battery MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 83 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-83

STEP 2. Check front-ECU connector A-11X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is front-ECU connector A-11X in good condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. The system should communicate with the

front-ECU normally.

STEP 3. Check the battery power supply circuit to the

front-ECU. Measure the voltage at front-ECU connector

A-11X.

(1) Disconnect front-ECU connector A-11X and measure the

voltage available at the relay box side of the connector.

(2) Measure the voltage between terminal 5 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 5.

NO : Go to Step 4.

Page 84 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-84

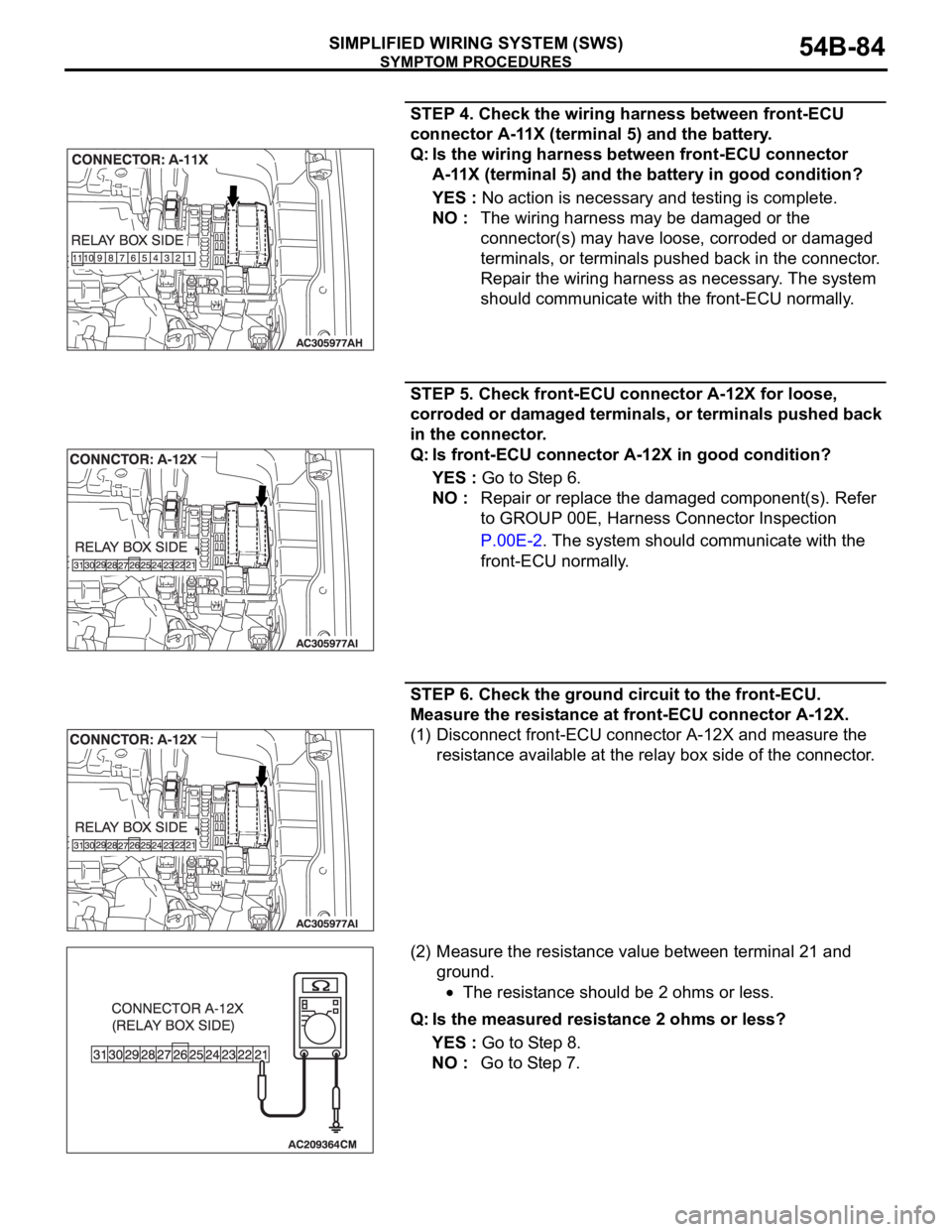

STEP 4. Check the wiring harness between front-ECU

connector A-11X (terminal 5) and the battery.

Q: Is the wiring harness between front-ECU connector

A-11X (terminal 5) and the battery in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The system

should communicate with the front-ECU normally.

STEP 5. Check front-ECU connector A-12X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is front-ECU connector A-12X in good condition?

YES : Go to Step 6.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. The system should communicate with the

front-ECU normally.

STEP 6. Check the ground circuit to the front-ECU.

Measure the resistance at front-ECU connector A-12X.

(1) Disconnect front-ECU connector A-12X and measure the

resistance available at the relay box side of the connector.

(2) Measure the resistance value between terminal 21 and

ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 8.

NO : Go to Step 7.

