turn signal MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 850 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-149

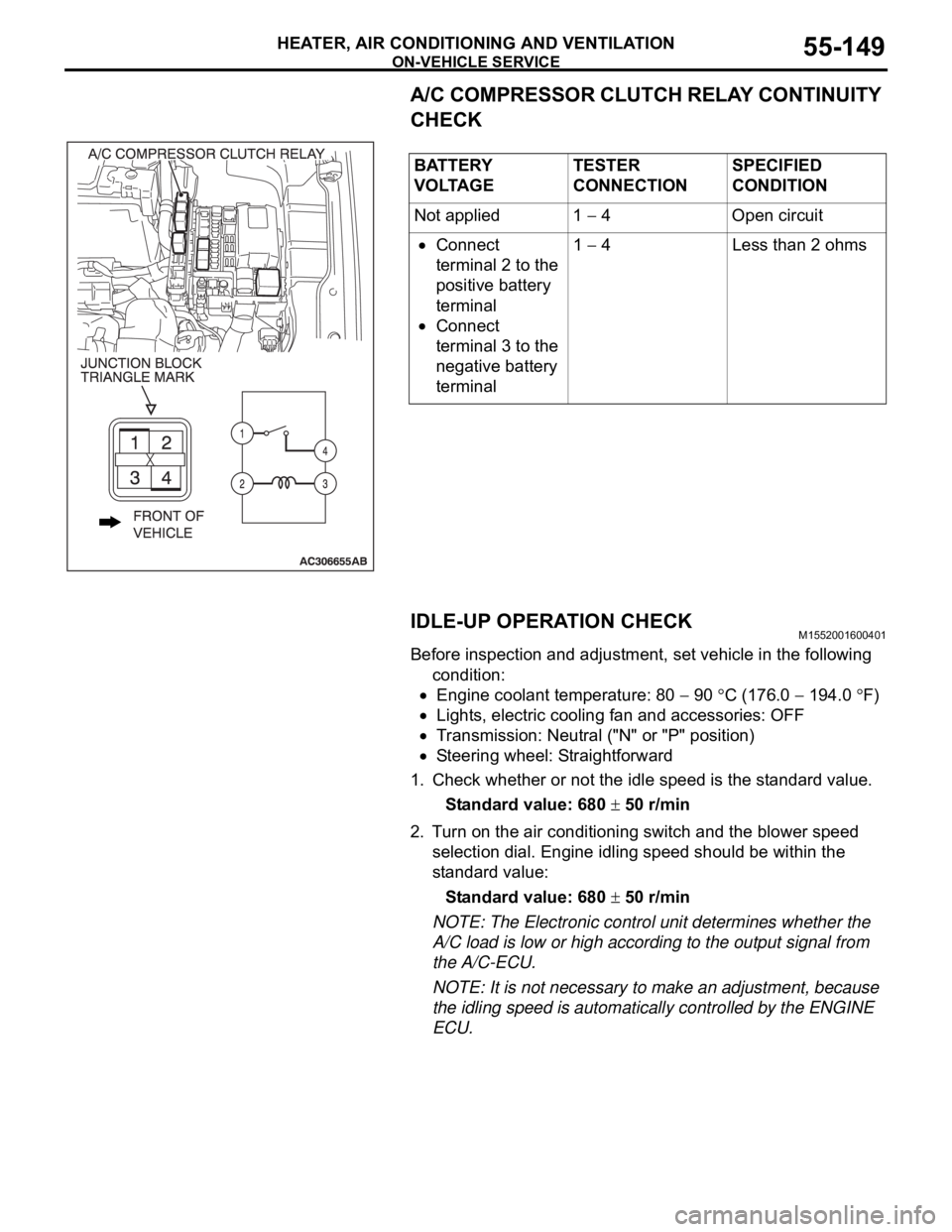

A/C COMPRESSOR CLUTCH RELAY CONTINUITY

CHECK

IDLE-UP OPERATION CHECK

M1552001600401

Before inspection and adjustment, set vehicle in the following

condition:

Engine coolant temperature: 80 90 C (176.0 194.0 F)

Lights, electric cooling fan and accessories: OFF

Transmission: Neutral ("N" or "P" position)

Steering wheel: Straightforward

1. Check whether or not the idle speed is the standard value.

Standard value: 680

50 r/min

2. Turn on the air conditioning switch and the blower speed

selection dial. Engine idling speed should be within the

standard value:

Standard value: 680

50 r/min

NOTE: The Electronic control unit determines whether the

A/C load is low or high according to the output signal from

the A/C-ECU.

NOTE: It is not necessary to make an adjustment, because

the idling speed is automatically controlled by the ENGINE

ECU. BATTERY

V O LTA G ETESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 1

4 Open circuit

Connect

terminal 2 to the

positive battery

terminal

Connect

terminal 3 to the

negative battery

terminal1

4 Less than 2 ohms

Page 935 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-20

STEP 23. MUT-III self-diag code

Check if an MPI system self-diag code is set. (Refer to GROUP

13A - Trouble shooting 13A-5).

Q: Diagnosis code set?

YES : Inspection chart for diagnosis code (Refer to GROUP

13A - Trouble shooting 13A-17)

NO : Replace the engine-ECU (Refer to GROUP 13A,

Engine-ECU 13A-675 ). Then go to Step 24.

STEP 24. Check the symptoms.

Q: Does the radiator fan motor and the condenser fan

motor operate correctly?

YES : This symptom is complete.

NO : Return to Step 1.

INSPECTION PROCEDURE 4: Radiator Fan and Condenser Fan do not Change Speed or Stop

.

