tow bar MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 852 of 1500

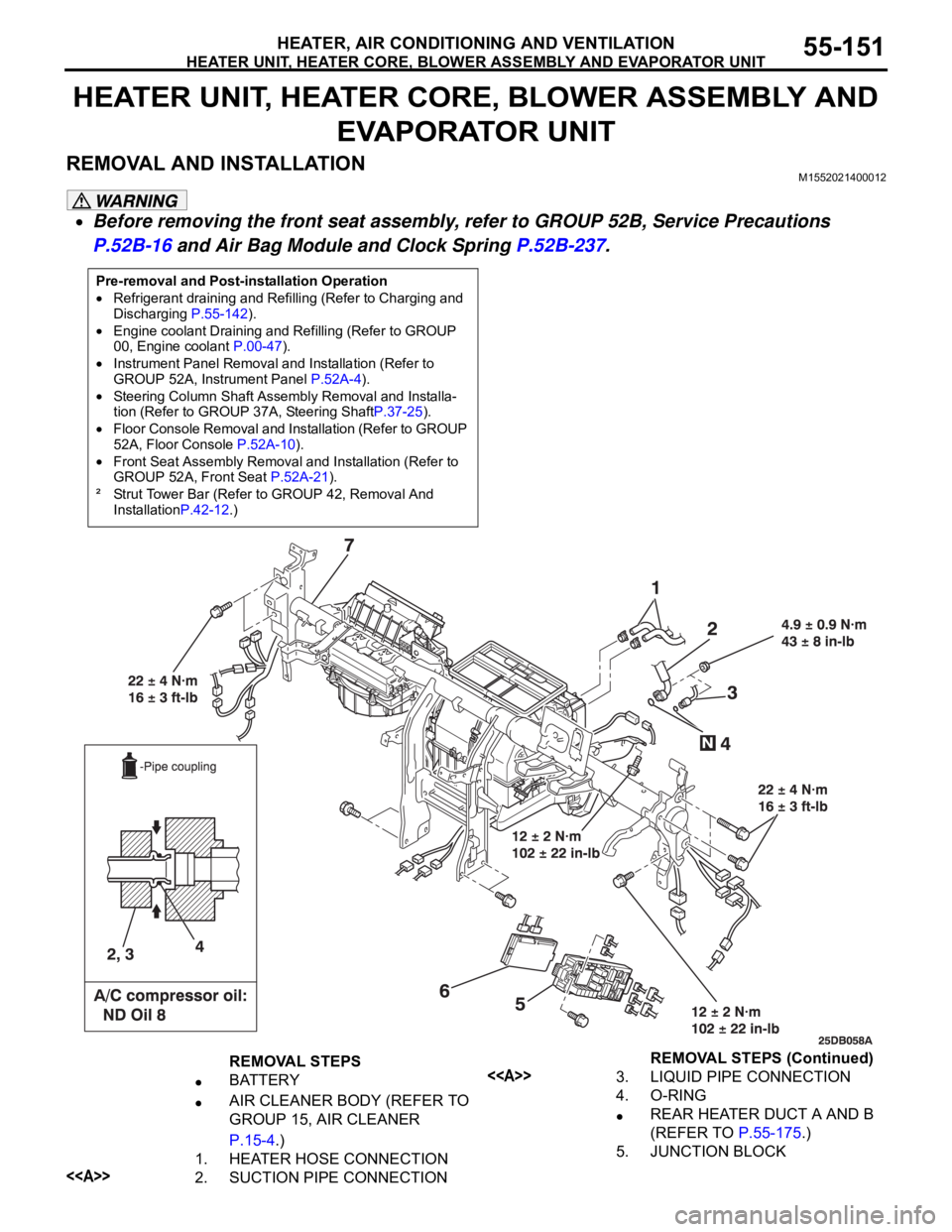

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONING AND VENTILATION55-151

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND

EVAPORATOR UNIT

REMOVAL AND INSTALLATIONM1552021400012

Before removing the front seat assembly, refer to GROUP 52B, Service Precautions

P.52B-16 and Air Bag Module and Clock Spring P.52B-237.

Pre-removal and Post-installation Operation

Refrigerant draining and Refilling (Refer to Charging and

Discharging P.55-142).

Engine coolant Draining and Refilling (Refer to GROUP

00, Engine coolant P.00-47).

Instrument Panel Removal and Installation (Refer to

GROUP 52A, Instrument Panel P.52A-4).

Steering Column Shaft Assembly Removal and Installa-

tion (Refer to GROUP 37A, Steering ShaftP.37-25).

Floor Console Removal and Installation (Refer to GROUP

52A, Floor Console P.52A-10).

Front Seat Assembly Removal and Installation (Refer to

GROUP 52A, Front Seat P.52A-21).

² Strut Tower Bar (Refer to GROUP 42, Removal And

InstallationP.42-12.)

REMOVAL STEPS

BATTERY

AIR CLEANER BODY (REFER TO

GROUP 15, AIR CLEANER

P.15-4.)

1. HEATER HOSE CONNECTION

<>2. SUCTION PIPE CONNECTION

<>3. LIQUID PIPE CONNECTION

4. O-RING

REAR HEATER DUCT A AND B

(REFER TO P.55-175.)

