trunk release MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 876 of 1500

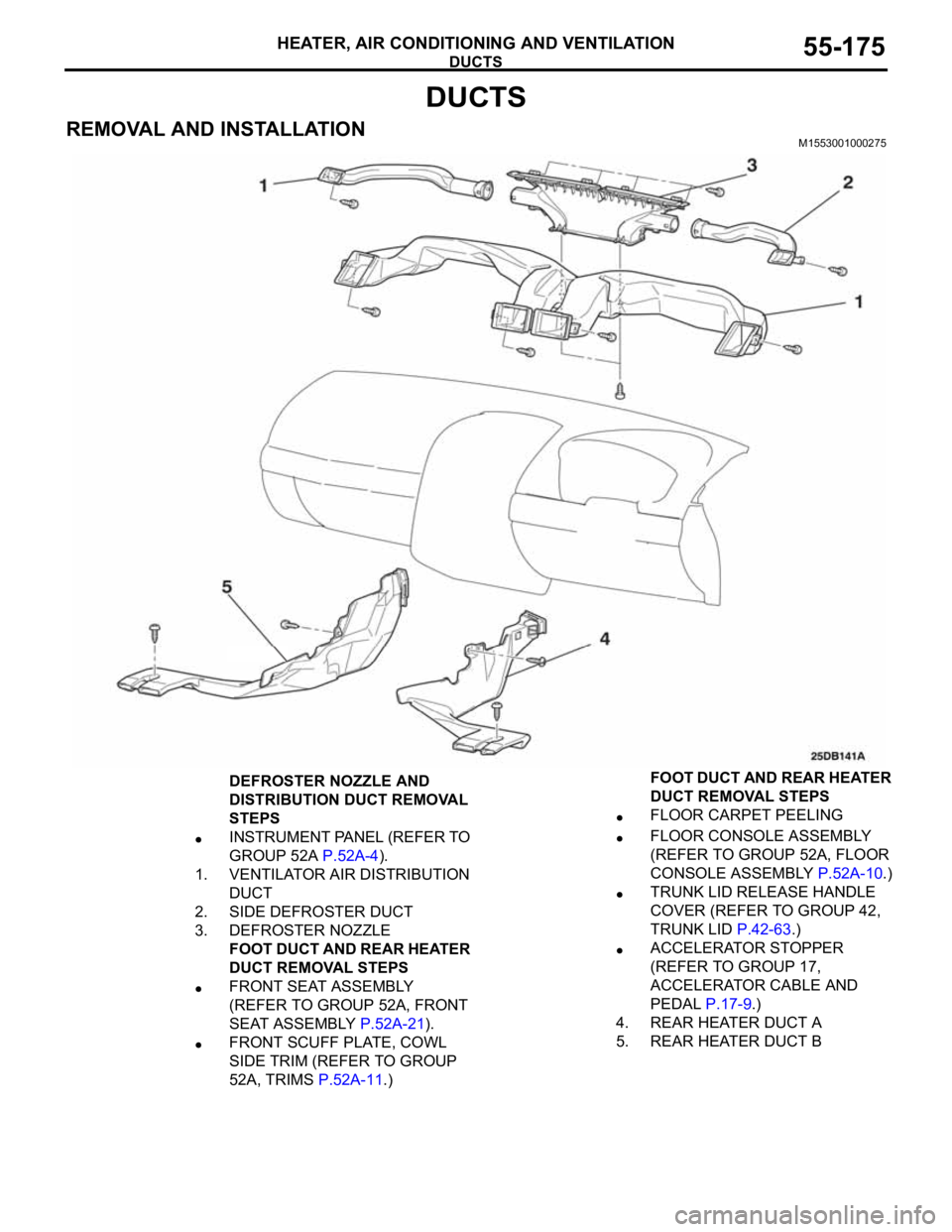

DUCTS

HEATER, AIR CONDITIONING AND VENTILATION55-175

DUCTS

REMOVAL AND INSTALLATIONM1553001000275

DEFROSTER NOZZLE AND

DISTRIBUTION DUCT REMOVAL

STEPS

INSTRUMENT PANEL (REFER TO

GROUP 52A P.52A-4).

