB991958 to the data link

connector. (Refer to P.17-11).

(2) Turn the ignition switch to the "ON" position.

(3) Set Diagnostic Tool MB991958 to data reading mode for

auto-cruise control system. (Refer to P.17-11).

Item 74, Stoplamp Switch.

When brake pedal is depressed, the display on

Diagnostic Tool MB991958 should be "ON".

When brake pedal is released, the display on

Diagnostic Tool MB991958 should be "OFF".

Item 89, Brake Switch.

When brake pedal is depressed, the display on

Diagnostic Tool MB991958 should be "ON".

When brake pedal is released, the display on

Diagnostic Tool MB991958 should be "OFF".

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect Diagnostic Tool MB991958.

Q: Is the switch operating properly?

YES : Go to Step 4.

NO : Refer to P.17-54, Symptom Procedures

Inspection

Procedure 1. Then go to Step 6.

Page 1396 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-65

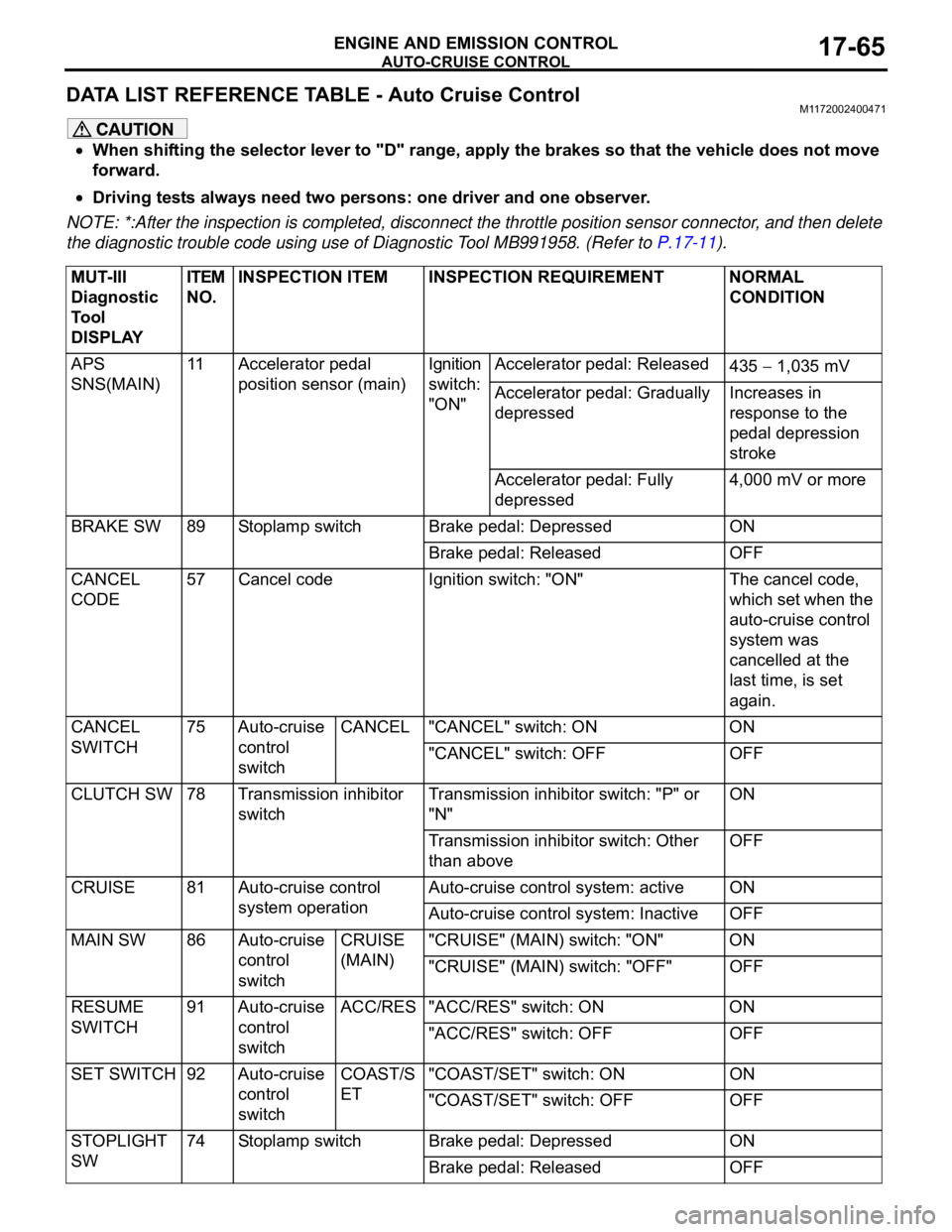

DATA LIST REFERENCE TABLE - Auto Cruise ControlM1172002400471

When shifting the selector lever to "D" range, apply the brakes so that the vehicle does not move

forward.