5. JUNCTION BLOCKREMOVAL STEPS (Continued)

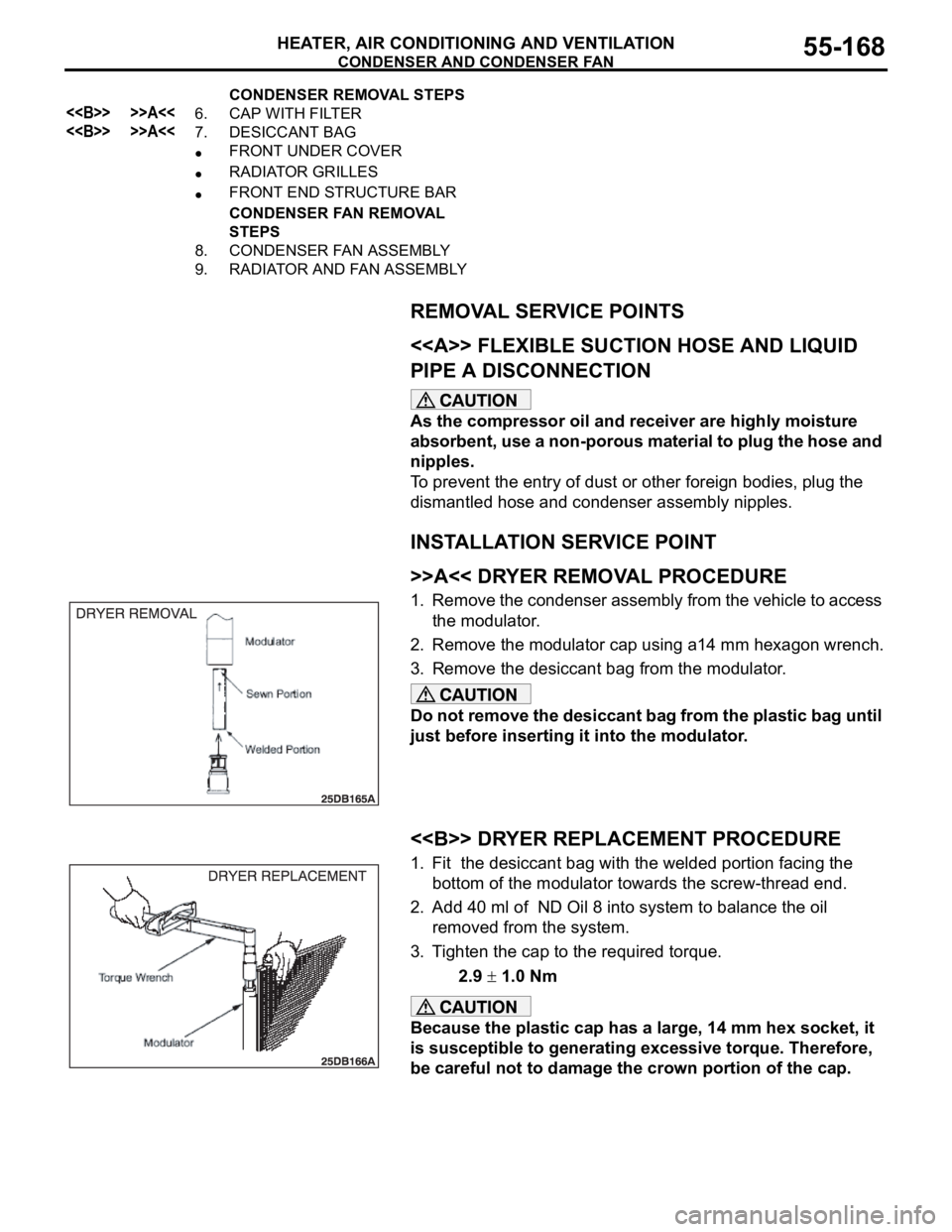

Page 869 of 1500

Page 950 of 1500

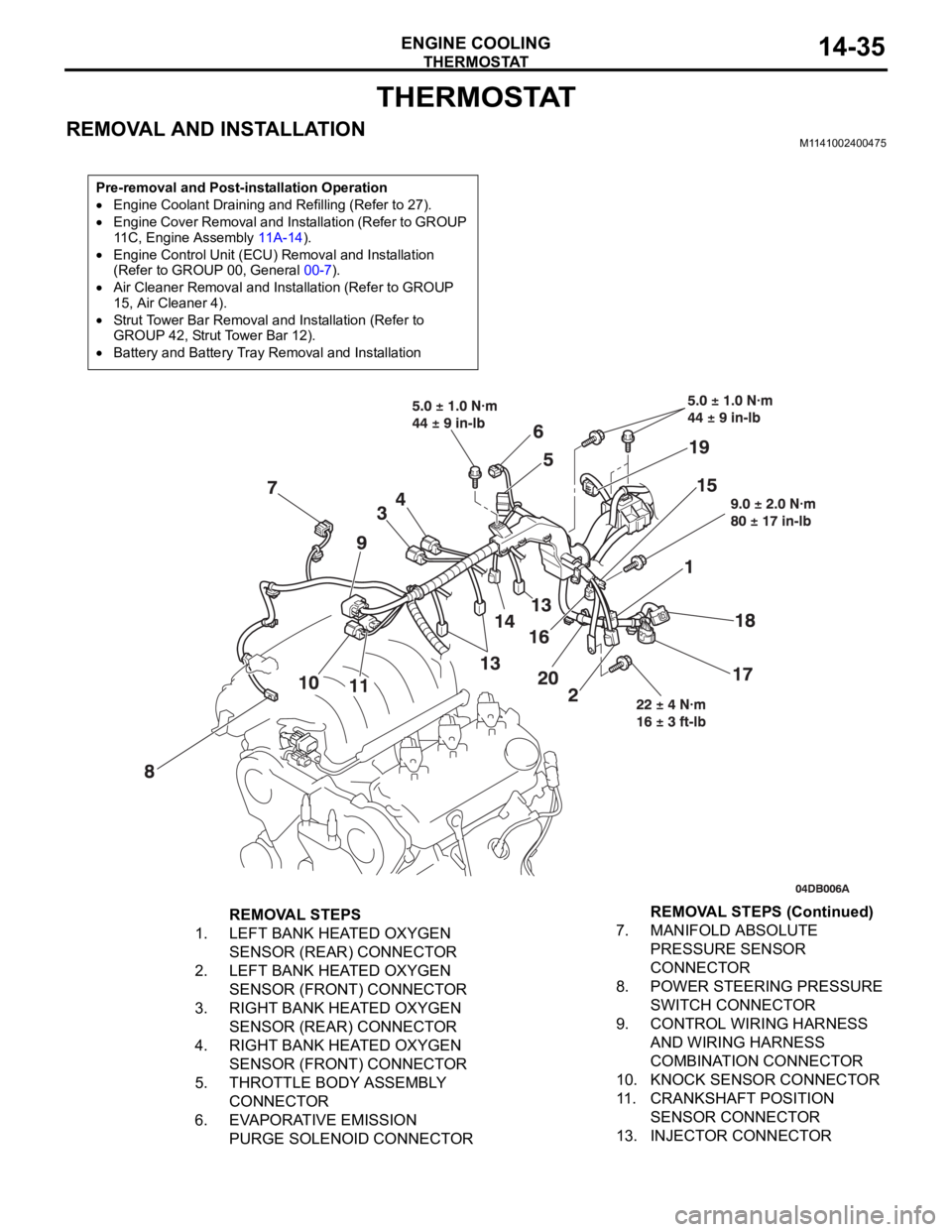

THERMOSTAT

ENGINE COOLING14-35

THERMOSTAT

REMOVAL AND INSTALLATIONM1141002400475

Pre-removal and Post-installation Operation

Engine Coolant Draining and Refilling (Refer to 27).

