oil pressure MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 977 of 1500

SPECIFICATIONS

INTAKE AND EXHAUST15-18

SERVICE SPECIFICATIONM1151000300462

SEALANTSM1151000500187

Intake manifold plenum

Evaporative emission purge solenoid bolt 9.0

1.0 Nm (80 9 in-lb)

Harness bracket bolt 11

1 Nm (98 8 in-lb)

Intake manifold plenum bolt 18

2 Nm (13 2 ft-lb)

Intake manifold plenum stay bolt M8 18

2 Nm (13 2 ft-lb)

M10 36

6 Nm (27 4 ft-lb)

Manifold absolute pressure sensor bolt 5.0

1.0 Nm (44 9 in-lb)

Power steering pressure hose clamp nut 12

2 Nm (102 22 in-lb)

Power steering pressure hose clamp bracket bolt 12

2 Nm (102 22 in-lb)

Power steering oil pump bracket connecting bolt 41

8 Nm (30 6 ft-lb) ITEMSPECIFICATION

ITEM STANDARD VALUE LIMIT

Manifold distortion of the installation surface mm (in) 0.15 (0.006) or less 0.20 (0.008)

ITEM SPECIFIED SEALANT

Thermostat case assembly 3M

AAD Part No.8672, 3M AAD Part No.8679/8678 or

equivalent

Thermostat case assembly bolt 3M

AAD Part No. 8730, 8731 or equivalent

Page 1265 of 1500

MAINTENANCE SERVICE

GENERAL00-44

8. EXHAUST SYSTEM (CONNECTIONS PORTION

OF MUFFLER, MUFFLER PIPES AND

CONVERTER HEAT SHIELDS) (CHECK AND

SERVICE AS REQUIRED)

M1001005800299

1. Check for holes and exhaust gas leaks due to damage,

corrosion, etc.

2. Check the joints and connections for looseness and exhaust

gas leaks.

