air condition MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 342 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-342

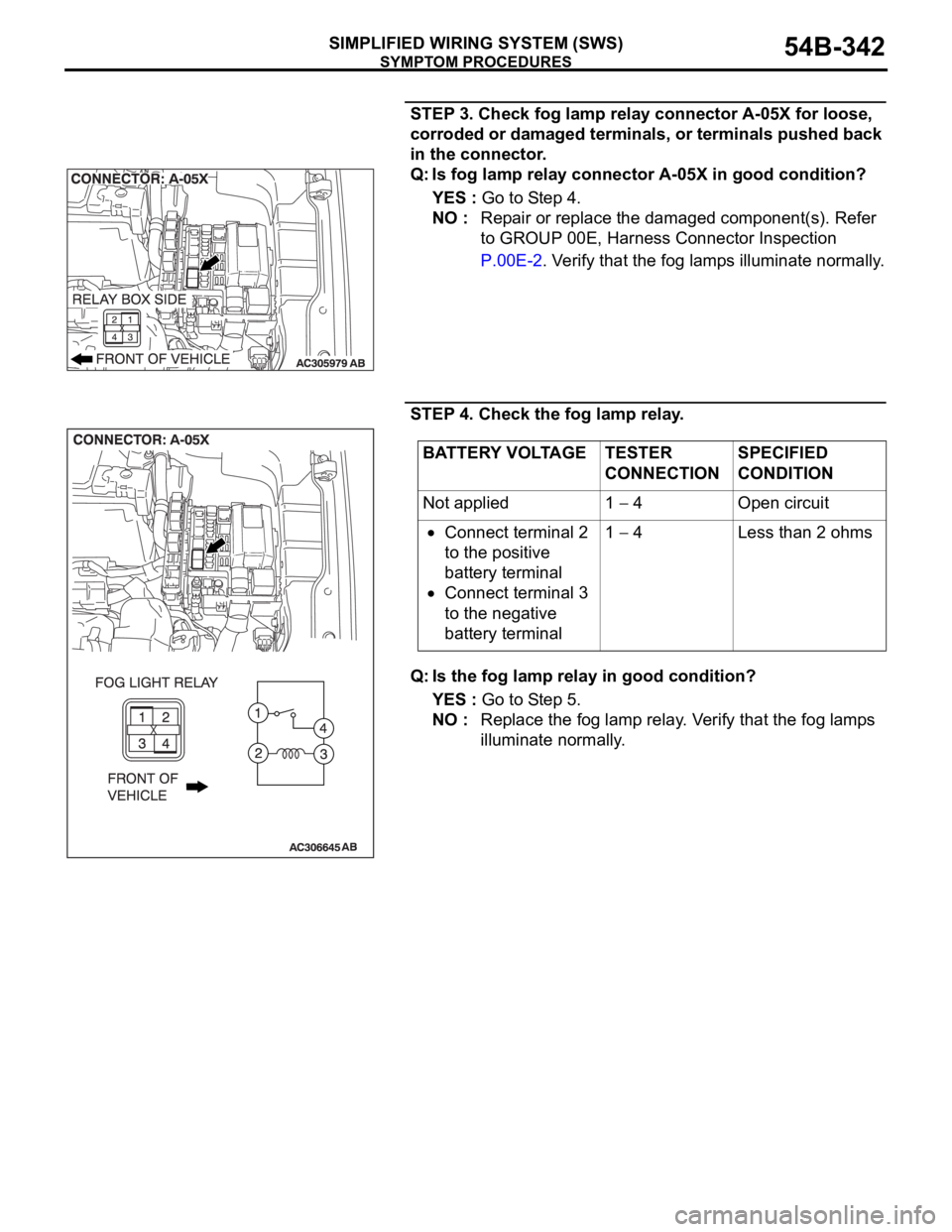

STEP 3. Check fog lamp relay connector A-05X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is fog lamp relay connector A-05X in good condition?

YES : Go to Step 4.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the fog lamps illuminate normally.

STEP 4. Check the fog lamp relay.

Q: Is the fog lamp relay in good condition?

YES : Go to Step 5.

NO : Replace the fog lamp relay. Verify that the fog lamps

illuminate normally.