Radiator Fan and Condenser Fan Drive

Circuit

Refer to 5.

.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the fan con-

troller power supply or earth circuit.

If the communication line wiring harness between

the fan controller and the engine-ECU is

short-circuited to earth, the radiator fan motor

and the condenser fan motor will not rotate.

The cause could also be a malfunction of input

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU.

The cause could also be a malfunction of the fan

controller or the engine-ECU.

.

TROUBLESHOOTING HINTS

Malfunction of fusible link No.2

Malfunction of fan control relay

Malfunction of cooling fan motor

Malfunction of fan controller

Malfunction of engine-ECU

Damaged wiring harness or connector

DIAGNOSIS

STEP 1. Check the fan control relay.

Refer to 14-31.

Q: Is the fan control relay in good condition?

YES : Go to Step 2.

NO : Replace the fan control relay. Then go to Step 8.

Page 1007 of 1500

IGNITION SYSTEM

ENGINE ELECTRICAL16-30

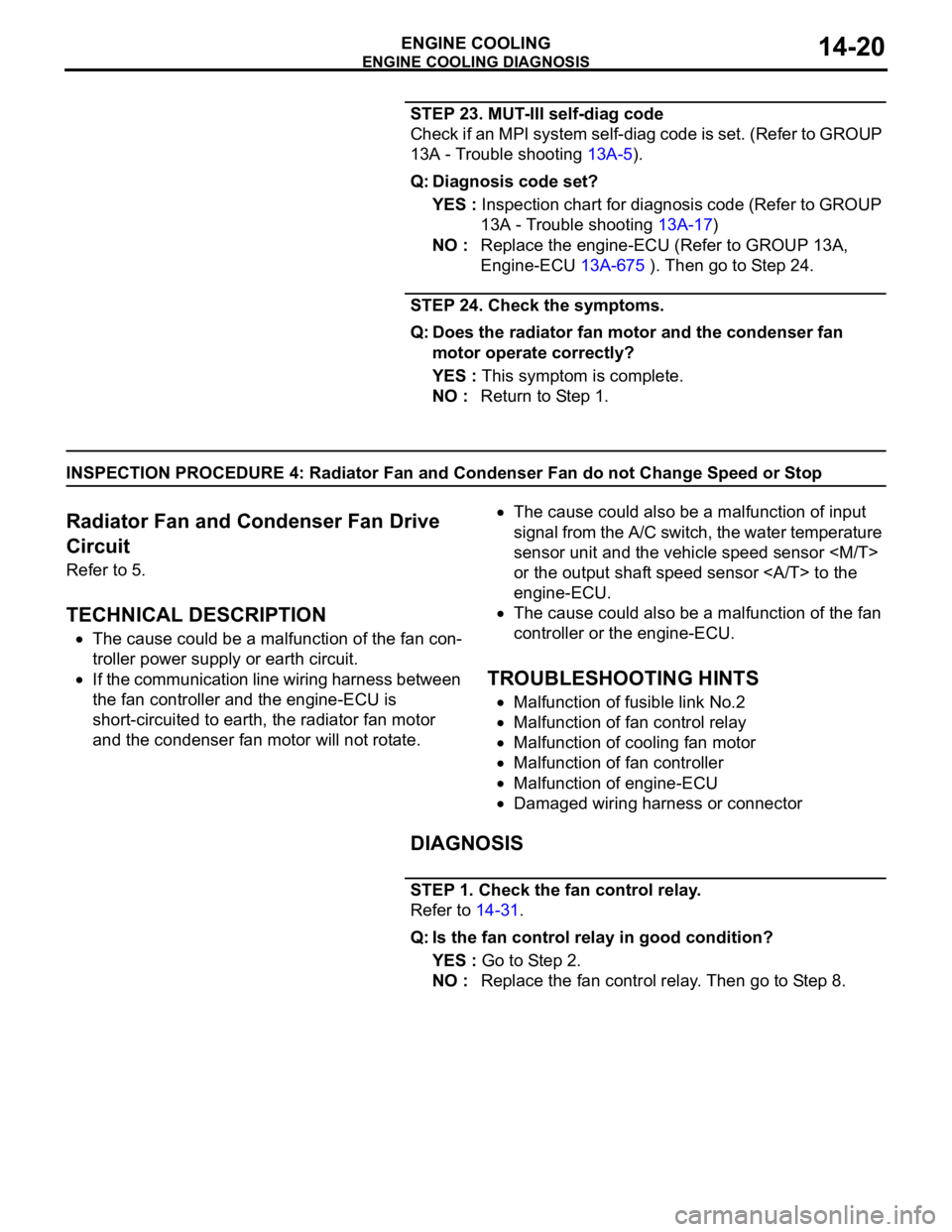

IGNITION SYSTEM

GENERAL DESCRIPTIONM1163000100528

This system is provided with six ignition coils with

built-in ignition power transistors for each of the cylin-

ders.

Interruption of the primary current flowing in the pri-

mary side of ignition coil generates a high voltage in

the secondary side of ignition coil.

The engine control unit (ECU) controls the three

ignition power transistors to turn them alternately ON

and OFF. This causes the primary currents in the

ignition coils to be alternately interrupted and allowed

to flow to fire the cylinders in the order 1-2-3-4-5-6.The ECU determines which ignition coil should be

controlled by means of the signals from the camshaft

position sensor which is incorporated in the camshaft

and from the crankshaft position sensor which is

incorporated in the crankshaft.

It also detects the crankshaft position to provide igni-

tion at the most appropriate timing in response to the

engine operation conditions.