3. Check the rubber hangers and brackets for damage.

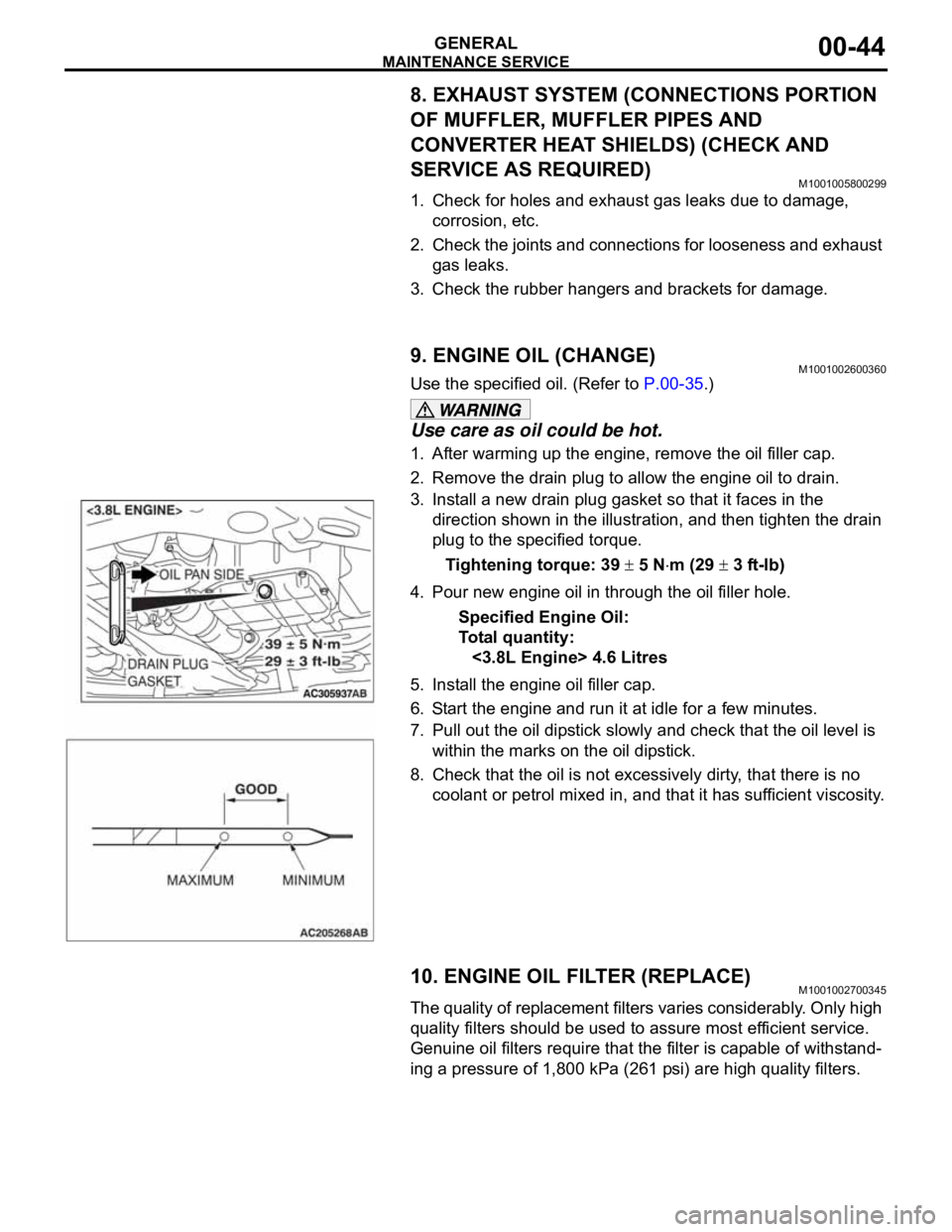

9. ENGINE OIL (CHANGE)M1001002600360

Use the specified oil. (Refer to P.00-35.)

Use care as oil could be hot.

1. After warming up the engine, remove the oil filler cap.

2. Remove the drain plug to allow the engine oil to drain.

3. Install a new drain plug gasket so that it faces in the

direction shown in the illustration, and then tighten the drain

plug to the specified torque.

Tightening torque: 39

5 Nm (29 3 ft-lb)

4. Pour new engine oil in through the oil filler hole.

Specified Engine Oil:

To ta l q u a n t i t y :

<3.8L Engine> 4.6 Litres

5. Install the engine oil filler cap.

6. Start the engine and run it at idle for a few minutes.

7. Pull out the oil dipstick slowly and check that the oil level is

within the marks on the oil dipstick.

8. Check that the oil is not excessively dirty, that there is no

coolant or petrol mixed in, and that it has sufficient viscosity.

10. ENGINE OIL FILTER (REPLACE)M1001002700345

The quality of replacement filters varies considerably. Only high

quality filters should be used to assure most efficient service.

Genuine oil filters require that the filter is capable of withstand-

ing a pressure of 1,800 kPa (261 psi) are high quality filters.

.

Page 1266 of 1500

MAINTENANCE SERVICE

GENERAL00-45

Engine Oil Filter Selection

This vehicle is equipped with a full-flow, throw-away oil filter.

The same type of filter is recommended as a replacement filter