Engine Cover Removal and Installation (Refer to GROUP

11C, Engine Assembly 11A-14).

Engine Control Unit (ECU) Removal and Installation

(Refer to GROUP 00, General 00-7).

Air Cleaner Removal and Installation (Refer to GROUP

15, Air Cleaner 4).

Strut Tower Bar Removal and Installation (Refer to

GROUP 42, Strut Tower Bar 12).

Battery and Battery Tray Removal and Installation

REMOVAL STEPS

1. LEFT BANK HEATED OXYGEN

SENSOR (REAR) CONNECTOR

2. LEFT BANK HEATED OXYGEN

SENSOR (FRONT) CONNECTOR

3. RIGHT BANK HEATED OXYGEN

SENSOR (REAR) CONNECTOR

4. RIGHT BANK HEATED OXYGEN

SENSOR (FRONT) CONNECTOR

5. THROTTLE BODY ASSEMBLY

CONNECTOR

6. EVAPORATIVE EMISSION

PURGE SOLENOID CONNECTOR7. MANIFOLD ABSOLUTE

PRESSURE SENSOR

CONNECTOR

8. POWER STEERING PRESSURE

SWITCH CONNECTOR

9. CONTROL WIRING HARNESS

AND WIRING HARNESS

COMBINATION CONNECTOR

10. KNOCK SENSOR CONNECTOR

11. CRANKSHAFT POSITION

SENSOR CONNECTOR

13. INJECTOR CONNECTORREMOVAL STEPS (Continued)

Page 964 of 1500

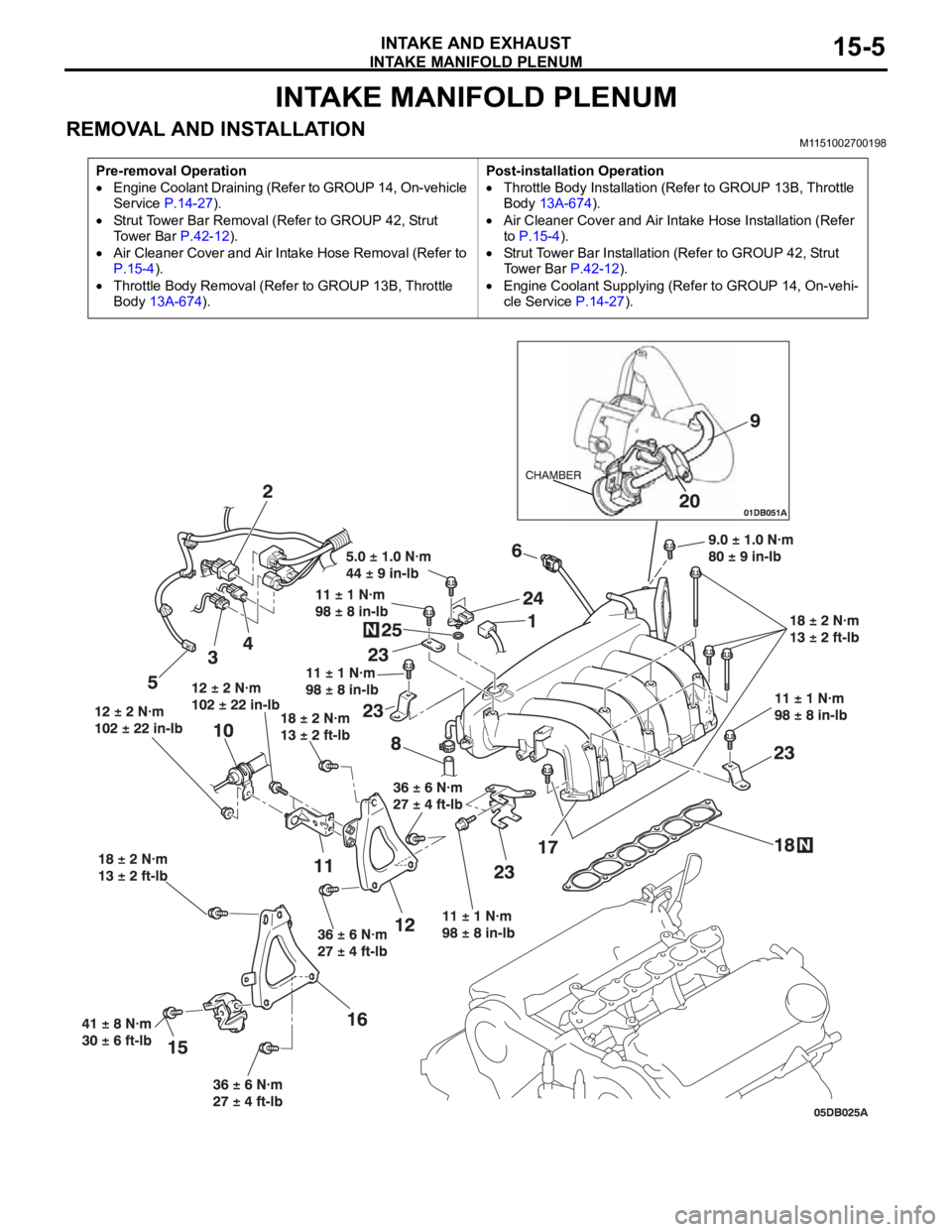

INTAKE MANIFOLD PLENUM

INTAKE AND EXHAUST15-5

INTAKE MANIFOLD PLENUM

REMOVAL AND INSTALLATION M1151002700198

Pre-removal Operation

Engine Coolant Draining (Refer to GROUP 14, On-vehicle

Service P.14-27).