1. VENTILATOR AIR DISTRIBUTION

DUCT

2. SIDE DEFROSTER DUCT

3. DEFROSTER NOZZLE

FOOT DUCT AND REAR HEATER

DUCT REMOVAL STEPS

FRONT SEAT ASSEMBLY

(REFER TO GROUP 52A, FRONT

SEAT ASSEMBLY P.52A-21).

FRONT SCUFF PLATE, COWL

SIDE TRIM (REFER TO GROUP

52A, TRIMS P.52A-11.)

FLOOR CARPET PEELING

FLOOR CONSOLE ASSEMBLY

(REFER TO GROUP 52A, FLOOR

CONSOLE ASSEMBLY P.52A-10.)

TRUNK LID RELEASE HANDLE

COVER (REFER TO GROUP 42,

TRUNK LID P.42-63.)

ACCELERATOR STOPPER

(REFER TO GROUP 17,

ACCELERATOR CABLE AND

PEDAL P.17-9.)

4. REAR HEATER DUCT A

5. REAR HEATER DUCT BFOOT DUCT AND REAR HEATER

DUCT REMOVAL STEPS

Page 1026 of 1500

CROSSMEMBER

POWER PLANT MOUNT32-9

CROSSMEMBER

REMOVAL AND INSTALLATIONM1321003200551

Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions (P.52B-16), Air bag Module and Clock Spring (P.52B-237). Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

*1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

*2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the ground in the unladen condition.

Pre-removal Operation

Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service Fluid Replacement P.37-18).

Power Steering Hoses Removal and Installation (Refer to

GROUP 37, Power Steering Hoses P.37A-57).

Air Bag Module and Steering Wheel Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-23).

Clock Spring Removal (Refer to GROUP 52B, Air Bag

Module and Clock Spring P.52B-237).

Floor Console Assembly Removal (Refer to GROUP 52A,

Floor Console Assembly P.52A-10).

Front Scuff Plate (LH) and Cowl Side Trim (LH) Removal

(Refer to GROUP 52A, Trims P.52A-11).

Trunk Lid Release Handle Cover Removal (Refer to

GROUP 42, Trunk Lid P.42-63).

Accelerator Stopper Removal (Refer to GROUP 17,

Accelerator Pedal P.17-9).

Front Floor Carpet Removal

Centremember Removal (Refer to P.32-7).Post-installation Operation

Centremember Installation (Refer to P.32-7).

Front Floor Carpet Installation

Accelerator Stopper Installation (Refer to GROUP 17,

Accelerator Pedal P.17-9).

Trunk Lid Release Handle Cover Installation (Refer to

GROUP 42, Trunk Lid P.42-63).

Front Scuff Plate (LH) and Cowl Side Trim (LH) Installa-

tion (Refer to GROUP 52A, Trims P.52A-11).

Floor Console Assembly Installation (Refer to GROUP

52A, Floor Console Assembly P.52A-10).

Clock Spring Installation (Refer to GROUP 52B, Air Bag

Module and Clock Spring P.52B-237).

Steering Wheel Assembly and Air Bag Module Installation

(Refer to P.37-23).

Check the dust cover for cracks or damage by pushing it

with your finger.

Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service Fluid Replacement P.37-18).

Power Steering Fluid Line Bleeding (Refer to P.37-18).

Checking Steering Wheel Position with Wheels Straight

Ahead.

Front Wheel Alignment Adjustment (Refer to GROUP 33,

On-vehicle Service

Front Wheel Alignment Check and

Adjustment P.33-6).