When the engine is cold or operated at high alti-

tudes, the ignition timing is slightly advanced to pro-

vide optimum performance.

SPECIAL TOOLSM1163000600073

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MD998773

Knock sensor wrenchMD998773-01 Knock sensor removal

and installation

Page 1047 of 1500

WINDSHIELD WIPER AND WASHER

EXTERIOR51-14

WINDSHIELD WIPER AND WASHER

GENERAL DESCRIPTIONM1511000100558

WINDSHIELD WIPER AND WASHER

OPERATION

.

WINDSHIELD LOW-SPEED (AND

HIGH-SPEED) WIPER OPERATION

If the windshield low-speed wiper switch is turned

to the ON position with the ignition switch at the

"ACC" or "ON" position, the column switch sends

a low-speed wiper ON and high-speed wiper OFF

signals to the front-ECU. This turns the wiper sig-

nal on and the wiper speed control relay off

(low-speed), causing the wipers to operate at

low-speed.

If the windshield high-speed wiper switch is

turned to the ON position, the column switch

sends a low-speed wiper OFF and high-speed

wiper ON signals to the front-ECU. This turns

both the wiper signal and the wiper speed control

relay on (high-speed), causing the wipers to

operate at high-speed.

NOTE: The windshield wiper speed is adjustable

with the built-in wiper speed control relay.

High-speed operations take place when the wiper

speed control relay is set to "ON" and low-speed

operations take place when the wiper speed control

relay is set to "OFF".

.

WINDSHIELD INTERMITTENT WIPER

OPERATION

The ETACS-ECU calculates the wiper operation

interval according to the voltage signal sent from the

column switch. Then the ETACS-ECU sends a signal

to the front-ECU. The front-ECU determines the

wiper operation interval and turns on the wiper relay

signal relay. This causes the wiper auto stop relay to

turn on. Then the wiper auto stop relay will turn off

after the wipers reach the park position. This causes

the wiper signal relay and then the wipers to turn off.

If the wiper signal relay remains off for the wiper

operation interval, the relay turns on again, causing

the wipers to operate in intermittent mode.

.

WINDSHIELD MIST WIPER OPERATION

If the windshield mist wiper switch is turned to the

ON position with the ignition switch at the "ACC"

or "ON" position, the mist wiper high-speed oper-

ation signal is sent to the front-ECU. This signal

turns on the wiper speed control relay, causing

the wipers to work at high-speed while the mist

switch is on.

While the windshield mist wiper switch remains

turned on when the intermittent mode is still work-

ing, the wipers work as the mist wiper. However,

the wipers return to the intermittent mode again

when the switch is changed back to "INT" posi-

tion.

To prevent the windshield mist wiper from operat-

ing when the windshield wiper switch is turned

OFF, the windshield mist wiper does not work for

0.5 second after the windshield intermittent wiper

switch, the windshield low-speed wiper switch

and the windshield high-speed wiper switch are

turned OFF.

.

WINDSHIELD WASHER OPERATION

If the windshield washer switch is turned to the

ON position with the ignition switch at "ACC" or

"ON" position, the windshield washer ON signal is

sent to the front-ECU. After 0.3 second, the wind-

shield wiper signal turns on. After the windshield

washer switch signal turns off, the windshield

wiper signal turns off in three seconds.

If the windshield washer switch is turned on while

the windshield wiper is at intermittent mode, and

the windshield washer switch is turned OFF

within 0.2 second, the wiper works only once to

perform mist operation. When the windshield

washer switch is turned on for more than 0.2 sec-

ond, the wiper performs the same movement as

normal condition from the time when 0.2 second

has elapsed, and then returns to intermittent

operation.

WINDSHIELD WIPER AND WASHER DIAGNOSISM1511000700389

The windshield wiper and washer are controlled by

the Simplified Wiring System (SWS). For trouble-

shooting, refer to GROUP 54B, SWS Diagnosis

P.54B-10.NOTE: Even when the ETACS-ECU has failed, the

windshield wiper can work at low speed as fail-safe

mode. (Normally, the windshield wiper operates

when the ignition switch is at the "ACC" position. But,

if it enters the fail-safe mode, the wiper can operate

only when the ignition switch is at the "ON" position.)