Page 88 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-88

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: DIAGNOSTIC TOOL (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

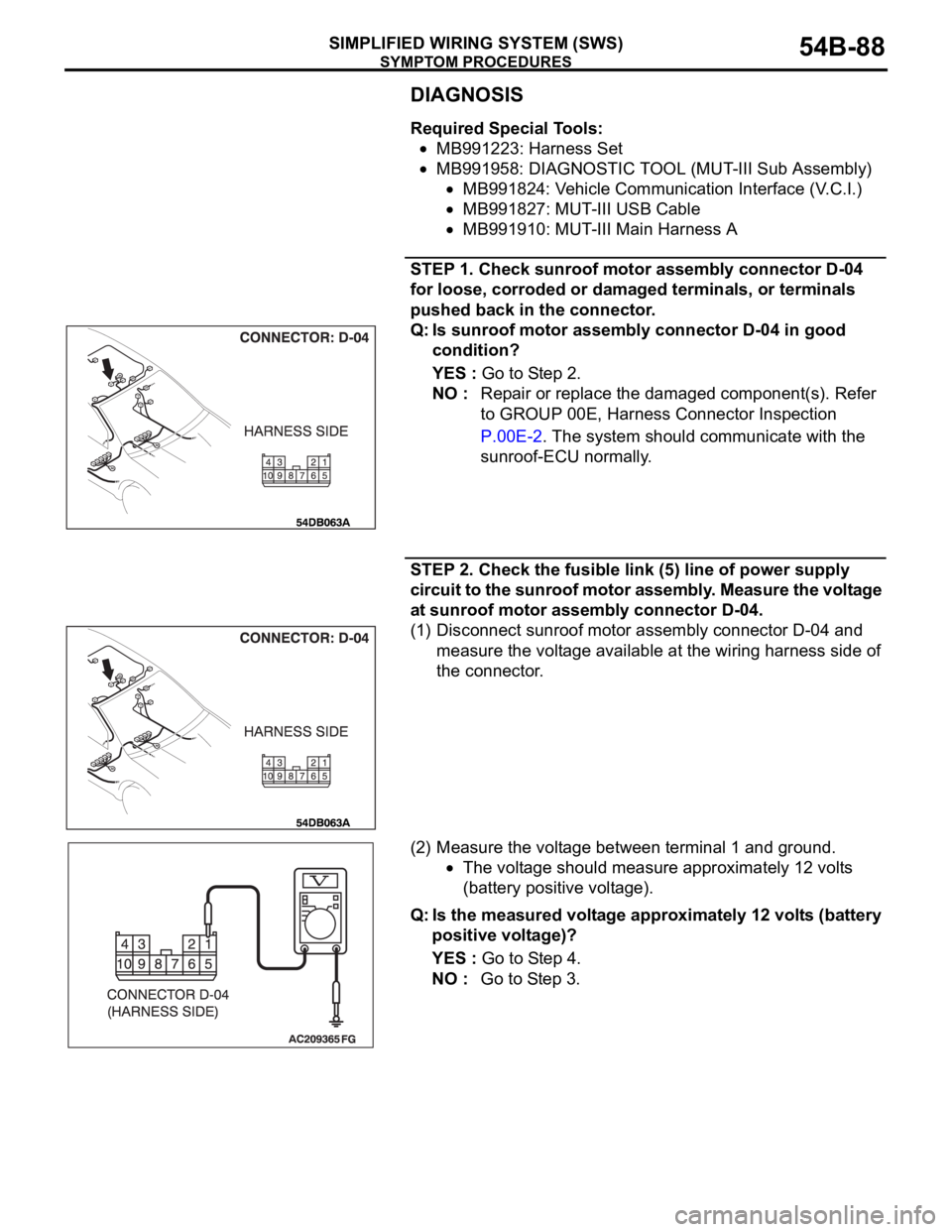

STEP 1. Check sunroof motor assembly connector D-04

for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is sunroof motor assembly connector D-04 in good

condition?

YES : Go to Step 2.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. The system should communicate with the

sunroof-ECU normally.

STEP 2. Check the fusible link (5) line of power supply

circuit to the sunroof motor assembly. Measure the voltage

at sunroof motor assembly connector D-04.

(1) Disconnect sunroof motor assembly connector D-04 and

measure the voltage available at the wiring harness side of

the connector.

(2) Measure the voltage between terminal 1 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 4.

NO : Go to Step 3.

