horn MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 198 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-198

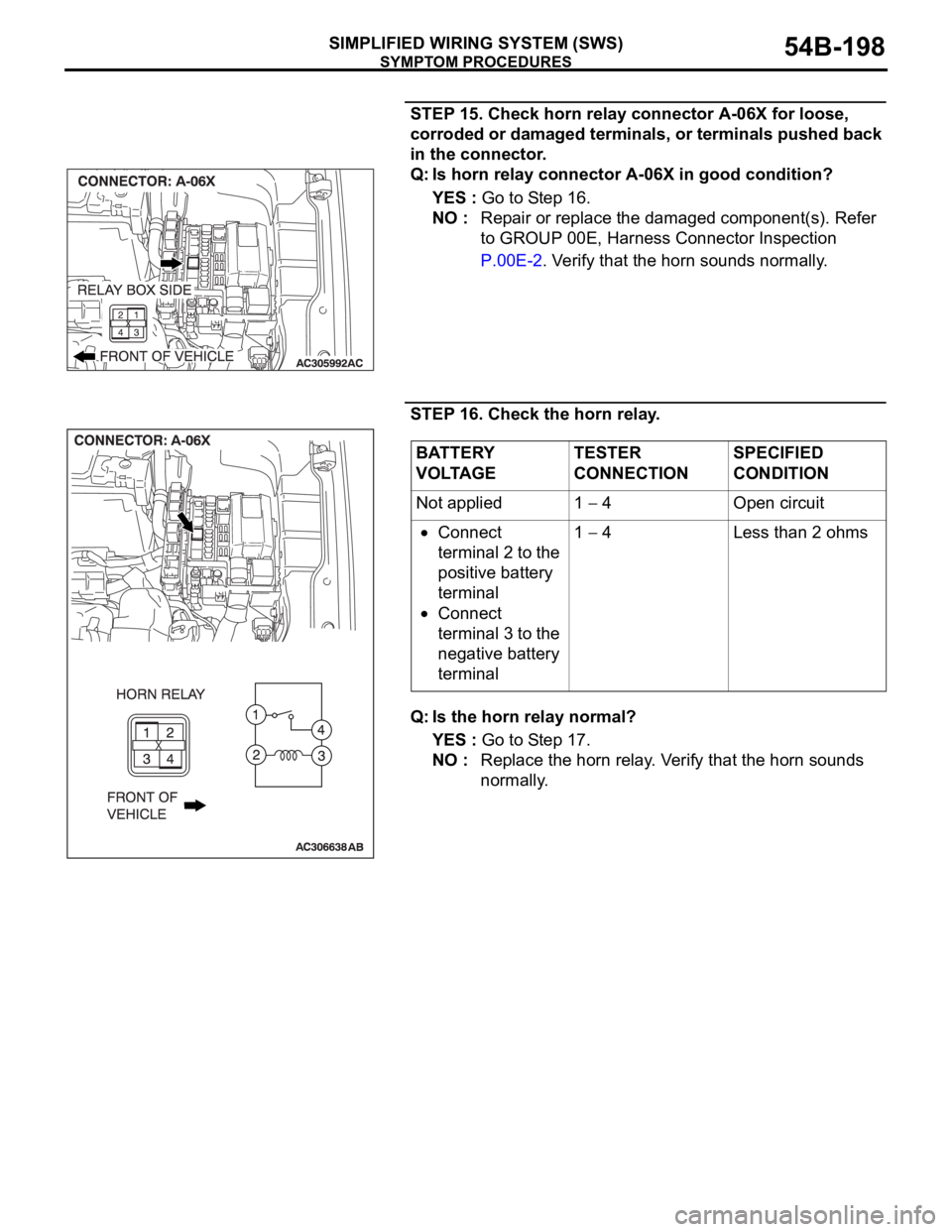

STEP 15. Check horn relay connector A-06X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is horn relay connector A-06X in good condition?

YES : Go to Step 16.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the horn sounds normally.

STEP 16. Check the horn relay.

Q: Is the horn relay normal?

YES : Go to Step 17.

NO : Replace the horn relay. Verify that the horn sounds

normally.