BATTERY VOLTAGE TESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 1

4 Open circuit

Connect terminal 2

to the positive

battery terminal

Connect terminal 3

to the negative

battery terminal1

4 Less than 2 ohms

Page 343 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-343

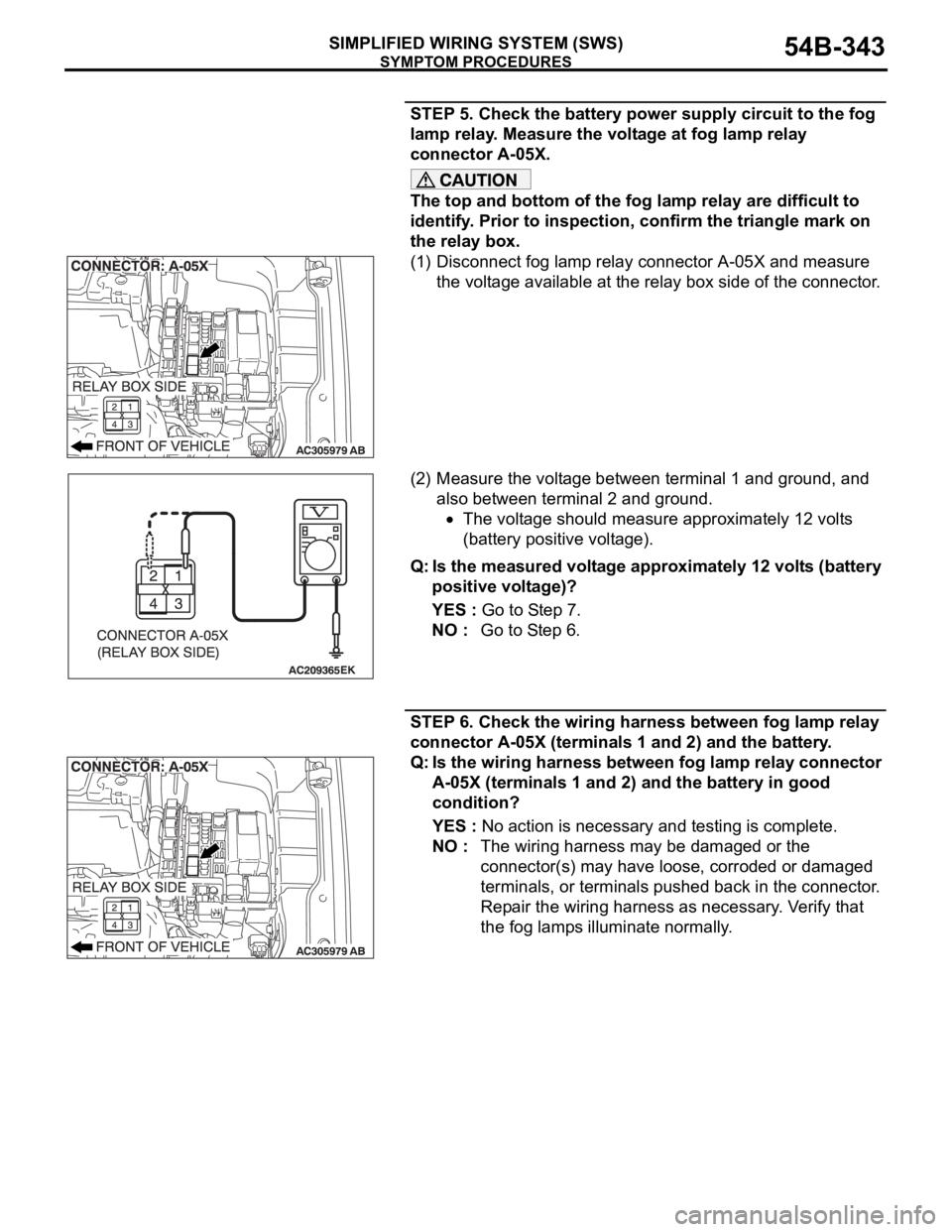

STEP 5. Check the battery power supply circuit to the fog

lamp relay. Measure the voltage at fog lamp relay

connector A-05X.

The top and bottom of the fog lamp relay are difficult to

identify. Prior to inspection, confirm the triangle mark on

the relay box.

(1) Disconnect fog lamp relay connector A-05X and measure

the voltage available at the relay box side of the connector.

(2) Measure the voltage between terminal 1 and ground, and

also between terminal 2 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 7.

NO : Go to Step 6.

STEP 6. Check the wiring harness between fog lamp relay

connector A-05X (terminals 1 and 2) and the battery.

Q: Is the wiring harness between fog lamp relay connector

A-05X (terminals 1 and 2) and the battery in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the fog lamps illuminate normally.