for this vehicle. It is possible, particularly in cold weather, that

this vehicle may develop high oil pressure for a short duration.

Make sure that any replacement filter used on this vehicle is a

high-quality filter. The filter must withstand a pressure of 1,800

kPa (261 psi) [manufacturer's specifications] to avoid filter and

ultimately engine damage. The Genuine Mitsubishi high-quality

filter and is strongly recommended for use on this vehicle.

Any replacement oil filter should be installed in accordance with

the oil filter manufacturer's installation instructions.

.

Oil Filter Replacement

Use care as oil could be hot.

1. Drain the engine oil by removing the oil drain plug.

2. Use an oil filter wrench to remove the engine oil filter.

3. Clean the filter bracket side mounting surface and ensure

the old O-ring has been removed.

4. Apply a small amount of engine oil to the O-ring of the new

oil filter.

5. Where the oil filter O-ring touches the oil pan flange, tighten

the oil filter to the specified torque using the

commercially-available tool.

Tightening torque:

: Approximately 3/4 turn [14

2 Nm]

6. Add new engine oil through the oil filler.

11. TRANSMISSION FLUIDM1001002900338

TRANSMISSION FLUID CHECK

1. Drive the vehicle until the transmission fluid temperature

rises to the normal operating temperature [70

80C (158

176

F)].

NOTE: The transmission fluid temperature is measured with

Diagnostic Tool (MUT-III).

