Brake pad MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1184 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-19

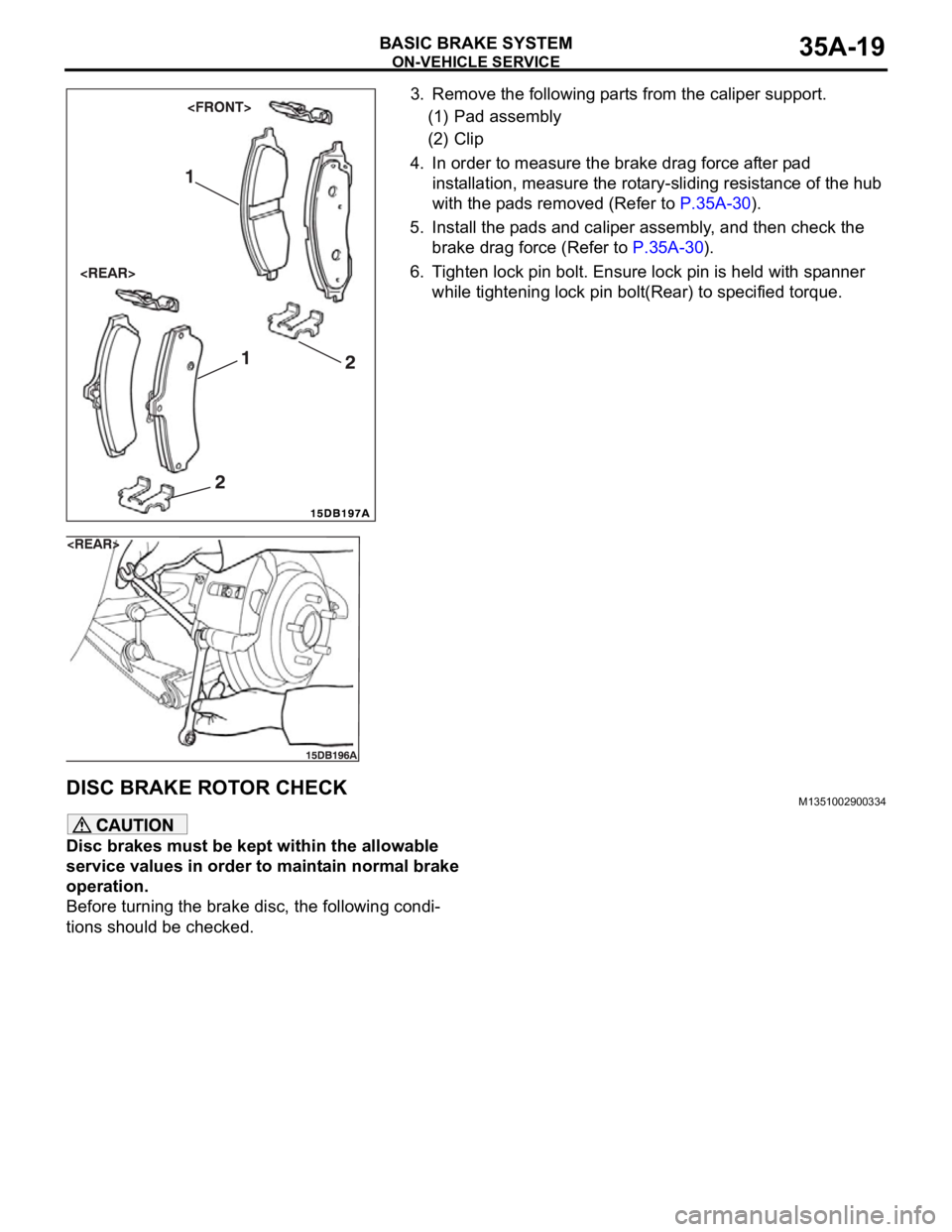

3. Remove the following parts from the caliper support.

(1) Pad assembly

(2) Clip

4. In order to measure the brake drag force after pad

installation, measure the rotary-sliding resistance of the hub

with the pads removed (Refer to P.35A-30).

5. Install the pads and caliper assembly, and then check the

brake drag force (Refer to P.35A-30).

6. Tighten lock pin bolt. Ensure lock pin is held with spanner

while tightening lock pin bolt(Rear) to specified torque.

DISC BRAKE ROTOR CHECKM1351002900334

Disc brakes must be kept within the allowable

service values in order to maintain normal brake

operation.

Before turning the brake disc, the following condi-

tions should be checked.

Page 1185 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-20

.