Page 344 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-344

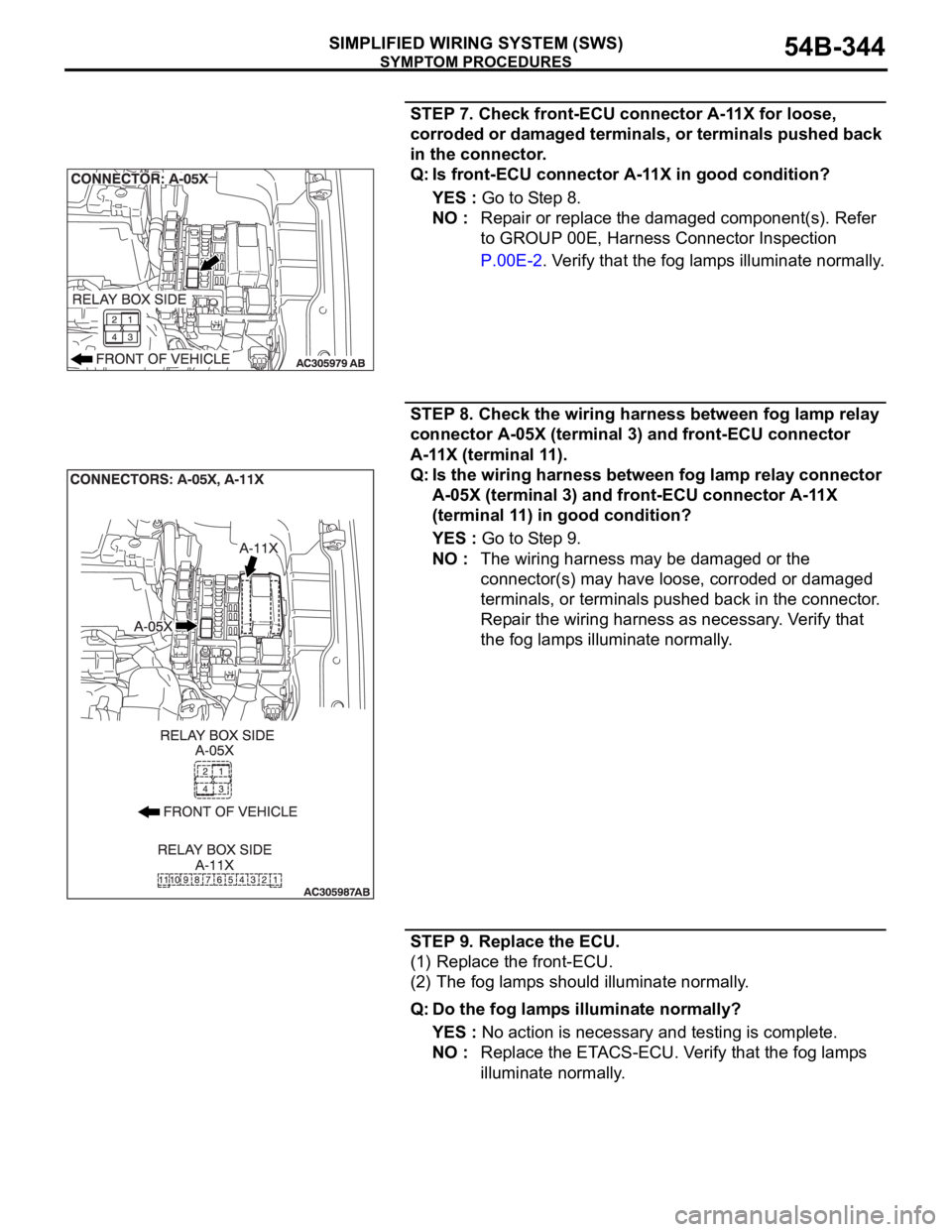

STEP 7. Check front-ECU connector A-11X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is front-ECU connector A-11X in good condition?

YES : Go to Step 8.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the fog lamps illuminate normally.

STEP 8. Check the wiring harness between fog lamp relay

connector A-05X (terminal 3) and front-ECU connector

A-11X (terminal 11).

Q: Is the wiring harness between fog lamp relay connector

A-05X (terminal 3) and front-ECU connector A-11X

(terminal 11) in good condition?

YES : Go to Step 9.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the fog lamps illuminate normally.

STEP 9. Replace the ECU.

(1) Replace the front-ECU.

(2) The fog lamps should illuminate normally.

Q: Do the fog lamps illuminate normally?

YES : No action is necessary and testing is complete.

NO : Replace the ETACS-ECU. Verify that the fog lamps

illuminate normally.

Page 346 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-346

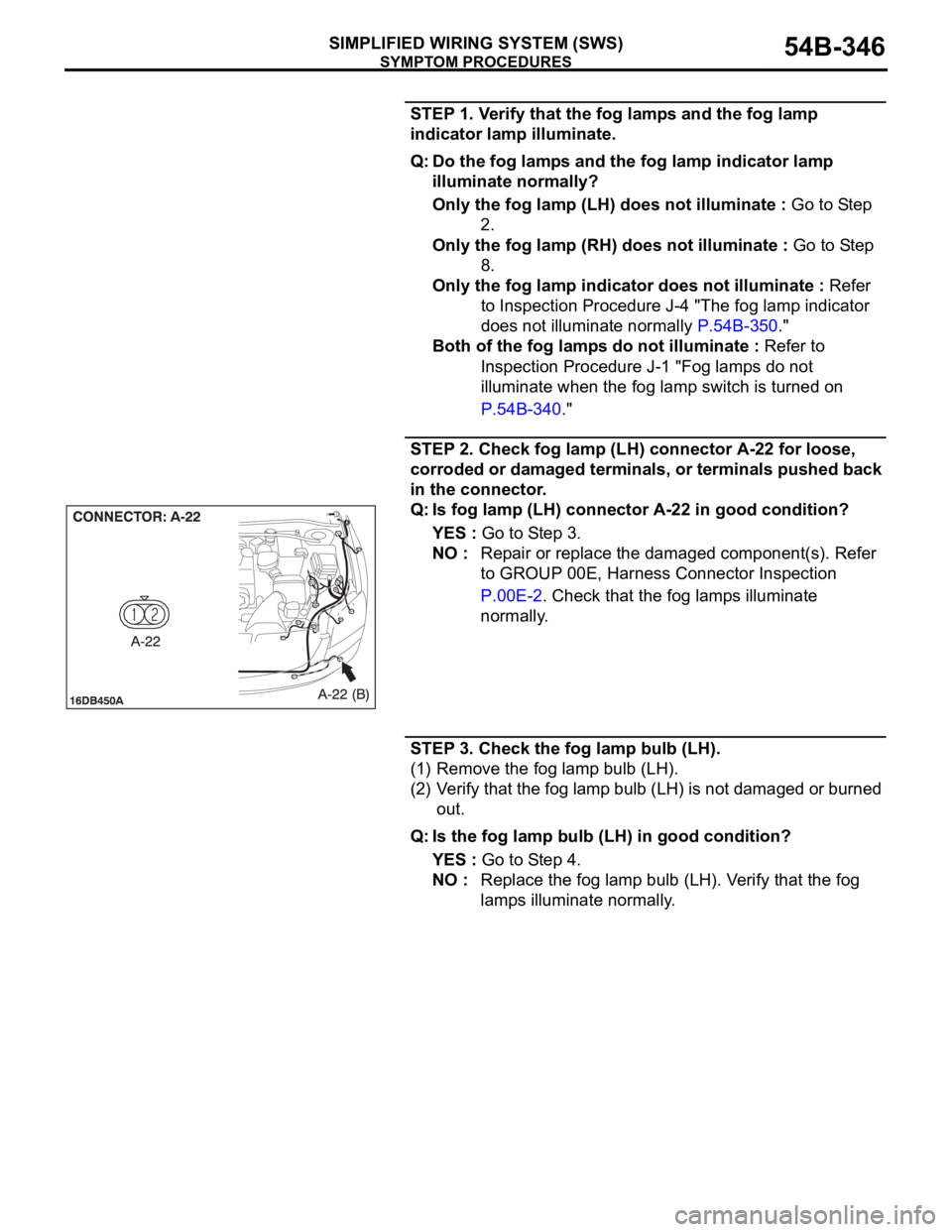

STEP 1. Verify that the fog lamps and the fog lamp

indicator lamp illuminate.