Strut Tower Bar Removal (Refer to GROUP 42, Strut

To w e r B a r P.42-12).

Air Cleaner Cover and Air Intake Hose Removal (Refer to

P.15-4).

Throttle Body Removal (Refer to GROUP 13B, Throttle

Body 13A-674).Post-installation Operation

Throttle Body Installation (Refer to GROUP 13B, Throttle

Body 13A-674).

Air Cleaner Cover and Air Intake Hose Installation (Refer

to P.15-4).

Strut Tower Bar Installation (Refer to GROUP 42, Strut

Tower Bar P.42-12).

Engine Coolant Supplying (Refer to GROUP 14, On-vehi-

cle Service P.14-27).

Page 970 of 1500

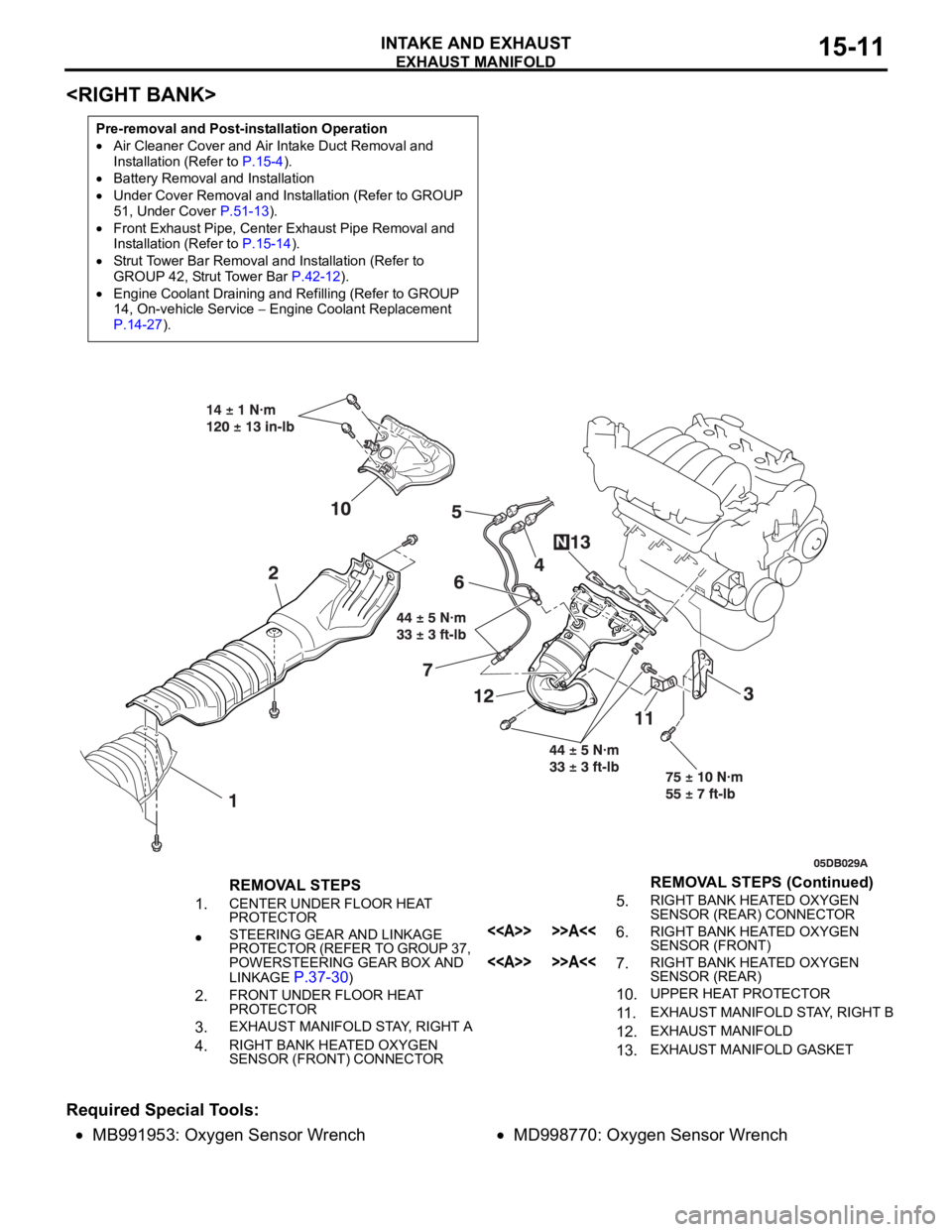

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-11

Required Special Tools:

MB991953: Oxygen Sensor WrenchMD998770: Oxygen Sensor Wrench

Pre-removal and Post-installation Operation

Air Cleaner Cover and Air Intake Duct Removal and

Installation (Refer to P.15-4).

Battery Removal and Installation

Under Cover Removal and Installation (Refer to GROUP

51, Under Cover P.51-13).

Front Exhaust Pipe, Center Exhaust Pipe Removal and

Installation (Refer to P.15-14).

Strut Tower Bar Removal and Installation (Refer to

GROUP 42, Strut Tower Bar P.42-12).

Engine Coolant Draining and Refilling (Refer to GROUP

14, On-vehicle Service Engine Coolant Replacement

P.14-27).

REMOVAL STEPS

1.

CENTER UNDER FLOOR HEAT

PROTECTOR

STEERING GEAR AND LINKAGE

PROTECTOR (REFER TO GROUP 37,

POWERSTEERING GEAR BOX AND

LINKAGE

P.37-30)

2.FRONT UNDER FLOOR HEAT

PROTECTOR

3.EXHAUST MANIFOLD STAY, RIGHT A

4.RIGHT BANK HEATED OXYGEN

SENSOR (FRONT) CONNECTOR

5.RIGHT BANK HEATED OXYGEN

SENSOR (REAR) CONNECTOR

<> >>A<<6.RIGHT BANK HEATED OXYGEN

SENSOR (FRONT)

<> >>A<<7.RIGHT BANK HEATED OXYGEN

SENSOR (REAR)

10.UPPER HEAT PROTECTOR

11 .EXHAUST MANIFOLD STAY, RIGHT B

12.EXHAUST MANIFOLD

13.EXHAUST MANIFOLD GASKET

REMOVAL STEPS (Continued)

Page 1068 of 1500

42-1

GROUP 42

BODY

CONTENTS

HOOD . . . . . . . . . . . . . . . . . . . . .