BATTERY

VOLTAGETESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 1

4 Open circuit

Connect

terminal 2 to the

positive battery

terminal

Connect

terminal 3 to the

negative battery

terminal1

4 Less than 2 ohms

Page 199 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-199

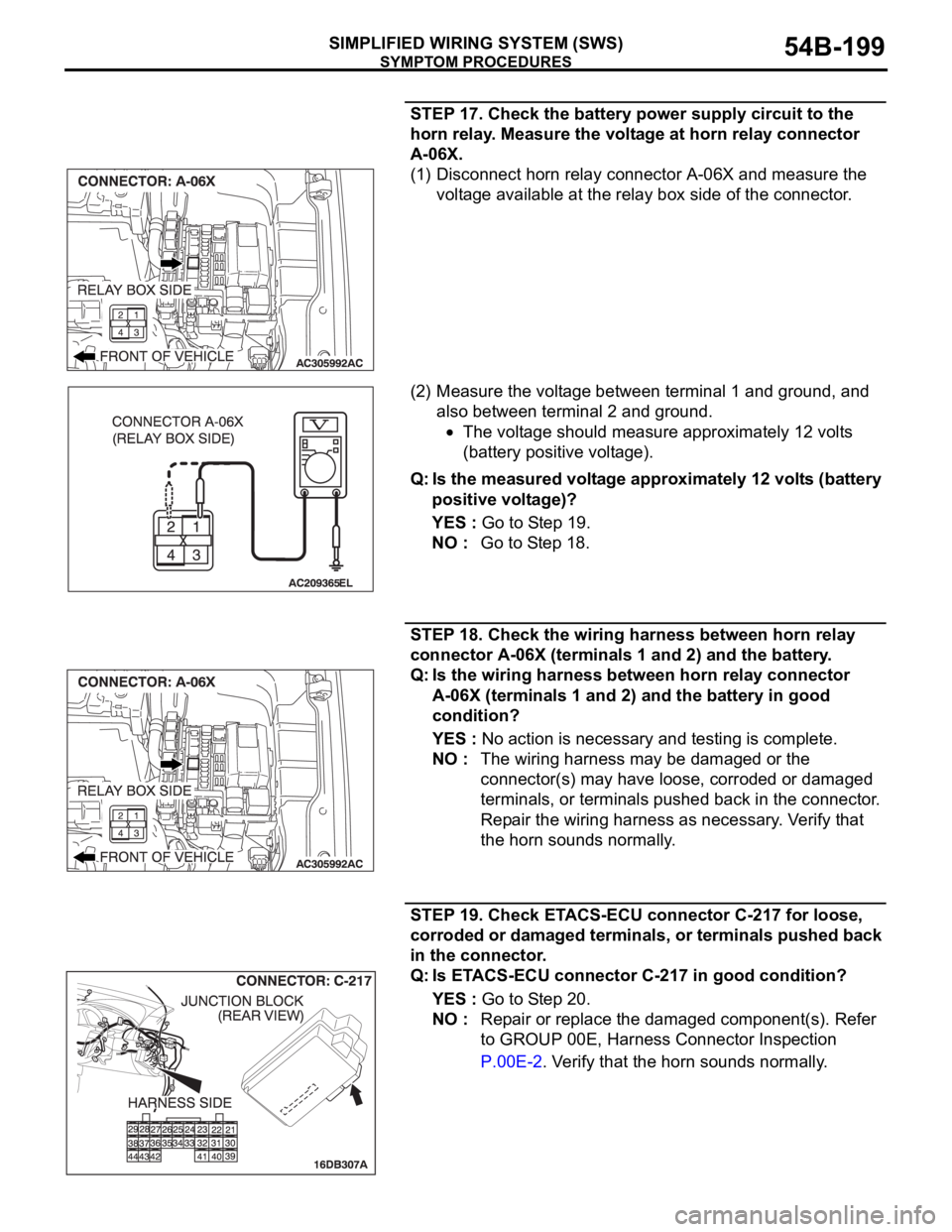

STEP 17. Check the battery power supply circuit to the

horn relay. Measure the voltage at horn relay connector

A-06X.

(1) Disconnect horn relay connector A-06X and measure the

voltage available at the relay box side of the connector.

(2) Measure the voltage between terminal 1 and ground, and

also between terminal 2 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 19.

NO : Go to Step 18.

STEP 18. Check the wiring harness between horn relay

connector A-06X (terminals 1 and 2) and the battery.

Q: Is the wiring harness between horn relay connector

A-06X (terminals 1 and 2) and the battery in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the horn sounds normally.

STEP 19. Check ETACS-ECU connector C-217 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is ETACS-ECU connector C-217 in good condition?

YES : Go to Step 20.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the horn sounds normally.