Q: Do the fog lamps and the fog lamp indicator lamp

illuminate normally?

Only the fog lamp (LH) does not illuminate : Go to Step

2.

Only the fog lamp (RH) does not illuminate : Go to Step

8.

Only the fog lamp indicator does not illuminate : Refer

to Inspection Procedure J-4 "The fog lamp indicator

does not illuminate normally P.54B-350."

Both of the fog lamps do not illuminate : Refer to

Inspection Procedure J-1 "Fog lamps do not

illuminate when the fog lamp switch is turned on

P.54B-340."

STEP 2. Check fog lamp (LH) connector A-22 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is fog lamp (LH) connector A-22 in good condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the fog lamps illuminate

normally.

STEP 3. Check the fog lamp bulb (LH).

(1) Remove the fog lamp bulb (LH).

(2) Verify that the fog lamp bulb (LH) is not damaged or burned

out.

Q: Is the fog lamp bulb (LH) in good condition?

YES : Go to Step 4.

NO : Replace the fog lamp bulb (LH). Verify that the fog

lamps illuminate normally.

Page 347 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-347

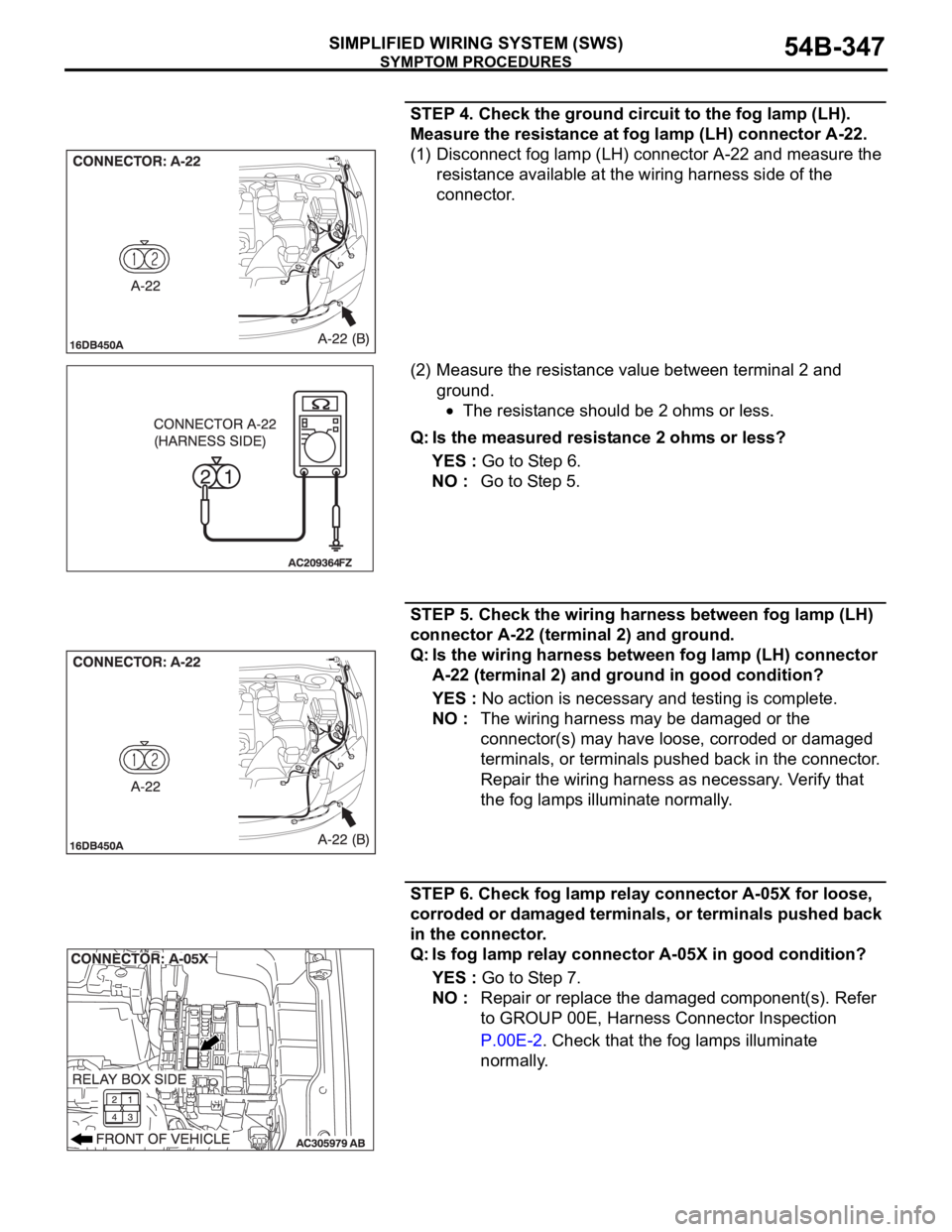

STEP 4. Check the ground circuit to the fog lamp (LH).

Measure the resistance at fog lamp (LH) connector A-22.

(1) Disconnect fog lamp (LH) connector A-22 and measure the

resistance available at the wiring harness side of the

connector.