Page 1128 of 1500

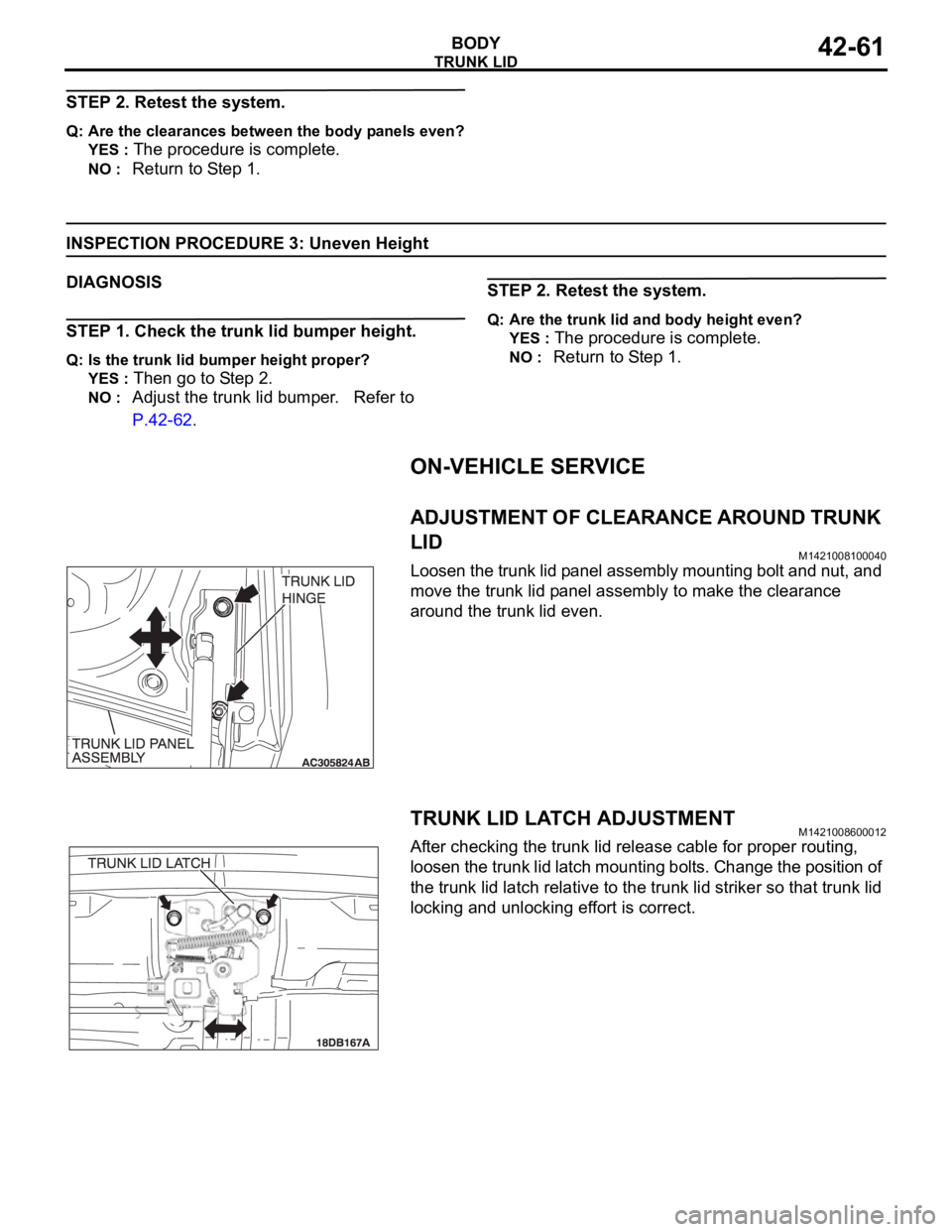

TRUNK LID

BODY42-61

STEP 2. Retest the system.

Q: Are the clearances between the body panels even?

YES :

The procedure is complete.

NO : Return to Step 1.