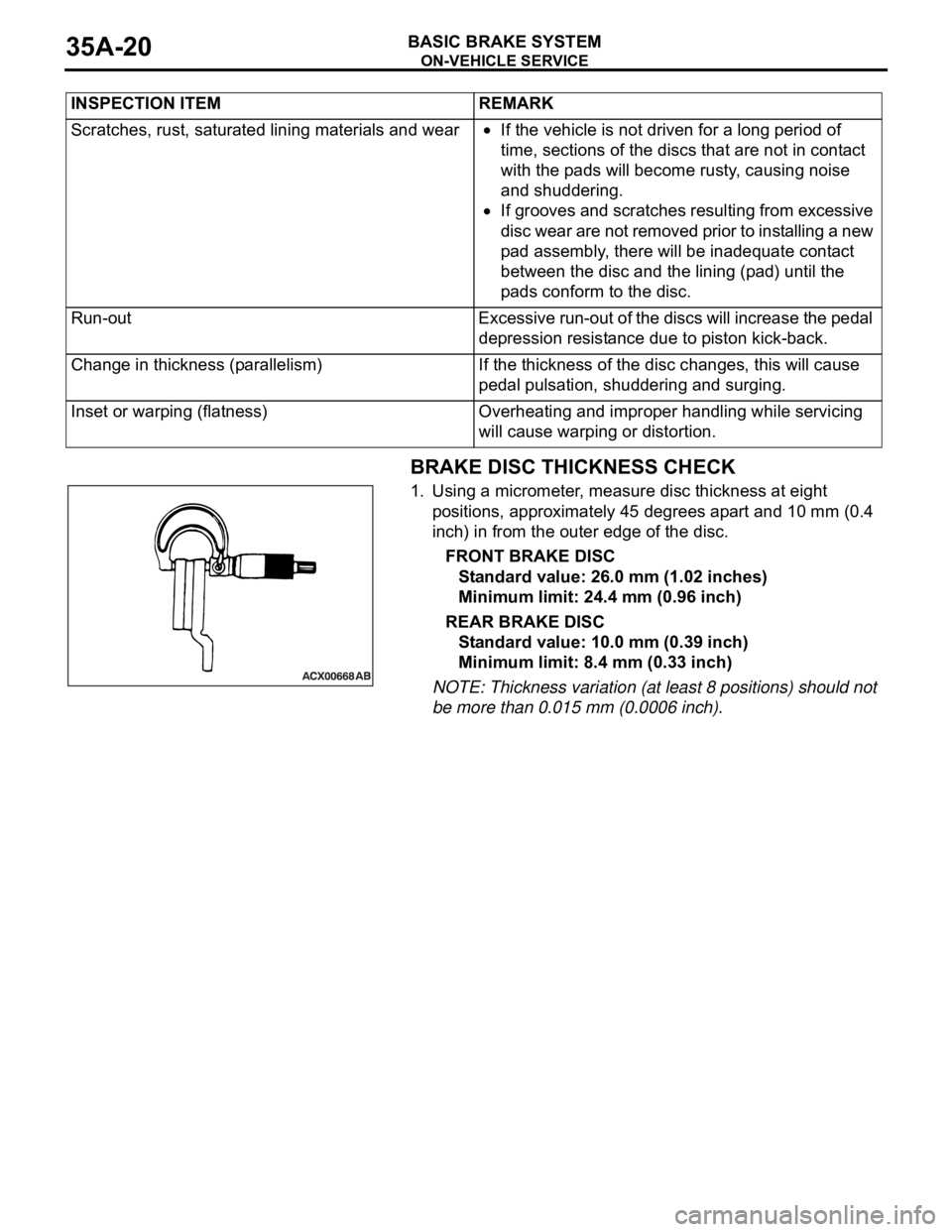

BRAKE DISC THICKNESS CHECK

1. Using a micrometer, measure disc thickness at eight

positions, approximately 45 degrees apart and 10 mm (0.4

inch) in from the outer edge of the disc.

FRONT BRAKE DISC

Standard value: 26.0 mm (1.02 inches)

Minimum limit: 24.4 mm (0.96 inch)

REAR BRAKE DISC

Standard value: 10.0 mm (0.39 inch)

Minimum limit: 8.4 mm (0.33 inch)

NOTE: Thickness variation (at least 8 positions) should not

be more than 0.015 mm (0.0006 inch). INSPECTION ITEM REMARK

Scratches, rust, saturated lining materials and wear

If the vehicle is not driven for a long period of

time, sections of the discs that are not in contact

with the pads will become rusty, causing noise

and shuddering.

If grooves and scratches resulting from excessive

disc wear are not removed prior to installing a new

pad assembly, there will be inadequate contact

between the disc and the lining (pad) until the

pads conform to the disc.

Run-out Excessive run-out of the discs will increase the pedal

depression resistance due to piston kick-back.

Change in thickness (parallelism) If the thickness of the disc changes, this will cause

pedal pulsation, shuddering and surging.

Inset or warping (flatness) Overheating and improper handling while servicing

will cause warping or distortion.