Page 200 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-200

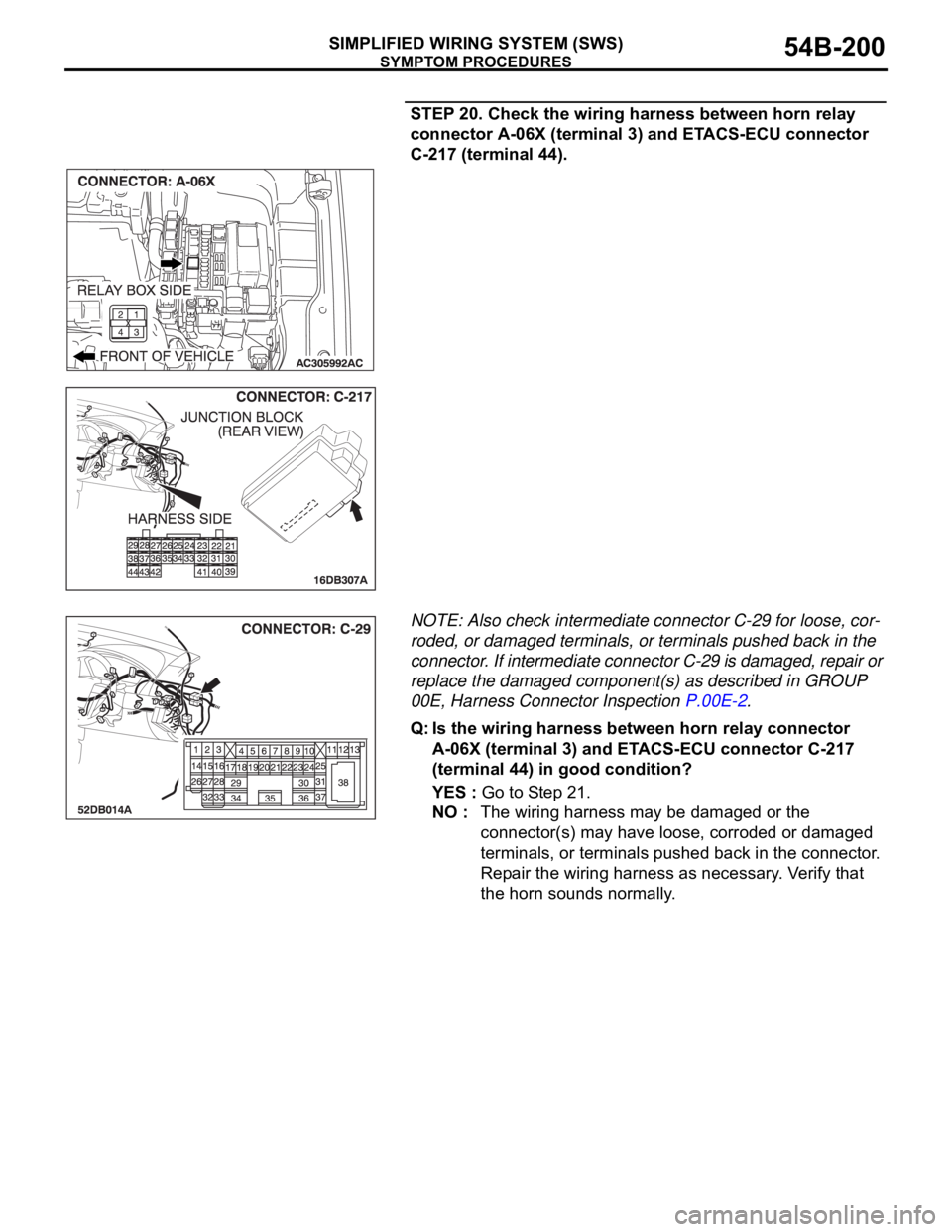

STEP 20. Check the wiring harness between horn relay

connector A-06X (terminal 3) and ETACS-ECU connector

C-217 (terminal 44).

NOTE: Also check intermediate connector C-29 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector C-29 is damaged, repair or

replace the damaged component(s) as described in GROUP

00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between horn relay connector

A-06X (terminal 3) and ETACS-ECU connector C-217

(terminal 44) in good condition?

YES : Go to Step 21.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the horn sounds normally.

Page 201 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-201

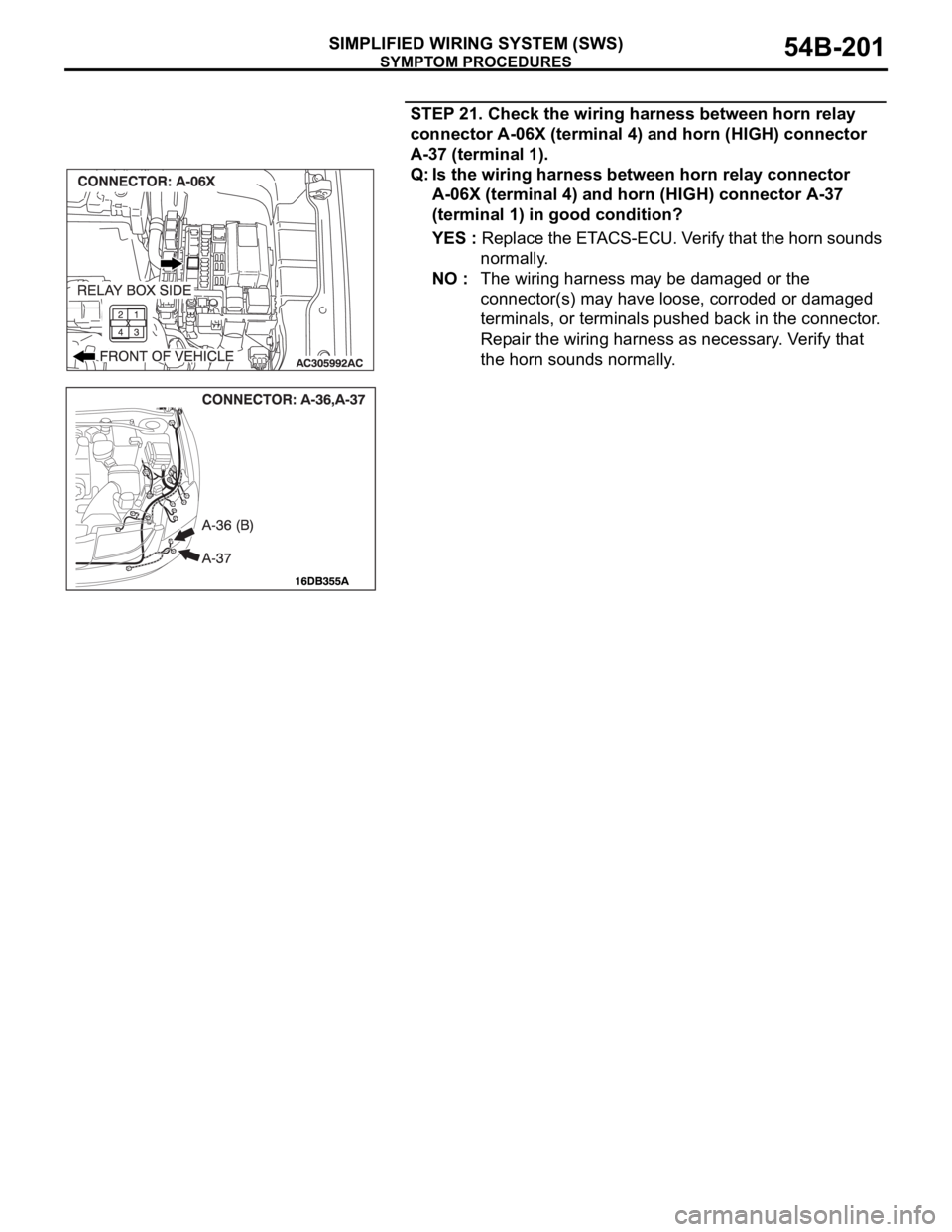

STEP 21. Check the wiring harness between horn relay

connector A-06X (terminal 4) and horn (HIGH) connector

A-37 (terminal 1).