42-4

BODY DIAGNOSIS . . . . . . . . . . . .

42-4

INTRODUCTION TO HOOD DIAGNOSIS42-4

HOOD DIAGNOSTIC TROUBLESHOOTING

STRATEGY . . . . . . . . . . . . . . . . . . . . . . 42-4

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-4

SYMPTOM PROCEDURES . . . . . . . . . 42-4

ON-VEHICLE SERVICE. . . . . . . . .42-6

ADJUSTMENT OF CLEARANCE

AROUND HOOD . . . . . . . . . . . . . . . . . . 42-6

ALIGNMENT OF HOOD LATCH AND

STRIKER . . . . . . . . . . . . . . . . . . . . . . . . 42-6

ADJUSTMENT OF HOOD HEIGHT . . . 42-7

HOOD . . . . . . . . . . . . . . . . . . . . . . .42-8

REMOVAL AND INSTALLATION . . . . . 42-8

FENDER . . . . . . . . . . . . . . . . . . .42-10

REMOVAL AND INSTALLATION .

42-10

FUEL FILLER LID . . . . . . . . . . .42-11

REMOVAL AND INSTALLATION .

42-11

STRUT TOWER BAR . . . . . . . . 42-12

REMOVAL AND INSTALLATION .

42-12

WINDOW GLASS . . . . . . . . . . . 42-12

GENERAL . . . . . . . . . . . . . . . . . . . .

42-12

WINDOW GLASS DIAGNOSIS . . .42-14

INTRODUCTION TO WINDOW GLASS

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-14

WINDOW GLASS DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . . 42-14

WINDOW GLASS DIAGNOSTIC TROUBLE

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-14

SYMPTOM PROCEDURES . . . . . . . . . . 42-14

SPECIAL TOOL . . . . . . . . . . . . . . .42-14

WINDSHIELD . . . . . . . . . . . . . . . . .42-15

REMOVAL AND INSTALLATION . . . . . . 42-15

REAR WINDOW GLASS . . . . . . . .42-20

REMOVAL AND INSTALLATION . . . . . . 42-20

Continued on next page

Page 1079 of 1500

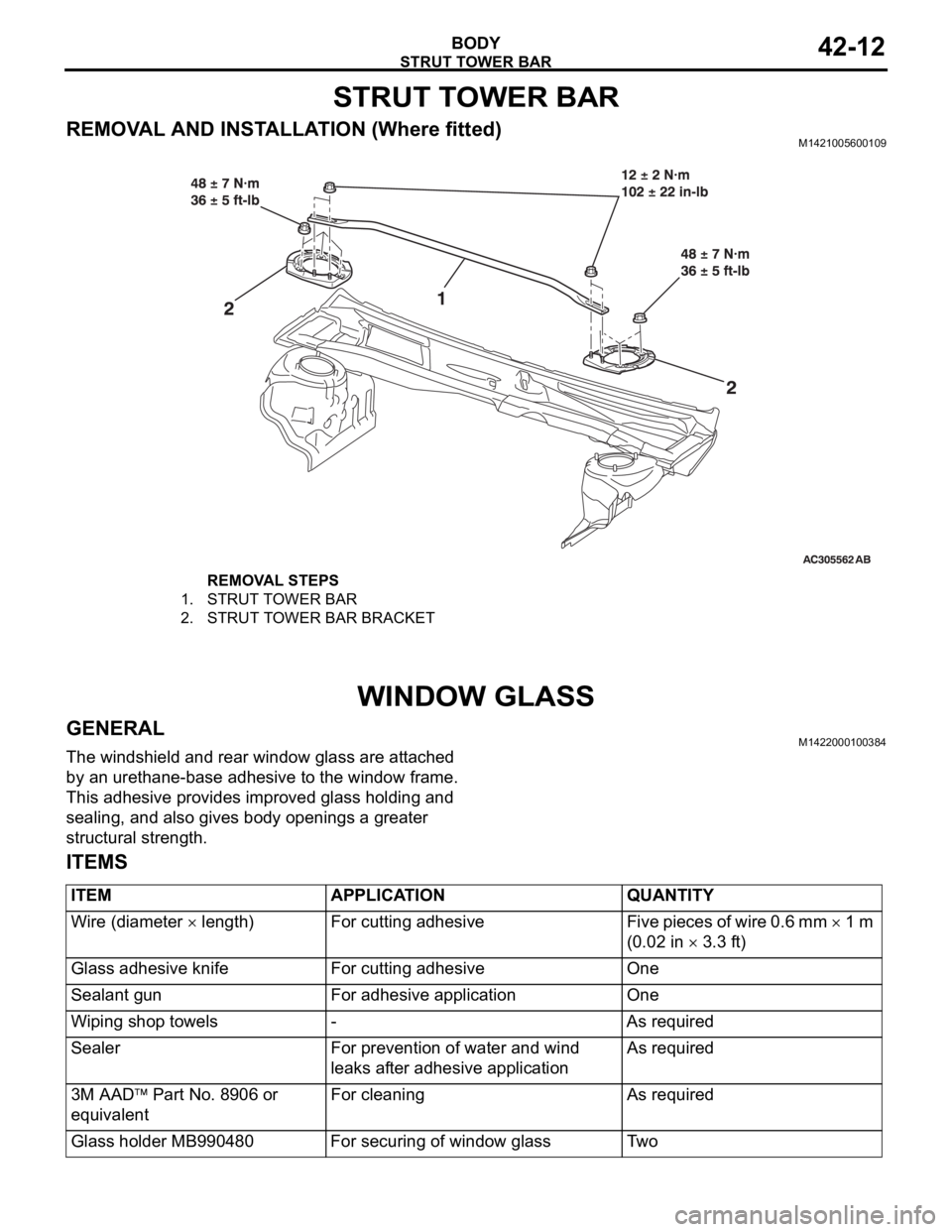

STRUT TOWER BAR

BODY42-12

STRUT TOWER BAR

REMOVAL AND INSTALLATION (Where fitted)M1421005600109

WINDOW GLASS

GENERALM1422000100384

The windshield and rear window glass are attached

by an urethane-base adhesive to the window frame.