Driving tests always need two persons: one driver and one observer.

NOTE: *:After the inspection is completed, disconnect the throttle position sensor connector, and then delete

the diagnostic trouble code using use of Diagnostic Tool MB991958. (Refer to P.17-11).

MUT-III

Diagnostic

To o l

DISPLAYITEM

NO.INSPECTION ITEM INSPECTION REQUIREMENT NORMAL

CONDITION

APS

SNS(MAIN)11 A c c e l e r a t o r p e d a l

position sensor (main)Ignition

switch:

"ON"Accelerator pedal: Released

435

1,035 mV

Accelerator pedal: Gradually

depressedIncreases in

response to the

pedal depression

stroke

Accelerator pedal: Fully

depressed4,000 mV or more

BRAKE SW 89 Stoplamp switch Brake pedal: Depressed ON

Brake pedal: Released OFF

CANCEL

CODE57 Cancel code Ignition switch: "ON" The cancel code,

which set when the

auto-cruise control

system was

cancelled at the

last time, is set

again.

CANCEL

SWITCH75 Auto-cruise

control

switchCANCEL "CANCEL" switch: ON ON

"CANCEL" switch: OFF OFF

CLUTCH SW 78 Transmission inhibitor

switchTransmission inhibitor switch: "P" or

"N"ON

Transmission inhibitor switch: Other

than aboveOFF

CRUISE 81 Auto-cruise control

system operationAuto-cruise control system: active ON

Auto-cruise control system: Inactive OFF

MAIN SW 86 Auto-cruise

control

switchCRUISE

(MAIN)"CRUISE" (MAIN) switch: "ON" ON

"CRUISE" (MAIN) switch: "OFF" OFF

RESUME

SWITCH91 Auto-cruise

control

switchACC/RES "ACC/RES" switch: ON ON

"ACC/RES" switch: OFF OFF

SET SWITCH 92 Auto-cruise

control

switchCOAST/S

ET"COAST/SET" switch: ON ON

"COAST/SET" switch: OFF OFF

STOPLIGHT

SW74 Stoplamp switch Brake pedal: Depressed ON