Q: Is the wiring harness between horn relay connector

A-06X (terminal 4) and horn (HIGH) connector A-37

(terminal 1) in good condition?

YES : Replace the ETACS-ECU. Verify that the horn sounds

normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the horn sounds normally.

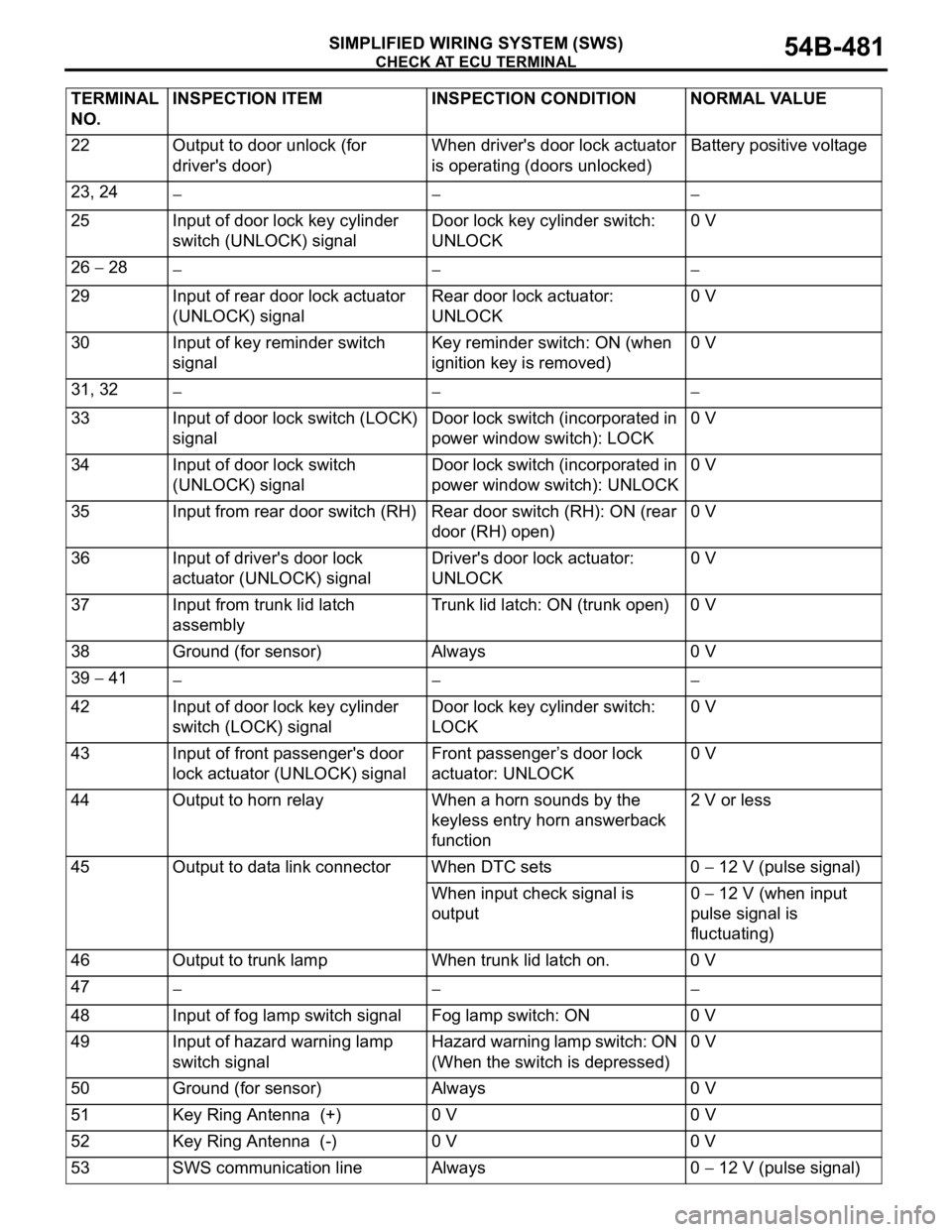

Page 481 of 1500

CHECK AT ECU TERMINAL

SIMPLIFIED WIRING SYSTEM (SWS)54B-481

22 Output to door unlock (for

driver's door)When driver's door lock actuator

is operating (doors unlocked)Battery positive voltage

23, 24

25 Input of door lock key cylinder

switch (UNLOCK) signalDoor lock key cylinder switch:

UNLOCK0 V

26

28

29 Input of rear door lock actuator

(UNLOCK) signalRear door lock actuator:

UNLOCK0 V

30 Input of key reminder switch

signalKey reminder switch: ON (when

ignition key is removed)0 V

31, 32

33 Input of door lock switch (LOCK)

signalDoor lock switch (incorporated in

power window switch): LOCK0 V

34 Input of door lock switch

(UNLOCK) signalDoor lock switch (incorporated in

power window switch): UNLOCK0 V

35 Input from rear door switch (RH) Rear door switch (RH): ON (rear

door (RH) open)0 V

36 Input of driver's door lock

actuator (UNLOCK) signalDriver's door lock actuator:

UNLOCK0 V

37 Input from trunk lid latch

assemblyTrunk lid latch: ON (trunk open) 0 V

38 Ground (for sensor) Always 0 V

39

41

42 Input of door lock key cylinder

switch (LOCK) signalDoor lock key cylinder switch:

LOCK0 V

43 Input of front passenger's door

lock actuator (UNLOCK) signalFront passenger’s door lock

actuator: UNLOCK0 V

44 Output to horn relay When a horn sounds by the

keyless entry horn answerback

function2 V or less

45 Output to data link connector When DTC sets 0

12 V (pulse signal)

When input check signal is

output0

12 V (when input

pulse signal is

fluctuating)