(2) Measure the resistance value between terminal 2 and

ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 6.

NO : Go to Step 5.

STEP 5. Check the wiring harness between fog lamp (LH)

connector A-22 (terminal 2) and ground.

Q: Is the wiring harness between fog lamp (LH) connector

A-22 (terminal 2) and ground in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the fog lamps illuminate normally.

STEP 6. Check fog lamp relay connector A-05X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is fog lamp relay connector A-05X in good condition?

YES : Go to Step 7.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the fog lamps illuminate

normally.

Page 348 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-348

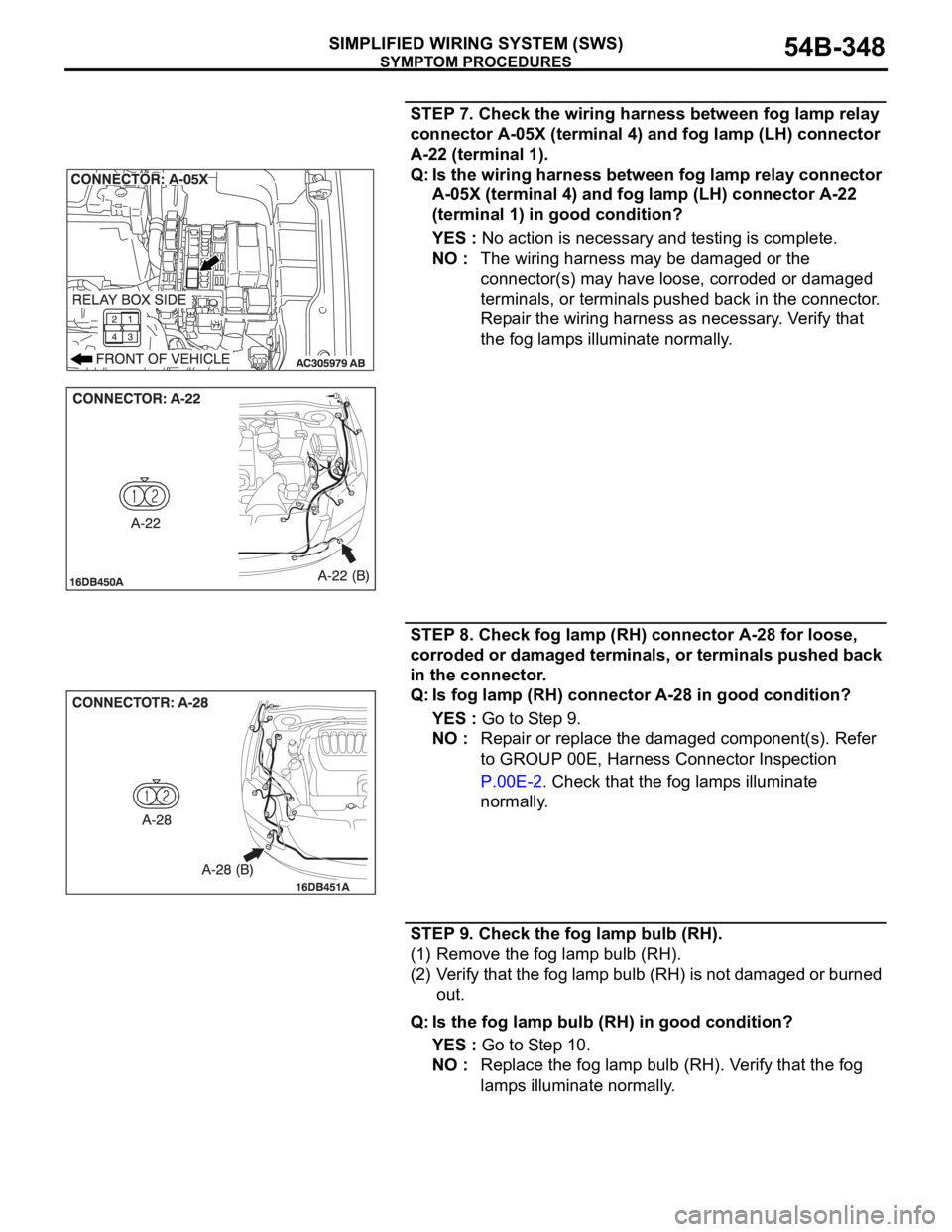

STEP 7. Check the wiring harness between fog lamp relay

connector A-05X (terminal 4) and fog lamp (LH) connector

A-22 (terminal 1).

Q: Is the wiring harness between fog lamp relay connector

A-05X (terminal 4) and fog lamp (LH) connector A-22

(terminal 1) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the fog lamps illuminate normally.

STEP 8. Check fog lamp (RH) connector A-28 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is fog lamp (RH) connector A-28 in good condition?

YES : Go to Step 9.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the fog lamps illuminate

normally.

STEP 9. Check the fog lamp bulb (RH).

(1) Remove the fog lamp bulb (RH).

(2) Verify that the fog lamp bulb (RH) is not damaged or burned

out.

Q: Is the fog lamp bulb (RH) in good condition?

YES : Go to Step 10.

NO : Replace the fog lamp bulb (RH). Verify that the fog

lamps illuminate normally.