INSPECTION PROCEDURE 3: Uneven Height

DIAGNOSIS

STEP 1. Check the trunk lid bumper height.

Q: Is the trunk lid bumper height proper?

YES :

Then go to Step 2.

NO : Adjust the trunk lid bumper. Refer to

P.42-62.

STEP 2. Retest the system.

Q: Are the trunk lid and body height even?

YES :

The procedure is complete.

NO : Return to Step 1.

ON-VEHICLE SERVICE

ADJUSTMENT OF CLEARANCE AROUND TRUNK

LID

M1421008100040

Loosen the trunk lid panel assembly mounting bolt and nut, and

move the trunk lid panel assembly to make the clearance

around the trunk lid even.

TRUNK LID LATCH ADJUSTMENTM1421008600012

After checking the trunk lid release cable for proper routing,

loosen the trunk lid latch mounting bolts. Change the position of

the trunk lid latch relative to the trunk lid striker so that trunk lid

locking and unlocking effort is correct.

Page 1130 of 1500

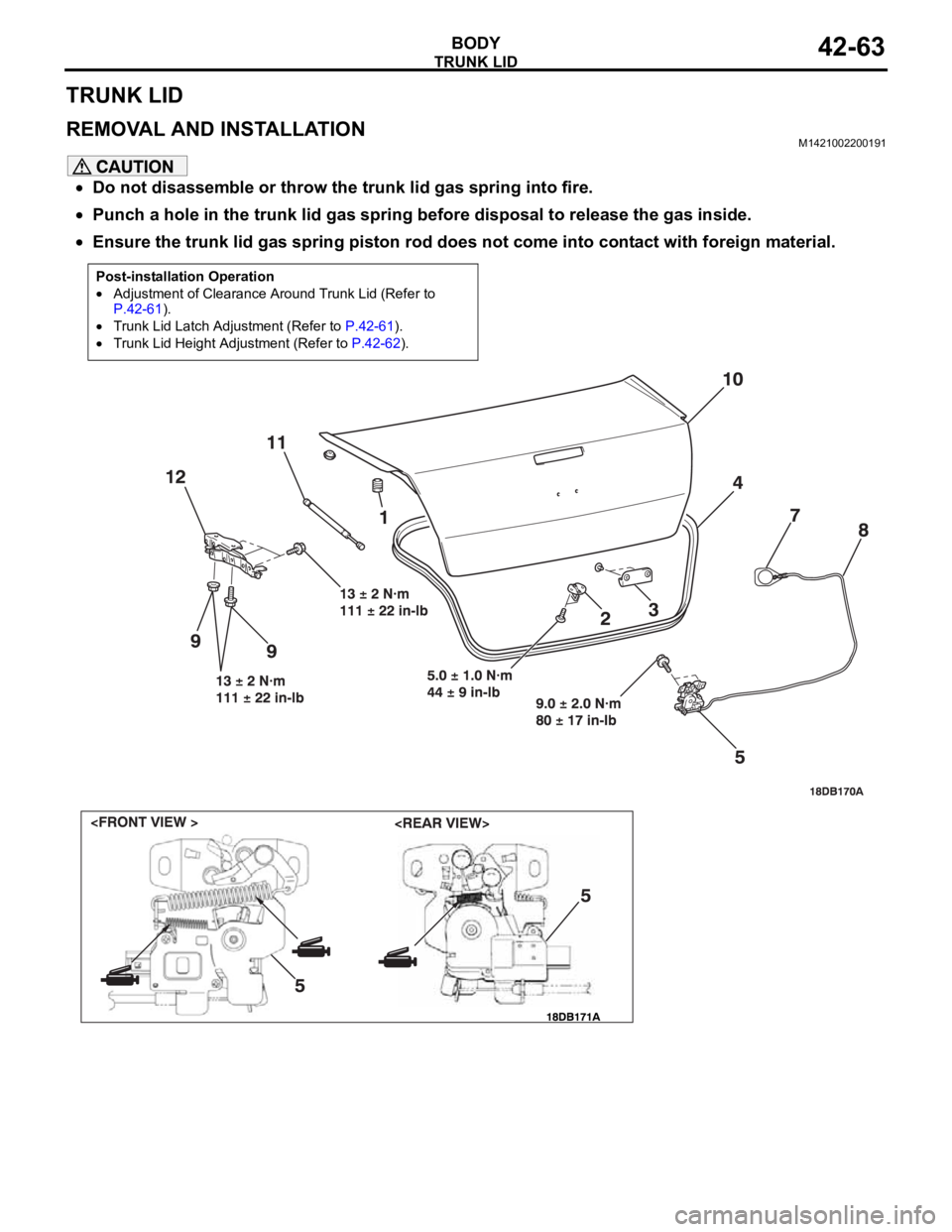

TRUNK LID

BODY42-63

TRUNK LID

REMOVAL AND INSTALLATIONM1421002200191

Do not disassemble or throw the trunk lid gas spring into fire.

Punch a hole in the trunk lid gas spring before disposal to release the gas inside.

Ensure the trunk lid gas spring piston rod does not come into contact with foreign material.

Post-installation Operation

Adjustment of Clearance Around Trunk Lid (Refer to

P.42-61).

Trunk Lid Latch Adjustment (Refer to P.42-61).

Trunk Lid Height Adjustment (Refer to P.42-62).