This adhesive provides improved glass holding and

sealing, and also gives body openings a greater

structural strength.

ITEMS

REMOVAL STEPS

1. STRUT TOWER BAR

2. STRUT TOWER BAR BRACKET

ITEM APPLICATION QUANTITY

Wire (diameter

length) For cutting adhesive Five pieces of wire 0.6 mm 1 m

(0.02 in

3.3 ft)

Glass adhesive knife For cutting adhesive One

Sealant gun For adhesive application One

Wiping shop towels - As required

Sealer For prevention of water and wind

leaks after adhesive applicationAs required

3M AAD

Part No. 8906 or

equivalentFor cleaning As required

Glass holder MB990480 For securing of window glass Two

Page 1097 of 1500

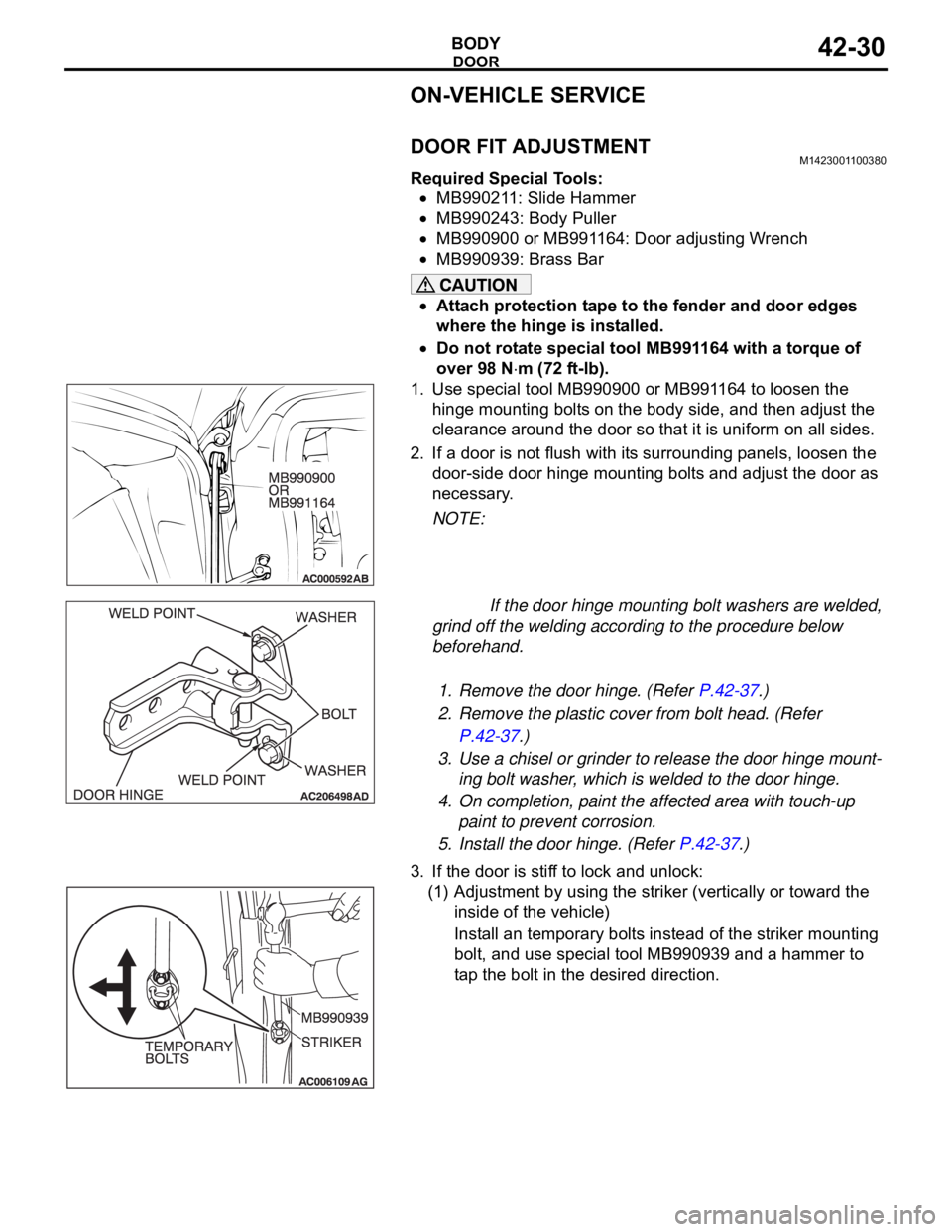

DOOR

BODY42-30

ON-VEHICLE SERVICE

DOOR FIT ADJUSTMENTM1423001100380

Required Special Tools:

MB990211: Slide Hammer

MB990243: Body Puller

MB990900 or MB991164: Door adjusting Wrench

MB990939: Brass Bar

Attach protection tape to the fender and door edges

where the hinge is installed.

Do not rotate special tool MB991164 with a torque of

over 98 N

m (72 ft-lb).

1. Use special tool MB990900 or MB991164 to loosen the

hinge mounting bolts on the body side, and then adjust the

clearance around the door so that it is uniform on all sides.

2. If a door is not flush with its surrounding panels, loosen the

door-side door hinge mounting bolts and adjust the door as

necessary.

NOTE:

If the door hinge mounting bolt washers are welded,

grind off the welding according to the procedure below

beforehand.

.

1. Remove the door hinge. (Refer P.42-37.)

2. Remove the plastic cover from bolt head. (Refer

P.42-37.)

3. Use a chisel or grinder to release the door hinge mount-

ing bolt washer, which is welded to the door hinge.

4. On completion, paint the affected area with touch-up

paint to prevent corrosion.