46 Output to trunk lamp When trunk lid latch on. 0 V

47

48 Input of fog lamp switch signal Fog lamp switch: ON 0 V

49 Input of hazard warning lamp

switch signalHazard warning lamp switch: ON

(When the switch is depressed)0 V

50 Ground (for sensor) Always 0 V

51 Key Ring Antenna (+) 0 V 0 V

52 Key Ring Antenna (-) 0 V 0 V

53 SWS communication line Always 0

12 V (pulse signal) TERMINAL

NO.INSPECTION ITEM INSPECTION CONDITION NORMAL VALUE

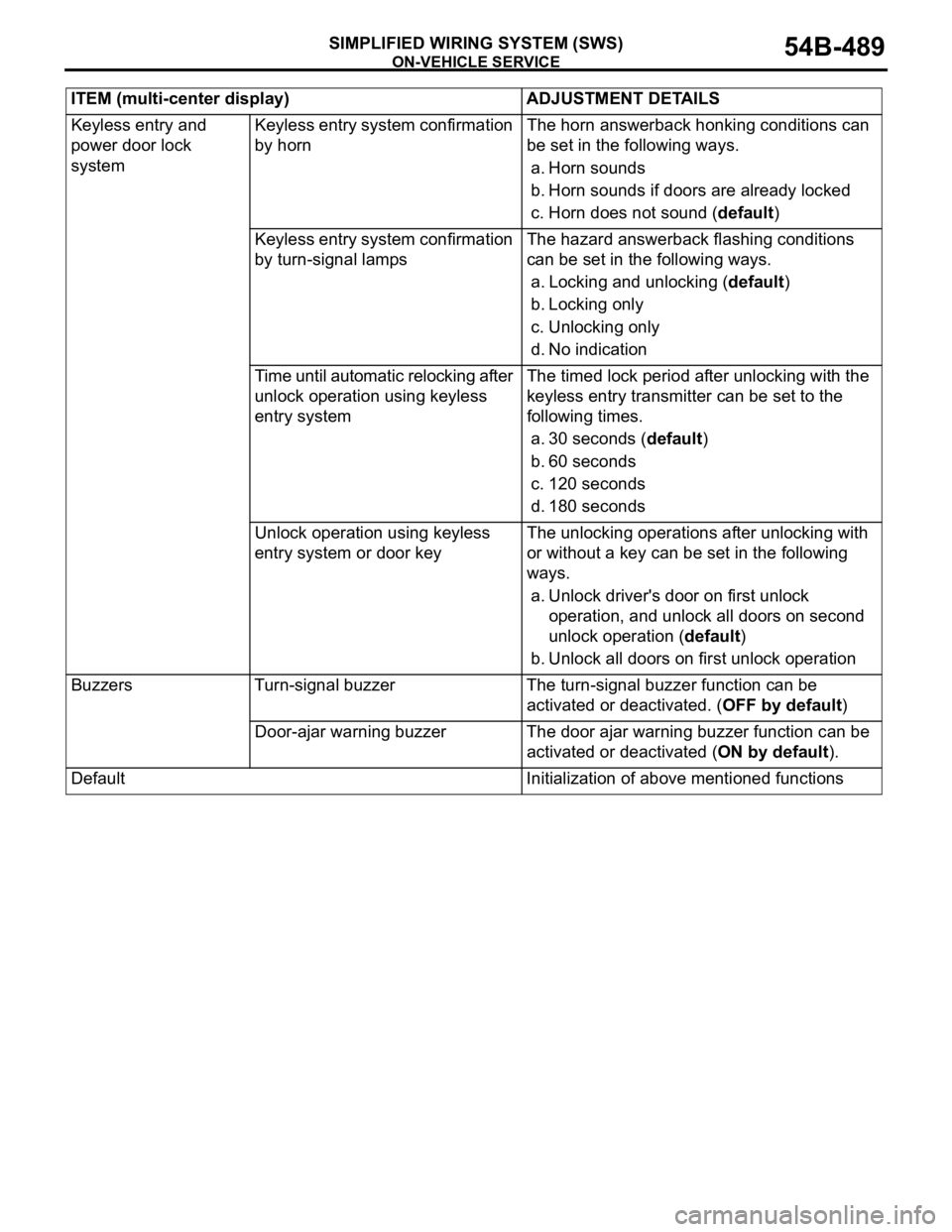

Page 489 of 1500

ON-VEHICLE SERVICE

SIMPLIFIED WIRING SYSTEM (SWS)54B-489

Keyless entry and

power door lock

systemKeyless entry system confirmation

by hornThe horn answerback honking conditions can

be set in the following ways.

a. Horn sounds

b. Horn sounds if doors are already locked

c. Horn does not sound (default)

Keyless entry system confirmation

by turn-signal lampsThe hazard answerback flashing conditions

can be set in the following ways.

a. Locking and unlocking (default)

b. Locking only

c. Unlocking only

d. No indication

Time until automatic relocking after

unlock operation using keyless

entry systemThe timed lock period after unlocking with the

keyless entry transmitter can be set to the

following times.

a. 30 seconds (default)

b. 60 seconds

c. 120 seconds

d. 180 seconds

Unlock operation using keyless

entry system or door keyThe unlocking operations after unlocking with

or without a key can be set in the following

ways.

a. Unlock driver's door on first unlock

operation, and unlock all doors on second

unlock operation (default)

b. Unlock all doors on first unlock operation

Buzzers Turn-signal buzzer The turn-signal buzzer function can be

activated or deactivated. (OFF by default)

Door-ajar warning buzzer The door ajar warning buzzer function can be

activated or deactivated (ON by default).