Page 1267 of 1500

![MITSUBISHI 380 2005 User Guide MAINTENANCE SERVICE

GENERAL00-46

NOTE: If it takes some amount of time until the transmission

fluid reaches its normal operating temperature [70

80C

(158

176F)], check the transmission fluid lev MITSUBISHI 380 2005 User Guide MAINTENANCE SERVICE

GENERAL00-46

NOTE: If it takes some amount of time until the transmission

fluid reaches its normal operating temperature [70

80C

(158

176F)], check the transmission fluid lev](/img/19/57086/w960_57086-1266.png)

MAINTENANCE SERVICE

GENERAL00-46

NOTE: If it takes some amount of time until the transmission

fluid reaches its normal operating temperature [70

80C

(158

176F)], check the transmission fluid level by refer-

ring to the left diagram.

2. Park the vehicle on a level surface.

3. Move the selector lever through all positions to fill the torque

converter and the hydraulic circuits with fluid, and then move

the selector lever to the "N" position.

4. After wiping off any dirt around the dipstick, remove the

dipstick and check the condition of the transmission fluid.

NOTE: If the transmission fluid smells as if it is burnt, it

means that the transmission fluid has been contaminated by

fine particles from the bushings and friction materials. Tran-

saxle overhaul and cooler line flushing may be necessary.

5. Check transmission fluid level is at the "HOT" mark on the

dipstick. If the transmission fluid level is less than this, add

DIAMOND ATF SP III until the level reaches the "HOT"

mark.

NOTE: If the transmission fluid level is too low, the oil pump

will draw in air along with the transmission fluid, which will

cause to form bubbles. If the transmission fluid level is too

high, rotating components inside the transaxle will churn the

fluid and air into a foamy liquid. Both conditions (level too

low or too high) will cause the hydraulic pressure to drop,

which will result in late shifting and slipping of the clutches

and brakes.

NOTE: In either case, air bubbles can interfere with normal

valve, clutch, and brake operation. Also, foaming can cause

transmission fluid to escape from the transaxle vent where it

may be mistaken for a leak.

Page 1268 of 1500

MAINTENANCE SERVICE

GENERAL00-47

6. Securely insert the dipstick.

NOTE: The transmission fluid should always be replaced

under the following conditions:

.

When troubleshooting the transaxle.

When overhauling the transaxle.

When the transmission fluid is noticeably dirty or burnt

(driving under severe conditions).

TRANSMISSION FLUID CHANGE

Refer to GROUP 23A, Automatic Transmission - On-vehicle

Service P.23A-296.

12. ENGINE COOLANT (CHANGE)M1001003100357

Check the cooling system parts such as the radiator, heater

and oil cooler hoses, thermostat and their connections for leak-

age and damage.

.

CHANGING COOLANT

1. Set the temperature control knob to the "HOT" position.

2. Run the engine until the engine coolant warms, and then

stop the engine.

When removing the radiator cap, use care to avoid

contact with hot coolant or steam. Place a shop towel

over the cap and turn the cap counterclockwise a lit-

tle to let the pressure escape through the vinyl tube.

After relieving the steam pressure, remove the cap by

slowly turning it counterclockwise.

3. Drain the water from the radiator, heater core and engine

after unplugging the radiator drain plug and removing the

radiator cap.