Brake pedal: Released OFF

Page 1398 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-67

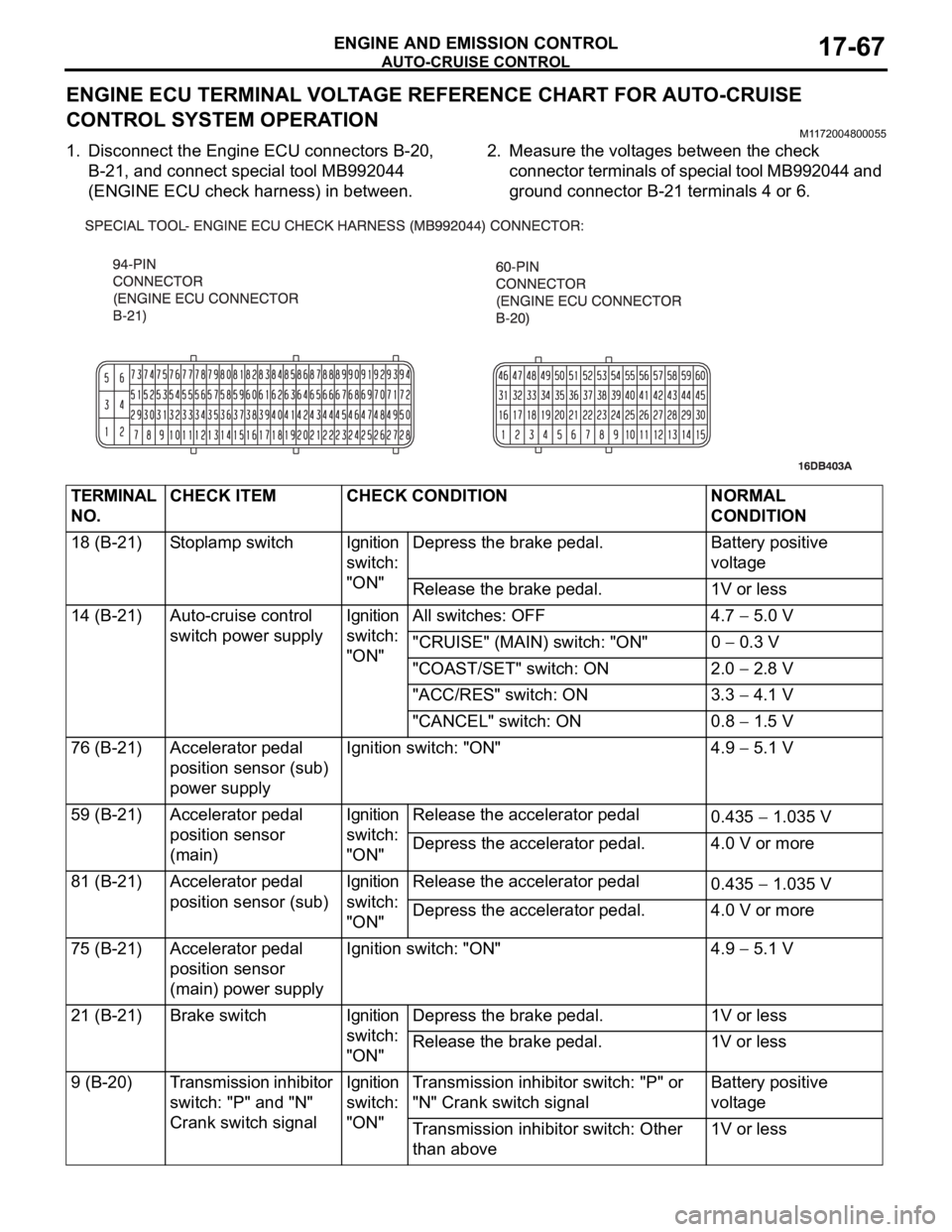

ENGINE ECU TERMINAL VOLTAGE REFERENCE CHART FOR AUTO-CRUISE

CONTROL SYSTEM OPERATION

M1172004800055

1. Disconnect the Engine ECU connectors B-20,

B-21, and connect special tool MB992044

(ENGINE ECU check harness) in between.2. Measure the voltages between the check

connector terminals of special tool MB992044 and

ground connector B-21 terminals 4 or 6.

TERMINAL

NO.CHECK ITEM CHECK CONDITION NORMAL

CONDITION

18 (B-21) Stoplamp switch Ignition

switch:

"ON"Depress the brake pedal. Battery positive

voltage

Release the brake pedal. 1V or less

14 (B-21) Auto-cruise control

switch power supplyIgnition

switch:

"ON"All switches: OFF 4.7

5.0 V

"CRUISE" (MAIN) switch: "ON" 0

0.3 V

"COAST/SET" switch: ON 2.0

2.8 V

"ACC/RES" switch: ON 3.3

4.1 V

"CANCEL" switch: ON 0.8

1.5 V

76 (B-21) Accelerator pedal

position sensor (sub)

power supplyIgnition switch: "ON" 4.9

5.1 V

59 (B-21) Accelerator pedal

position sensor

(main)Ignition

switch:

"ON"Release the accelerator pedal

0.435

1.035 V

Depress the accelerator pedal. 4.0 V or more

81 (B-21) Accelerator pedal

position sensor (sub)Ignition

switch:

"ON"Release the accelerator pedal

0.435

1.035 V

Depress the accelerator pedal. 4.0 V or more

75 (B-21) Accelerator pedal

position sensor

(main) power supplyIgnition switch: "ON" 4.9

5.1 V

21 (B-21) Brake switch Ignition

switch:

"ON"Depress the brake pedal. 1V or less

Release the brake pedal. 1V or less

9 (B-20) Transmission inhibitor

switch: "P" and "N"

Crank switch signalIgnition

switch:

"ON"Transmission inhibitor switch: "P" or

"N" Crank switch signalBattery positive

voltage

Transmission inhibitor switch: Other

than above1V or less

Page 1403 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-72

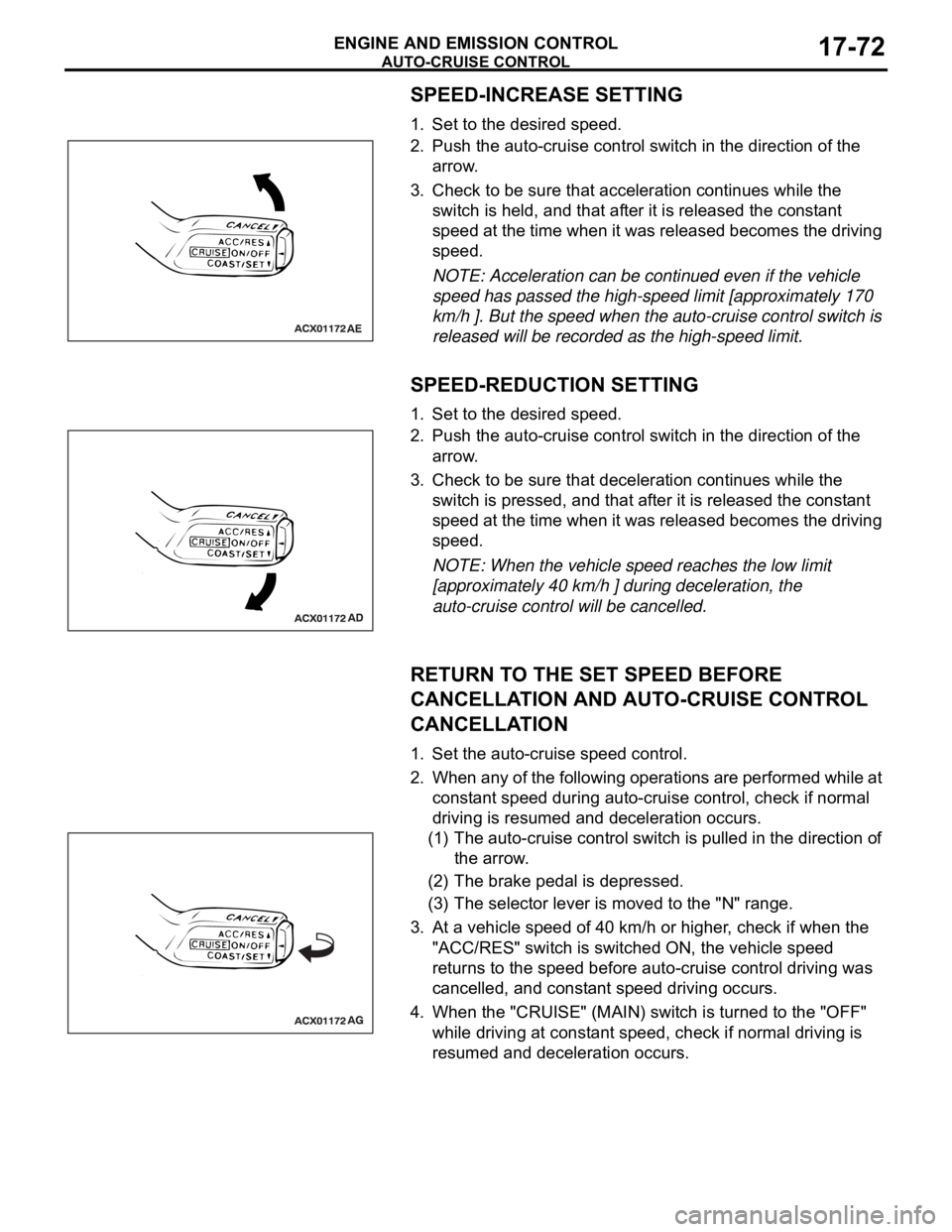

SPEED-INCREASE SETTING

1. Set to the desired speed.

2. Push the auto-cruise control switch in the direction of the

arrow.

3. Check to be sure that acceleration continues while the

switch is held, and that after it is released the constant

speed at the time when it was released becomes the driving

speed.

NOTE: Acceleration can be continued even if the vehicle

speed has passed the high-speed limit [approximately 170

km/h ]. But the speed when the auto-cruise control switch is

released will be recorded as the high-speed limit.