Default Initialization of above mentioned functions ITEM (multi-center display) ADJUSTMENT DETAILS

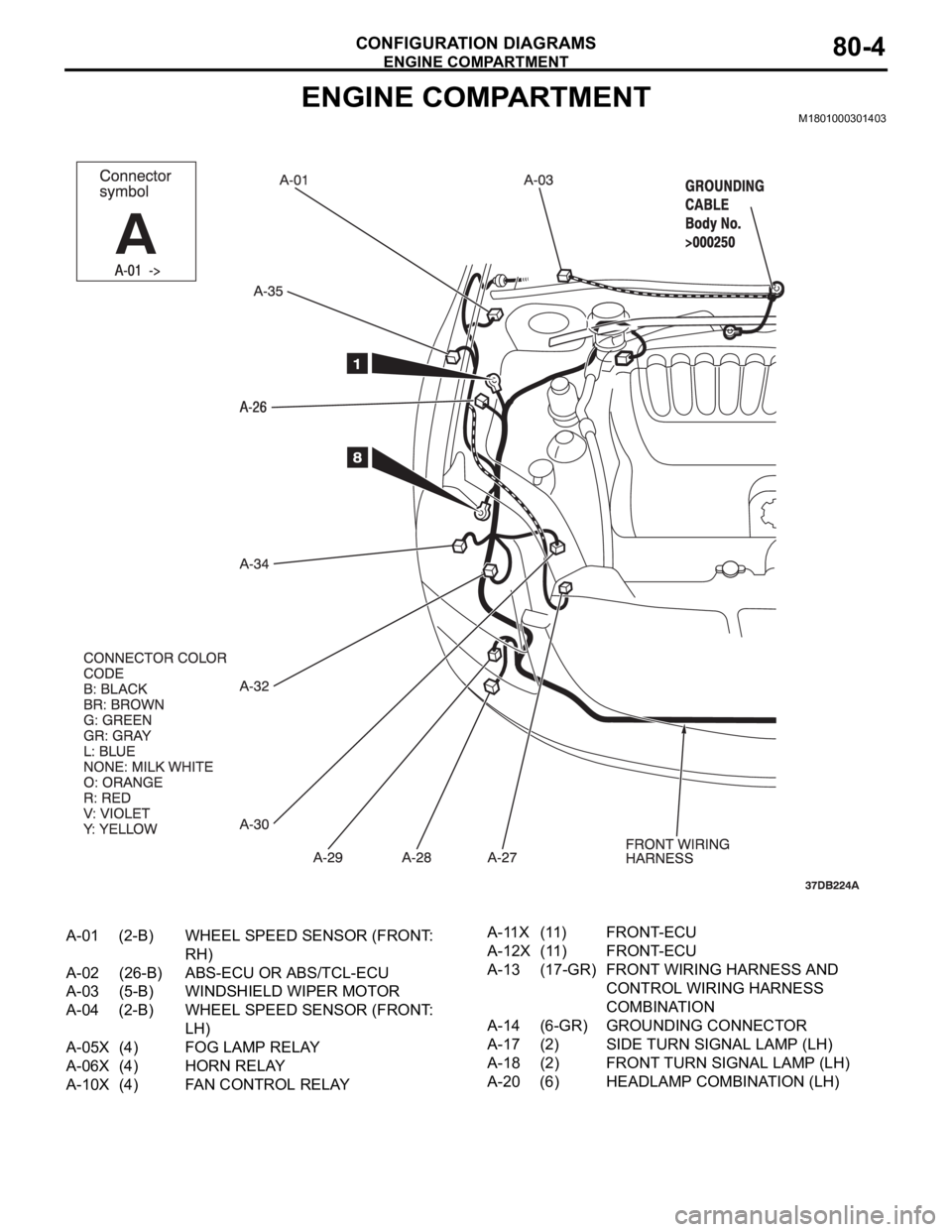

Page 553 of 1500

ENGINE COMPARTMENT

CONFIGURATION DIAGRAMS80-4

ENGINE COMPARTMENTM1801000301403

A-01 (2-B) WHEEL SPEED SENSOR (FRONT:

RH)

A-02 (26-B) ABS-ECU OR ABS/TCL-ECU

A-03 (5-B) WINDSHIELD WIPER MOTOR

A-04 (2-B) WHEEL SPEED SENSOR (FRONT:

LH)

A-05X (4) FOG LAMP RELAY

A-06X (4) HORN RELAY

A-10X (4) FAN CONTROL RELAYA-11X (11) FRONT-ECU

A-12X (11) FRONT-ECU

A-13 (17-GR) FRONT WIRING HARNESS AND

CONTROL WIRING HARNESS

COMBINATION

A-14 (6-GR) GROUNDING CONNECTOR

A-17 (2) SIDE TURN SIGNAL LAMP (LH)

A-18 (2) FRONT TURN SIGNAL LAMP (LH)

A-20 (6) HEADLAMP COMBINATION (LH)