5. Install the door hinge. (Refer P.42-37.)

3. If the door is stiff to lock and unlock:

(1) Adjustment by using the striker (vertically or toward the

inside of the vehicle)

Install an temporary bolts instead of the striker mounting

bolt, and use special tool MB990939 and a hammer to

tap the bolt in the desired direction.

Page 1153 of 1500

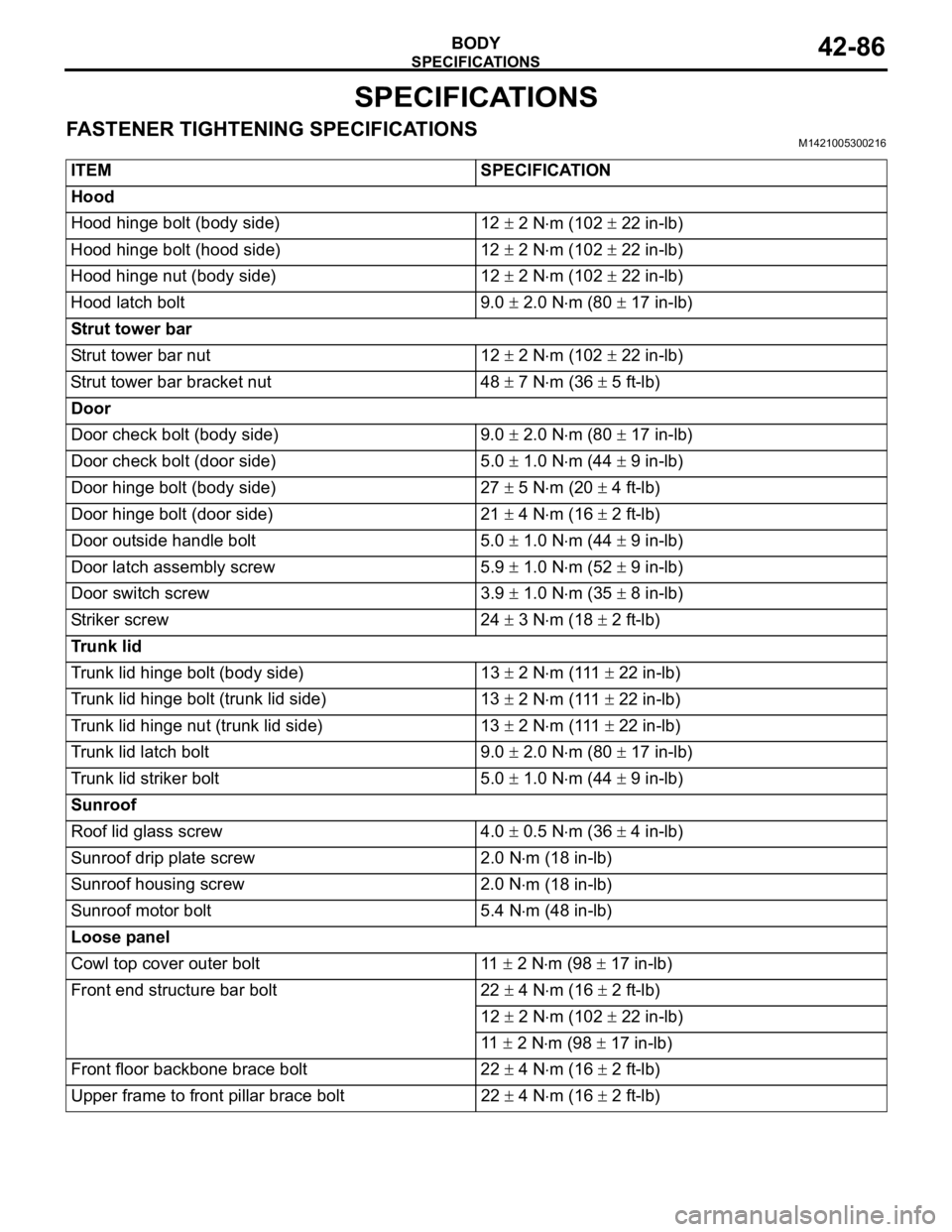

SPECIFICATIONS

BODY42-86

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1421005300216

ITEM SPECIFICATION

Hood

Hood hinge bolt (body side) 12

2 Nm (102 22 in-lb)

Hood hinge bolt (hood side) 12

2 Nm (102 22 in-lb)

Hood hinge nut (body side) 12

2 Nm (102 22 in-lb)

Hood latch bolt 9.0

2.0 Nm (80 17 in-lb)

Strut tower bar

Strut tower bar nut 12

2 Nm (102 22 in-lb)

Strut tower bar bracket nut 48

7 Nm (36 5 ft-lb)

Door

Door check bolt (body side) 9.0

2.0 Nm (80 17 in-lb)

Door check bolt (door side) 5.0

1.0 Nm (44 9 in-lb)

Door hinge bolt (body side) 27

5 Nm (20 4 ft-lb)

Door hinge bolt (door side) 21

4 Nm (16 2 ft-lb)

Door outside handle bolt 5.0

1.0 Nm (44 9 in-lb)

Door latch assembly screw 5.9

1.0 Nm (52 9 in-lb)

Door switch screw 3.9

1.0 Nm (35 8 in-lb)

Striker screw 24

3 Nm (18 2 ft-lb)

Trunk lid

Trunk lid hinge bolt (body side) 13

2 Nm ( 111 22 in-lb)

Trunk lid hinge bolt (trunk lid side) 13

2 Nm ( 111 22 in-lb)

Trunk lid hinge nut (trunk lid side) 13

2 Nm ( 111 22 in-lb)

Trunk lid latch bolt 9.0

2.0 Nm (80 17 in-lb)

Trunk lid striker bolt 5.0

1.0 Nm (44 9 in-lb)

Sunroof

Roof lid glass screw 4.0

0.5 Nm (36 4 in-lb)

Sunroof drip plate screw 2.0 N

m (18 in-lb)

Sunroof housing screw 2.0 N

m (18 in-lb)

Sunroof motor bolt 5.4 N

m (48 in-lb)