Page 1131 of 1500

TRUNK LID

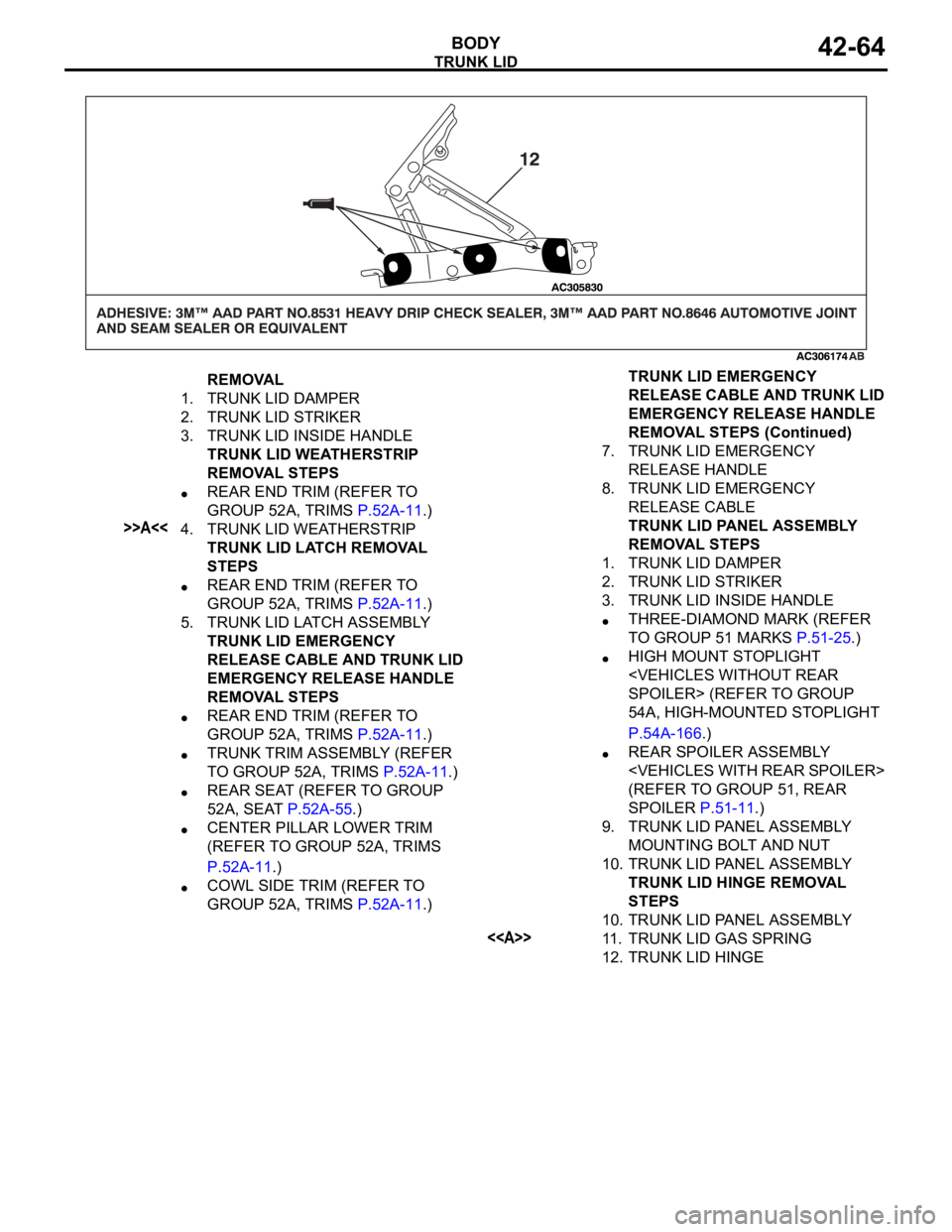

BODY42-64

REMOVAL

1. TRUNK LID DAMPER

2. TRUNK LID STRIKER

3. TRUNK LID INSIDE HANDLE

TRUNK LID WEATHERSTRIP

REMOVAL STEPS

REAR END TRIM (REFER TO

GROUP 52A, TRIMS P.52A-11.)

>>A<<4. TRUNK LID WEATHERSTRIP

TRUNK LID LATCH REMOVAL

STEPS

REAR END TRIM (REFER TO

GROUP 52A, TRIMS P.52A-11.)

5. TRUNK LID LATCH ASSEMBLY

TRUNK LID EMERGENCY

RELEASE CABLE AND TRUNK LID

EMERGENCY RELEASE HANDLE

REMOVAL STEPS

REAR END TRIM (REFER TO

GROUP 52A, TRIMS P.52A-11.)

TRUNK TRIM ASSEMBLY (REFER

TO GROUP 52A, TRIMS P.52A-11.)

REAR SEAT (REFER TO GROUP

52A, SEAT P.52A-55.)

CENTER PILLAR LOWER TRIM

(REFER TO GROUP 52A, TRIMS

P.52A-11.)