Page 91 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-91

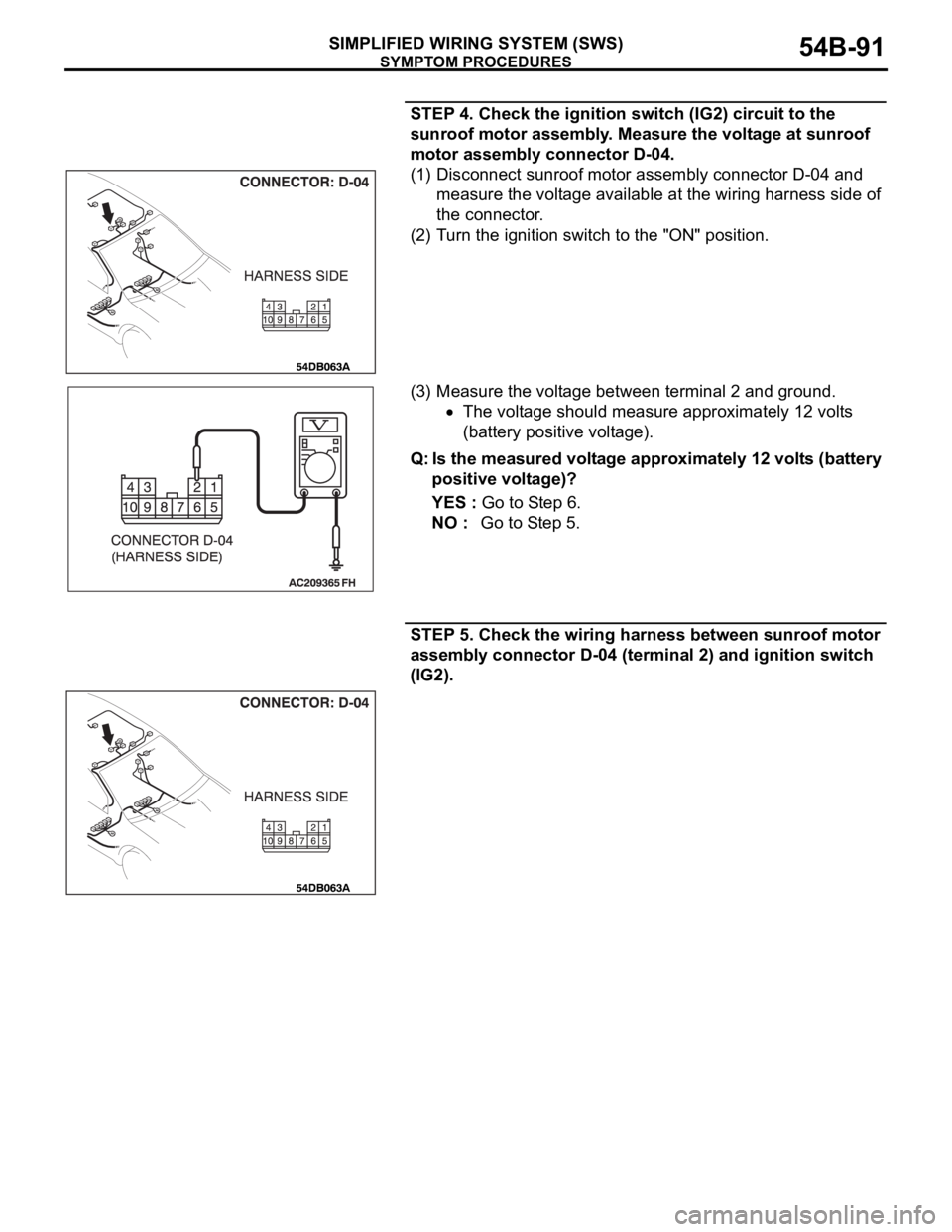

STEP 4. Check the ignition switch (IG2) circuit to the

sunroof motor assembly. Measure the voltage at sunroof

motor assembly connector D-04.

(1) Disconnect sunroof motor assembly connector D-04 and

measure the voltage available at the wiring harness side of

the connector.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal 2 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 6.

NO : Go to Step 5.

STEP 5. Check the wiring harness between sunroof motor

assembly connector D-04 (terminal 2) and ignition switch

(IG2).