Page 1189 of 1500

BRAKE PEDAL

BASIC BRAKE SYSTEM35A-24

BRAKE PEDAL

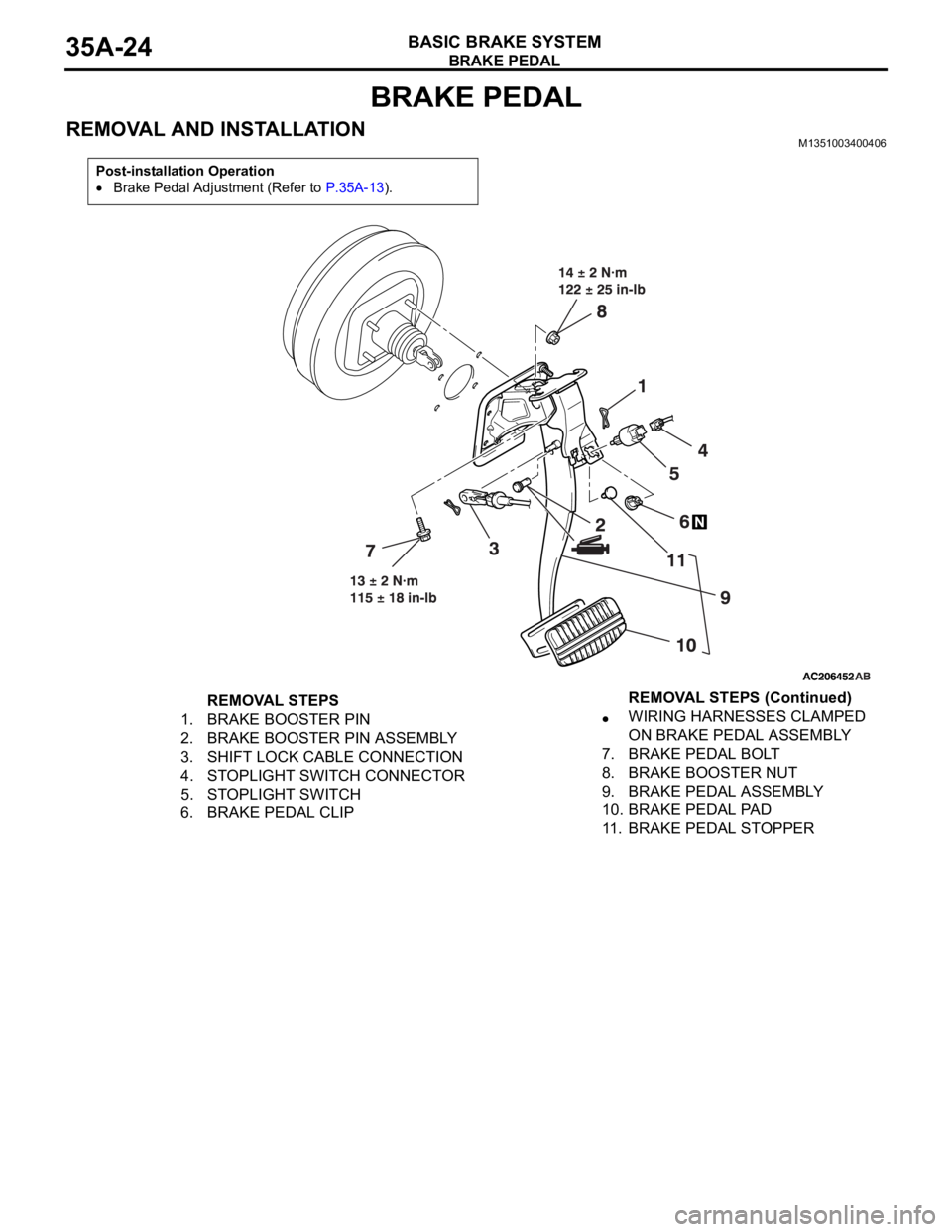

REMOVAL AND INSTALLATIONM1351003400406

Post-installation Operation

Brake Pedal Adjustment (Refer to P.35A-13).

REMOVAL STEPS

1. BRAKE BOOSTER PIN

2. BRAKE BOOSTER PIN ASSEMBLY

3. SHIFT LOCK CABLE CONNECTION

4. STOPLIGHT SWITCH CONNECTOR

5. STOPLIGHT SWITCH

6. BRAKE PEDAL CLIPWIRING HARNESSES CLAMPED

ON BRAKE PEDAL ASSEMBLY

7. BRAKE PEDAL BOLT

8. BRAKE BOOSTER NUT

9. BRAKE PEDAL ASSEMBLY

10. BRAKE PEDAL PAD

11. BRAKE PEDAL STOPPERREMOVAL STEPS (Continued)

Page 1196 of 1500

DISC BRAKE ASSEMBLY

BASIC BRAKE SYSTEM35A-31

INSTALLATION SERVICE POINT

.