SPEED-REDUCTION SETTING

1. Set to the desired speed.

2. Push the auto-cruise control switch in the direction of the

arrow.

3. Check to be sure that deceleration continues while the

switch is pressed, and that after it is released the constant

speed at the time when it was released becomes the driving

speed.

NOTE: When the vehicle speed reaches the low limit

[approximately 40 km/h ] during deceleration, the

auto-cruise control will be cancelled.

RETURN TO THE SET SPEED BEFORE

CANCELLATION AND AUTO-CRUISE CONTROL

CANCELLATION

1. Set the auto-cruise speed control.

2. When any of the following operations are performed while at

constant speed during auto-cruise control, check if normal

driving is resumed and deceleration occurs.

(1) The auto-cruise control switch is pulled in the direction of

the arrow.

(2) The brake pedal is depressed.

(3) The selector lever is moved to the "N" range.

3. At a vehicle speed of 40 km/h or higher, check if when the

"ACC/RES" switch is switched ON, the vehicle speed

returns to the speed before auto-cruise control driving was

cancelled, and constant speed driving occurs.

4. When the "CRUISE" (MAIN) switch is turned to the "OFF"

while driving at constant speed, check if normal driving is

resumed and deceleration occurs.

Page 1404 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-73

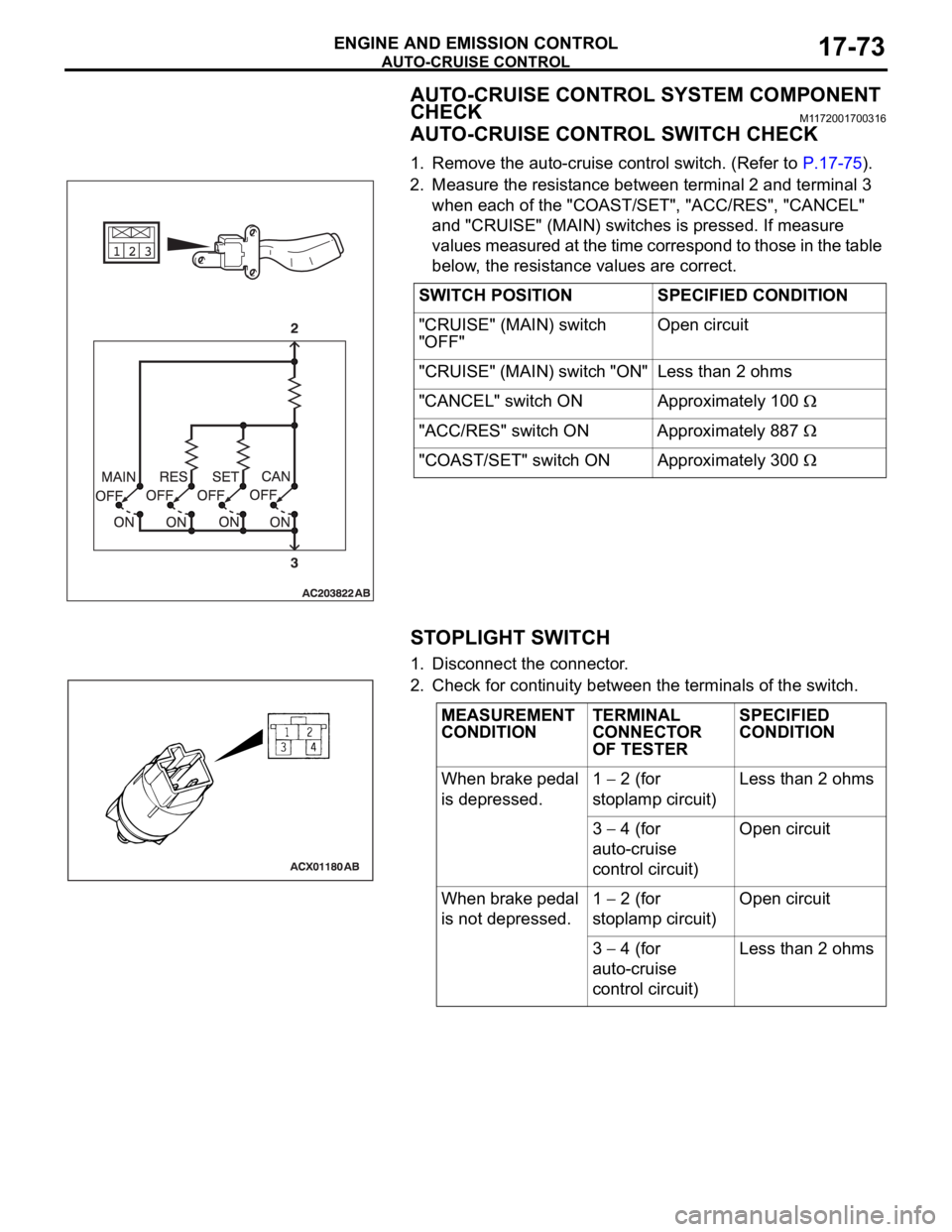

AUTO-CRUISE CONTROL SYSTEM COMPONENT

CHECK

M1172001700316

AUTO-CRUISE CONTROL SWITCH CHECK

1. Remove the auto-cruise control switch. (Refer to P.17-75).

2. Measure the resistance between terminal 2 and terminal 3

when each of the "COAST/SET", "ACC/RES", "CANCEL"

and "CRUISE" (MAIN) switches is pressed. If measure

values measured at the time correspond to those in the table

below, the resistance values are correct.