Page 1134 of 1500

KEYLESS ENTRY SYSTEM

BODY42-67

KEYLESS ENTRY SYSTEM

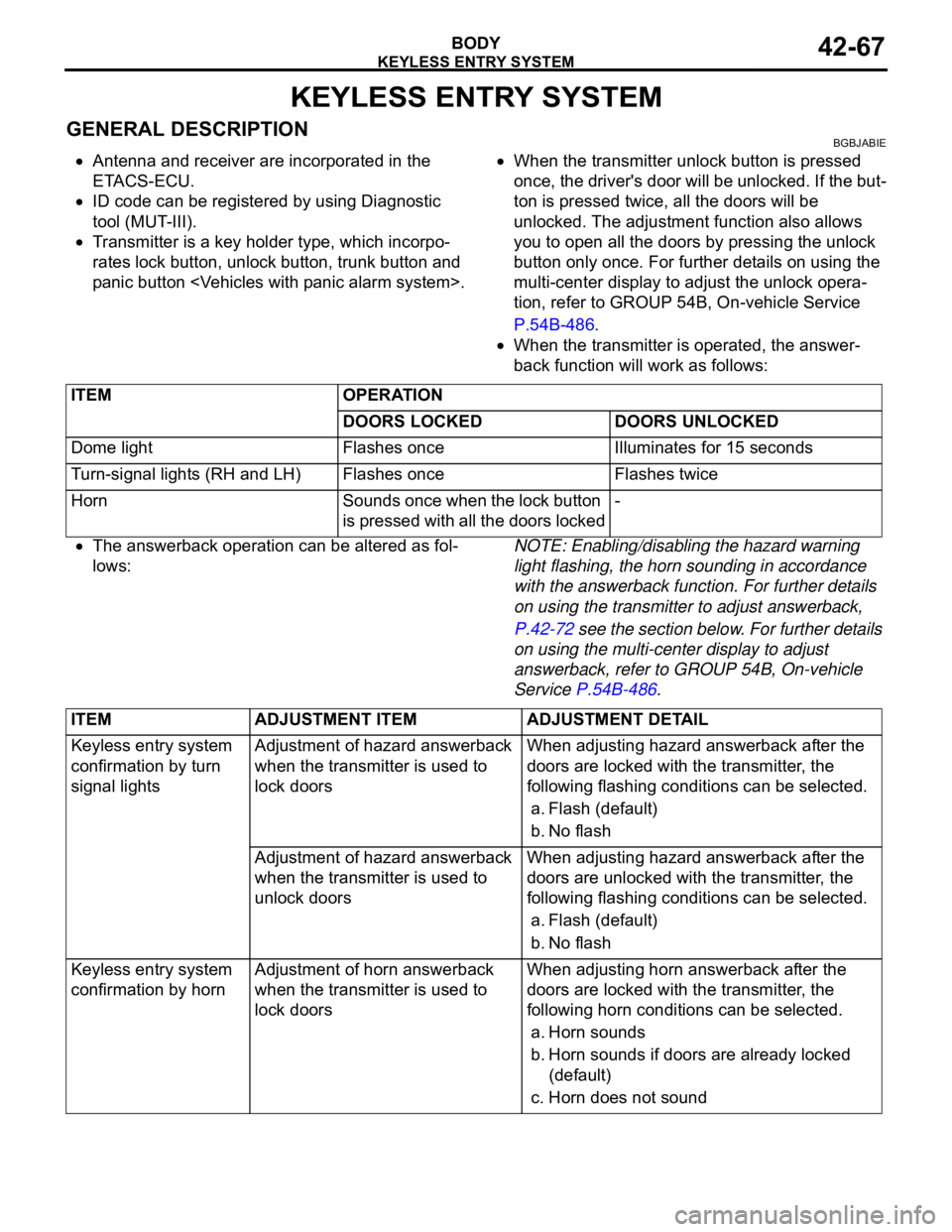

GENERAL DESCRIPTIONBGBJABIE

Antenna and receiver are incorporated in the

ETACS-ECU.

ID code can be registered by using Diagnostic

tool (MUT-III).

Transmitter is a key holder type, which incorpo-

rates lock button, unlock button, trunk button and

panic button

When the transmitter unlock button is pressed

once, the driver's door will be unlocked. If the but-

ton is pressed twice, all the doors will be

unlocked. The adjustment function also allows

you to open all the doors by pressing the unlock

button only once. For further details on using the

multi-center display to adjust the unlock opera-

tion, refer to GROUP 54B, On-vehicle Service

P.54B-486.

When the transmitter is operated, the answer-

back function will work as follows:

The answerback operation can be altered as fol-

lows:NOTE: Enabling/disabling the hazard warning

light flashing, the horn sounding in accordance

with the answerback function. For further details

on using the transmitter to adjust answerback,

P.42-72 see the section below. For further details

on using the multi-center display to adjust

answerback, refer to GROUP 54B, On-vehicle

Service P.54B-486. ITEM OPERATION

DOORS LOCKED DOORS UNLOCKED

Dome light Flashes once Illuminates for 15 seconds

Turn-signal lights (RH and LH) Flashes once Flashes twice

Horn Sounds once when the lock button

is pressed with all the doors locked-

ITEM ADJUSTMENT ITEM ADJUSTMENT DETAIL

Keyless entry system

confirmation by turn

signal lightsAdjustment of hazard answerback

when the transmitter is used to

lock doorsWhen adjusting hazard answerback after the

doors are locked with the transmitter, the

following flashing conditions can be selected.

a. Flash (default)

b. No flash

Adjustment of hazard answerback

when the transmitter is used to

unlock doorsWhen adjusting hazard answerback after the

doors are unlocked with the transmitter, the

following flashing conditions can be selected.

a. Flash (default)

b. No flash

Keyless entry system

confirmation by hornAdjustment of horn answerback

when the transmitter is used to

lock doorsWhen adjusting horn answerback after the

doors are locked with the transmitter, the

following horn conditions can be selected.

a. Horn sounds

b. Horn sounds if doors are already locked

(default)