Loose panel

Cowl top cover outer bolt 11

2 Nm (98 17 in-lb)

Front end structure bar bolt 22

4 Nm (16 2 ft-lb)

12

2 Nm (102 22 in-lb)

11

2 Nm (98 17 in-lb)

Front floor backbone brace bolt 22

4 Nm (16 2 ft-lb)

Upper frame to front pillar brace bolt 22

4 Nm (16 2 ft-lb)

Page 1191 of 1500

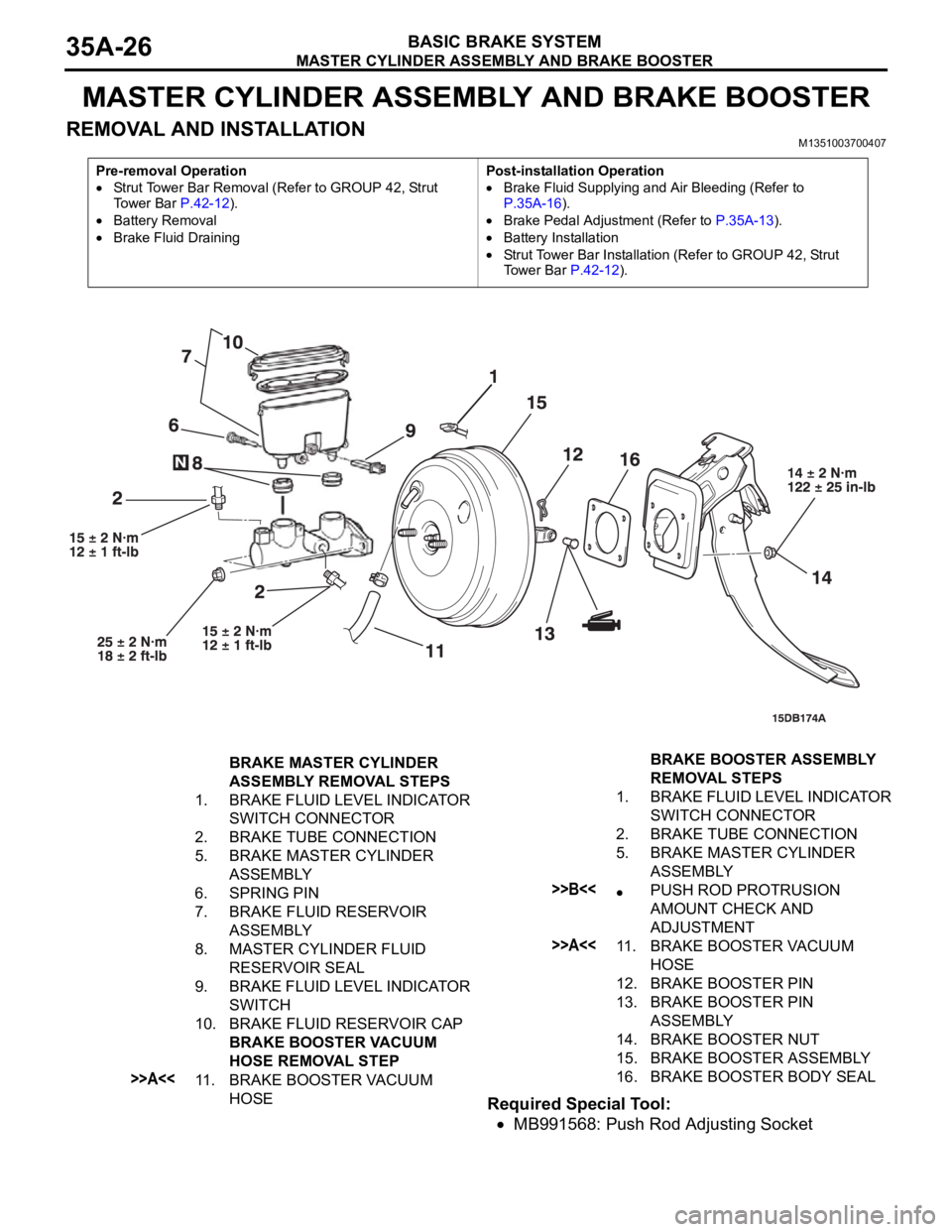

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER

BASIC BRAKE SYSTEM35A-26

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER

REMOVAL AND INSTALLATIONM1351003700407

Required Special Tool:

MB991568: Push Rod Adjusting Socket

Pre-removal Operation

Strut Tower Bar Removal (Refer to GROUP 42, Strut

To w e r B a r P.42-12).

Battery Removal

Brake Fluid DrainingPost-installation Operation

Brake Fluid Supplying and Air Bleeding (Refer to

P.35A-16).

Brake Pedal Adjustment (Refer to P.35A-13).

Battery Installation

Strut Tower Bar Installation (Refer to GROUP 42, Strut

Tower Bar P.42-12).

BRAKE MASTER CYLINDER

ASSEMBLY REMOVAL STEPS

1. BRAKE FLUID LEVEL INDICATOR

SWITCH CONNECTOR

2. BRAKE TUBE CONNECTION

5. BRAKE MASTER CYLINDER

ASSEMBLY

6. SPRING PIN

7. BRAKE FLUID RESERVOIR

ASSEMBLY

8. MASTER CYLINDER FLUID

RESERVOIR SEAL

9. BRAKE FLUID LEVEL INDICATOR

SWITCH

10. BRAKE FLUID RESERVOIR CAP

BRAKE BOOSTER VACUUM

HOSE REMOVAL STEP

>>A<<11. BRAKE BOOSTER VACUUM

HOSE BRAKE BOOSTER ASSEMBLY

REMOVAL STEPS

1. BRAKE FLUID LEVEL INDICATOR

SWITCH CONNECTOR

2. BRAKE TUBE CONNECTION

5. BRAKE MASTER CYLINDER

ASSEMBLY

>>B<

ADJUSTMENT

>>A<<11. BRAKE BOOSTER VACUUM

HOSE

12. BRAKE BOOSTER PIN

13. BRAKE BOOSTER PIN

ASSEMBLY

14. BRAKE BOOSTER NUT

15. BRAKE BOOSTER ASSEMBLY

16. BRAKE BOOSTER BODY SEAL