STOPLIGHT SWITCH

1. Disconnect the connector.

2. Check for continuity between the terminals of the switch.SWITCH POSITION SPECIFIED CONDITION

"CRUISE" (MAIN) switch

"OFF"Open circuit

"CRUISE" (MAIN) switch "ON" Less than 2 ohms

"CANCEL" switch ON Approximately 100

"ACC/RES" switch ON Approximately 887

"COAST/SET" switch ON Approximately 300

MEASUREMENT

CONDITIONTERMINAL

CONNECTOR

OF TESTERSPECIFIED

CONDITION

When brake pedal

is depressed.1

2 (for

stoplamp circuit)Less than 2 ohms

3

4 (for

auto-cruise

control circuit)Open circuit

When brake pedal

is not depressed.1

2 (for

stoplamp circuit)Open circuit

3

4 (for

auto-cruise

control circuit)Less than 2 ohms

Page 1406 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-75

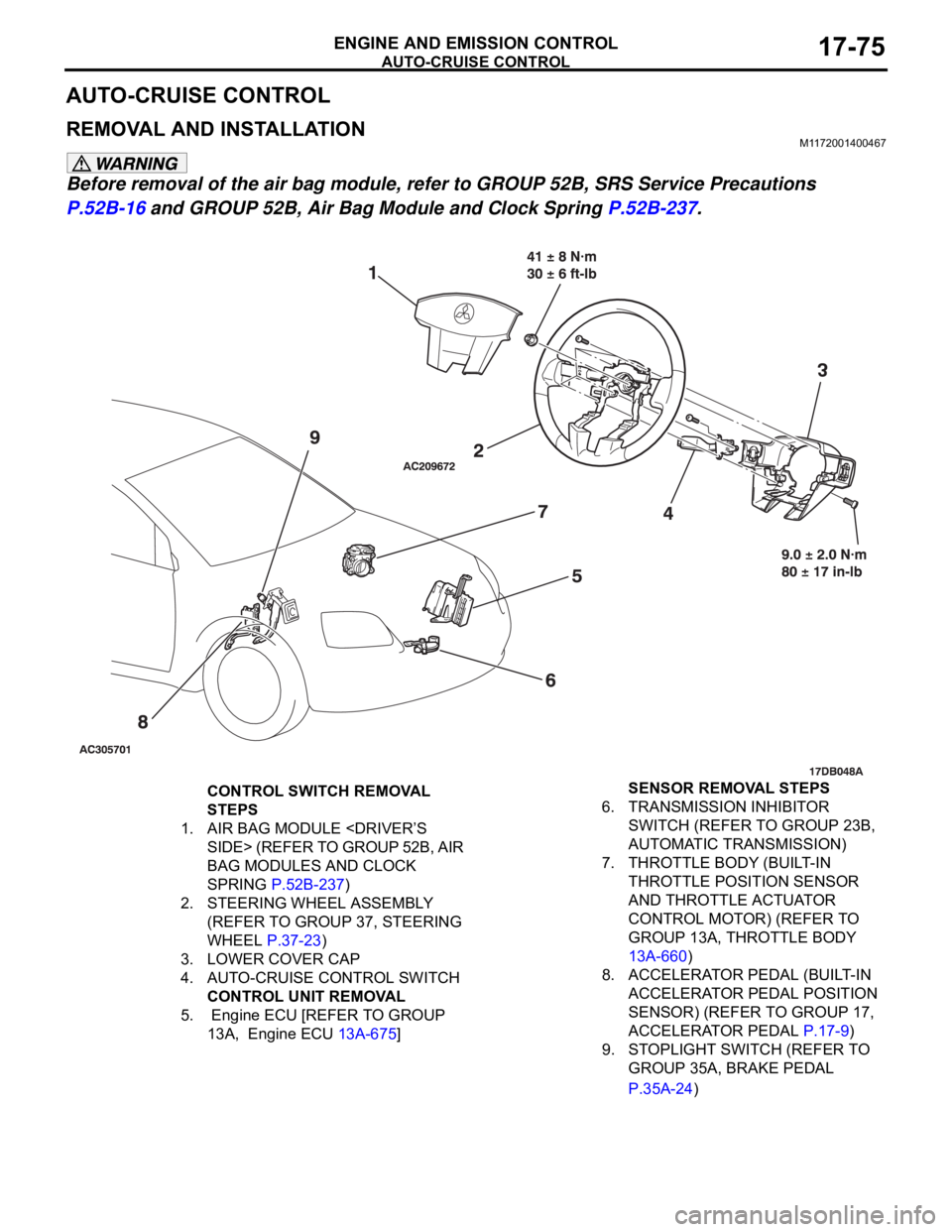

AUTO-CRUISE CONTROL

REMOVAL AND INSTALLATIONM1172001400467