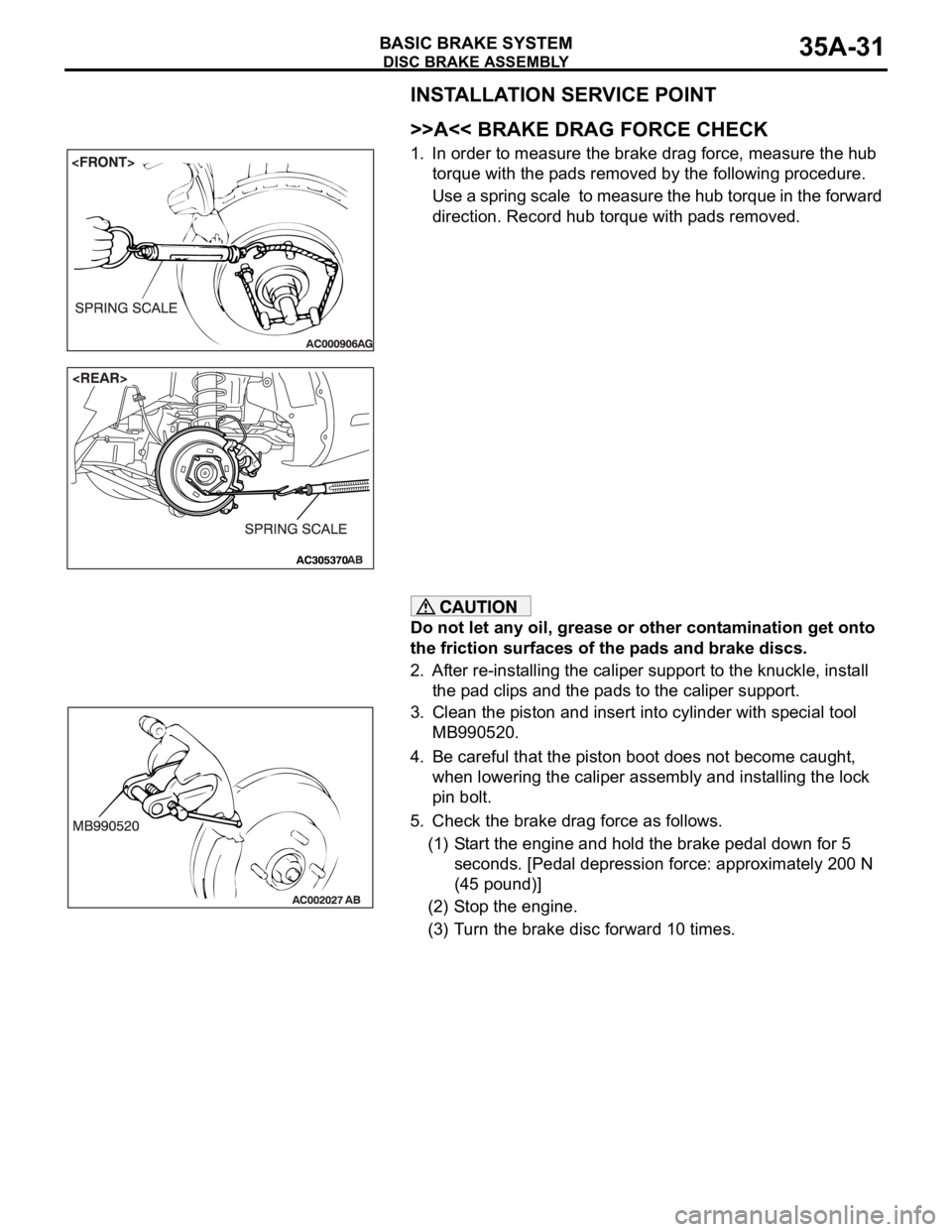

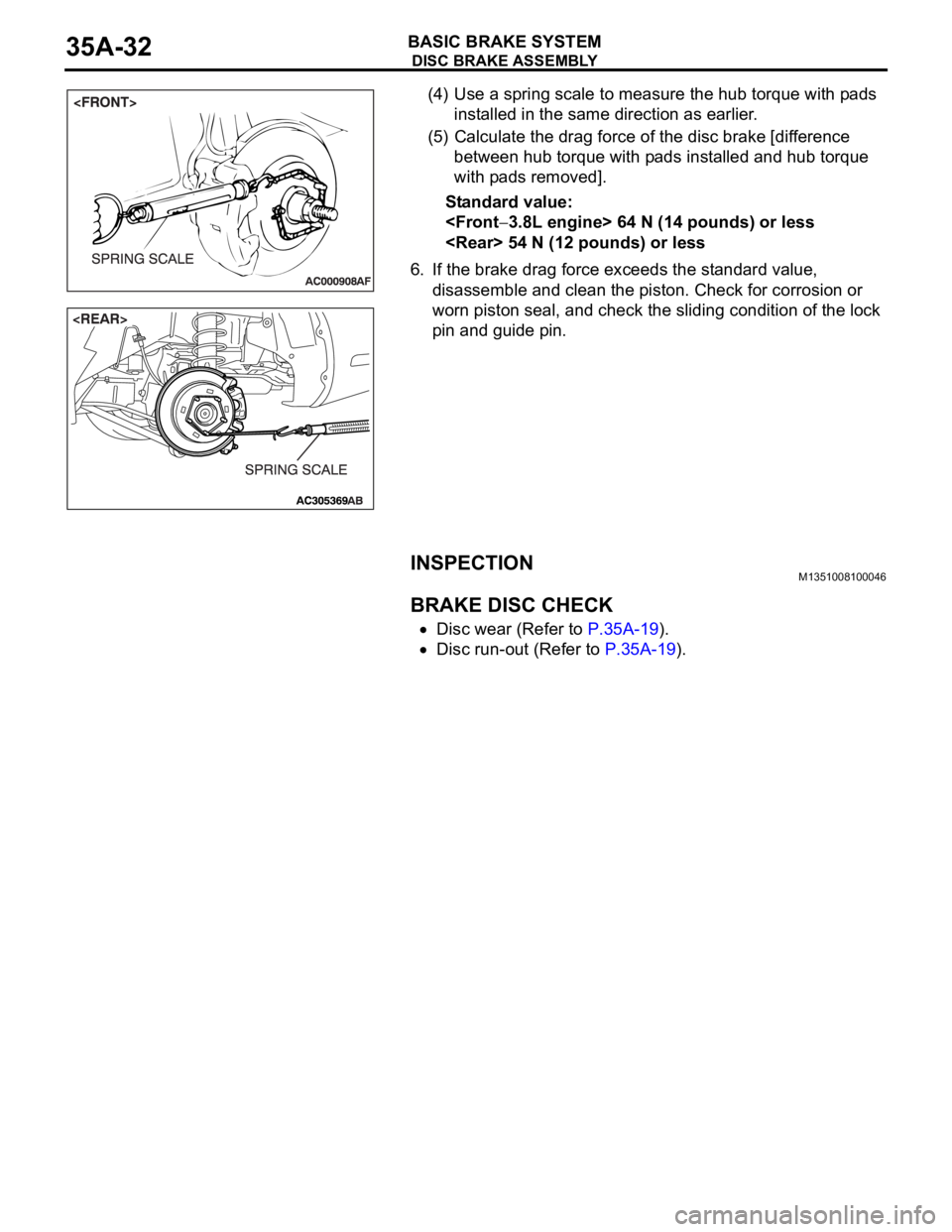

>>A<< BRAKE DRAG FORCE CHECK

1. In order to measure the brake drag force, measure the hub

torque with the pads removed by the following procedure.

Use a spring scale to measure the hub torque in the forward

direction. Record hub torque with pads removed.

Do not let any oil, grease or other contamination get onto

the friction surfaces of the pads and brake discs.

2. After re-installing the caliper support to the knuckle, install

the pad clips and the pads to the caliper support.

3. Clean the piston and insert into cylinder with special tool

MB990520.

4. Be careful that the piston boot does not become caught,

when lowering the caliper assembly and installing the lock

pin bolt.

5. Check the brake drag force as follows.

(1) Start the engine and hold the brake pedal down for 5

seconds. [Pedal depression force: approximately 200 N

(45 pound)]

(2) Stop the engine.

(3) Turn the brake disc forward 10 times.

Page 1197 of 1500

DISC BRAKE ASSEMBLY

BASIC BRAKE SYSTEM35A-32

(4) Use a spring scale to measure the hub torque with pads

installed in the same direction as earlier.

(5) Calculate the drag force of the disc brake [difference

between hub torque with pads installed and hub torque

with pads removed].

Standard value:

6. If the brake drag force exceeds the standard value,

disassemble and clean the piston. Check for corrosion or

worn piston seal, and check the sliding condition of the lock

pin and guide pin.

INSPECTIONM1351008100046.

BRAKE DISC CHECK

Disc wear (Refer to P.35A-19).

Disc run-out (Refer to P.35A-19).