Page 124 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-124

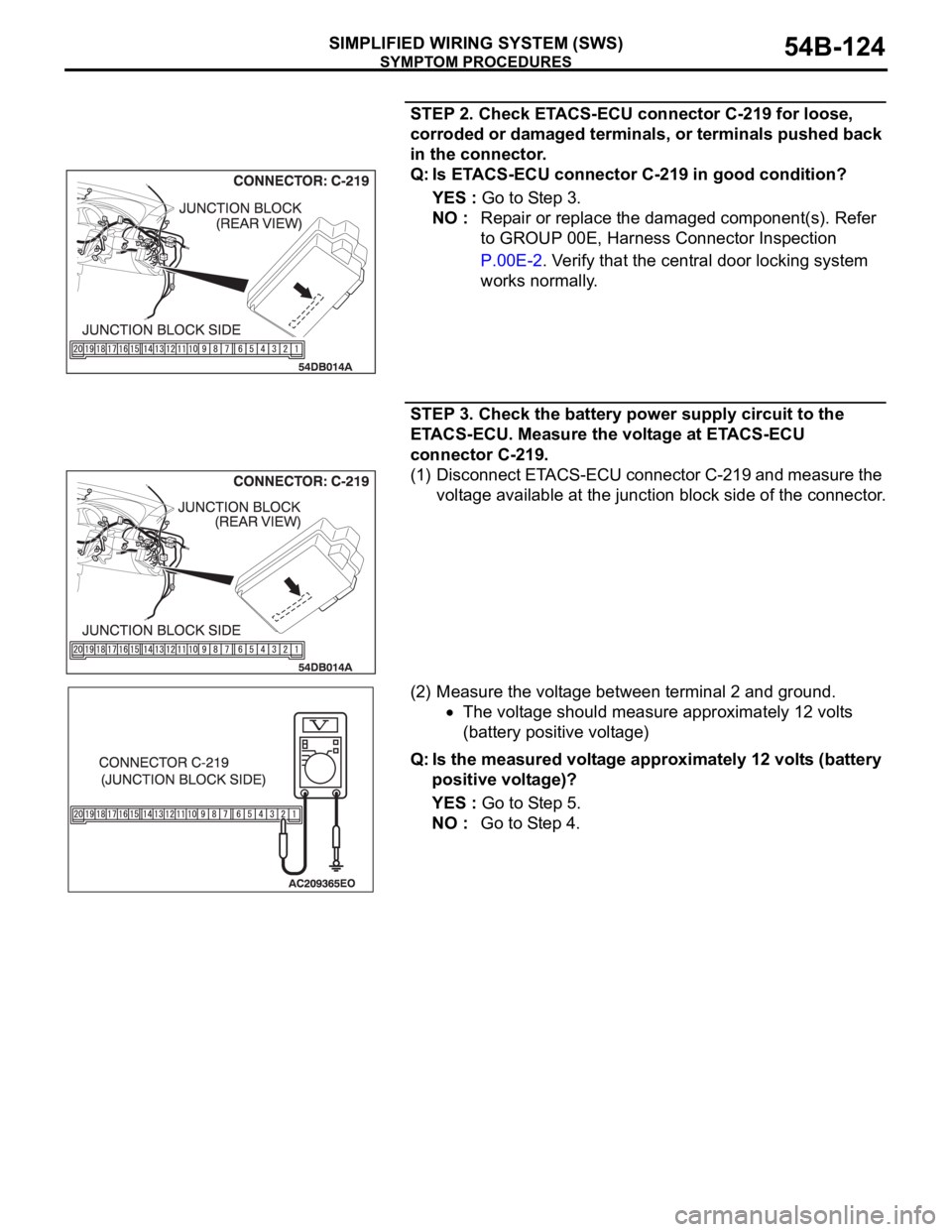

STEP 2. Check ETACS-ECU connector C-219 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is ETACS-ECU connector C-219 in good condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the central door locking system

works normally.

STEP 3. Check the battery power supply circuit to the

ETACS-ECU. Measure the voltage at ETACS-ECU

connector C-219.

(1) Disconnect ETACS-ECU connector C-219 and measure the

voltage available at the junction block side of the connector.

(2) Measure the voltage between terminal 2 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage)

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 5.

NO : Go to Step 4.