Before removal of the air bag module, refer to GROUP 52B, SRS Service Precautions

P.52B-16 and GROUP 52B, Air Bag Module and Clock Spring P.52B-237.

CONTROL SWITCH REMOVAL

STEPS

1. AIR BAG MODULE

BAG MODULES AND CLOCK

SPRING P.52B-237)

2. STEERING WHEEL ASSEMBLY

(REFER TO GROUP 37, STEERING

WHEEL P.37-23)

3. LOWER COVER CAP

4. AUTO-CRUISE CONTROL SWITCH

CONTROL UNIT REMOVAL

5. Engine ECU [REFER TO GROUP

13A, Engine ECU 13A-675] SENSOR REMOVAL STEPS

6. TRANSMISSION INHIBITOR

SWITCH (REFER TO GROUP 23B,

AUTOMATIC TRANSMISSION)

7. THROTTLE BODY (BUILT-IN

THROTTLE POSITION SENSOR

AND THROTTLE ACTUATOR

CONTROL MOTOR) (REFER TO

GROUP 13A, THROTTLE BODY

13A-660)

8. ACCELERATOR PEDAL (BUILT-IN

ACCELERATOR PEDAL POSITION

SENSOR) (REFER TO GROUP 17,

ACCELERATOR PEDAL P.17-9)

9. STOPLIGHT SWITCH (REFER TO

GROUP 35A, BRAKE PEDAL

P.35A-24)