c. Horn does not sound

Page 1138 of 1500

KEYLESS ENTRY SYSTEM

BODY42-71

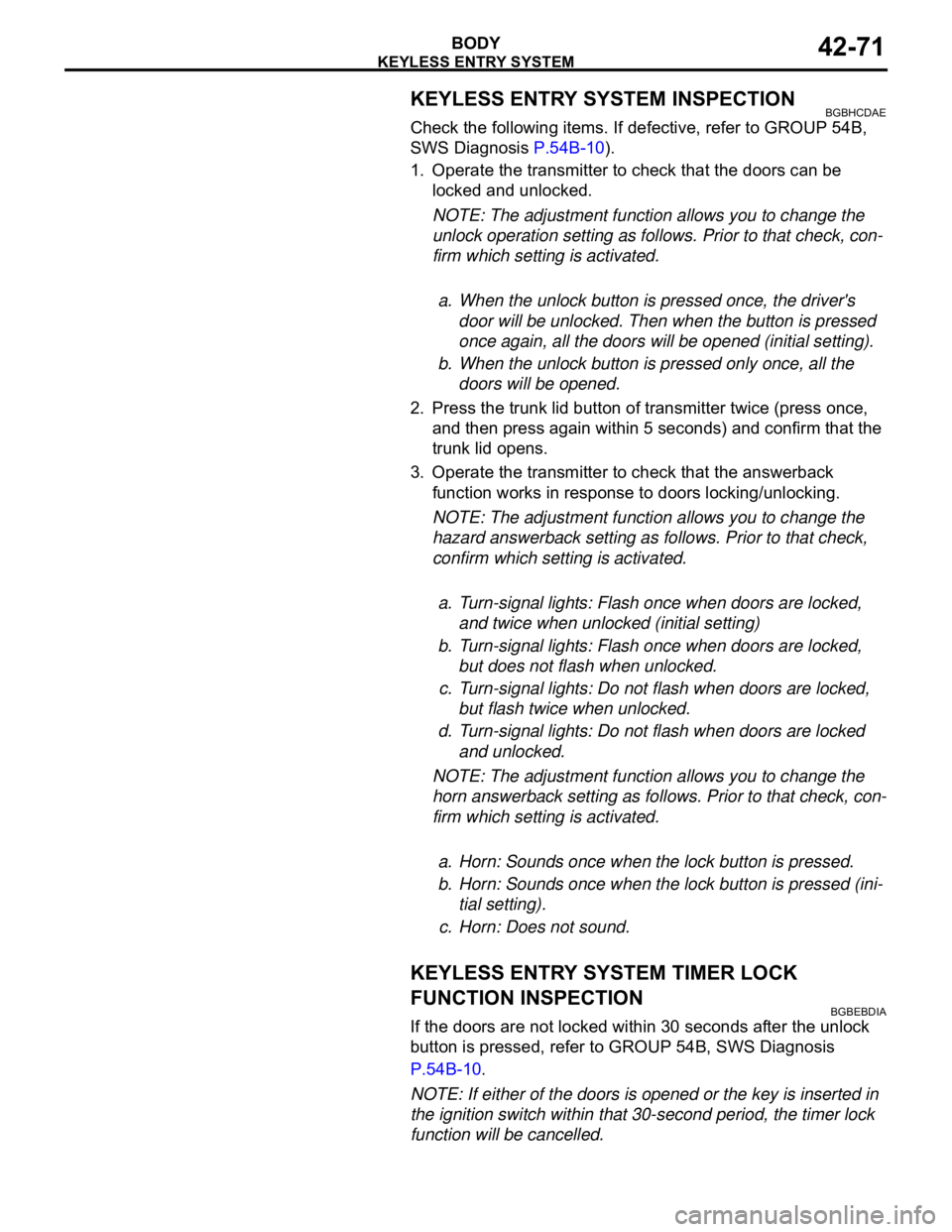

KEYLESS ENTRY SYSTEM INSPECTIONBGBHCDAE

Check the following items. If defective, refer to GROUP 54B,

SWS Diagnosis P.54B-10).

1. Operate the transmitter to check that the doors can be

locked and unlocked.

NOTE: The adjustment function allows you to change the

unlock operation setting as follows. Prior to that check, con-

firm which setting is activated.

.

a. When the unlock button is pressed once, the driver's

door will be unlocked. Then when the button is pressed

once again, all the doors will be opened (initial setting).

b. When the unlock button is pressed only once, all the

doors will be opened.

2. Press the trunk lid button of transmitter twice (press once,

and then press again within 5 seconds) and confirm that the

trunk lid opens.

3. Operate the transmitter to check that the answerback

function works in response to doors locking/unlocking.

NOTE: The adjustment function allows you to change the

hazard answerback setting as follows. Prior to that check,

confirm which setting is activated.

.

a. Turn-signal lights: Flash once when doors are locked,

and twice when unlocked (initial setting)

b. Turn-signal lights: Flash once when doors are locked,

but does not flash when unlocked.

c. Turn-signal lights: Do not flash when doors are locked,

but flash twice when unlocked.

d. Turn-signal lights: Do not flash when doors are locked

and unlocked.

NOTE: The adjustment function allows you to change the

horn answerback setting as follows. Prior to that check, con-

firm which setting is activated.

.

a. Horn: Sounds once when the lock button is pressed.

b. Horn: Sounds once when the lock button is pressed (ini-

tial setting).

c. Horn: Does not sound.

KEYLESS ENTRY SYSTEM TIMER LOCK

FUNCTION INSPECTION

BGBEBDIA

If the doors are not locked within 30 seconds after the unlock

button is pressed, refer to GROUP 54B, SWS Diagnosis

P.54B-10.

NOTE: If either of the doors is opened or the key is inserted in

the ignition switch within that 30-second period, the timer lock

function will be cancelled.