Page 1434 of 1500

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-17

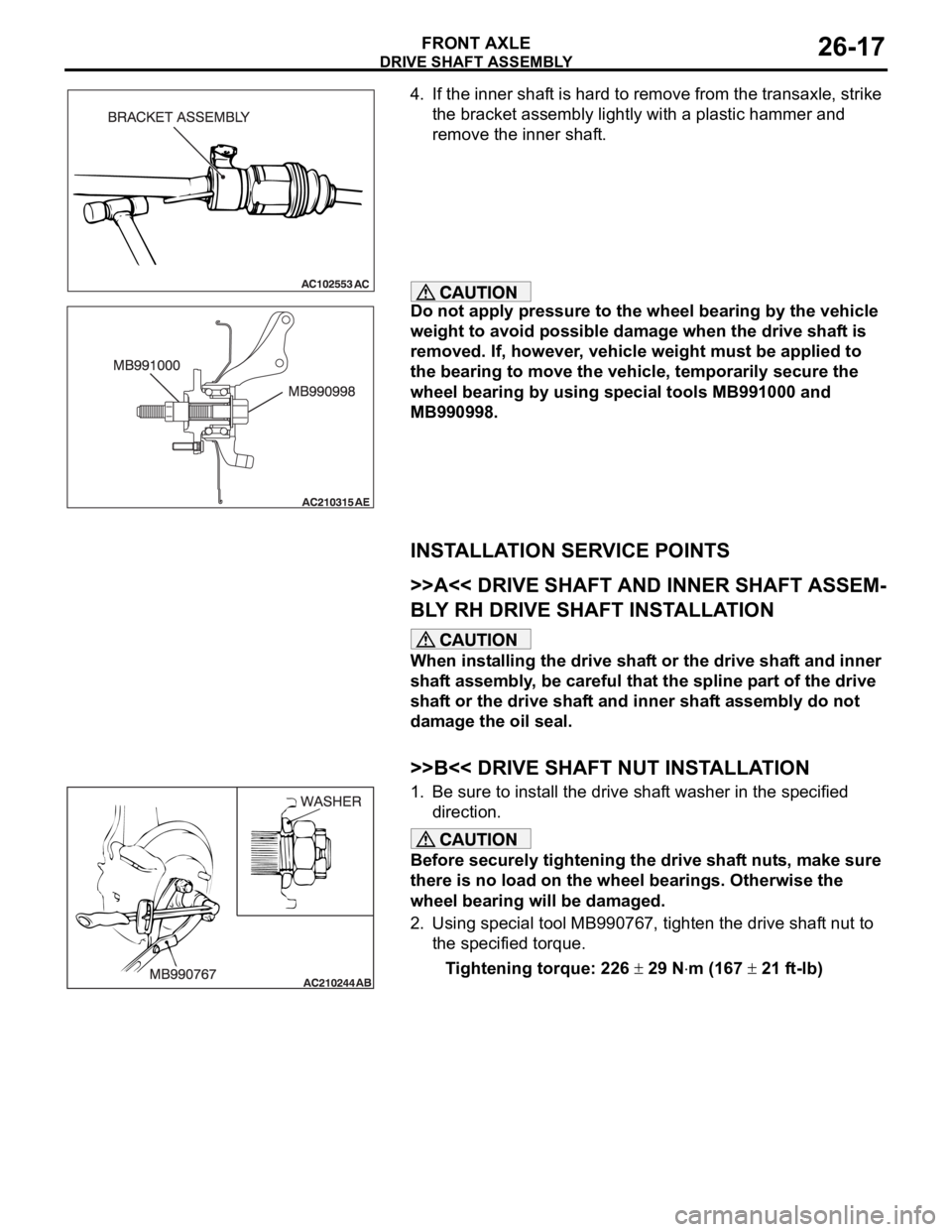

4. If the inner shaft is hard to remove from the transaxle, strike

the bracket assembly lightly with a plastic hammer and

remove the inner shaft.

Do not apply pressure to the wheel bearing by the vehicle

weight to avoid possible damage when the drive shaft is

removed. If, however, vehicle weight must be applied to

the bearing to move the vehicle, temporarily secure the

wheel bearing by using special tools MB991000 and

MB990998.

INSTALLATION SERVICE POINTS

.

>>A<< DRIVE SHAFT AND INNER SHAFT ASSEM-

BLY RH DRIVE SHAFT INSTALLATION

When installing the drive shaft or the drive shaft and inner

shaft assembly, be careful that the spline part of the drive

shaft or the drive shaft and inner shaft assembly do not

damage the oil seal.

.

>>B<< DRIVE SHAFT NUT INSTALLATION

1. Be sure to install the drive shaft washer in the specified

direction.

Before securely tightening the drive shaft nuts, make sure

there is no load on the wheel bearings. Otherwise the

wheel bearing will be damaged.

2. Using special tool MB990767, tighten the drive shaft nut to

the specified torque.

Tightening torque: 226

29 Nm (167 21 ft-lb)

Page 1486 of 1500

![MITSUBISHI 380 2005 User Guide AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-27

3. Connect the special tools (3.0 MPa (427 psi) oil pressure

gauge [MD998330] and adapters [MD998332, MD998900])

to each pressure discha MITSUBISHI 380 2005 User Guide AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-27

3. Connect the special tools (3.0 MPa (427 psi) oil pressure

gauge [MD998330] and adapters [MD998332, MD998900])

to each pressure discha](/img/19/57086/w960_57086-1485.png)

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-27

3. Connect the special tools (3.0 MPa (427 psi) oil pressure

gauge [MD998330] and adapters [MD998332, MD998900])

to each pressure discharge port.