Page 1198 of 1500

DISC BRAKE ASSEMBLY

BASIC BRAKE SYSTEM35A-33

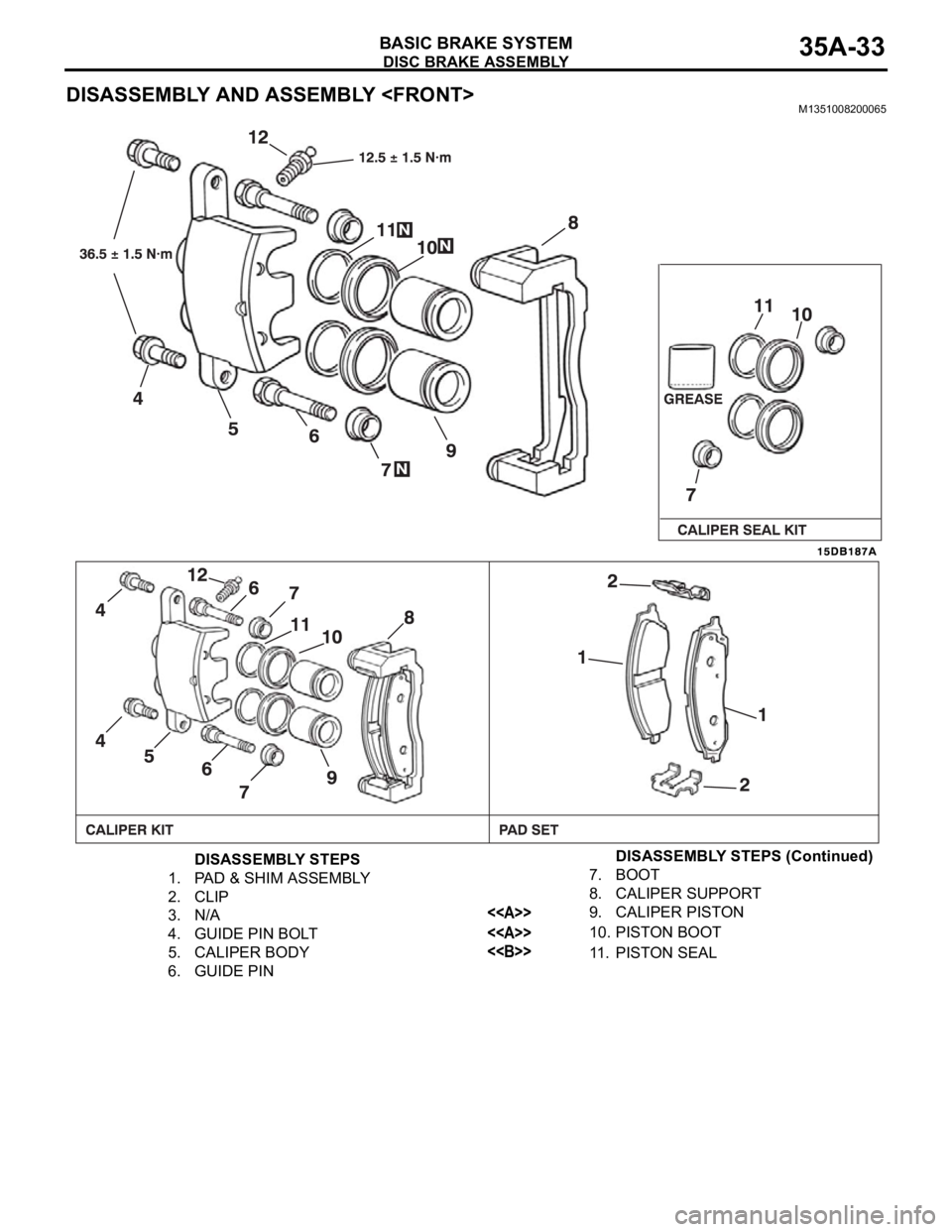

DISASSEMBLY AND ASSEMBLY

DISASSEMBLY STEPS

1. PAD & SHIM ASSEMBLY

2. CLIP

3. N/A

4. GUIDE PIN BOLT

5. CALIPER BODY

6. GUIDE PIN7. BOOT

8. CALIPER SUPPORT

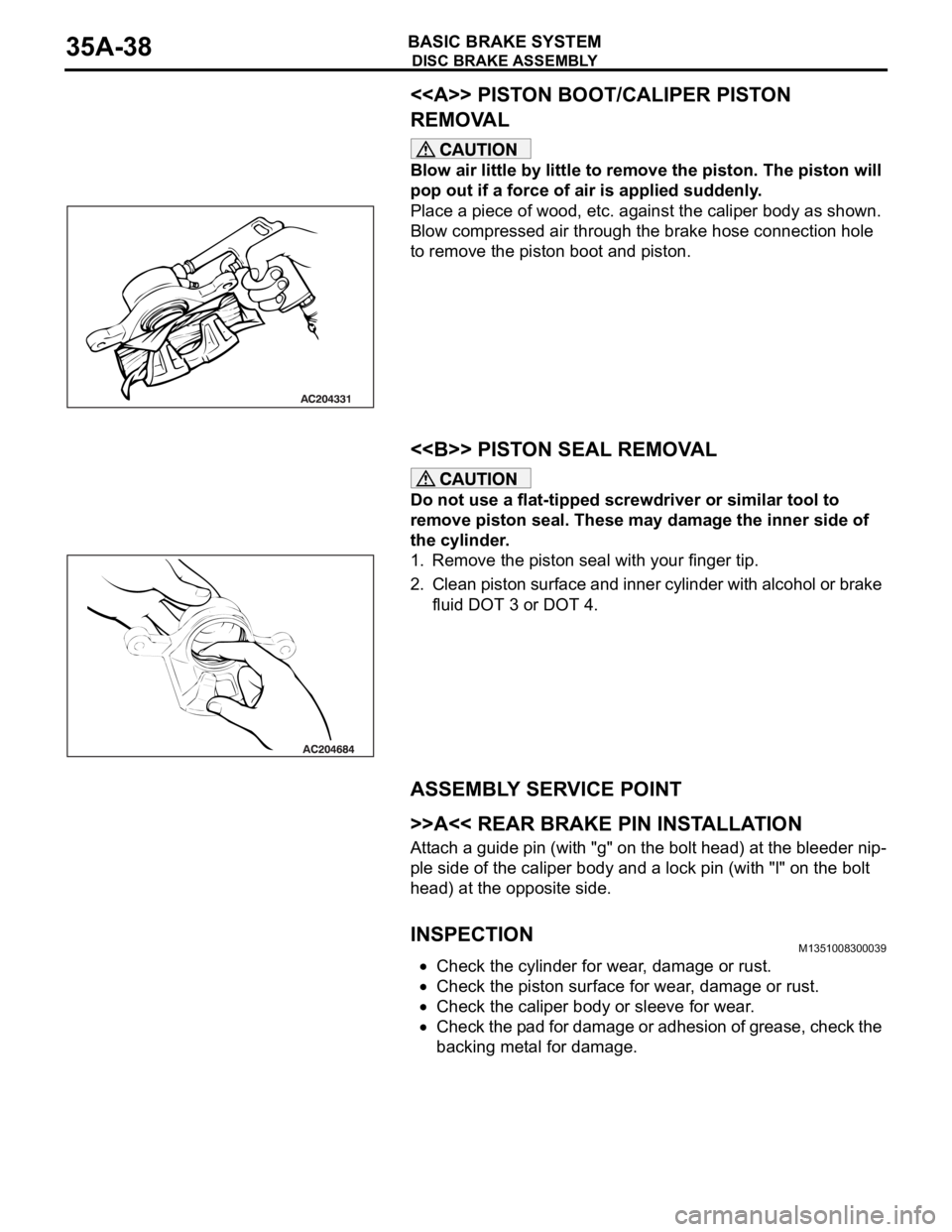

<>9. CALIPER PISTON

<>10. PISTON BOOT

<>11. PISTON SEALDISASSEMBLY STEPS (Continued)

Page 1201 of 1500

DISC BRAKE ASSEMBLY

BASIC BRAKE SYSTEM35A-36

DISASSEMBLY AND ASSEMBLY

DISASSEMBLY STEPS

1. PAD & SHIM ASSEMBLY

2. CLIP

3. N/A

>>A<<4. REAR BRAKE BOLT

5. CALIPER BODY

6. GUIDE PIN7. PIN BOOT

8. CALIPER SUPPORT

<>9. PISTON

<>10. PISTON BOOT

<>11. PISTON SEAL

12. BLEEDERDISASSEMBLY STEPS (Continued)

Page 1203 of 1500

Page 1204 of 1500

DISC BRAKE ASSEMBLY

BASIC BRAKE SYSTEM35A-39

PAD WEAR CHECK

Always replace both brake pads on each wheel as

a set (both front wheels or both rear wheels). Fail-

ure to do so will result in uneven braking, which

may cause unreliable brake operation.

If there is significant difference in the thickness of

the pads on the left and right sides, check the slid-

ing condition of the piston and slide pins.

1. Measure thickness at the thinnest and most worn area of the

pad.

Standard value: 10 mm (0.39 inch)

Minimum limit: 2.0 mm (0.08 inch)

2. Replace the pad assembly if pad thickness is less than the

limit value.