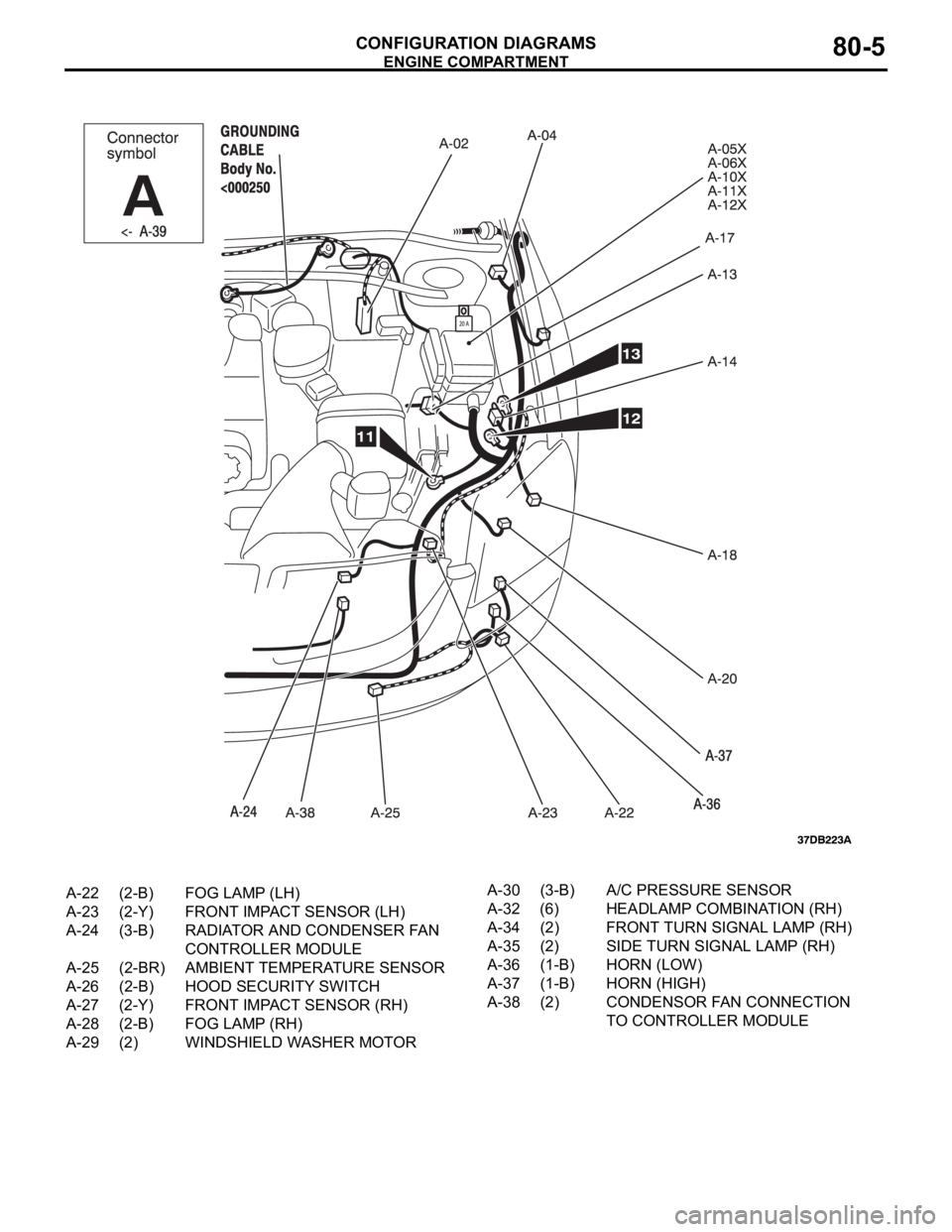

Page 554 of 1500

ENGINE COMPARTMENT

CONFIGURATION DIAGRAMS80-5

A-22 (2-B) FOG LAMP (LH)

A-23 (2-Y) FRONT IMPACT SENSOR (LH)

A-24 (3-B) RADIATOR AND CONDENSER FAN

CONTROLLER MODULE

A-25 (2-BR) AMBIENT TEMPERATURE SENSOR

A-26 (2-B) HOOD SECURITY SWITCH

A-27 (2-Y) FRONT IMPACT SENSOR (RH)

A-28 (2-B) FOG LAMP (RH)

A-29 (2) WINDSHIELD WASHER MOTORA-30 (3-B) A/C PRESSURE SENSOR

A-32 (6) HEADLAMP COMBINATION (RH)

A-34 (2) FRONT TURN SIGNAL LAMP (RH)

A-35 (2) SIDE TURN SIGNAL LAMP (RH)

A-36 (1-B) HORN (LOW)

A-37 (1-B) HORN (HIGH)