Page 131 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-131

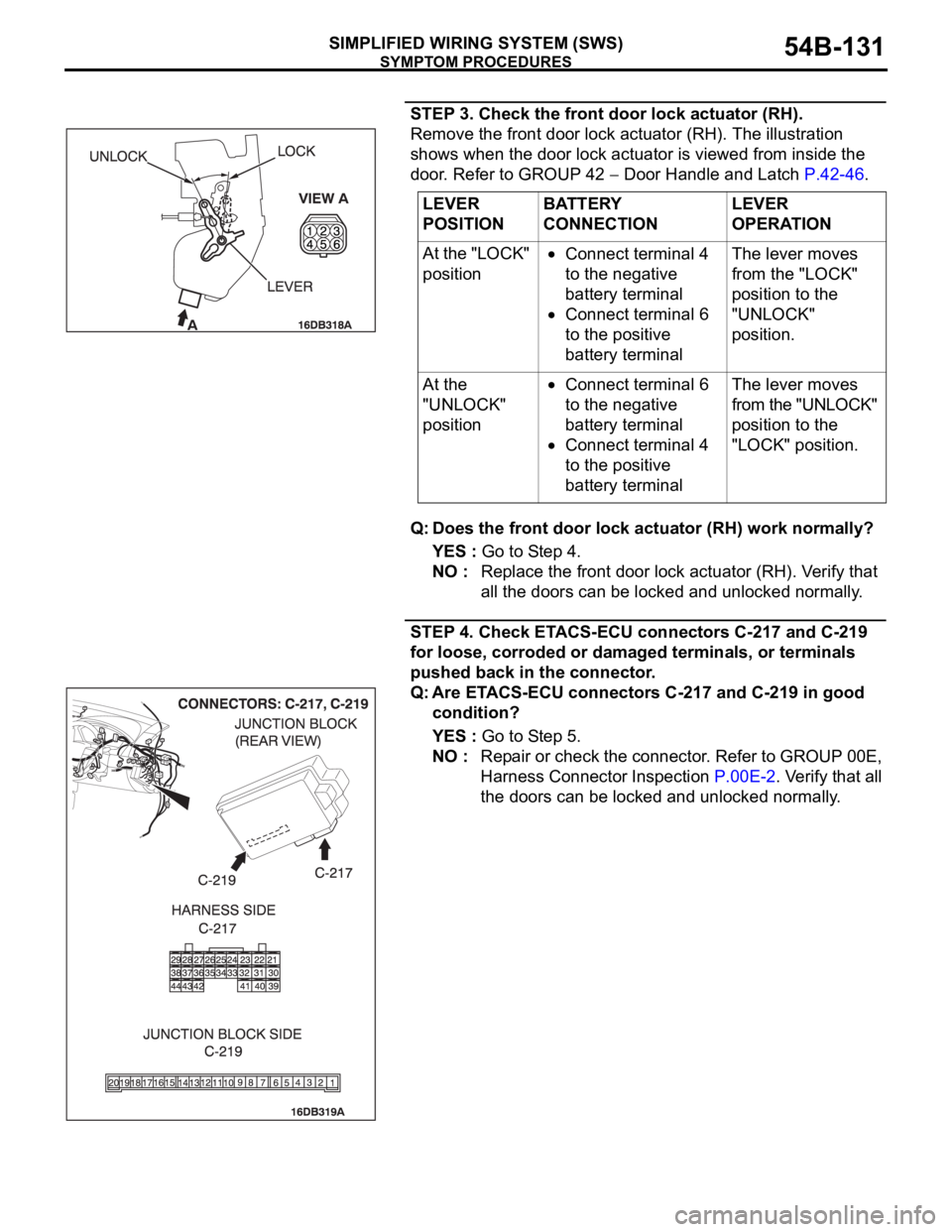

STEP 3. Check the front door lock actuator (RH).

Remove the front door lock actuator (RH). The illustration

shows when the door lock actuator is viewed from inside the

door. Refer to GROUP 42

Door Handle and Latch P.42-46.

Q: Does the front door lock actuator (RH) work normally?

YES : Go to Step 4.

NO : Replace the front door lock actuator (RH). Verify that

all the doors can be locked and unlocked normally.

STEP 4. Check ETACS-ECU connectors C-217 and C-219

for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Are ETACS-ECU connectors C-217 and C-219 in good

condition?

YES : Go to Step 5.

NO : Repair or check the connector. Refer to GROUP 00E,

Harness Connector Inspection P.00E-2. Verify that all

the doors can be locked and unlocked normally. LEVER

POSITIONBATTERY

CONNECTIONLEVER

OPERATION

At the "LOCK"

position

Connect terminal 4

to the negative

battery terminal

Connect terminal 6

to the positive

battery terminalThe lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal 6

to the negative

battery terminal

Connect terminal 4

to the positive

battery terminalThe lever moves

from the "UNLOCK"

position to the

"LOCK" position.

Page 134 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-134

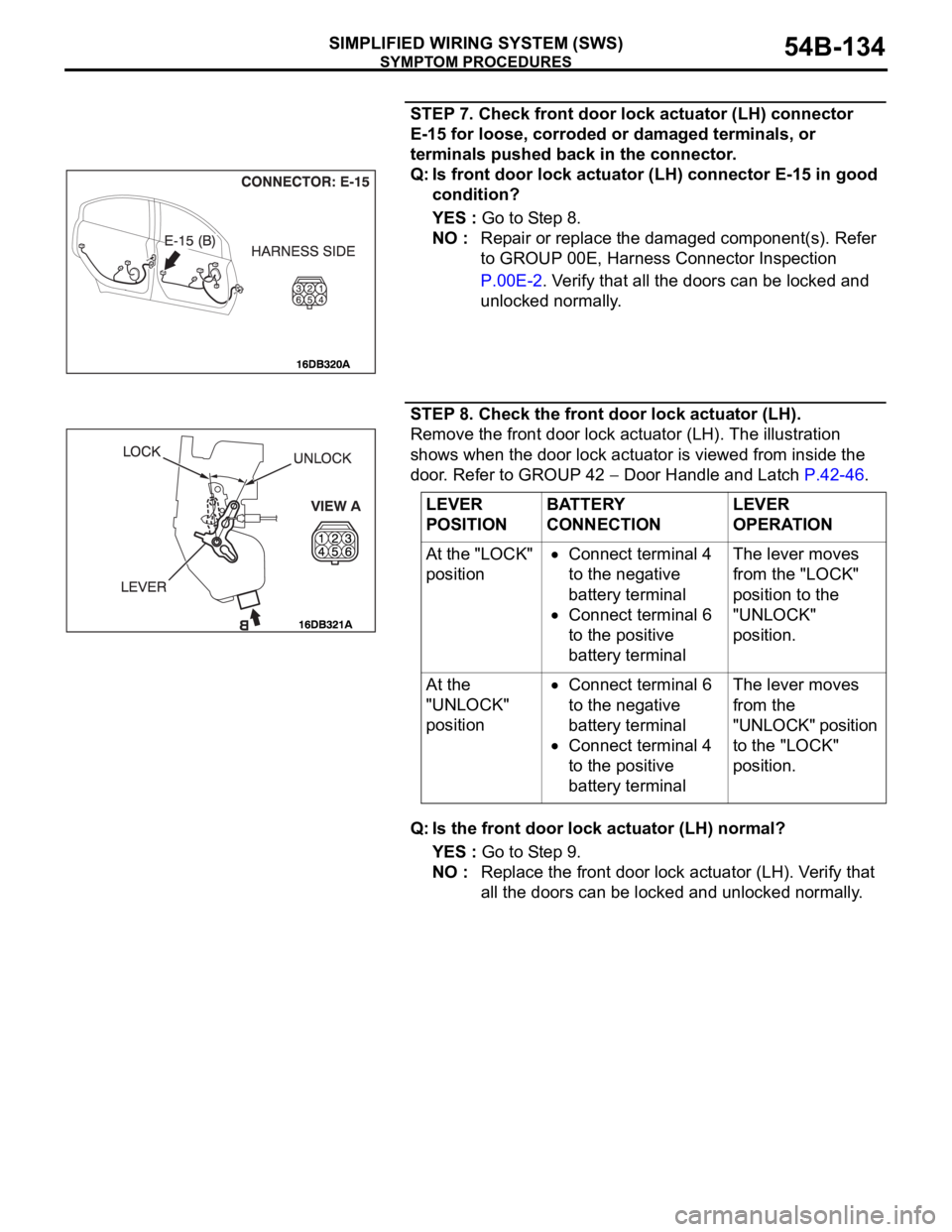

STEP 7. Check front door lock actuator (LH) connector

E-15 for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Is front door lock actuator (LH) connector E-15 in good

condition?