Page 1205 of 1500

SPECIFICATIONS

BASIC BRAKE SYSTEM35A-40

SPECIFICATIONS

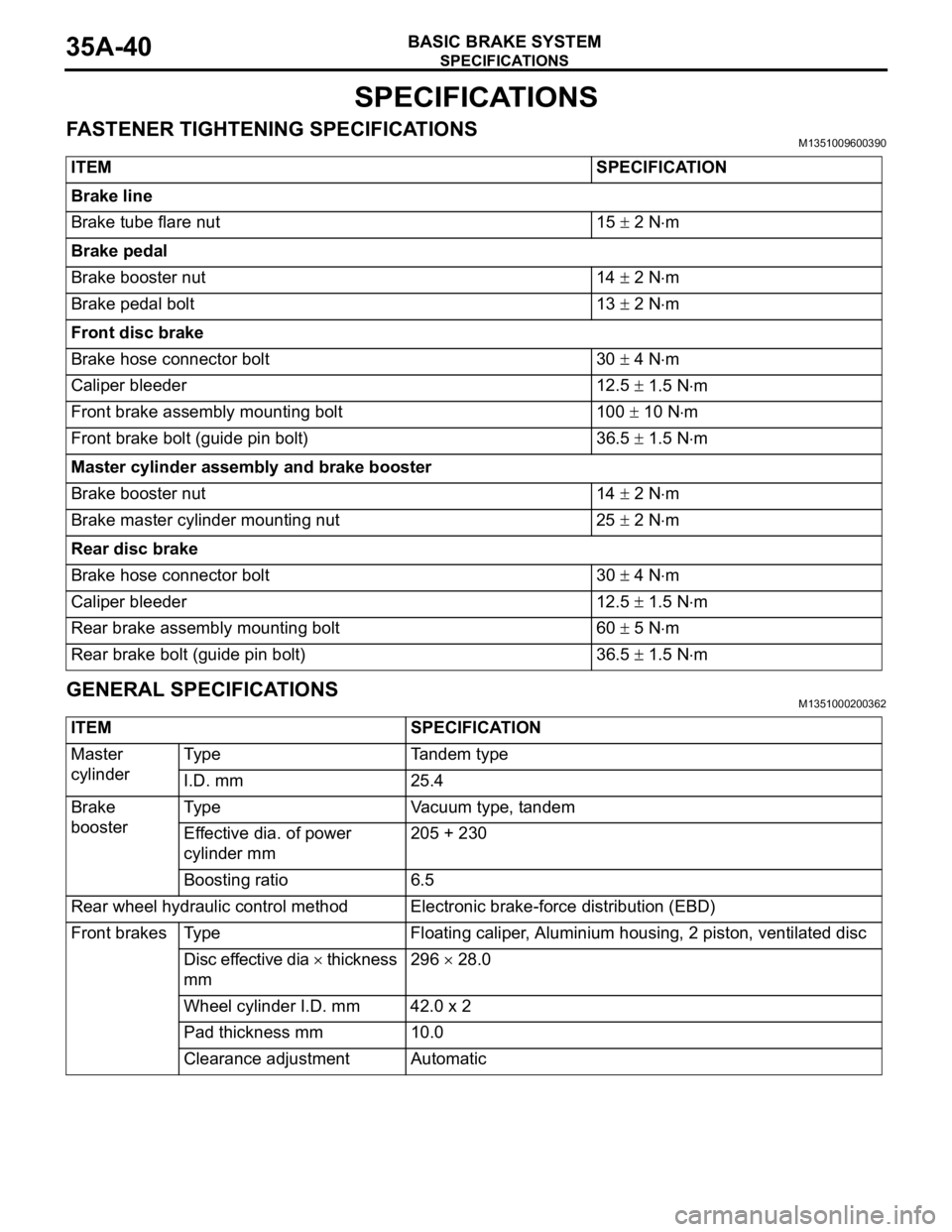

FASTENER TIGHTENING SPECIFICATIONSM1351009600390

GENERAL SPECIFICATIONSM1351000200362

ITEM SPECIFICATION

Brake line

Brake tube flare nut 15

2 Nm

Brake pedal

Brake booster nut 14

2 Nm

Brake pedal bolt 13

2 Nm

Front disc brake

Brake hose connector bolt 30

4 Nm

Caliper bleeder 12.5

1.5 Nm

Front brake assembly mounting bolt 100

10 Nm

Front brake bolt (guide pin bolt) 36.5

1.5 Nm

Master cylinder assembly and brake booster

Brake booster nut 14

2 Nm

Brake master cylinder mounting nut 25

2 Nm

Rear disc brake

Brake hose connector bolt 30

4 Nm

Caliper bleeder 12.5

1.5 Nm

Rear brake assembly mounting bolt 60

5 Nm

Rear brake bolt (guide pin bolt) 36.5

1.5 Nm

ITEM SPECIFICATION

Master

cylinderType Tandem type

I.D. mm 25.4

Brake

boosterType Vacuum type, tandem

Effective dia. of power

cylinder mm 205 + 230

Boosting ratio 6.5

Rear wheel hydraulic control method Electronic brake-force distribution (EBD)

Front brakes Type Floating caliper, Aluminium housing, 2 piston, ventilated disc

Disc effective dia

thickness

mm 296 28.0

Wheel cylinder I.D. mm 42.0 x 2

Pad thickness mm 10.0

Clearance adjustment Automatic