Page 349 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-349

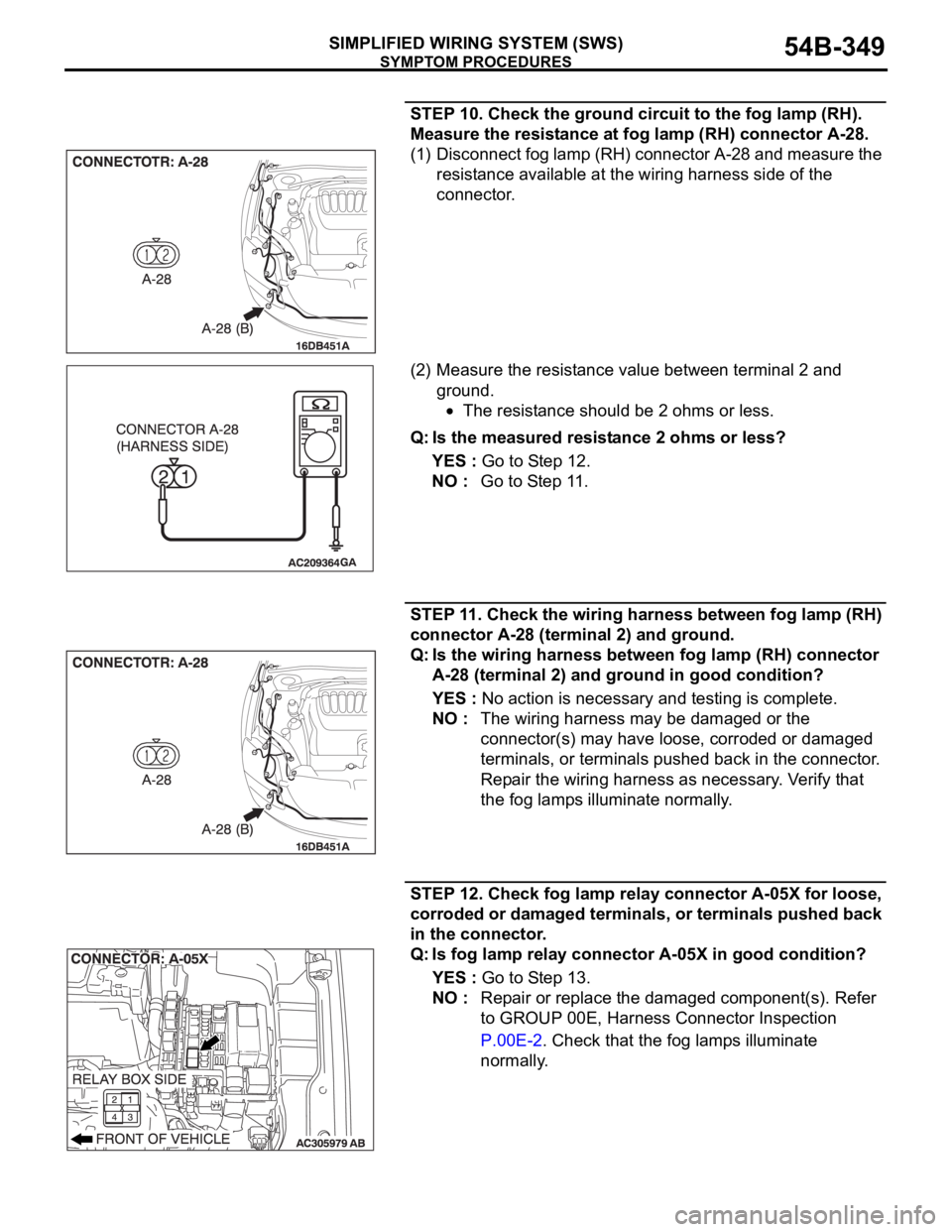

STEP 10. Check the ground circuit to the fog lamp (RH).

Measure the resistance at fog lamp (RH) connector A-28.

(1) Disconnect fog lamp (RH) connector A-28 and measure the

resistance available at the wiring harness side of the

connector.

(2) Measure the resistance value between terminal 2 and

ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 12.

NO : Go to Step 11.

STEP 11. Check the wiring harness between fog lamp (RH)

connector A-28 (terminal 2) and ground.

Q: Is the wiring harness between fog lamp (RH) connector

A-28 (terminal 2) and ground in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the fog lamps illuminate normally.

STEP 12. Check fog lamp relay connector A-05X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is fog lamp relay connector A-05X in good condition?

YES : Go to Step 13.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the fog lamps illuminate

normally.