YES : Go to Step 8.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that all the doors can be locked and

unlocked normally.

STEP 8. Check the front door lock actuator (LH).

Remove the front door lock actuator (LH). The illustration

shows when the door lock actuator is viewed from inside the

door. Refer to GROUP 42

Door Handle and Latch P.42-46.

Q: Is the front door lock actuator (LH) normal?

YES : Go to Step 9.

NO : Replace the front door lock actuator (LH). Verify that

all the doors can be locked and unlocked normally.

LEVER

POSITIONBATTERY

CONNECTIONLEVER

OPERATION

At the "LOCK"

position

Connect terminal 4

to the negative

battery terminal

Connect terminal 6

to the positive

battery terminalThe lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal 6

to the negative

battery terminal

Connect terminal 4

to the positive

battery terminalThe lever moves

from the

"UNLOCK" position

to the "LOCK"

position.

Page 137 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-137

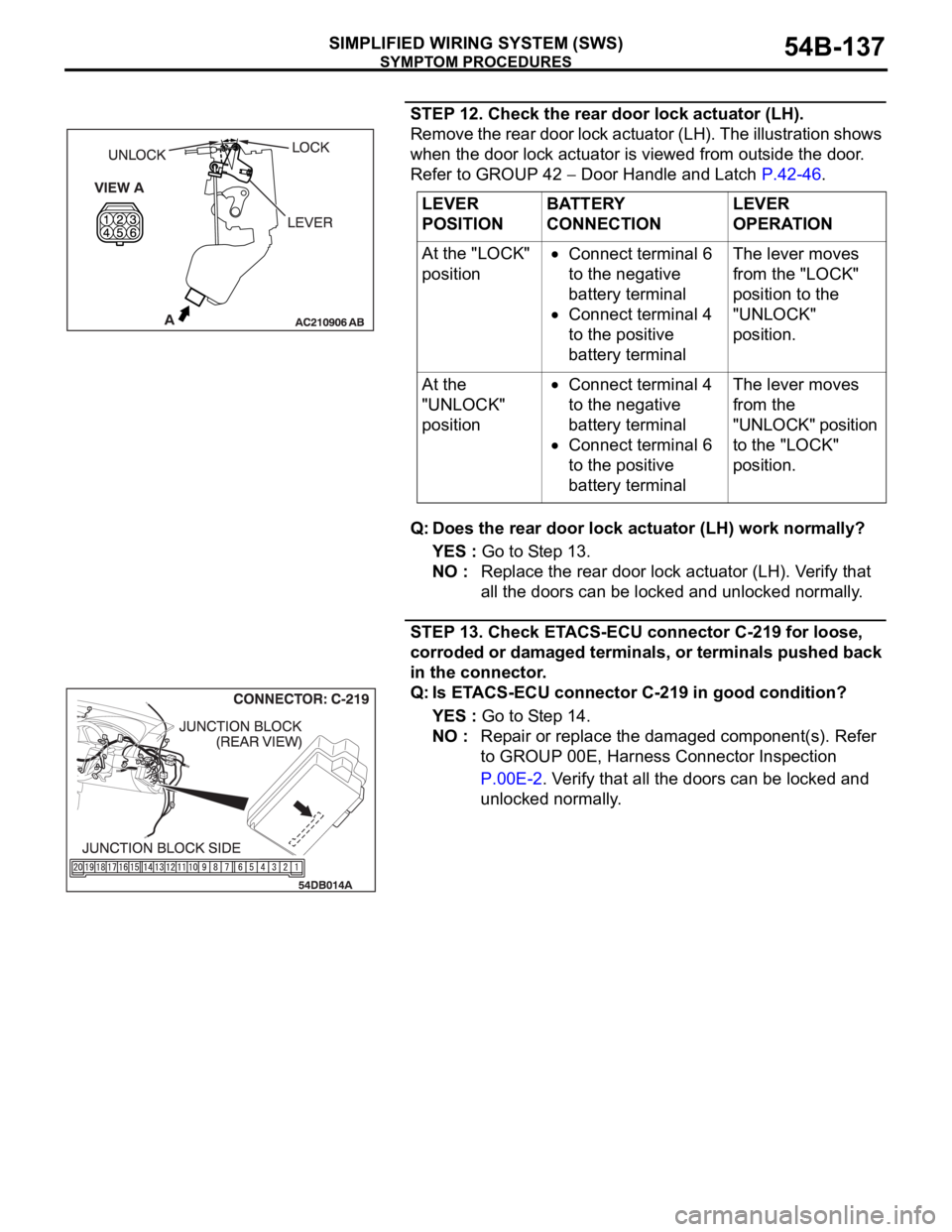

STEP 12. Check the rear door lock actuator (LH).