Page 1139 of 1500

KEYLESS ENTRY SYSTEM

BODY42-72

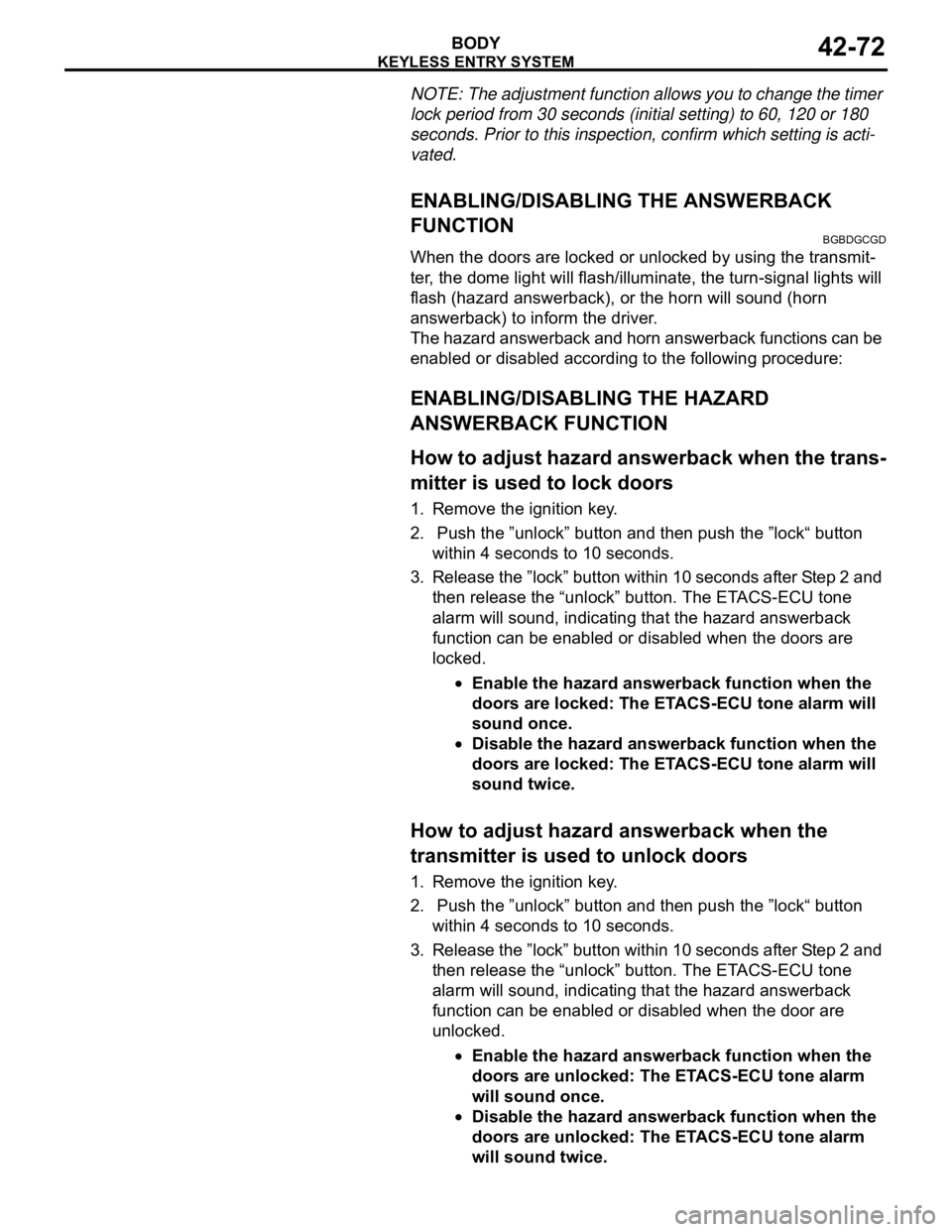

NOTE: The adjustment function allows you to change the timer

lock period from 30 seconds (initial setting) to 60, 120 or 180

seconds. Prior to this inspection, confirm which setting is acti-

vated.

ENABLING/DISABLING THE ANSWERBACK

FUNCTION

BGBDGCGD

When the doors are locked or unlocked by using the transmit-

ter, the dome light will flash/illuminate, the turn-signal lights will

flash (hazard answerback), or the horn will sound (horn

answerback) to inform the driver.

The hazard answerback and horn answerback functions can be

enabled or disabled according to the following procedure:

ENABLING/DISABLING THE HAZARD

ANSWERBACK FUNCTION

.

How to adjust hazard answerback when the trans-

mitter is used to lock doors

1. Remove the ignition key.

2. Push the ”unlock” button and then push the ”lock“ button

within 4 seconds to 10 seconds.

3. Release the ”lock” button within 10 seconds after Step 2 and

then release the “unlock” button. The ETACS-ECU tone

alarm will sound, indicating that the hazard answerback

function can be enabled or disabled when the doors are

locked.

Enable the hazard answerback function when the

doors are locked: The ETACS-ECU tone alarm will

sound once.

Disable the hazard answerback function when the

doors are locked: The ETACS-ECU tone alarm will

sound twice.

.

How to adjust hazard answerback when the

transmitter is used to unlock doors

1. Remove the ignition key.

2. Push the ”unlock” button and then push the ”lock“ button

within 4 seconds to 10 seconds.

3. Release the ”lock” button within 10 seconds after Step 2 and

then release the “unlock” button. The ETACS-ECU tone

alarm will sound, indicating that the hazard answerback

function can be enabled or disabled when the door are

unlocked.

Enable the hazard answerback function when the

doors are unlocked: The ETACS-ECU tone alarm

will sound once.

Disable the hazard answerback function when the

doors are unlocked: The ETACS-ECU tone alarm

will sound twice.