COWL SIDE TRIM (REFER TO

GROUP 52A, TRIMS P.52A-11.)7. TRUNK LID EMERGENCY

RELEASE HANDLE

8. TRUNK LID EMERGENCY

RELEASE CABLE

TRUNK LID PANEL ASSEMBLY

REMOVAL STEPS

1. TRUNK LID DAMPER

2. TRUNK LID STRIKER

3. TRUNK LID INSIDE HANDLE

THREE-DIAMOND MARK (REFER

TO GROUP 51 MARKS P.51-25.)

HIGH MOUNT STOPLIGHT

54A, HIGH-MOUNTED STOPLIGHT

P.54A-166.)

REAR SPOILER ASSEMBLY

(REFER TO GROUP 51, REAR

SPOILER P.51-11.)

9. TRUNK LID PANEL ASSEMBLY

MOUNTING BOLT AND NUT

10. TRUNK LID PANEL ASSEMBLY

TRUNK LID HINGE REMOVAL

STEPS

10. TRUNK LID PANEL ASSEMBLY

<>11. TRUNK LID GAS SPRING

12. TRUNK LID HINGETRUNK LID EMERGENCY

RELEASE CABLE AND TRUNK LID

EMERGENCY RELEASE HANDLE

REMOVAL STEPS (Continued)