Remove the rear door lock actuator (LH). The illustration shows

when the door lock actuator is viewed from outside the door.

Refer to GROUP 42

Door Handle and Latch P.42-46.

Q: Does the rear door lock actuator (LH) work normally?

YES : Go to Step 13.

NO : Replace the rear door lock actuator (LH). Verify that

all the doors can be locked and unlocked normally.

STEP 13. Check ETACS-ECU connector C-219 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is ETACS-ECU connector C-219 in good condition?

YES : Go to Step 14.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that all the doors can be locked and

unlocked normally. LEVER

POSITIONBATTERY

CONNECTIONLEVER

OPERATION

At the "LOCK"

position

Connect terminal 6

to the negative

battery terminal

Connect terminal 4

to the positive

battery terminalThe lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal 4

to the negative

battery terminal

Connect terminal 6

to the positive

battery terminalThe lever moves

from the

"UNLOCK" position

to the "LOCK"

position.

Page 139 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-139

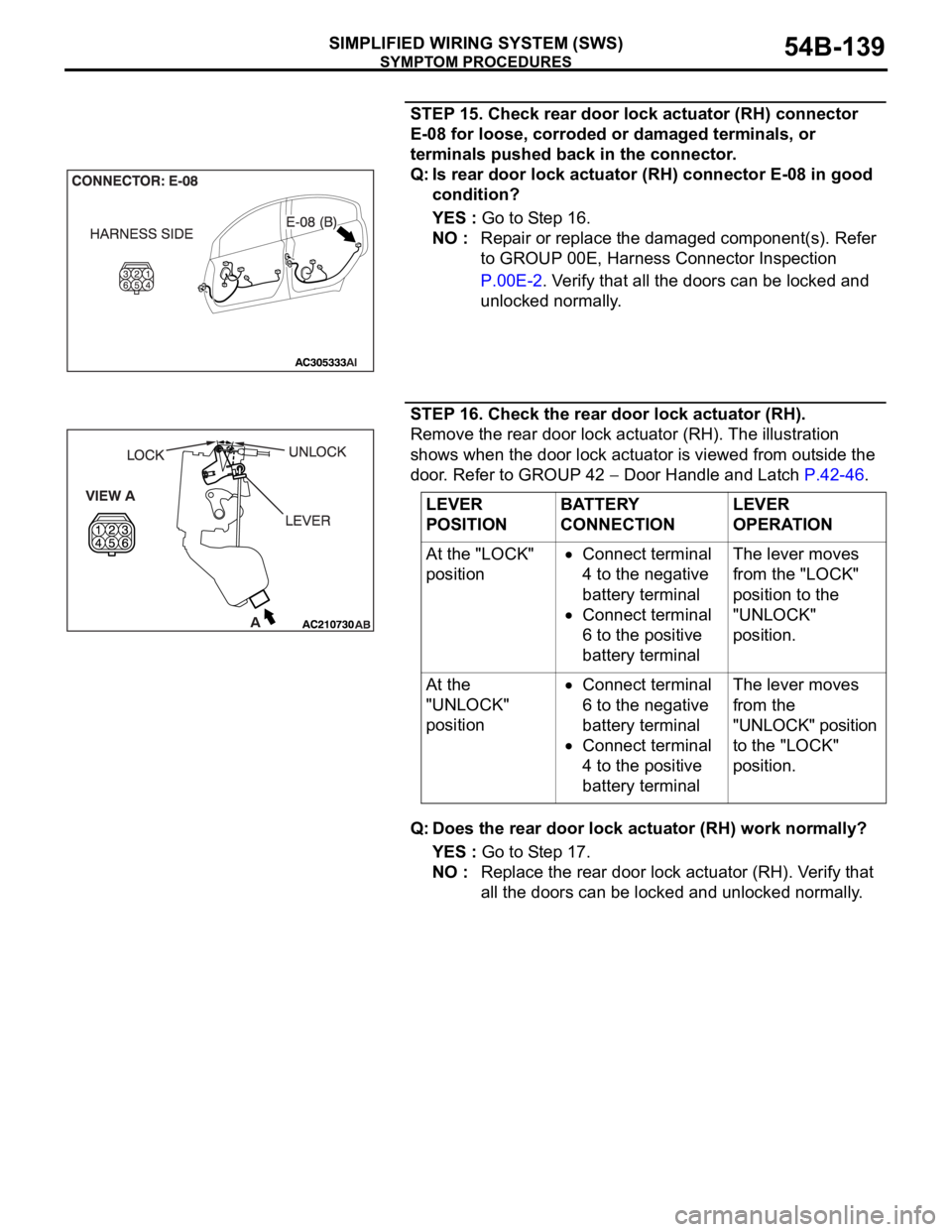

STEP 15. Check rear door lock actuator (RH) connector

E-08 for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Is rear door lock actuator (RH) connector E-08 in good

condition?

YES : Go to Step 16.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that all the doors can be locked and

unlocked normally.

STEP 16. Check the rear door lock actuator (RH).