Page 350 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-350

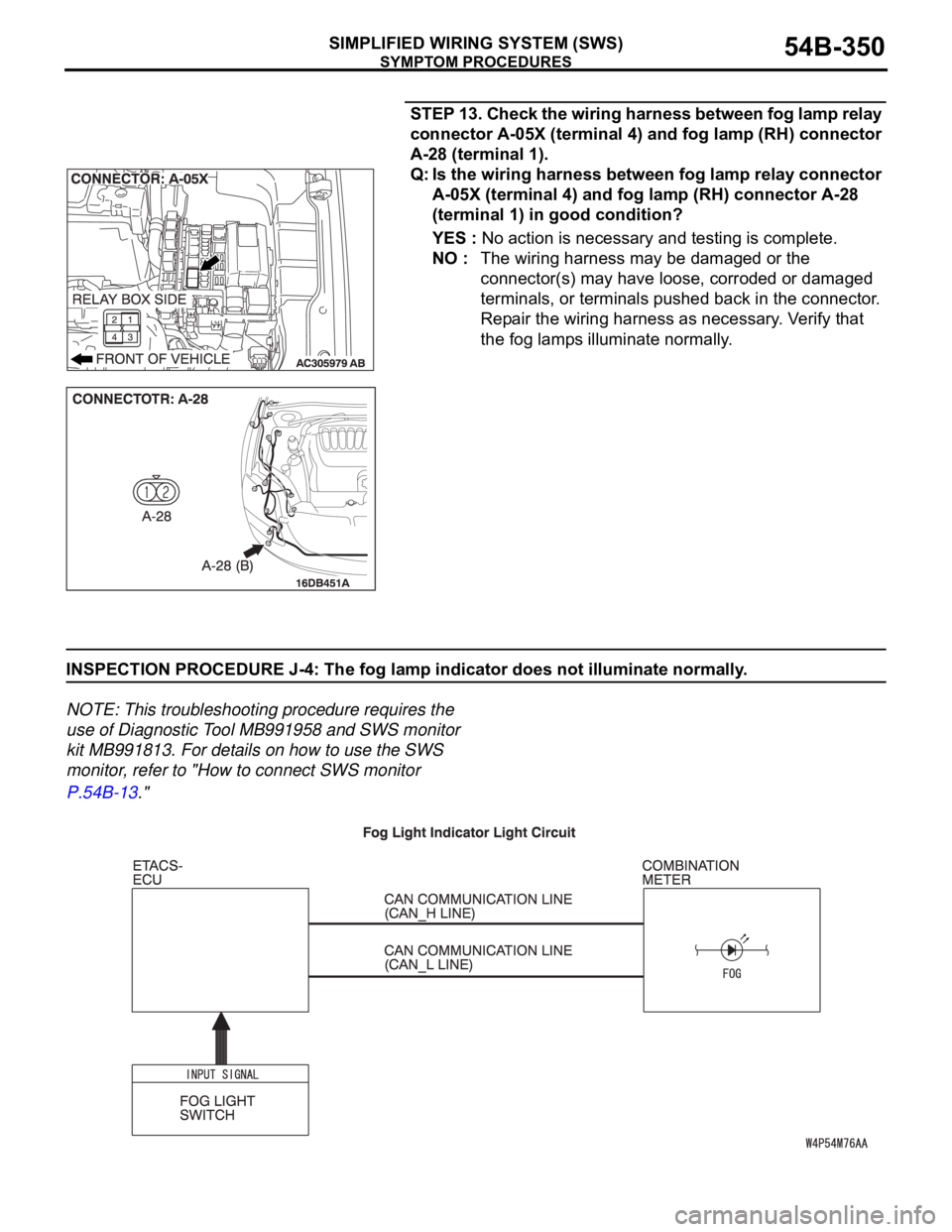

STEP 13. Check the wiring harness between fog lamp relay

connector A-05X (terminal 4) and fog lamp (RH) connector

A-28 (terminal 1).

Q: Is the wiring harness between fog lamp relay connector

A-05X (terminal 4) and fog lamp (RH) connector A-28

(terminal 1) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the fog lamps illuminate normally.

INSPECTION PROCEDURE J-4: The fog lamp indicator does not illuminate normally.

NOTE: This troubleshooting procedure requires the

use of Diagnostic Tool MB991958 and SWS monitor

kit MB991813. For details on how to use the SWS

monitor, refer to "How to connect SWS monitor

P.54B-13."

.