Page 1420 of 1500

FRONT AXLE DIAGNOSIS

FRONT AXLE26-3

2. Verify that the condition described by the

customer exists.3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

SYMPTOM CHARTM1261005700269

SYMPTOM PROCEDURES

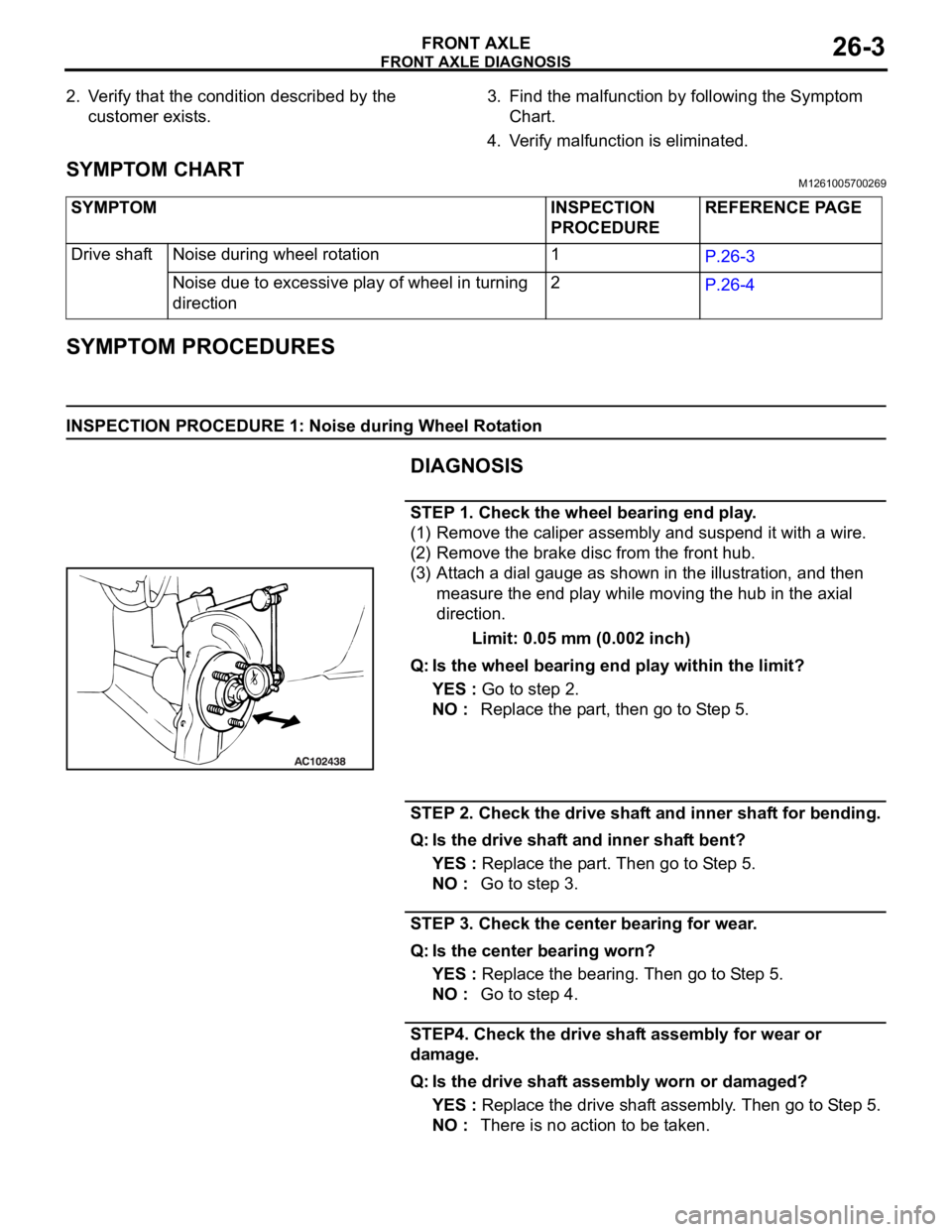

INSPECTION PROCEDURE 1: Noise during Wheel Rotation

DIAGNOSIS

STEP 1. Check the wheel bearing end play.

(1) Remove the caliper assembly and suspend it with a wire.

(2) Remove the brake disc from the front hub.

(3) Attach a dial gauge as shown in the illustration, and then

measure the end play while moving the hub in the axial

direction.

Limit: 0.05 mm (0.002 inch)

Q: Is the wheel bearing end play within the limit?

YES : Go to step 2.

NO : Replace the part, then go to Step 5.

STEP 2. Check the drive shaft and inner shaft for bending.

Q: Is the drive shaft and inner shaft bent?

YES : Replace the part. Then go to Step 5.

NO : Go to step 3.

STEP 3. Check the center bearing for wear.

Q: Is the center bearing worn?

YES : Replace the bearing. Then go to Step 5.

NO : Go to step 4.

STEP4. Check the drive shaft assembly for wear or

damage.

Q: Is the drive shaft assembly worn or damaged?

YES : Replace the drive shaft assembly. Then go to Step 5.

NO : There is no action to be taken. SYMPTOM INSPECTION

PROCEDUREREFERENCE PAGE

Drive shaft Noise during wheel rotation 1

P.26-3

Noise due to excessive play of wheel in turning

direction2

P.26-4