Page 1287 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-8

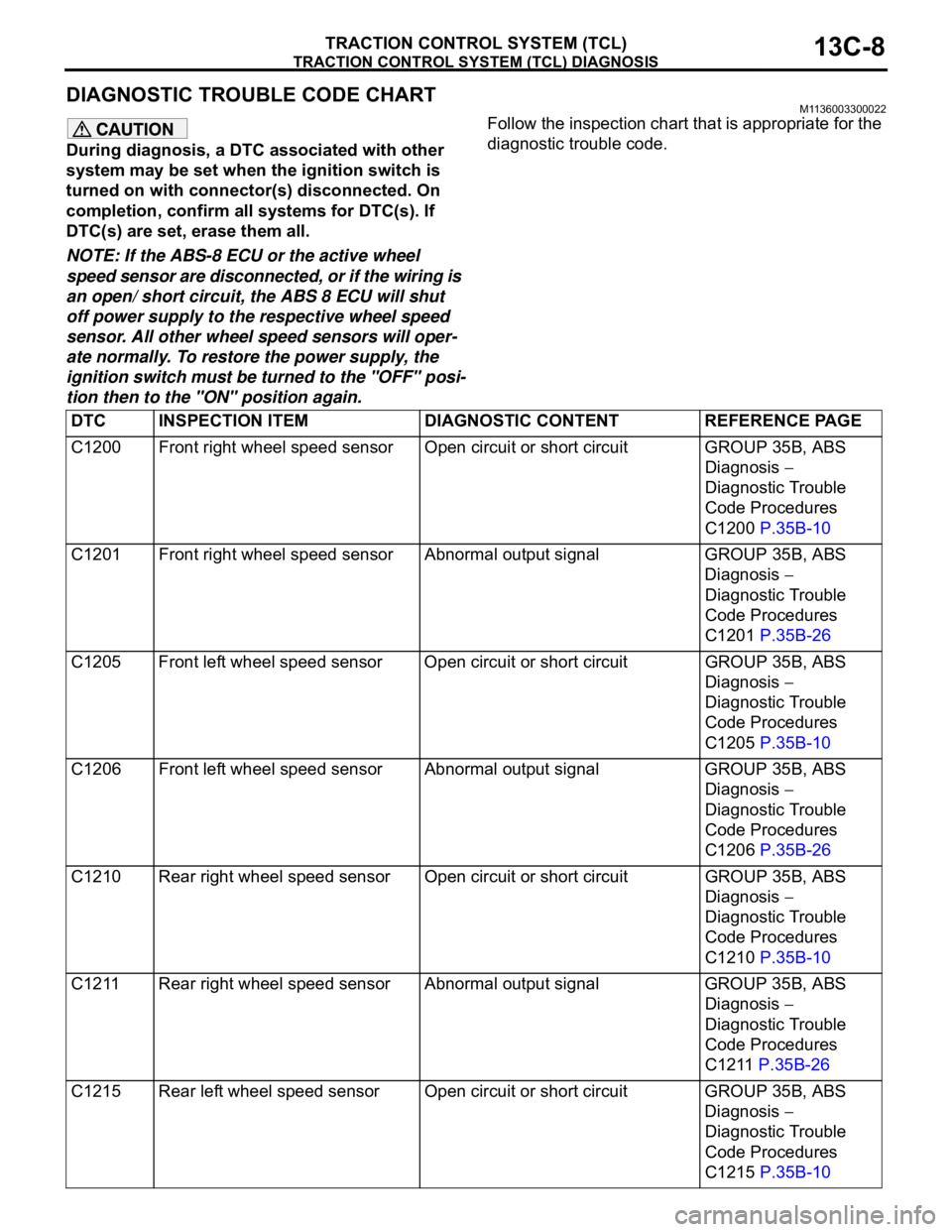

DIAGNOSTIC TROUBLE CODE CHARTM1136003300022

During diagnosis, a DTC associated with other

system may be set when the ignition switch is

turned on with connector(s) disconnected. On

completion, confirm all systems for DTC(s). If

DTC(s) are set, erase them all.

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.Follow the inspection chart that is appropriate for the

diagnostic trouble code.

DTC INSPECTION ITEM DIAGNOSTIC CONTENT REFERENCE PAGE

C1200 Front right wheel speed sensor Open circuit or short circuit GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1200 P.35B-10

C1201 Front right wheel speed sensor Abnormal output signal GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1201 P.35B-26

C1205 Front left wheel speed sensor Open circuit or short circuitGROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1205 P.35B-10

C1206 Front left wheel speed sensor Abnormal output signal GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1206 P.35B-26

C1210 Rear right wheel speed sensor Open circuit or short circuitGROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1210 P.35B-10

C1211 Rear right wheel speed sensor Abnormal output signal GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1211 P.35B-26

C1215 Rear left wheel speed sensor Open circuit or short circuit GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1215 P.35B-10