Remove the rear door lock actuator (RH). The illustration

shows when the door lock actuator is viewed from outside the

door. Refer to GROUP 42

Door Handle and Latch P.42-46.

Q: Does the rear door lock actuator (RH) work normally?

YES : Go to Step 17.

NO : Replace the rear door lock actuator (RH). Verify that

all the doors can be locked and unlocked normally.

LEVER

POSITIONBATTERY

CONNECTIONLEVER

OPERATION

At the "LOCK"

position

Connect terminal

4 to the negative

battery terminal

Connect terminal

6 to the positive

battery terminalThe lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal

6 to the negative

battery terminal

Connect terminal

4 to the positive

battery terminalThe lever moves

from the

"UNLOCK" position

to the "LOCK"

position.

Page 154 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-154

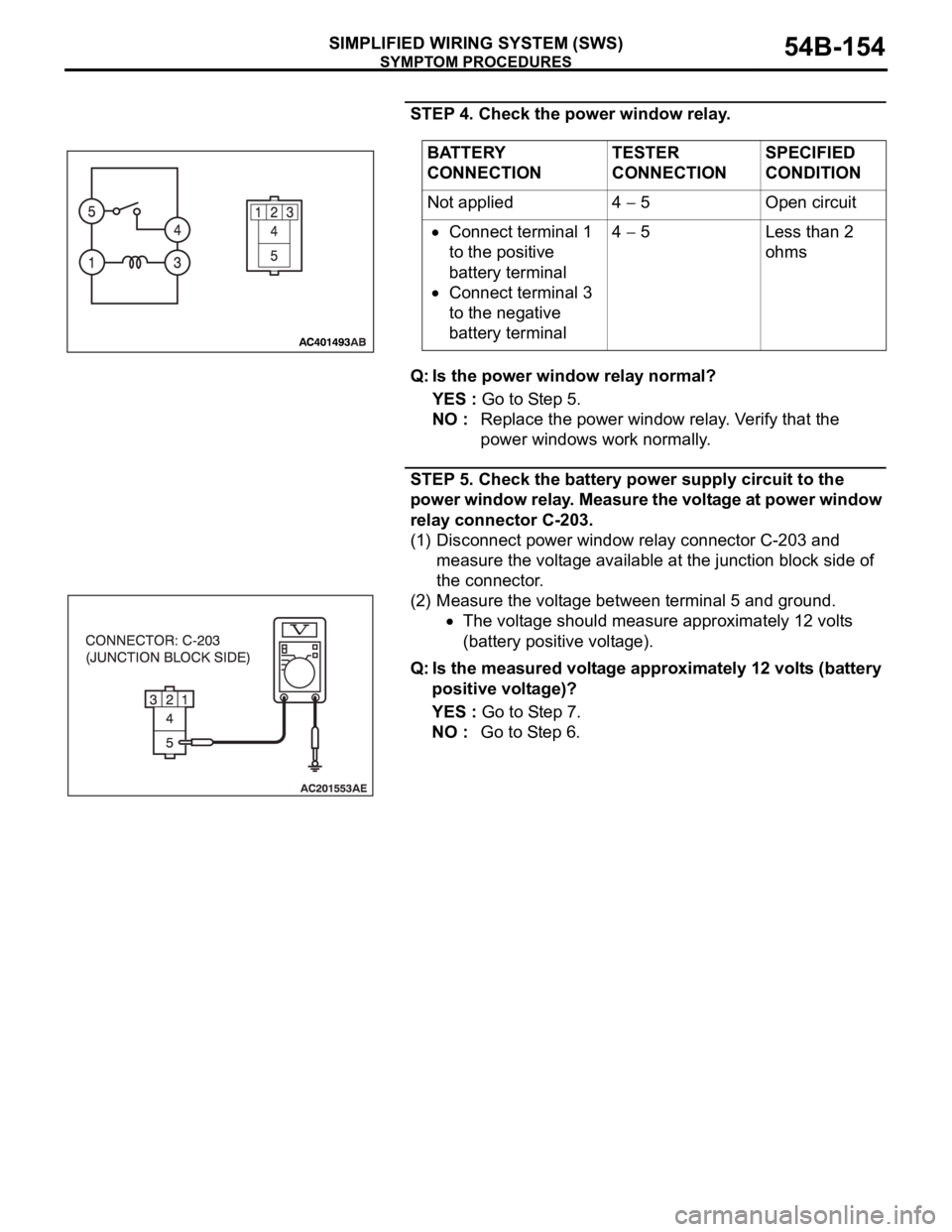

STEP 4. Check the power window relay.

Q: Is the power window relay normal?

YES : Go to Step 5.

NO : Replace the power window relay. Verify that the

power windows work normally.

STEP 5. Check the battery power supply circuit to the

power window relay. Measure the voltage at power window

relay connector C-203.

(1) Disconnect power window relay connector C-203 and

measure the voltage available at the junction block side of

the connector.

(2) Measure the voltage between terminal 5 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 7.

NO : Go to Step 6. BATTERY

CONNECTIONTESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 4

5 Open circuit

Connect terminal 1

to the positive

battery terminal

Connect terminal 3

to the negative

battery terminal4

5 Less than 2

ohms