NOTE: .

2ND: Second brake pressure port

UD: Underdrive clutch pressure port

LR: Low-reverse brake pressure port

DR: Torque converter release pressure port

DA: Torque converter apply pressure port

RV: Reverse clutch pressure port

OD: Overdrive clutch pressure port

DIR: Direct clutch pressure port

RED: Reduction clutch pressure port

4. Restart the engine.

5. Check that there are no leaks around the special tool port

adapters.

6. Measure the hydraulic pressure at each port under the

conditions given in the standard hydraulic pressure table,

and check that the measured values are within the standard

value ranges.

7. If the pressure is not within the standard value, stop the

engine and refer to the hydraulic pressure test diagnosis

table.

8. Remove the O-ring from the port plug and replace it.

9. Remove the special tool, and install the plugs to the

hydraulic pressure ports.

10.Start the engine and check that there are no leaks around

the plugs.

Page 1487 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-28

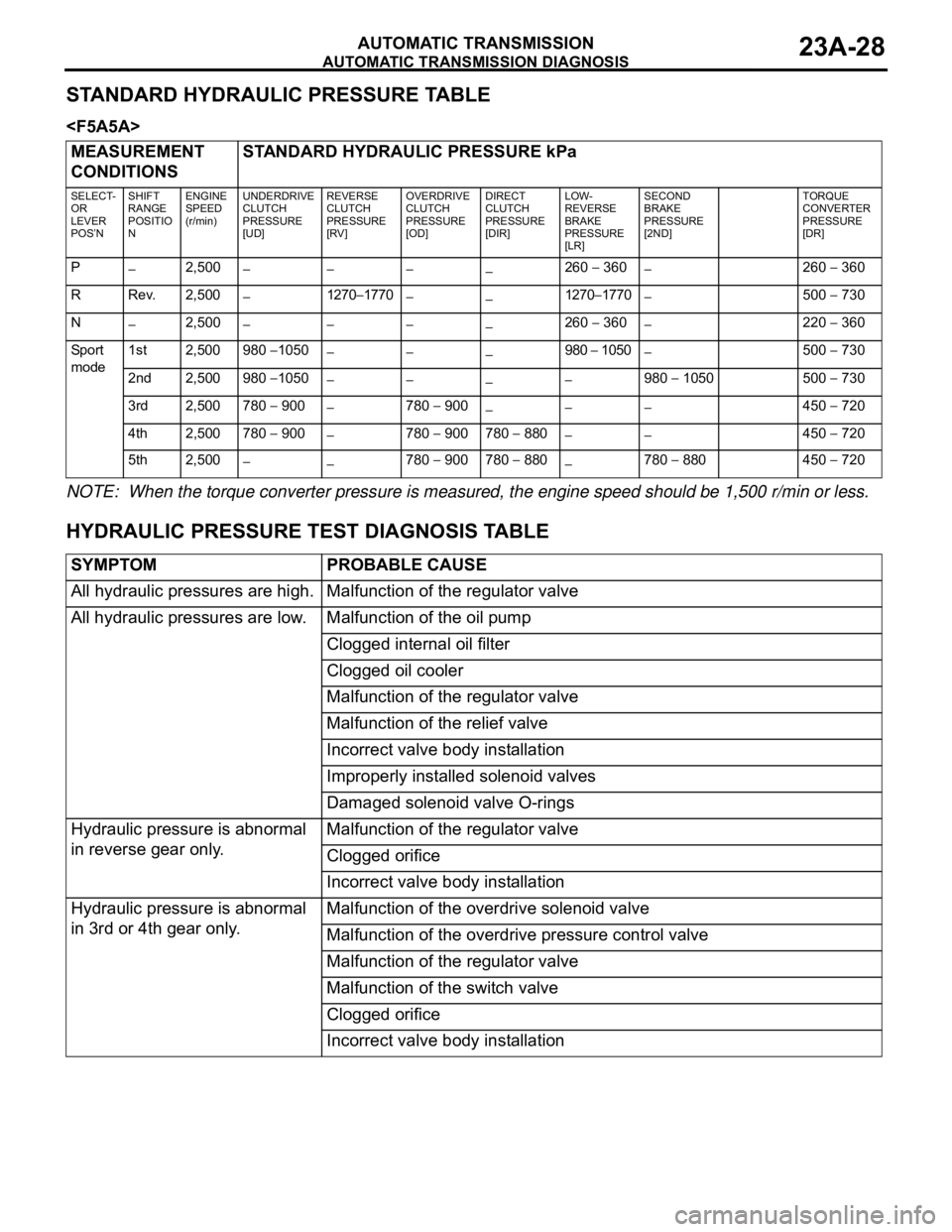

STANDARD HYDRAULIC PRESSURE TABLE

NOTE: When the torque converter pressure is measured, the engine speed should be 1,500 r/min or less.

HYDRAULIC PRESSURE TEST DIAGNOSIS TABLE

MEASUREMENT

CONDITIONSSTANDARD HYDRAULIC PRESSURE kPa

SELECT-

OR

LEVER

POS’N SHIFT

RANGE

POSITIO

NENGINE

SPEED

(r/min)UNDERDRIVE

CLUTCH

PRESSURE

[UD]REVERSE

CLUTCH

PRESSURE

[RV]OVERDRIVE

CLUTCH

PRESSURE

[OD]DIRECT

CLUTCH

PRESSURE

[DIR]LOW-

REVERSE

BRAKE

PRESSURE

[LR]SECOND

BRAKE

PRESSURE

[2ND]TORQUE

CONVERTER

PRESSURE

[DR]