Page 364 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-364

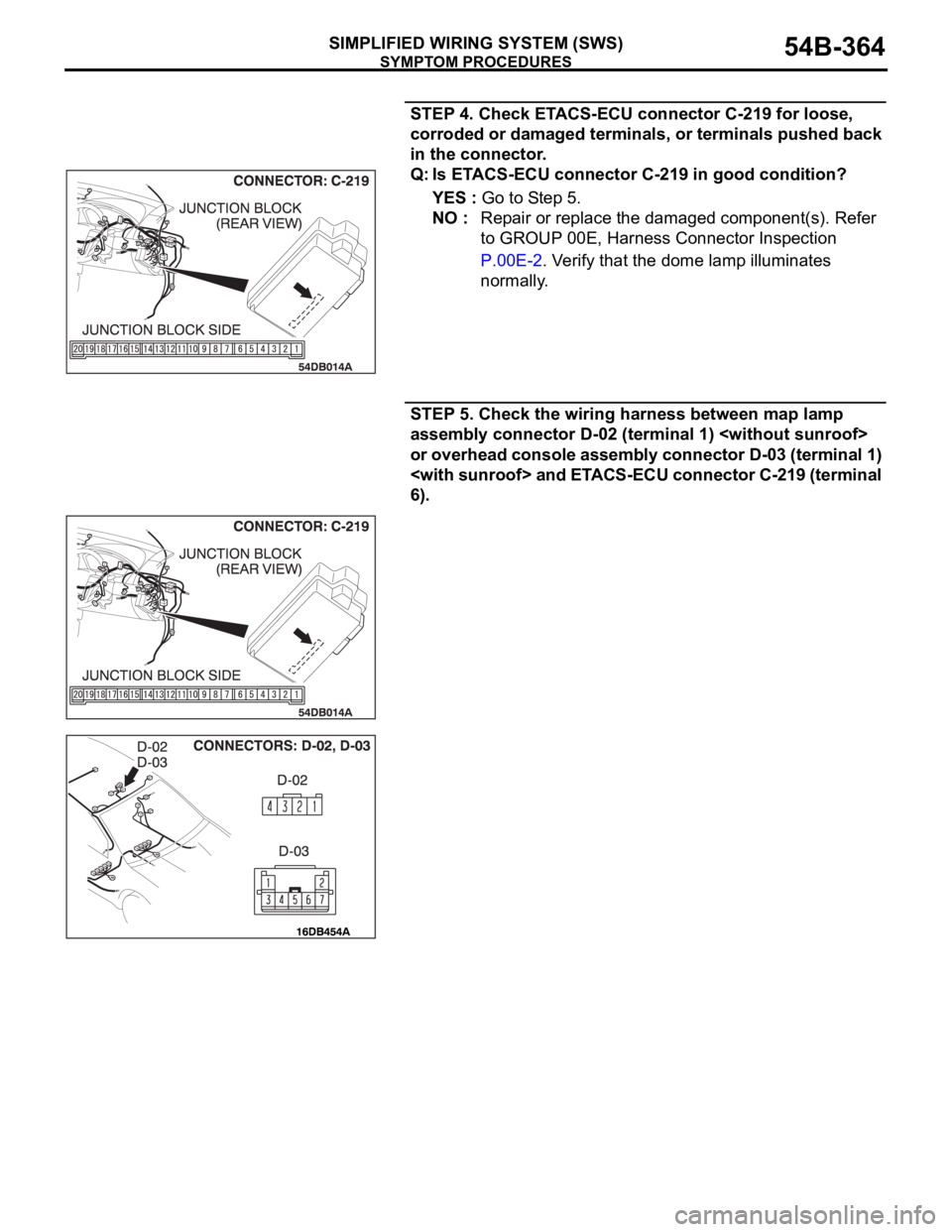

STEP 4. Check ETACS-ECU connector C-219 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is ETACS-ECU connector C-219 in good condition?

YES : Go to Step 5.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the dome lamp illuminates

normally.

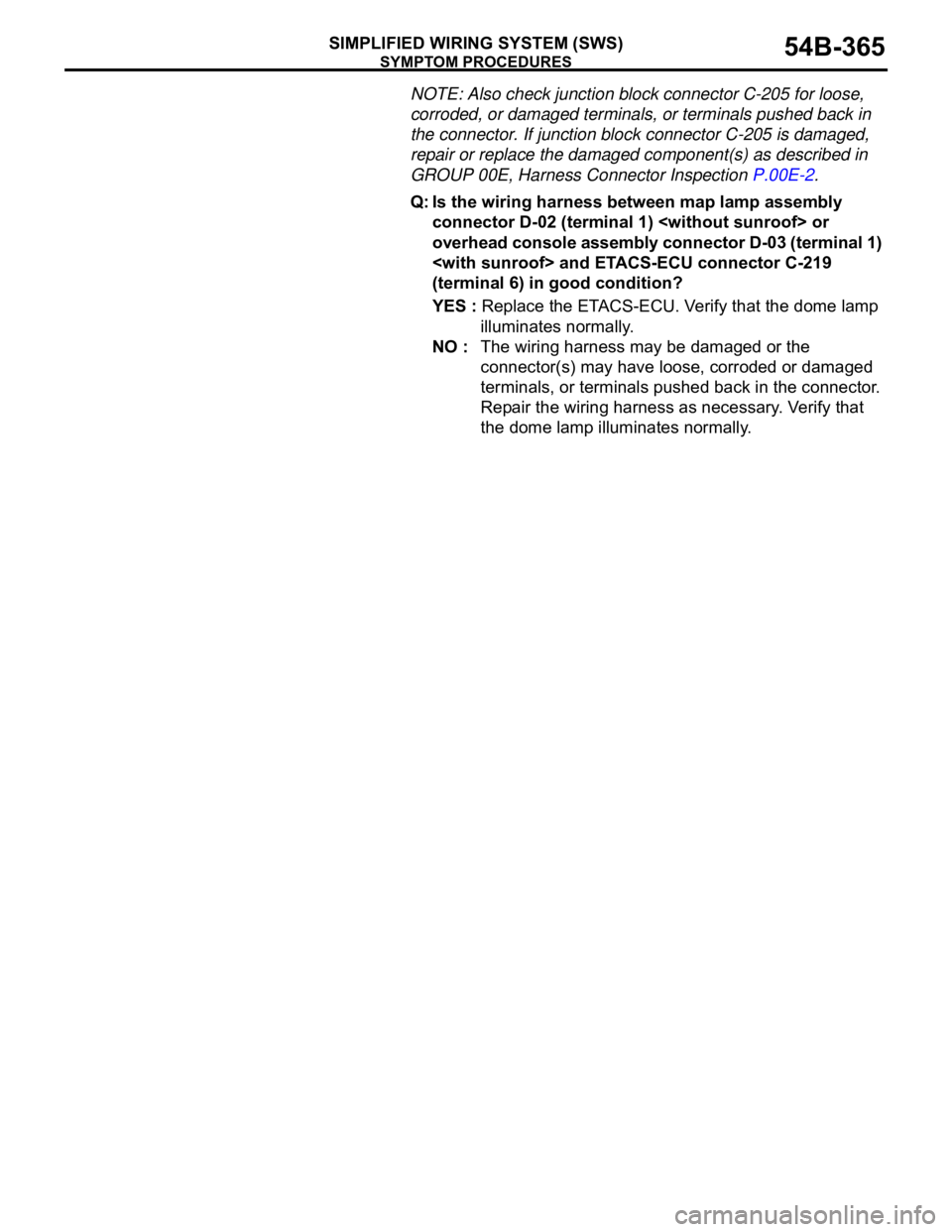

STEP 5. Check the wiring harness between map lamp

assembly connector D-02 (terminal 1)

or overhead console assembly connector D-03 (terminal 1)

6).

Page 365 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-365

NOTE: Also check junction block connector C-205 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-205 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between map lamp assembly

connector D-02 (terminal 1)

overhead console assembly connector D-03 (terminal 1)

(terminal 6) in good condition?

YES : Replace the ETACS-ECU. Verify that the dome lamp

illuminates normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the dome lamp illuminates normally.