A-38 (2) CONDENSOR FAN CONNECTION

TO CONTROLLER MODULE

Page 565 of 1500

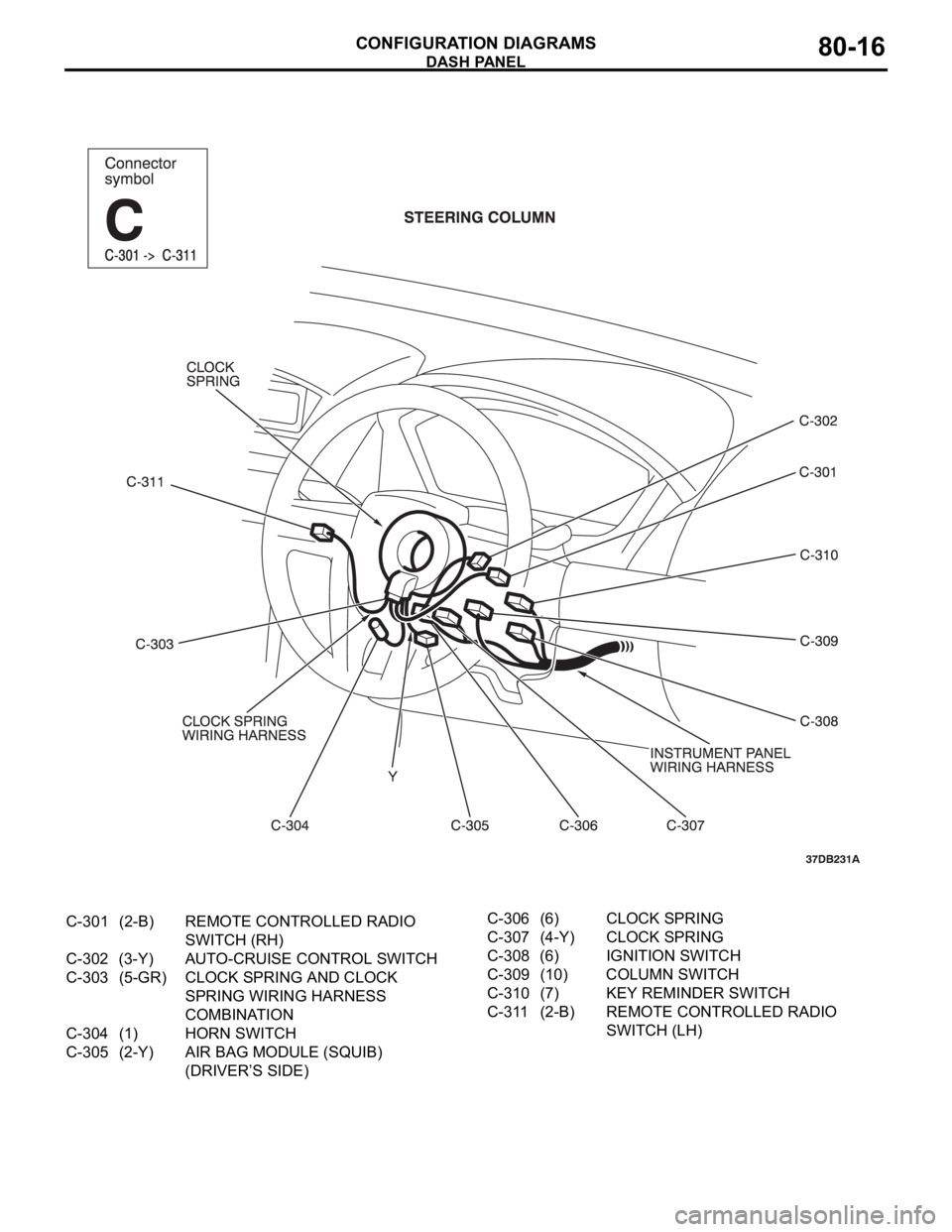

DASH PANEL

CONFIGURATION DIAGRAMS80-16

C-301 (2-B) REMOTE CONTROLLED RADIO

SWITCH (RH)

C-302 (3-Y) AUTO-CRUISE CONTROL SWITCH

C-303 (5-GR) CLOCK SPRING AND CLOCK

SPRING WIRING HARNESS

COMBINATION

C-304 (1) HORN SWITCH

C-305 (2-Y) AIR BAG MODULE (SQUIB)

(DRIVER’S SIDE)C-306 (6) CLOCK SPRING

C-307 (4-Y) CLOCK SPRING

C-308 (6) IGNITION SWITCH

C-309 (10) COLUMN SWITCH

C-310 (7) KEY REMINDER SWITCH

C-311 (2-B) REMOTE CONTROLLED RADIO

SWITCH (LH)

Page 578 of 1500

90-1

GROUP 90

CIRCUIT DIAGRAMS

CONTENTS

HOW TO READ CIRCUIT DIAGRAMS90-3

JUNCTION BLOCK . . . . . . . . . . . . . .90-9

JOINT CONNECTOR . . . . . . . . . . . . .90-11

CENTRALISED JUNCTION . . . . . . . .90-12

POWER DISTRIBUTION SYSTEM . .90-18

STARTING SYSTEM . . . . . . . . . . . . .90-21

IGNITION SYSTEM . . . . . . . . . . . . . .90-22

CHARGING SYSTEM . . . . . . . . . . . .90-23

MULTIPOINT FUEL INJECTION (MPI)

SYSTEM . . . . . . . . . . . . . . . . . . . . . . .90-24

COOLING SYSTEM . . . . . . . . . . . . . .90-29

INVECS-II 5A/T . . . . . . . . . . . . . . . . .90-30

HEADLAMPS . . . . . . . . . . . . . . . . . . .90-35

TAIL LAMP, POSITION LAMP, AND

LICENCE PLATE LAMP . . . . . . . . . .90-38

FOG LAMPS . . . . . . . . . . . . . . . . . . .90-41FRONT DOME LAMP, REAR DOME LAMP,

TRUNK LAMP AND IGNITION KEY HOLE

ILLUMINATION LAMP . . . . . . . . . . . .90-44

GLOVE BOX LAMP . . . . . . . . . . . . . .90-48

VANITY MIRROR LAMP. . . . . . . . . . .90-49

TURN-SIGNAL LAMP AND HAZARD

WARNING LAMP . . . . . . . . . . . . . . . .90-50

BACKUP LAMP . . . . . . . . . . . . . . . . .90-54

STOPLAMP. . . . . . . . . . . . . . . . . . . . .90-55

HORN . . . . . . . . . . . . . . . . . . . . . . . . .90-56

METER AND GAUGE . . . . . . . . . . . . .90-57

BRAKE WARNING LAMP, OIL

PRESSURE WARNING LAMP, FUEL

WARNING LAMP . . . . . . . . . . . . . . . .90-60

POWER WINDOWS . . . . . . . . . . . . . .90-62

CENTRAL DOOR LOCKING

SYSTEM . . . . . . . . . . . . . . . . . . . . . . .90-64

Continued on next page