P2,500260 360260 360

R Rev. 2,500

12701770 12701770 500 730

N

2,500260 360 220 360

Spo rt

mode1st 2,500 980

1050 980 1050 500 730

2nd 2,500 980

1050 980 1050 500 730

3rd 2,500 780

900 780 900 450 720

4th 2,500 780

900 780 900 780 880 450 720

5th 2,500

780 900 780 880 780 880 450 720

SYMPTOM PROBABLE CAUSE

All hydraulic pressures are high. Malfunction of the regulator valve

All hydraulic pressures are low. Malfunction of the oil pump

Clogged internal oil filter

Clogged oil cooler

Malfunction of the regulator valve

Malfunction of the relief valve

Incorrect valve body installation

Improperly installed solenoid valves

Damaged solenoid valve O-rings

Hydraulic pressure is abnormal

in reverse gear only.Malfunction of the regulator valve

Clogged orifice

Incorrect valve body installation

Hydraulic pressure is abnormal

in 3rd or 4th gear only.Malfunction of the overdrive solenoid valve

Malfunction of the overdrive pressure control valve

Malfunction of the regulator valve

Malfunction of the switch valve

Clogged orifice

Incorrect valve body installation

Page 1488 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-29

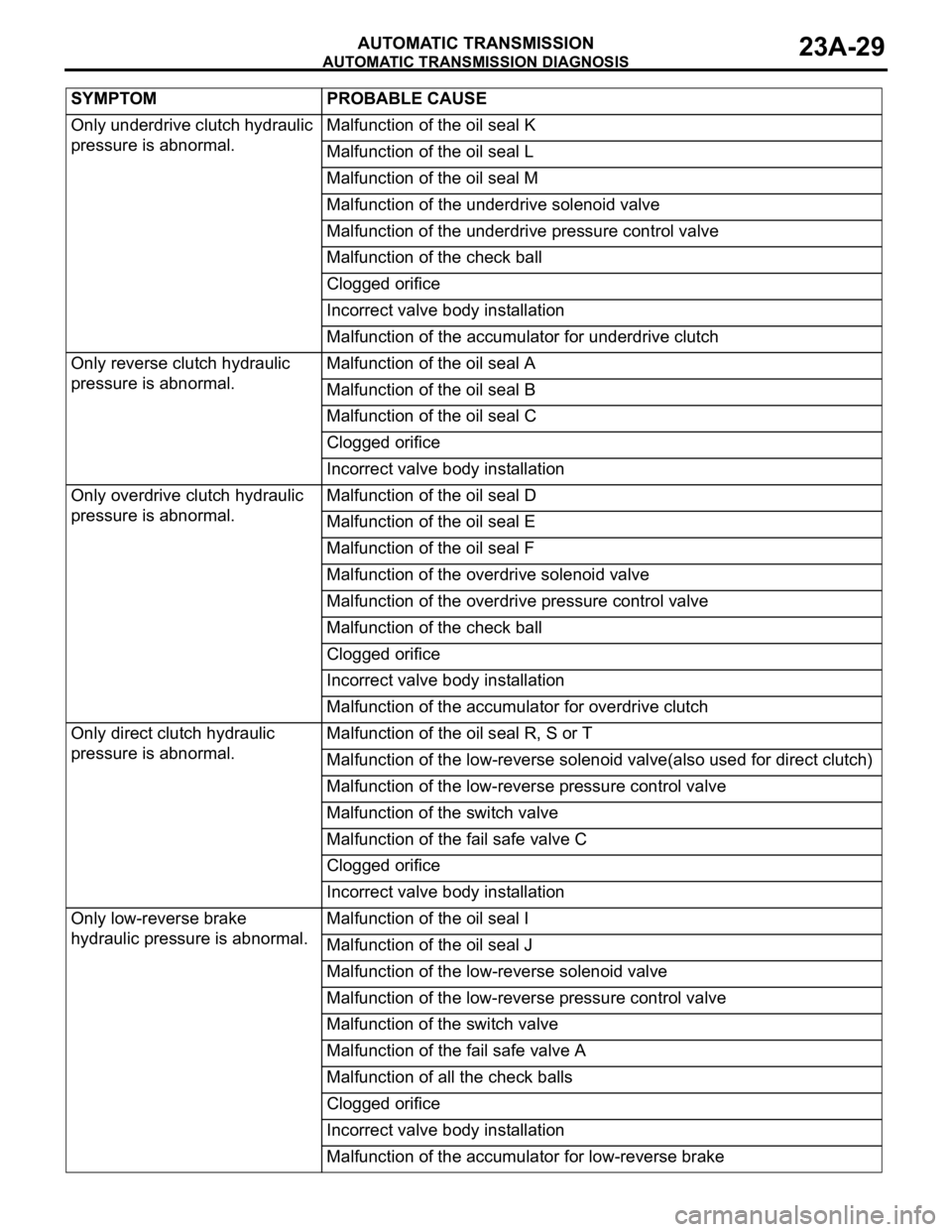

Only underdrive clutch hydraulic

pressure is abnormal.Malfunction of the oil seal K

Malfunction of the oil seal L

Malfunction of the oil seal M

Malfunction of the underdrive solenoid valve

Malfunction of the underdrive pressure control valve

Malfunction of the check ball

Clogged orifice

Incorrect valve body installation

Malfunction of the accumulator for underdrive clutch

Only reverse clutch hydraulic

pressure is abnormal.Malfunction of the oil seal A

Malfunction of the oil seal B

Malfunction of the oil seal C

Clogged orifice

Incorrect valve body installation

Only overdrive clutch hydraulic

pressure is abnormal.Malfunction of the oil seal D

Malfunction of the oil seal E

Malfunction of the oil seal F

Malfunction of the overdrive solenoid valve

Malfunction of the overdrive pressure control valve

Malfunction of the check ball

Clogged orifice

Incorrect valve body installation

Malfunction of the accumulator for overdrive clutch

Only direct clutch hydraulic

pressure is abnormal.Malfunction of the oil seal R, S or T

Malfunction of the low-reverse solenoid valve(also used for direct clutch)