Page 1289 of 1500

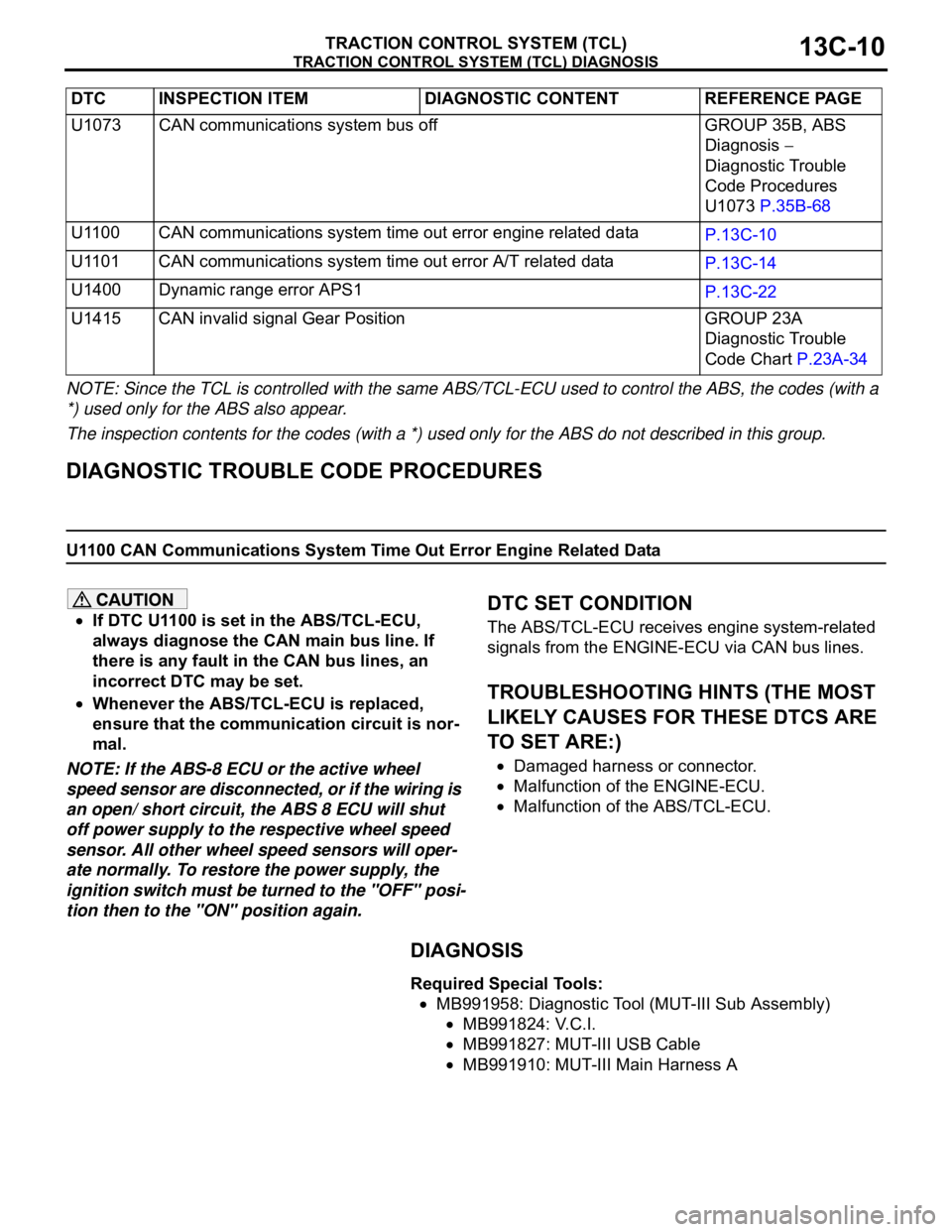

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-10

NOTE: Since the TCL is controlled with the same ABS/TCL-ECU used to control the ABS, the codes (with a

*) used only for the ABS also appear.

The inspection contents for the codes (with a *) used only for the ABS do not described in this group.

DIAGNOSTIC TROUBLE CODE PROCEDURES

U1100 CAN Communications System Time Out Error Engine Related Data

If DTC U1100 is set in the ABS/TCL-ECU,

always diagnose the CAN main bus line. If

there is any fault in the CAN bus lines, an

incorrect DTC may be set.

Whenever the ABS/TCL-ECU is replaced,

ensure that the communication circuit is nor-

mal.

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.

.

DTC SET CONDITION

The ABS/TCL-ECU receives engine system-related

signals from the ENGINE-ECU via CAN bus lines.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THESE DTCS ARE

TO SET ARE:)

Damaged harness or connector.

Malfunction of the ENGINE-ECU.

Malfunction of the ABS/TCL-ECU.

DIAGNOSIS

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A U1073 CAN communications system bus off GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

U1073 P.35B-68

U1100 CAN communications system time out error engine related data

P.13C-10

U1101 CAN communications system time out error A/T related data

P.13C-14

U1400 Dynamic range error APS1

P.13C-22

U1415 CAN invalid signal Gear Position GROUP 23A

Diagnostic Trouble

Code Chart P.23A-34 DTC INSPECTION ITEM DIAGNOSTIC CONTENT REFERENCE PAGE

Page 1297 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-18

STEP 6. Using diagnostic tool MB991958, read the

diagnostic trouble code.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

(2) Turn the ignition switch to the "ON" position.

(3) Use diagnostic tool MB991958 to read the TCL diagnostic

trouble codes. (Refer to P.13C-3).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect diagnostic tool MB991958.

Q: Is DTC U1101 set?

YES : Return to Step 1.

NO : The procedure is complete.

U1120 CAN Communications System TCL Uncontrollable by Engine Malfunction

If DTC U1120 is set in the ABS/TCL-ECU,

always diagnose the CAN main bus line. If

there is any fault in the CAN bus lines, an

incorrect DTC may be set.

Whenever the ABS/TCL-ECU is replaced,

ensure that the communication circuit is nor-

mal.

The engine control system-related DTC may

be set when DTC U1120 is set. (For details

refer to GROUP 00, Intersystem Affiliated DTC

Reference Table P.00-17). Diagnose the

engine control system first when the engine

control system-related DTC is set.

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.

.

DTC SET CONDITION

The ABS/TCL-ECU receives engine system-related

signals from the Engine-ECU via CAN bus lines. If a

fail-safe related data is contained in the signal from

the Engine-ECU, DTC U1120 will be stored.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THESE DTCS ARE

TO SET ARE:)

Damaged harness or connector.

Malfunction of the Engine-ECU.

Malfunction of the ABS/TCL-ECU.