Malfunction of the low-reverse pressure control valve

Malfunction of the switch valve

Malfunction of the fail safe valve C

Clogged orifice

Incorrect valve body installation

Only low-reverse brake

hydraulic pressure is abnormal.Malfunction of the oil seal I

Malfunction of the oil seal J

Malfunction of the low-reverse solenoid valve

Malfunction of the low-reverse pressure control valve

Malfunction of the switch valve

Malfunction of the fail safe valve A

Malfunction of all the check balls

Clogged orifice

Incorrect valve body installation

Malfunction of the accumulator for low-reverse brake SYMPTOM PROBABLE CAUSE

Page 1489 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-30

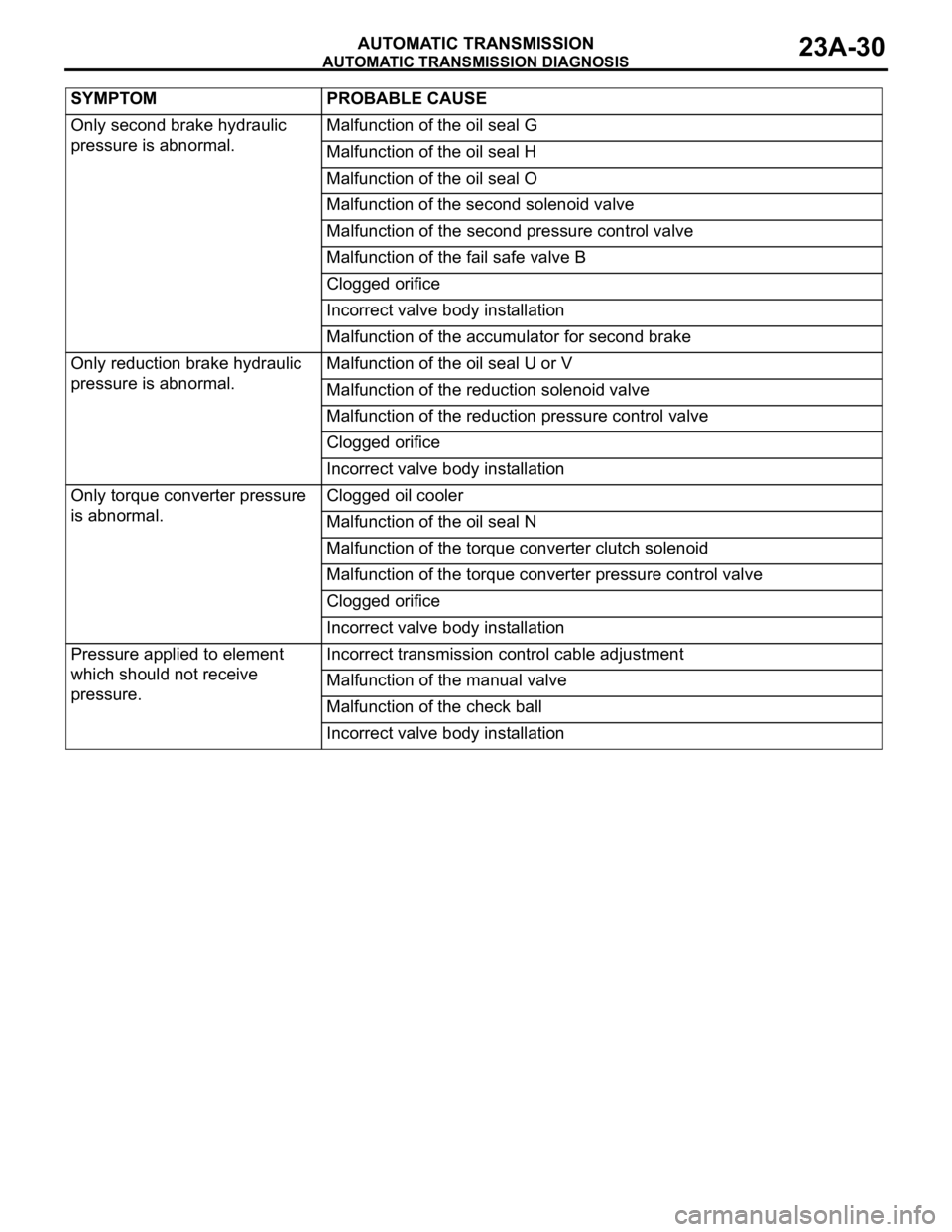

Only second brake hydraulic

pressure is abnormal.Malfunction of the oil seal G

Malfunction of the oil seal H

Malfunction of the oil seal O

Malfunction of the second solenoid valve

Malfunction of the second pressure control valve

Malfunction of the fail safe valve B

Clogged orifice

Incorrect valve body installation

Malfunction of the accumulator for second brake

Only reduction brake hydraulic

pressure is abnormal.Malfunction of the oil seal U or V

Malfunction of the reduction solenoid valve

Malfunction of the reduction pressure control valve

Clogged orifice

Incorrect valve body installation

Only torque converter pressure

is abnormal.Clogged oil cooler

Malfunction of the oil seal N

Malfunction of the torque converter clutch solenoid

Malfunction of the torque converter pressure control valve

Clogged orifice

Incorrect valve body installation

Pressure applied to element

which should not receive

pressure.Incorrect transmission control cable adjustment

Malfunction of the manual valve

Malfunction of the check ball

Incorrect valve body installation SYMPTOM PROBABLE CAUSE